Page 2

Top

Module

4

Module

3

Module

2

Module

1

RED

WHT/ORN

BLK

VIO

GRY

WHT/VIO

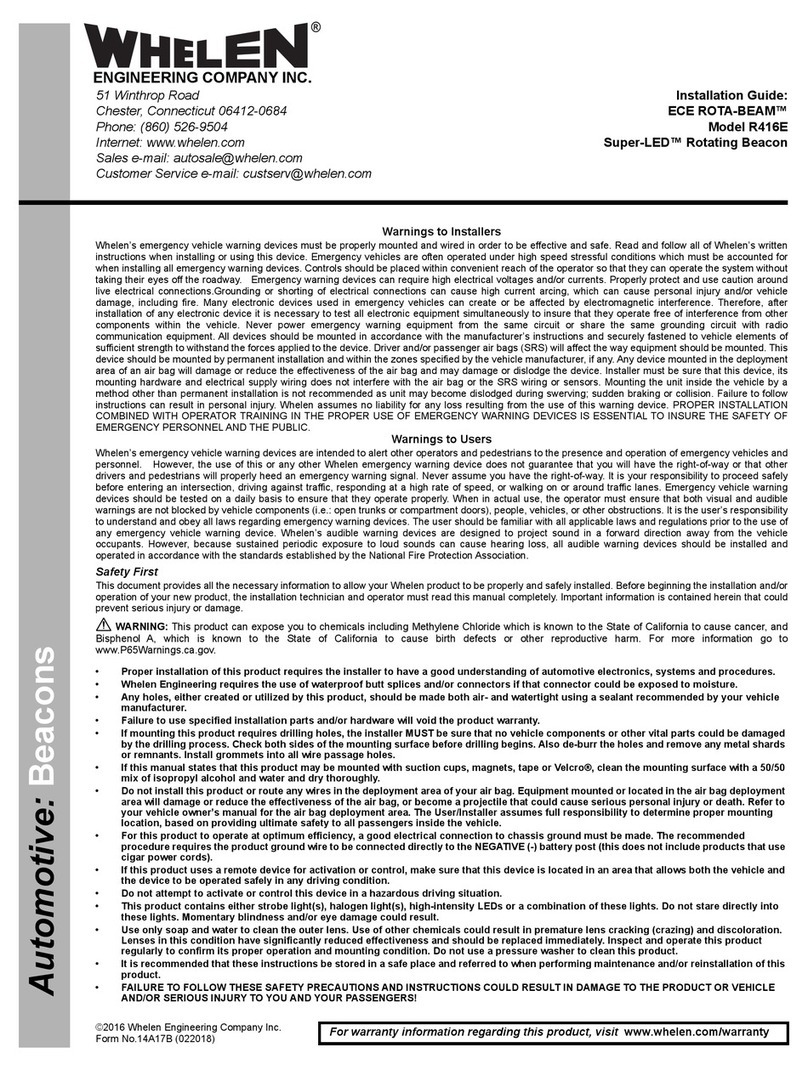

Patterns 1-14:

7 Patterns, each having

a Phase 1 and Phase 2.

SYNC Note:

Set both Beacons to

Phase 1 for simultaneous

display or set one to

Phase 1 and the other to

Phase 2 for alternating

display.

Patterns 22-25:

2 Patterns (Non-SYNC).

Note: Each pattern has

an Alternating (ALT) and

Simultaneous (SIM)

display.

Patterns 26-29:

4 Patterns (Non-SYNC)

Note: These patterns are

only available when both

input wires are active.

Pattern 30:

1 Pattern (Non-SYNC)

Patterns 15-21:

7 Patterns (SYNC).

Module

1+2

Top=Off

Module

1+2

Top=Off

Module

1 then 2

Top=Off

ALT:

Module

1 then 2

Top=Off

SIM:

Module

1+2

Top=Off

ALT:

Module

3 then 4

Top=Off

SIM:

Module

3+4

Top=Off

Module

3+4

Top=Off

Module

3+4

Top=Off

Module

3 then 4

Top=Off

Module

1+2+3+4

Top=On

Module

1+2+3+4

Top=Off

Module

1+2+3+4

Top=On

Module

1+3

then 2+4

Top=Off

ALT:

Module

1+3

then 2+4

Top=Off

SIM:

Module

1+2+3+4

Top=On

RED WHT/ORG RED +

WHT/ORG

INPUT WIRESDETAILSPATTERN LIST

1

2

SignalAlert™ Freedom PH 1

SignalAlert Freedom PH 2

Comet Flash® PH 1

Comet Flash PH 2

DoubleFlash 150 PH 1

DoubleFlash 150 PH 2

DoubleFlash 75 PH 1

DoubleFlash 75 PH 2

SingleFlash 375 PH 1

SingleFlash 375 PH 2

SingleFlash 150 PH 1

SingleFlash 150 PH 2

SingleFlash 75 PH 1

SingleFlash 75 PH 2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

SignalAlert Freedom

Comet Flash

DoubleFlash 150

DoubleFlash 75

SingleFlash 375

SingleFlash 150

SingleFlash 75

22

23

24

25

ActionFlash™ ALT

ActionFlash SIM

ModuFlash™ ALT

ModuFlash SIM

26

27

28

29

50 RPM

75 RPM

118 RPM

250 RPM

30 ActionScan™

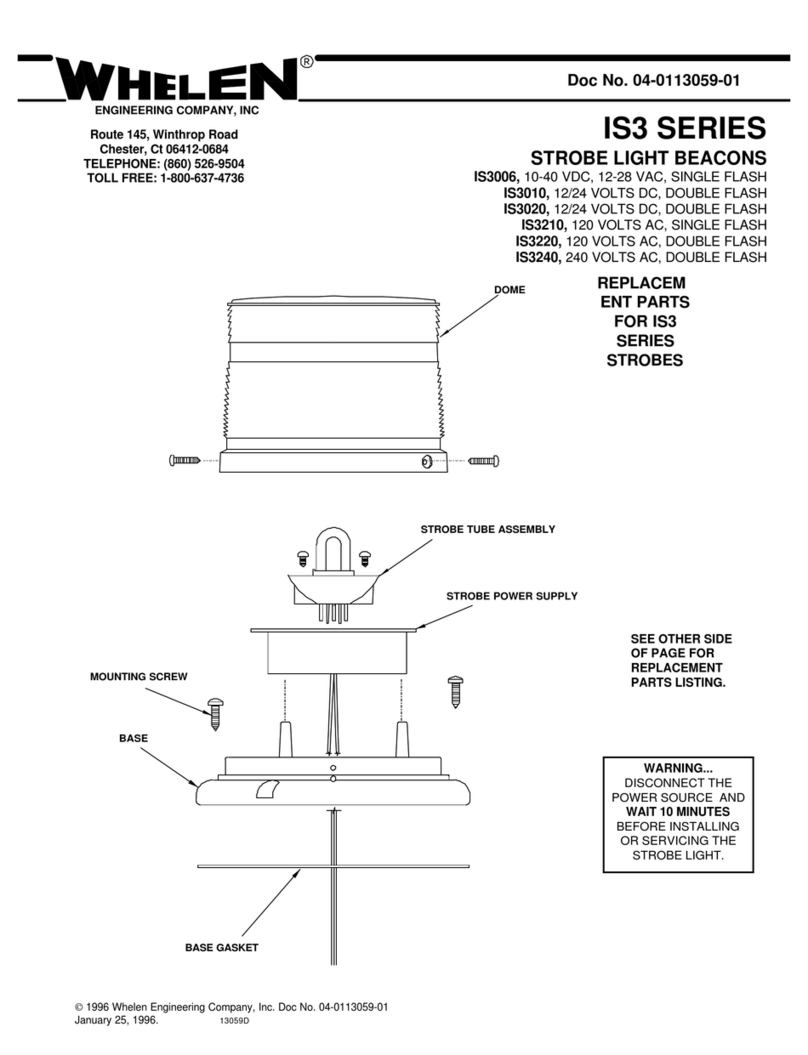

Mounting:

This beacon uses a base that may be mounted one of three ways. It is designed to

be mounted in a normal dome-up position.

Permanent surface mount:

CAUTION: Permanent mounting of this product will require drilling. It is absolutely

necessary to make sure that no other vehicle components could be damaged by this

process. Check both sides of the mounting surface before starting. If damage is

likely, select a different mounting location.

1. Remove the screws securing the dome to the base and remove the dome.

Position the beacon in its proposed mounting location (refer to safety warnings

on page 1).

2. Locate the 3, round mounting holes on the inside bottom of the base. Using the

base as a template, mark the location of the these holes onto the mounting

surface. Remove the beacon and make a mark in the center of the beacon’s

mounted position for a wire passage hole.

3. Using an appropriately sized drill bit (based on the mounting hardware used

and the thickness of the mounting surface), drill the three mounting holes

marked in step 2. The wire access hole should be drilled using a 3/8” drill bit.

Deburr all holes and install a rubber grommet (customer supplied) to protect

the wires.

4. Turn the beacon upside-down so that the bottom of the base is facing up.

Remove protective backing from the base gasket and apply to the beacon

base. It is critical that the gasket be centered on the base with its slot

aligned with the base notch! Make sure the gasket is flat against the base.

5. Feed the wires through the wire access hole in the mounting surface.

6. Align the base with the mounting holes and secure with 3 sheet metal screws.

Position the O-ring onto the base as shown and carefully return the dome to its

mounted position. After visually confirming that the gasket is properly seated,

secure the dome to the base using the hardware removed in step 1.

1” N.P.T. Pipe Mount (optional):

1. Turn the beacon upside-down so the bottom of the base is facing up. Remove

the base gasket from the base and discard. Install the grommets (included with

the kit) into the three, square mounting holes in the bottom of the base.

2. Feed the beacon wires through the pipe mount base plate. Secure the base

plate onto the beacon base using the provided hardware.

3. Feed the beacon wires through the pipe and connect the beacon wires as

outlined in the Permanent Mount section.

4. Install the plugs (included with kit) into the unused permanent mounting holes.

5. Screw the strobe beacon onto the pipe, being careful not to pinch or strain the

wires. Hand tighten the unit onto pipe.

Operation:

This beacon features low power operation, Scan-Lock pattern control and

SYNChronization capabilities. These functions operate as outlined below.

Low Power - Activate the VIO wire to put the beacon into low power operation.

Disable this wire to restore normal, high power operation.

Scan-Lock™ - Activate the RED wire to turn on the beacon. Activate the WHT/VIO

wire for less than 1 second and release to cycle forward through patterns. Activating

the WHT/VIO wire for more than 1 second will cause the lighthead to cycle backward

through patterns. When the desired pattern is displayed, allow it to run for more than

5 seconds. The lighthead will now display this pattern when active. To reset to the

factory default pattern, turn off power, activate the WHT/VIO wire, then turn power

back on.

See below for pattern information:

All lightheads configured to display the Phase 1 mode of a given pattern will flash

simultaneously. Any lightheads configured to display the Phase 2 mode of a pattern,

will alternate with any Phase 1 lightheads with the same pattern.

Sync - To sync two lightheads, configure both lightheads to display the same Phase

1 pattern. With the power off, connect the GREY wires from each lighthead together.

When the lightheads are activated, their patterns will be synchronized. To configure

the two lightheads to alternate their patterns, advance the pattern of either lighthead

to the Phase 2 mode of the current pattern.

The following example will demonstrate how to use the SYNC feature with more than

2 lightheads. In this sample system, there are 4 lightheads. 2 are mounted on the

rear, driver side of the vehicle and 2 mounted on the rear, passenger side of the

vehicle.

With all the wiring complete, turn on the 4 lightheads. As shipped from the factory, all

the lightheads will simultaneously display the same pattern (SignalAlert 75 Phase 1).

To configure, for example, the passenger side lightheads to alternate with the driver

side lightheads, change the flash patterns for either the passenger or driver side

lightheads to Phase 2 mode of the same pattern. Do not SYNC more than 8 (eight)

beacons!

The beacon wires function as outlined below:

Color Function Connect to: Switch Type Fuse @

RED . . . . . . . Power (Modules 1&2) . . . .+12VDC . . . . . . SP/ST . . . . . . . . . . . . 3 Amp

WHT/ORN . . Power (Modules 3&4) . . . .+12VDC . . . . . . SP/ST . . . . . . . . . . . . 3 Amp

VIO . . . . . . . Low Power . . . . . . . . . . . . .+12VDC . . . . . . SP/ST . . . . . . . . . . . . 1 Amp

WHT/VIO . . . Scan-Lock™ . . . . . . . . . . . .+12VDC . . . . . . MOM (N.Open) . . . . . 1 Amp

BLK . . . . . . . Ground . . . . . . . . . . . . . . . .Ground . . . . . . . n/a. . . . . . . . . . . . . . . . . N/A

GRY. . . . . . . SYNC . . . . . . . . . . . . . . . . .See text . . . . . . n/a. . . . . . . . . . . . . . . . . N/A

WARNING! All customer supplied wires that connect to the positive terminal

of the battery must be sized to supply at least 125% of the maximum operating

current and FUSED at the battery to carry that load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

Refer to the “Operation” section for wire function information.

Temporary Mount (Magnetic, Suction Cup, etc.)

WARNING: The use of any magnetically mounted warning device on the

outside of a vehicle in motion is not recommended and is at the sole risk

and responsibility of the user.

Magnetic/suction: Thoroughly clean the proposed mounting surface prior to

mounting. For suction cup mounting, wipe the suction cup clean, place the beacon

onto its mounting surface and apply gentle pressure to ensure a good seal has been

achieved. The Magnetic/Suction Cups mount the same way as standard suction cups

but are best suited to a flat, steel surface. Magnetic: Simply place the beacon onto

the mounting surface and plug it into the vehicle cigar lighter.

NOTE: The magnetic mount model does not offer Scan-Lock™, Cruise Light,

Low Power or SYNC.