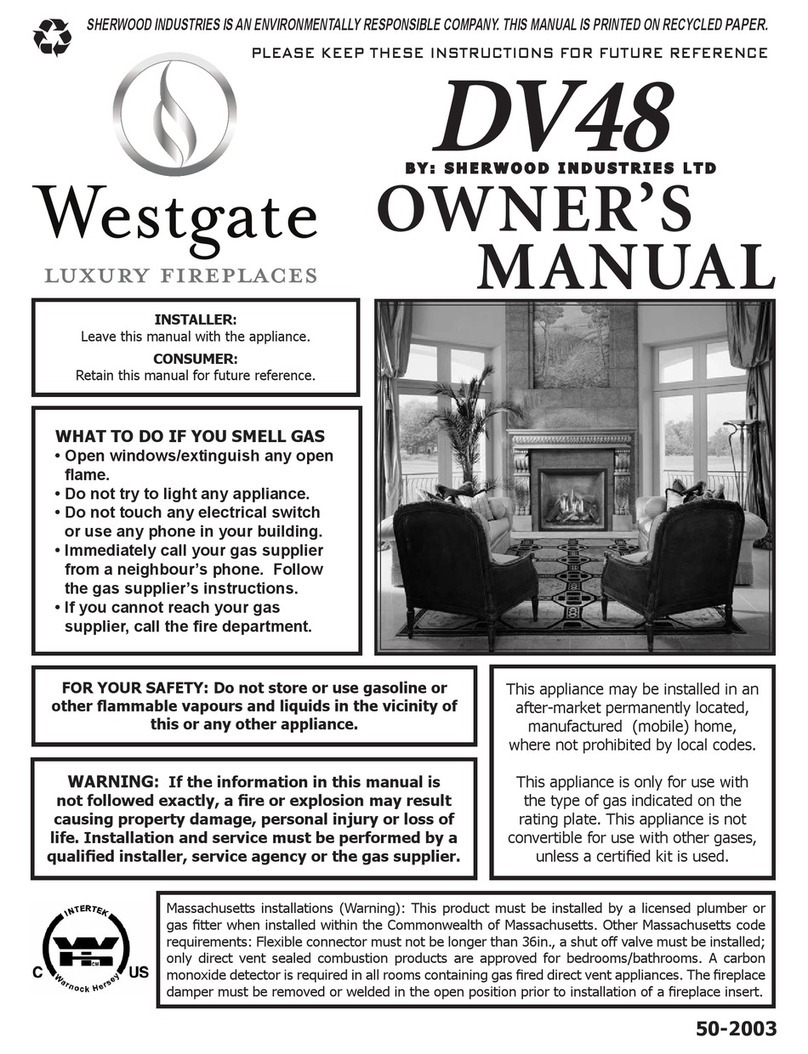

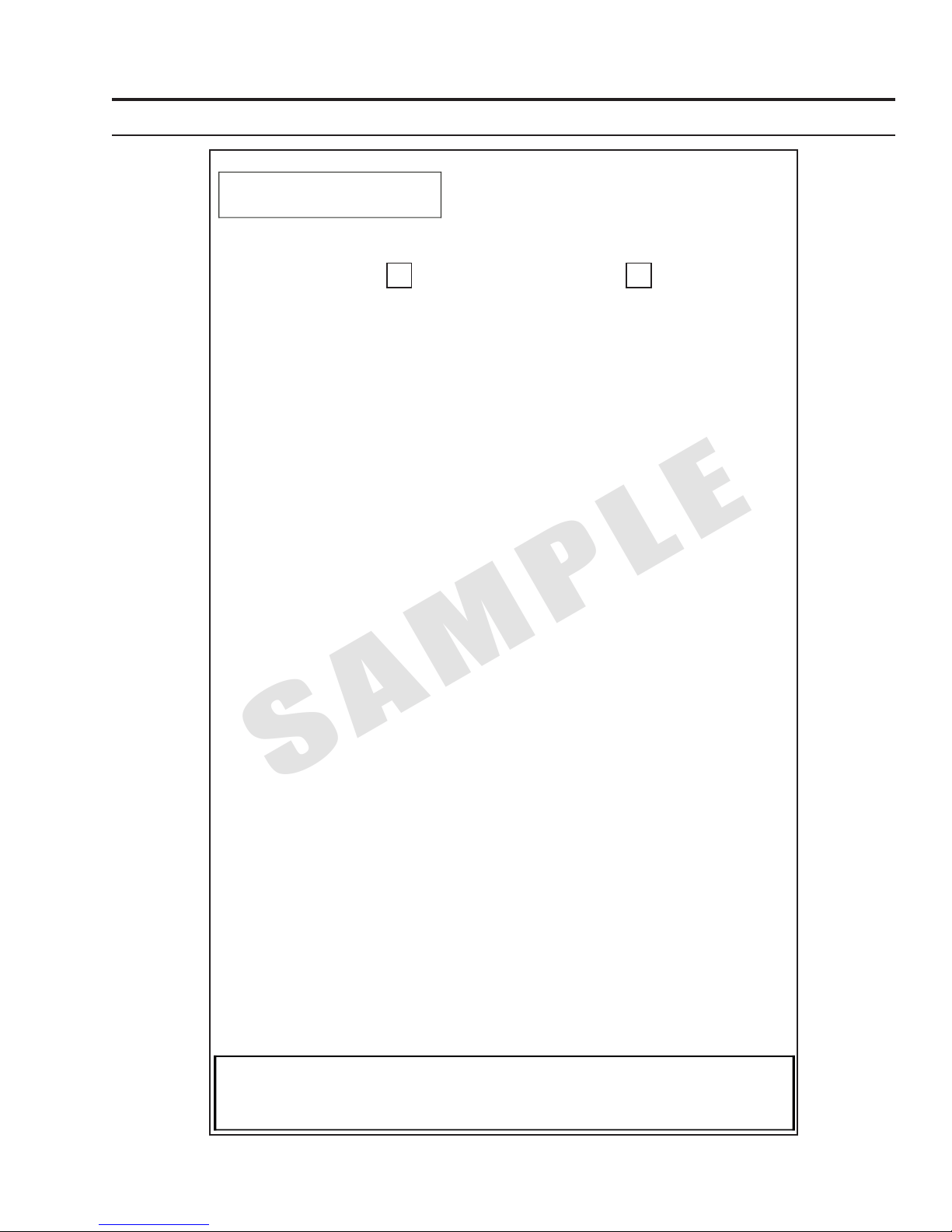

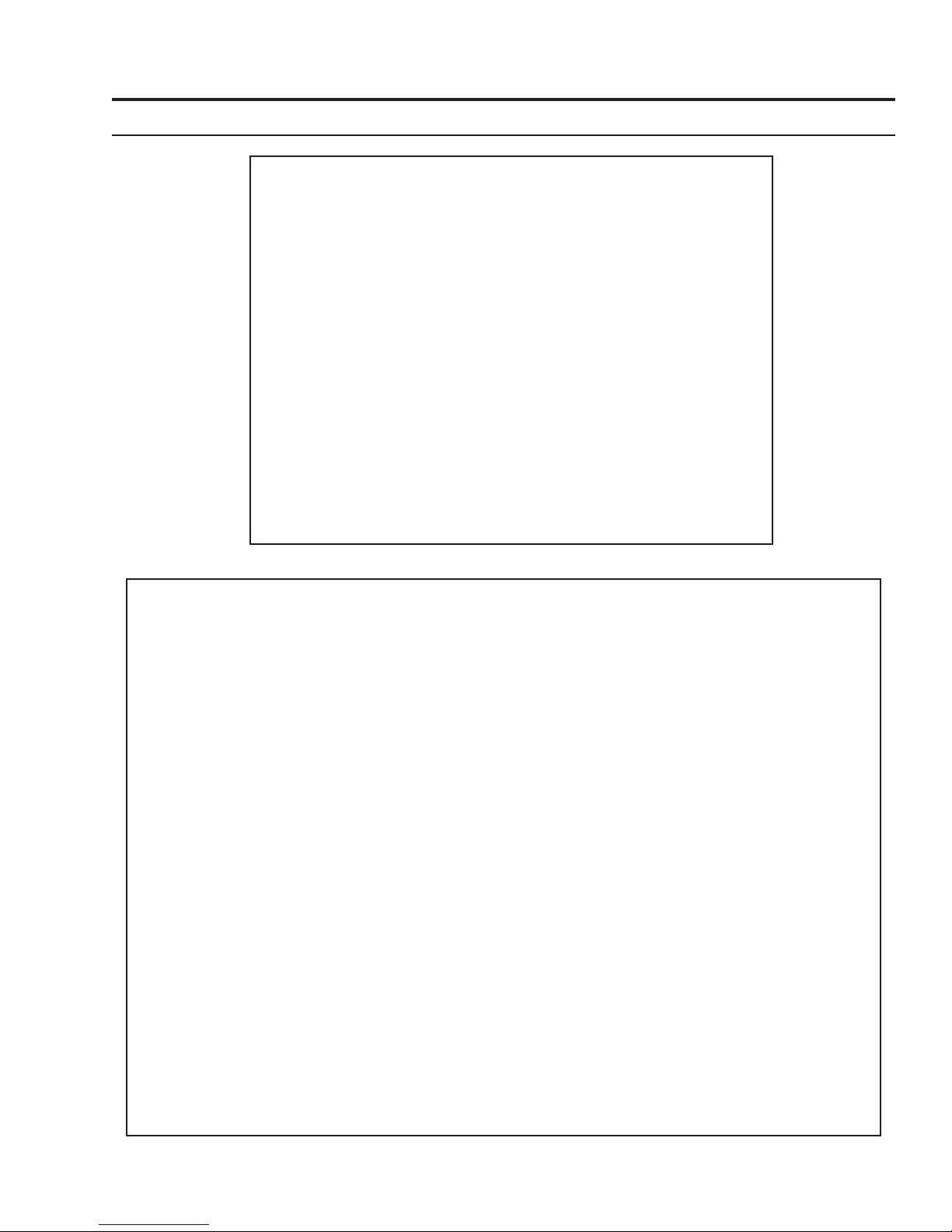

Figure 3. Rating Label.

CAUTION:

Hot while operating. Do not touch. Severe burns may result. Keep

children, clothing, furniture, gasoline or other flammable vapors away.

CAUTION: Do not operate this fireplace with the glass removed, cracked or broken.

Replacement of the panel(s) should be done by a licensed or qualified person! This

appliance needs fresh air for safe operation and must be installed with provisions for

combustion and ventilation air. See installation and operating instructions manual.

Keep burner and control compartment clean.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause injury or property damage, or loss of life. Refer to owner's manual provided

with this appliance. See installation and operating instructions accompanying

appliance. Installation and service must be performed by a qualified installer, service

agency, or the gas supplier.

WARNING:

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

A) This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to

light the pilot by hand.

B) BEFORE LIGHTING smell all around the appliance

area for gas and next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance. Do not touch any

electrical switch: do not use any phone in your

building. Immediately call your gas supplier from a

neighbors' phone. Follow the gas suppliers

instructions. If you cannot reach your gas supplier,

call the fire department.

C) If any portion of this appliance

does not operate as the instructions

indicate, don't try to repair it, call a

qualified service technician. Do not

use tools. Force or attempted repair

may result in a fire or explosion.

D) Do not use this appliance if any

part has been under water.

Immediately call a qualified service

technician to inspect the appliance

and to replace any part of the

control system and any gas control

which has been under water.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Read the owner's manual including the section on "Remote

Control" operation.

3. Do not attempt to light the pilot by hand.

4. If you smell gas, STOP! Follow "B" in the safety

information above on this label. If you don't smell gas, go

to the next step.

5. Using the remote control, set

thermostat to desired setting, or

switch press the ON/OFF key on the

remote. "ON" will be indicated on the

display of the remote and an audible

"beep" will be heard at the unit to

idicate the command has been

received.

TO TURN OFF GAS TO APPLIANCE

1. Set thermostat to lowest setting, or press the ON/OFF Key. "OFF" will be indicated on the display

and an audible "Beep" will be heard at the unit to indicate the command has been received.

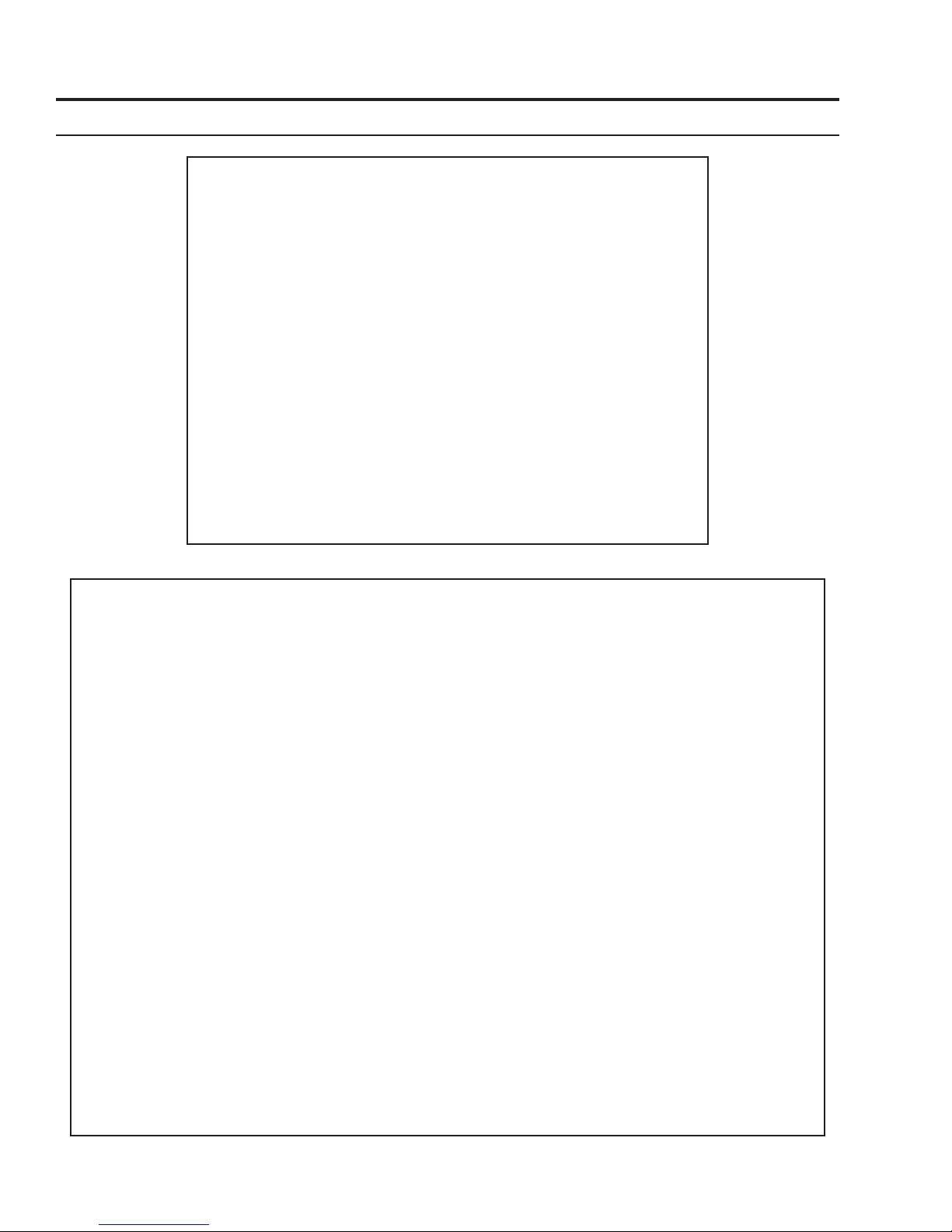

FOR YOUR SAFETY READ BEFORE OPERATING

C-11800

6. This appliance is equipped with a

completely automatic ignition and

lighting control. The control will

attempt to light the pilot several

timesif necessary. If it is

unsuccessful, it will discontinue

operations. If the appliance does

not operate, follow the

instructions "To Turn Off Gas To

Appliance" and call your service

technician or gas supplier.

Blue LCD Display

THERMOSTAT Key

ON/OFF Key

UP/DOWN Arrow Key

MODE Key

ELECTRICAL RATING:(EXIGENCES ÉLECTRIQUES)

Fan type circulator (Ventilateur circulaire) : 120 volts AC 60 hz / Less than 7 Amperes

CLEARANCES TO COMBUSTIBLES: (DISTANCE OBLIGATOIRE DES COMBUSTIBLES)

Stove side (Côté de poêle): 4 inches (10.2cm), Back (Arriére): 4 inches (10.2cm), Ceiling from bottom of unit (Du fond

d'unité au Plafond): 80” inches (203.2cm), From fireplace frame to side wall (Du frome de la cheminée au mur latéral): 10"

(25.5 cm), From base of the unit to shelf, header, or 12" (30.5cm) mantel (De la base de l'unité à une étagère, un en-tête,

ou un 12" manteau de cheminée): 52.25" (133cm)

VENT PIPE CLEARANCES:(ESPACES LIBRES DE VENTILATION) See manufacturer’s listing, label and installation

instructions. Verifeez l’identifaction, l’etiquette et les instructionsd’installation du fabricant. This appliance must be properly

connected to a venting system in accordance with the manufacturer's installation instructions. Cet appareil doit être

convenablement connecté à un système donner vent conformément aux instructions d'installation du fabricant.

VENTED GAS FIREPLACE HEATER - NOT FOR USE WITH SOLID FUELS.

MAY BE INSTALLED IN

BEDROOM OR BEDSITTING ROOM (IN CANADA with a listed wall thermostat). THIS APPLIANCE MUST BE PROPERLY

CONNECTED TO A VENTING SYSTEM. ONLY FOR DIRECT DISCHARGE WITHOUT DUCT CONNECTION. This

appliance must be installed as per manufacturers installation instructions and in accordance with local codes if any. If none

exist, use current installation code CAN/CSA B149.1 in Canada or ANSI Z223.1/NFPA 54 in the USA. This vented gas

fireplace is not for use with air filters. FOR USE WITH GLASS DOORS CERTIFIED WITH THE APPLIANCE ONLY. This

appliance is only for use with the type(s) of gas indicated on the rating plate. A conversion kit is available for this appliance.

This appliance is not convertible for use with other gases, unless a certified kit is used.

Sections of the venting system

have not been installed. WARNING: Do not operate the appliance until all sections have been assembled

and installed in accordance with the manufacturers instructions.

FOYER AU GAZ A EVACUATION - NE PAS EMPLOYER AVEC DES COMBUSTIBLES SOLIDES.

Cet

appareil peut être installé dans une chambre à coucher ou un studio. Cet appareil doit être branché correctement à un

système de conduits. Uniquement pour l'échappement direct sans raccord de conduit.Cet appareil doit être installé selon les

directives d'installation du manufacturier et selon les codes locaux, s'il y a lieu. Autrement, employez le code d'installation

en vigueur au Canada CAN/CSA B149.1. Ne pas utilliser de filtre a air avec ce foyer au gaz a evacuation. POUR L'USAGE

AVEC PORTES VITREES A CERTIFIE AVEC L'APPAREIL SEULEMENT. Cet apperareil doit etre utilise uniquement avec

le type de gaz indique sur la plaque. Cet appareil ne peut etre converti a d’autres gaz sauf si une trouse de conversion

certifee est utilisee.

ADVERTISSEMENT: Ne pas utiliser l’appareil tant que toutes les sections n’ont pas ete

assemblees et installees selon les instructions du fabricant.

MOBILE HOME: May be installed in an aftermarket, permanently located, manufactured home (USA only) or mobile home,

where not prohibited by local codes. See owner's manual for details. This appliance must be installed in accordance with the

current Standard for Mobile Homes, CAN/CSA Z240, or the Manufactured Home Construction and Safety Standard, Title 24

CFR, Part 3280, or when such standard is not applicable, the current Standard for Fire Safety Criteria for Manufactured

Home Installations, sites, and Communitties, ANSI/NFPA 501A.

LA MAISON MOBILE :

Peut être installé dans une maison mobile. Cet appareil doit être installé conformement aux Normes actuelles

pour Maisons Mobiles, le BOITE/CSA Z240, ou les Normes de Construction et de Sureté des Maisons Pré-fabriquées (Titre 24 CFR, la

Partie 3280). Quand ces Normes ne sont pas en vigueur, il faut suivre les criteres pour la sureté (contre les increndies) et pour la

construction des Maisons Pré-fabriquées, leurs sites, ANSI/NFPA 501A, et des communautées aux Instructions du manufacturier.

MANUFACTURED BY (FABRIQUE PAR) : SHERWOOD INDUSTRIES LTD. 6782 OLDFIELD RD. SAANICHTON, BC, CANADA

WH-

DV48

VENTED GAS FIREPLACE HEATER ENVIRO MODEL:

FOYER AU GAZ A EVACUATION MODELE ENVIRO:

TESTED TO / TESTÉE SELON LES NORMES:

ANSI Z21.88a-2007/CSA 2.33a-2007 VENTED GAS FIREPLACE HEATERS / FOYER AU GAZ EVACUATION;

CAN/CGA 2.17-M91 GAS FIRED APPLIANCES FOR HIGH ALTITUDES / LES APPAREILS BRULANT GAZ POUR

UTILISATION EN HAUTES ALTITUDES; Can/CSA P.4.1-02 (R2006) TESTING METHOD FOR MEASURING ANNUAL

FIREPLACE EFFICIENCY / LA METHODE D'ESSAI POUR MESURER L'EFFICACITE DE CHEMINEE ANNUELLE.

INPUT (ENTRÉE): NAT: 0-4500 FT (1372 M) MAX: 48,000 BTU (14.07 KW•h)

MIN: 16,000 BTU (4.68 KW•h)

LPG: 0-4500 FT (1372 M) MAX: 48,000 BTU (14.07 KW•h)

MIN: 17,000 BTU (4.98 KW•h)

MANIFOLD PRESSURE (PRESSION D’ADMISSION):

NAT: 3.5 in. WC (0.87kPa) / 1.6 in. WC (0.40kPa) LPG: 10 in. WC (2.48kPa) / 6.4 in. WC (1.59kPa)

MINIMUM GAS SUPPLY PRESSURE: (PRESSION MINIMALE D'ALIMENTATION DE GAZ PERMISE)

NAT: 5 in. Wc (1.24kPa) LPG: 12 in. Wc (2.98kPa)

ORIFICE SIZE: (DIMENSIONS DE L’ORIFICE)

NAT: Left # 45 DMS, Right # 41 DMS LPG: Left # 55 DMS, Right # 53 DMS

PILOT ORIFICE SIZE: (DIMENSIONS DE PILOTER L’ORIFICE)

NAT: # 62 DMS LPG: Left # 35 DMS

NAT: (Gaz naturel) LPG (Propane)

DUE TO HIGH SURFACE TEMPERATURES KEEP CHILDREN, CLOTHING, AND FURNITURE AWAY

DUES AUX TEMPERATURES ELEVEES, GARDEZ LES ENFANTS, LES VETEMENT ET LES MEUBLES ELOIGNES

DATE OF MANUFACTURE: DATE DE FABRICATION:

J F M A M J J A S O N D 2009 2010 2011 2012

DO NOT REMOVE THIS LABEL / N'ENLEVEZ PAS CETTE ETIQUETTE

DV48

WH# 16354