Westin STRATUS Air Installation and operating instructions

STRATUS Air

Ceiling Built-in Unit

Installation, Operation and Maintenance

CONTENTS

INTRODUCTION

IMPORTANT INFORMATION

EXTRACTION PERFORMANCE

INSTALLATION

SPECIFICATIONS

OPERATING INSTRUCTIONS

MAINTENANCE

GENERAL ARRANGEMENT

DRAWINGS & ILLUSTRATIONS

1

2

3

4

5

6

7

8

Unpacking

Remove all items from the packaging. Retain the packaging.

If items are missing or damaged, please contact Westin for assistance.

The following items are included:

Remote Control

Console

W S Westin Ltd

Phoenix Mills, Leeds Road, Huddersfield, HD1 6NG, UK

Tel: 01484 421585 Fax: 01484 432420 Email:

www.westin.co.uk

Documentation:

This Manual,

Warranty Card,

Product Fiche and

Energy Label

Stratus Air Main Unit

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 2 Westin

1. INTRODUCTION

During the cooking process, there will be heat, vapours and

fumes produced. Your Westin Ceiling Extractor has been

designed to complement your kitchen both in looks and

performance in order to create a good environment for creative

cooking.

2. IMPORTANT INFORMATION

The exhaust air must not be discharged into a flue which is

used for exhausting fumes from appliances supplied with

energy other than electricity e.g. oil- or gas-fired central

heating boilers, gas-fired water heaters, etc.

Requirements of the relevant authorities concerning the

discharge of exhaust air must be complied with.

Pay particular attention to fire risk when frying. To minimise

the risk of fire, all instructions relating to cleaning the grease

filters and removing grease deposits must be adhered to.

Do not flambé under the extractor.

The clearance between the hob burners and the bottom

surface of the extractor must be at least 750mm to prevent

overheating of the extractor and its components.

Please also note that a 90o bend in flexible ducting will require

215mm minimum headroom to give a smooth radius with no

kinking.

You are advised to install measures designed to reduce the

incidence of cold draughts entering the property via any

ductwork.

For extractors with internal or inline motors, this

should, at the very least, consist of an external duct

termination with integrated non-return flaps (e.g.

gravity shutter wall grille/louvre) and/or an inline

backdraught shutter.

For wall-mounted motors, an inline backdraught

shutter is recommended.

3. EXTRACTION PERFORMANCE

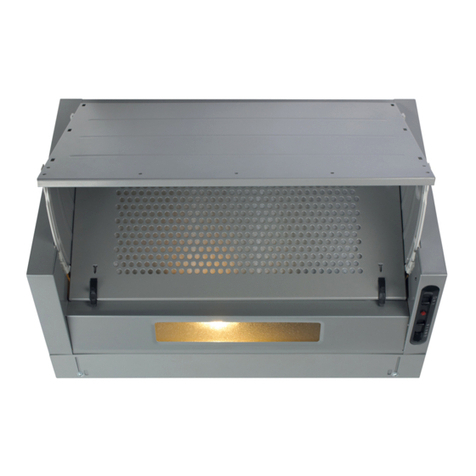

As its name suggests, this type of extractor is designed to fit

into the ceiling void, with only the underside and outer flange

visible when installed.

Because fumes spread out as they rise, a unit larger than the

hob area is desirable, although not always possible. The

perimeter extraction system is designed to conceal the grease

filters and to minimise fume escape. Warm cooking fumes that

do escape tend, initially, to accumulate in the highest part of

the room, so situating the unit at the highest point is of benefit.

It will perform best when it is situated directly over the hob.

The primary influence on the overall performance of the

extractor is the design of the ducting which takes the exhaust

air from the extractor to the outside. The duct route should be

a prime consideration during the initial stages of the kitchen

design (Westin do not recommend recirculating air back into

the kitchen).

Please note the following:

Easy access to the duct route during installation is

important. Lack of access may require the “blind” fitting of

flexible ducting, with increased risk of unseen kinks and

impaired efficiency.

The extractor is provided with a spigot suitable for

connecting 150mm diameter ducting.

Note: the cross-sectional area of 150mm diameter duct is

the minimum area consistent with efficient extraction.

The most efficient configuration is to duct straight through

an outside wall, so try to position the cooker against an

outside wall when designing your kitchen.

Your extractor can be set to vent to the rear, front, left or

right. Use the exhaust position which gives the shortest

achievable duct route and least number of bends. Joist

positions will often determine what is achievable.

Rigid 150mm round ducting or an equivalent flat channel

system (available from Westin) will perform best, with

semi-rigid (often referred to as flue liner) being the second-

best solution. Flexible ducting is economical but it’s use

should be minimised as it gives the worst performance and

should only be used for short duct runs or initial connection

(and should be pulled taut to prevent significant losses in

extraction efficiency).

For maximum efficiency, ducting should be kept as short

as possible and as straight as possible with a constant

cross-sectional area being no less than that recommended

by Westin. Bends in the duct will also degrade

performance so the number of bends in a duct run should

be kept to a minimum and be gradual and smooth to

prevent turbulence. Avoid kinks in flexible ducting; pull

flexible ducting taut over straight runs to ensure that the

internal surface is as smooth as possible.

WARNING.

Proper care must be taken to ensure that the negative

pressures caused by high performance extraction

systems do not adversely affect the safe operation of

certain types of fuel-burning appliances (gas, oil or solid

fuel), including those installed in the kitchen and

possibly also those installed in other parts of the house.

Where such fuel-burning appliances are installed,

adequate ventilation MUST be provided in the room of

installation, located and sized such that the negative

pressure in the room created by the extractor does not

exceed 4Pa.

In case of doubt, do not operate the extractor and fuel-

burning appliance(s) simultaneously and consult an

appropriate (for the fuel type) expert for advice.

ELECTRICAL SAFETY.

This appliance requires an earth connection.

Ensure that the supply voltage corresponds to that

marked on the rating label inside the extractor.

The extractor must be isolated from the electrical

supply before carrying out any cleaning or

maintenance operations.

This extractor has no lights, however there is a light

control button on the remote-control console.

So this button may be of use, a switched 230V AC

electrical output is provided, operated by the light

button. You will find a terminal box, containing Live,

Neutral & Earth wires that can be used to power your

own auxiliary lights (up to 100W), or ignored according

to preference.

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 3 Westin

4. INSTALLATION

The extractor is designed for installation within a cut-out in the

underside of the kitchen ceiling. Alternatively, it may be

installed within a lowered area of ceiling or a soffit panel within

your furniture – remember though that it is desirable to install

directly into the ceiling (see section 3).

Please note the following.

The extractor is made up of two main parts*:

o The “top box”, which houses the exhaust ducting

spigot, grease filter, electrical connection points and

any internal motor.

o The “baseplate”, which is essentially the visible parts

when installed, comprising hinged filter concealment

door panel assembly and outer frame.

The ducting spigot must be set to the required outlet

position prior to installation (Left, Right, Front, Rear or

Top).

The Stratus Air “top box” has 3 possible duct spigot

positions. It is easily separated from the baseplate and can

be rotated through 180 degrees in order to achieve all 5

possible outlet directions. It is secured via screws

accessible only when the filter concealment door panel is

in the open position.

The extractor fixing holes are located behind the door

panel. We recommend pan-head or flanged screws are

used to secure the extractor, rather than countersunk.

Screw heads will be visible only when the door is open.

If your extractor is a recirculating model (optional extra

and not the standard configuration) then adequate

provision must be made for exhausted air to return to the

kitchen, such as by ducting to a vent in the kitchen ceiling

(located so as to minimise uncomfortable draughts onto

occupants). Failure to do so may cause the unit to

overheat and fail, and will invalidate your warranty.

This extractor has no lights, however there is a light control

button on the remote-control console.

So this button may be of use, a switched 230V AC

electrical output, operated by the light button is provided.

You will find a terminal box, containing Live, Neutral &

Earth wires, that can be used to power your own auxiliary

lights (up to 100W) or ignored according to preference.

4.1. Opening the filter concealment door panel.

The panel is held shut with magnetic catches.

Open the panel by grasping it close to the corners on the

catch side (the long edge opposite the hinges) and pulling to

release the panel from the magnets. Take care not to let the

panel fall open freely, it should be supported and moved

carefully into the open position.

4.2. Setting the Duct Spigot Position.

Your extractor ducting spigot can be set to vent to the Left

(factory default), Right, Front, Rear or Top.

The front of the unit, when installed, is the side with the

magnetic catches.

Note: If you wish to vent upwards and space is restricted, then

you may find your installation easier if you use a side outlet

position and put a bend in your ducting.

The “top box” exhaust spigot assembly refers to the removable

150mm ducting spigot plate, which in the case of Internal

blower models has the motor attached to it.

As described earlier, the Stratus Air “top box” has 3

possible duct spigot positions, with the remainder being

achieved by rotating the top box through 180 degrees.

To change the exhaust spigot position of the "top box"

proceed as follows:

Suspend the extractor on its back such that the “top box” is

clear of the ground. Tip. This can be achieved by placing

the product across the top of the open box it came in so

that the "top box" hangs down into the box.

Open the filter concealment panel and remove the filter(s).

Each exhaust position has 4 captive nuts into which can

be bolted either the exhaust spigot assembly or a blanking

plate.

Bolt the exhaust spigot assembly into the required location

by swapping it with a blanking plate as necessary.

Note: For internal blower models, where space within the

top box is limited, only the screws nearest to the filter

opening need to be fully removed. The screws farthest

away need only to be backed off as the plate has slots for

easier removal/replacement of the motor.

To rotate the "top box" proceed as follows:

Suspend the extractor on its back such that the “top box” is

clear of the ground. Tip. This can be achieved by placing

the product across the top of the open box it came in so

that the "top box" hangs down into the box.

Open the filter concealment door panel to reveal the fixing

screws securing the “top box” to the “baseplate” and

remove the screws.

Carefully lift the "top box" out of the "baseplate" opening,

rotate it to face the required direction and carefully refit it in

its new position, taking care not to trap any wires. Secure it

with the screws previously removed.

4.3. Revealing the Fixing Holes.

The extractor is secured through 4 fixing holes located close

to each corner of the baseplate (see diagrams on Page 7

Onwards for detail).

The fixing holes are only accessible with the door panel open.

4.4. Prepare Opening

Prepare an opening in the ceiling into which the unit will be

fitted (see table below). Refer to the drawings on Page 7 & 8

for detailed opening design and clearance height information.

Unit Size (mm)

(Width x Depth)

Cut-out Size (mm)

(Width x Depth)

880 x 420 860 x 400

1180 x 420 1160 x 400

Reinforce the opening as necessary and make suitable

provisions for the screws that will hold the unit in place.

Tip: Because much of the baseplate only intrudes into the

ceiling by 30mm (see diagrams on Page 7 Onwards),

providing the joist direction runs such that the top box can be

Dimensioned drawings and illustrations to help with

your installation can be found on page 7 onwards.

Important.

The "top box" needs to be angled during removal and

refitting to allow the duct spigot, electrical connection

points and cables to clear the opening in the "baseplate"

.

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 4 Westin

accommodated, alterations to joists and any boxing down can

be kept to a minimum, or avoided altogether if the ceiling

thickness is sufficient or ceiling can be lowered slightly.

4.5. Ducting

Install ducting taking note of the advice given in section 2 & 3.

We recommend using semi-rigid round ducting for this

extractor – the initial connection to the extractor spigot must

be in semi-rigid (or flexible duct) to allow the unit (or top box if

fitting separately) to be installed with the duct connected.

Run the ducting such that there is enough to easily reach just

beyond the centre point of the extractor, thus allowing for a

short length to be pulled through the opening for later

connection to the top box spigot. Try to avoid tight bends

immediately adjacent to where the top box will be, as this will

make pushing the unit/top box into position more difficult.

When terminating ducting on an outside wall, a suitable

weather louvre should be used. Ducting components and

complete kits are available from Westin for most installations.

If you need to use expanding foam, make sure that any soft

flexible ducting is supported internally to prevent it crushing, or

use semi-rigid/rigid ducting where foam is used.

For roof or chimney duct terminations, please contact Westin

or seek alternative specialist advice.

If you are fitting a wall-mounted external motor with semi-rigid

or flexible ducting, then you must leave a short length (approx.

200mm) of expanded (stretched out) ducting proud of the wall

to facilitate connection to the motor spigot before pushing both

into position flush with the wall.

Standard external motors come with a cable assembly that

must pass through the wall and run back to the extractor –

usually this passes alongside the ducting so it is

recommended to oversize your cut-out by at least 25mm to

allow for this and easy installation of the duct.

4.6. Remote External Wall and Inline Motors

If your extractor has been purchased to operate with a

standard inline or external remote motor (SEM), then you will

find a black plastic box outside the extractor (on flying leads)

containing electrical terminals for connection to the remote

motor cable assembly. This box is referred to as the remote

motor terminal box.

Run the remote motor cable such that sufficient hangs down

through the ceiling opening prepared for the extractor to allow

for easy connection to the remote motor terminal box.

Each terminal inside the remote motor terminal box has one

side connected to a coloured wire (leading back to the hood

control system). The remote motor cable also has coloured

wires and these are connected to the empty terminals such

that corresponding colours are opposite and connect to each

other; i.e. red connects to red, blue to blue, and so on…

Not all terminals will be used as each remote motor type is

configured differently.

No separate power supply is required for the external motor.

An electrician (or Part P registered electrical installer) should

undertake any work associated with the electrical installation

of SEM remote motors.

Please refer to the REMOTE MOTOR ILLUSTRATIONS on

page 9 for more information.

If you need to extend the remote motor cable, then additional

cable can be purchased from Westin. Alternatively, it can be

extended using 7 core x 0.5mm flex. It is vital to ensure that

any new cable is inserted such that the core colour integrity is

maintained; i.e. a core that started as red must terminate as

red, blue as blue, purple as purple, and so on.

Any remote motor should be installed in accordance with the

installation instructions that accompany it. It must be installed

in an easily accessible location for future maintenance. Westin

are not responsible for providing the means of access (e.g.

scaffolding or any alterations to the building and/or furniture

necessary to make access possible) in the event of any

maintenance requirement.

4.7. Electrical Installation

The extractor is a fixed electrical appliance and must have a

provision for isolating the electrical supply via a switched-

fused spur located in an accessible position within the kitchen.

A qualified electrical technician must perform the installation of

the electrical supply to the extractor.

The hood must be fed from a dedicated 230Vac single

phase electrical supply terminated with a switched spur

fitted with a 3A fuse. The switch should be located so that the

supply can be disconnected from the extractor using the

switch at any time following installation (the switch must be

accessible). The means of disconnection from the supply must

have a minimum contact separation of 3mm in all poles.

Alternatively, a means of disconnection in the fixed wiring

according to the relevant wiring rules must be fitted.

A supply cord for connecting the extractor to the spur is

included. The mains supply is connected to the free end of this

cord as follows:

INCOMING SUPPLY CORD CONNECTIONS

Core Core Colour

Live Brown

Neutral Blue

Protective Earth Green/Yellow

For your convenience during installation we recommend

terminating the electrical supply from the switched- fused spur

with a standard UK 3 pin 240V socket positioned close to the

extractors intended location. The extractor's electrical supply

cord can then be fitted with a standard 240V 3 pin plug for

easy connection to the supply during installation.

Make sure the switched - fused spur supplying the extractor is

in the ‘off’ position before connecting the appliance to the

electrical supply.

Because this extractor has no lights but the remote controller

retains a light control button, we provide a switched 230V AC

electrical output that can be used to power your own auxiliary

lights (up to 100W) or ignored according to preference. You

will find a small terminal box containing Live, Neutral & Earth

wires to power lights, should you wish to use it.

4.8. Fixing the Extractor in Position

Please note the following prior to commencing fixing the

extractor in position:

You will need at least 2 people to fit this extractor; to lift,

hold and fix the unit in position:

A working platform or scaffold should be used so that the

ceiling opening can be reached and the unit fixed without

the use of ladders.

ELECTRICAL HAZARD.

DISCONNECT ELECTRICAL SUPPLY

BEFORE PROCEEDING FURTHER

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 5 Westin

Screws for fixing the extractor into position are not

provided. You must use suitable fixings capable of

supporting 30kg.

If you are screwing into timber, then you should use

screws no smaller than 5mm (No 10) with a head diameter

of 10mm or more and ensure that at least 35mm of thread

is screwed into the timber and that the timber will not split

when the screws are inserted.

The unit will need supporting close to the opening when

attaching the ducting and making electrical connections –

do not be tempted to install excessive ducting as this will

impair performance.

As described earlier, a length of semi-rigid ducting

protruding a short distance through the centre of the

ceiling opening is sufficient for the final connection to the

extractor spigot. This will allow the unit to be fixed into

position with the duct connected and prevents excessive

lengths of flexible ducting being pushed into the opening

(and the resultant losses in efficiency which that would

cause (see section 3)).

Note that it is possible to separate and withdraw the spigot

assembly back into the top box (working through the filter

opening). Whilst this should not be necessary, it is worth

noting as it may help you overcome difficulties, particularly

if your ducting has been cut too short, as you will be able

to attach it to the spigot from inside the extractor.

If you have not already done so, set the top box to duct out in

the required direction, as described in section 4.2, and reveal

the corner fixing holes, as described in section 4.3.

If you wish to power lights of your own with this extractor,

then these should be wired into the switched 230V AC

output terminals provided now. Note: Should you wish to,

auxiliary mains powered lighting of up to 100W can be

powered by this extractor. Terminals can be found within the

small lighting terminal box (see diagrams on Page 7

Onwards). A qualified electrical technician must be used to

connect any auxiliary lighting to this appliance.

If using a remote motor, connect it now, as described in

4.6. The illustrations on page 9 will help you.

Support the extractor just below the prepared cut-out so that

the spigot and electrical connections are accessible.

Make sure that the electrical supply to the electrical

supply spur is isolated (switched off) and connect the

electrical supply cord of the extractor to the spur.

Attach the ducting to the spigot using suitable clamps or

straps. We do not recommend using duct tape as the only

means of fixing ductwork.

Now push the extractor (and any wires and terminal

boxes) up into the cut-out, taking care not to crush or

introduce excessive bends/kinks in the ducting and making

sure that no wires are trapped or damaged in the process.

Note: If the duct or any wires are trapped, then you must lower

the extractor and make corrections to the cut-out area as

necessary, before fixing the appliance in position.

Secure the extractor in place using suitable fixings (not

supplied) through the fixing hole in each corner of the

baseplate.

Now test the function of the unit as described in the operating

instructions (Section 6).

If the unit does not function correctly then isolate the electrical

supply and check all the electrical connections before

contacting Westin.

If you experience any difficulties, please call Westin for advice.

4.9. Removing the Motor Transport Ties (If Fitted) (see fig.2)

Note: Transport Ties are only used on smaller appliances to

protect the motor during unpalletised transit.

5. SPECIFICATIONS

All Models

Supply voltage:

230V~ 50Hz

Recommended fuse size for electrical supply:

3A

Extractor Duct spigot

diameter:

150mm

Stratus Air with Internal Motor

Motor airflow in free air:

800 m3/hr

Blower power input:

275W

Total power:

276W

Stratus Air with SEM1 EL Inline Motor

Motor airflow in free air:

800 m3/hr

Motor power input:

275W

Total power:

276W

Stratus Air with SEM2 EL External Wall Motor

Motor airflow in free air:

900 m

3

/hr

Motor power input:

200W

Total power:

201W

Stratus Air with SEM7 EL External Wall Motor

SEM7 airflow, in free air: 200mm Dia Duct

1,700 m

3

/hr

SEM7 airflow, in free air: 150mm Dia Duct

1,500 m

3

/hr

Motor power input:

490W

Total power:

491W

Note: The motor has a 200mm diameter spigot and is supplied with a

reducer for connection to 150mm ducting.

Stratus Air with SEM8 EL Inline Motor

SEM8 airflow, in free air: 200mm Dia Duct

1,300 m

3

/hr

SEM8 airflow, in free air: 150mm Dia Duct

1,100 m

3

/hr

Motor power input:

250W

Total power:

251W

Note: The motor has a 200mm diameter spigot and is supplied with a

reducer for connection to

150mm ducting.

Important Note: Any optional auxiliary lighting powered by this appliance is

not included in the stated power figures shown above.

Maximum wattage of auxiliary lights (not supplied or)

you may power with this appliance:

100W

You must consider and allow for the future removal

of the extractor and any remote motor when

planning and undertaking your installation in case

future access for servicing is required.

ELECTRICAL HAZARD.

DISCONNECT ELECTRICAL SUPPLY

BEFORE PROCEEDING

FURTHER

Fig. 2

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 6 Westin

6. OPERATING INSTRUCTIONS

Switch on the power at the fused spur.

The unit is operated by radio remote control.

Should the extractor fail to respond to commands from the

remote-control console, then please check that the power

is on and the internal appliance reset switch is in the ‘On’

position (factory default). The reset switch is a latching red

push-switch located in the chamber behind the grease

filter(s).

Press the switch fully in to change between ‘on’ and ‘off’

modes. If you are unsure as to the position of the switch,

you can repeatedly press the light switch on the remote

control console during the boot sequence (which lasts

about 15 seconds) to register the remote to the appliance.

- When registered, if the switch is in the ‘on’ position, you

should hear the lighting relay inside the hood click quietly,

or if you have lights connected, they will illuminate.

Should your remote-control stop working, you should

install a new battery before seeking further assistance.

If you experience interference problems or the remote

appears to be faulty from new, then a different radio

transmission code may be required.

Refer to the instruction leaflet included with the radio

remote control console regarding battery replacement and

transmission code changes before seeking assistance.

* The automatic speed reduction feature is required to

comply with EU Ecodesign and Energy Labelling

legislation. Our highest performance SEM remote motors

require speeds to automatically reduce to speed 2.

5. MAINTENANCE

Regular maintenance is essential to ensure good performance

and long-life.

To maintain the immaculate appearance of the extractor, and

to minimise fire risk, ensure that grease deposits on the

extractor surfaces are kept to a minimum by regular cleaning.

To clean the stainless-steel surfaces of the extractor, use a

soft cloth and a suitable cleaning agent, such as a specially

produced stainless-steel cleaner or washing up detergent and

warm water.

Painted surfaces should be cleaned using a soft cloth,

detergent and warm water.

Glass surfaces should be cleaned with a suitable glass

cleaning agent.

Do not use abrasive cleaning materials or products.

Do not use bleach-based cleaning materials or

products.

Clean the grease filters in a dishwasher or by hand-washing in

hot water and detergent every 2 months - sooner if the

extractor is used extensively and filters become grease laden.

Whilst you can expect years of service from mesh grease

filters, they are considered a consumable item and may

deteriorate over time and need replacement, particularly

when cleaned in a dishwasher. For dishwasher users

adhering to a 2 monthly cleaning interval we recommend

grease filter replacement every 5 years to maintain

optimum performance, even if they show no visible signs

of deterioration. For all users, filters should be replaced

whenever they exhibit signs of physical wear.

Accessing the filter(s) and baseplate

The panel is held shut with magnetic catches.

Open the panel by grasping it close to the corners on the catch

side (usually the long edge opposite the hinges) and pulling to

release the panel from the magnets. Take care not to let the

panel fall open freely, it should be supported and lowered

carefully into the open position.

No lights are supplied with this extractor.

CAUTION.

To minimise the risk of fire, all instructions relating

to cleaning the grease filters and removing grease

deposits must be adhered to.

W S Westin Ltd

Phoenix Mills, Leeds Road, Huddersfield, HD1 6NG, UK

Tel: 01484 421585 Fax: 01484 432420 Email:

www.westin.co.uk

Remote Control Functions

The extractor controller will automatically switch

off the appliance if there has been no operator

action for 4 hours.

Motor ON /OFF DECREASE SPEED

RUN ON TIMER

(MOTOR OFF after 10

minutes to clear fumes)

INCREASE SPEED

Speeds 2,3 and Timed

Intensive Speed 4

(Intensive speed reverts

automatically to a lower

speed after 5 minutes *)

Lights

ON/OFF

(only if auxiliary are

lights connected)

Function Pressed

Indicator LEDs

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 7 Westin

This extractor has no lights, however there is a light control button on the remote control console.

We therefore provide a switched 230Vac electrical output (switched on/off when the light button is

pressed) and a terminal box (containing Live, Neutral & Earth wires) that can be used to power your own

auxiliary lights (up to 100W) or ignored according to preference.

This extractor has no lights, however there is a light control button on the remote control console.

We therefore provide a switched 230Vac electrical output (switched on/off when the light button is

pressed) and a terminal box (containing Live, Neutral & Earth wires) that can be used to power your own

auxiliary lights (up to 100W) or ignored according to preference.

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 8 Westin

Typical cut-out detail:

Joists running in line.

Magnetic

Catch

Top Box

Fixing

Screws

Fixing Holes

(screws not

supplied)

Stratus Air with Door Open

Showing Fixing Arrangement

Unit placed within

typical cut-out detail

Set support surface 35mm

up from opening so the

extractor can be pulled up

flat against the ceiling by

your fixing screws.

Do not overtighten screws.

The extractor hangs within

the aperture created.

Ceiling Built-in Unit

STRATUS AIR

Installation, Operating & Maintenance Instructions

W1524 WSW STRATUS AIR Ceiling Extract O&M Oct 16.docx Page 9 Westin

SEM-EL REMOTE MOTOR WIRING ILLUSTRATIONS for Energy Labelling Directive Compliant Motors SEM1, 2, 7 and 8

Red

Blue

White

Grey

Black

Green/Yellow

Brown

Orange

Yellow

Purple

Fig. 4 SEM 1 / SEM 2

Electrical Connections

Fig. 5 SEM 7/ SEM 8

Electrical Connections

Fig. 3 Terminal Colour Positions

Remote Motor

Cable Assembly

(Orange/Yellow link

wire

is

included

)

Remote Motor

Cable Assembly

(Orange/Purple link

wire

is

included

)

Remote Motor

Terminal Box

Fig. 1 Open Terminal Box

Empty Terminal for

Motor Connections

Extractor

Fig. 2 Typical System (SEM2 Shown)

SEM 7

Only

Other manuals for STRATUS Air

1

Table of contents

Popular Scrubber manuals by other brands

Bulldog Scrubbers

Bulldog Scrubbers SS20 user manual

Tornado

Tornado BD 14/4 Operation & maintenance manual

HAKO

HAKO Scrubmaster B260 R operating manual

Matrix

Matrix MEH Manual for installation, use and maintenance

Bergman Pro

Bergman Pro 3190738 instruction manual

Nilfisk-Advance

Nilfisk-Advance BR 652 Instructions for use