ProCal

Operating Instructions

Product Overview

The Pro Cal Calibration Kit is a professional grade

instrumentation system designed to rapidly monitor the

calibration status of your furnace, and automatically

recalibrate the furnace to factory specifications.

It is recommended that you read this manual thoroughly

before using the kit as there are valuable examples of

procedures and decisions you will want to be acquainted

with in order to maximize the benefits you’ve invested in.

What You Can Do With It

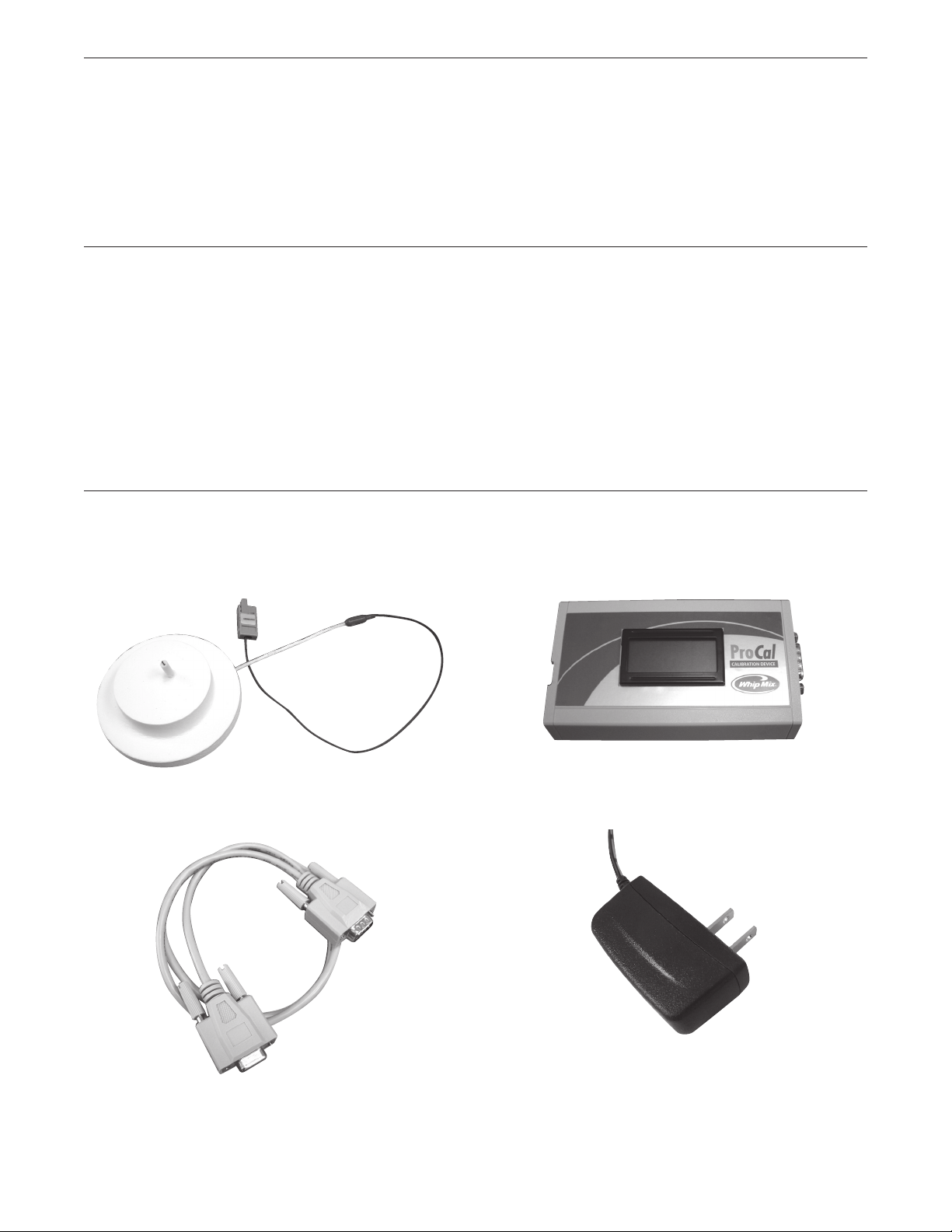

QC = Quick Check (Pro 200 Series). For FireLite refer to

page 9.

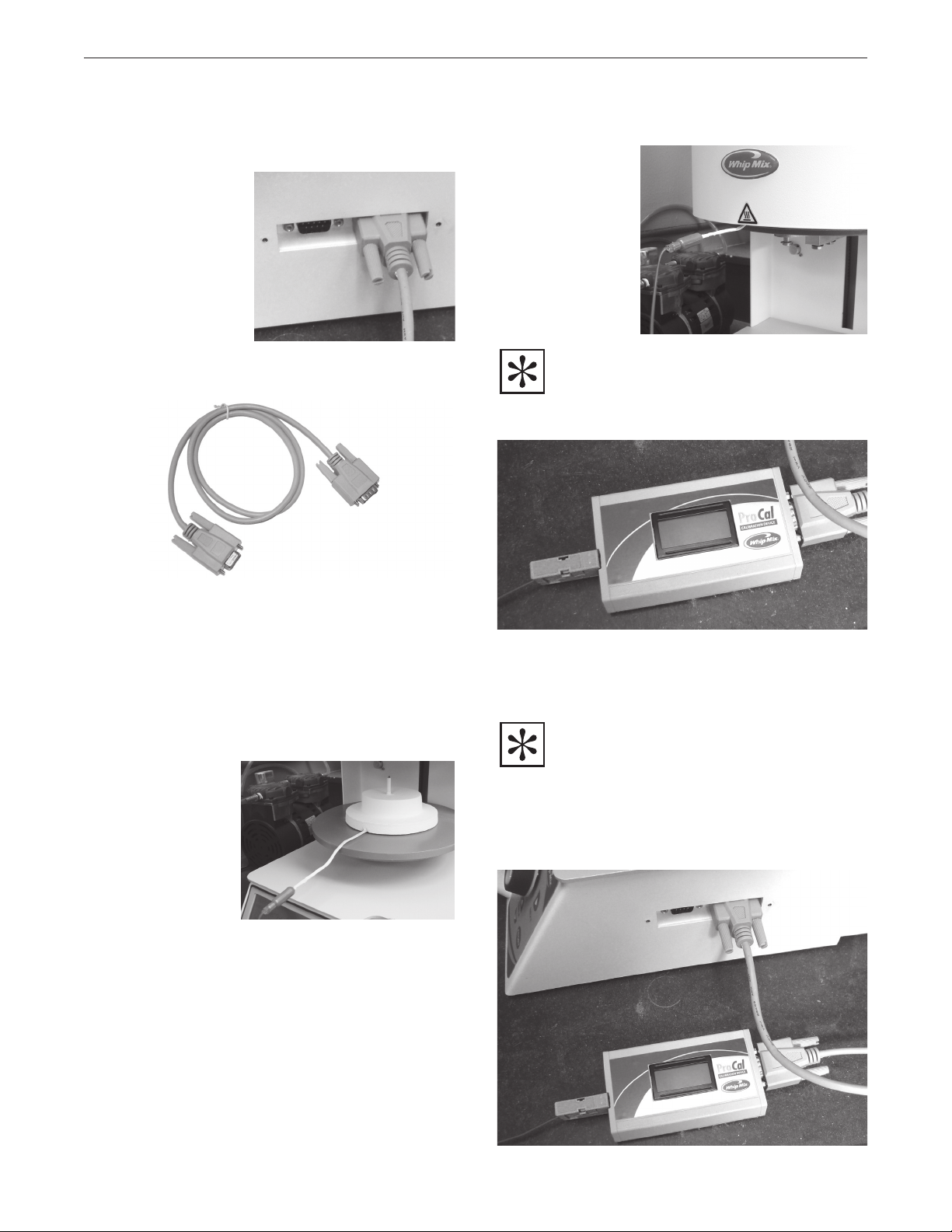

The Quick Check feature allows you to rapidly spot check

the need for calibration. Simply place the Special Firing

Tray on the Lift Table, connect the Tray to the Instrument

Box and the Instrument Box to the furnace calibration

port, and dial in the desired temperature you want to

verify. The LCD readout on the ProCal box should agree

with the furnace display to within three degrees Celsius. If

not, you can choose one of several options:

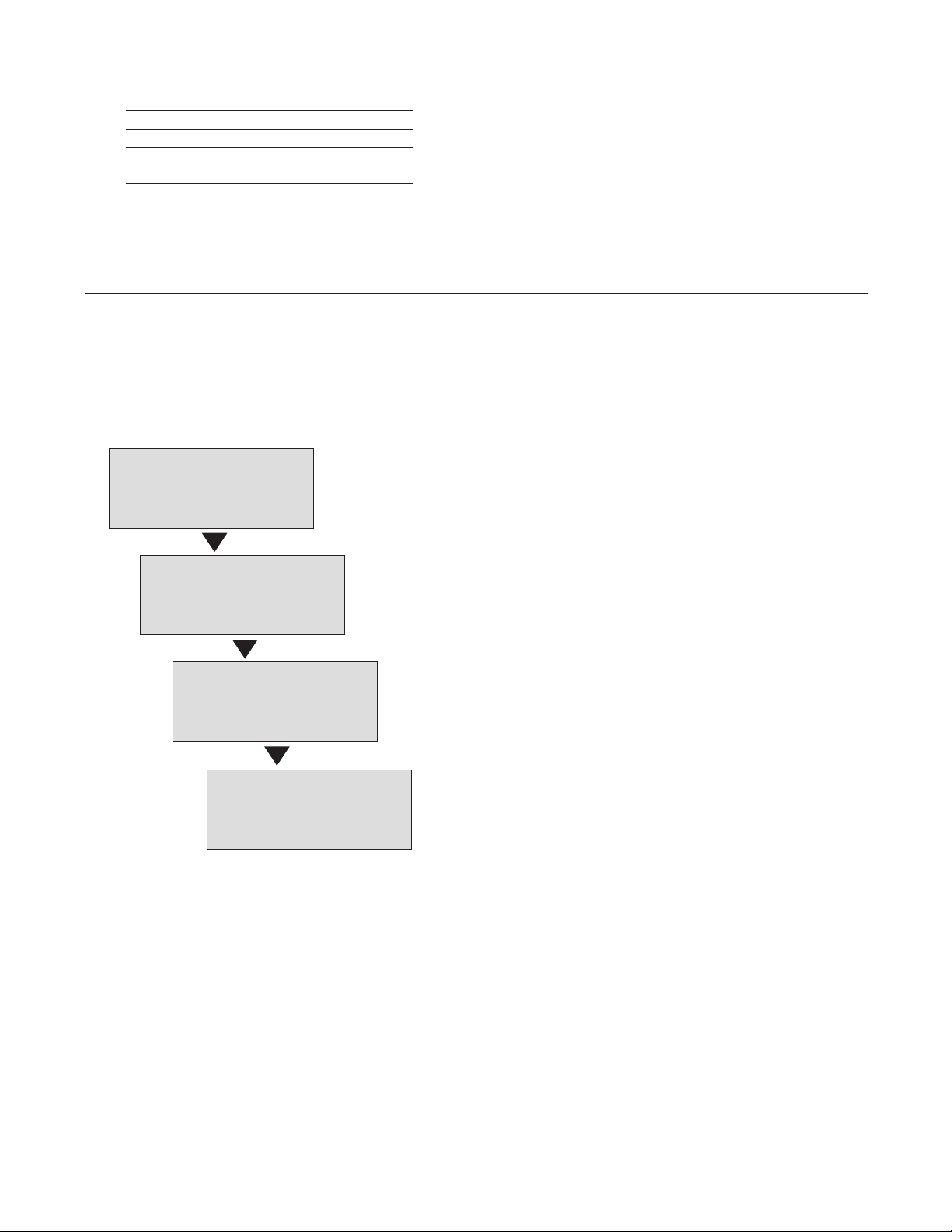

1. If you check several temperatures and only one

seems to be different, you can go into the firing

programs which have hold temperatures at that

value and use the Program Level Fusing Adjust to

fine tune just those programs.

2. If you check several temperatures and they all either

overfire or underfire, you can go into the Special

Functions menu and select High Fusing Adjust for

temperatures over 800°C or Low Fusing Adjust for

temperatures under 800°C and enter the average

correction value needed.

3. You can do a fully automated calibration.

Full Recalibration (Pro 200 Series Only)

The full recalibration mode requires several hours to

complete, so you’ll want to reserve it for times when the

temperature is more than three degrees from nominal.

Why does it take so long? To get a valid calibration

which will most closely match the conditions in which it

is used every day the furnace must be fully heat soaked.

Secondly, the automatic calibration program requires

one pass at three separate temperatures to build the

calibration file. Thirdly, a second complete pass is

necessary to confirm that the calibration pass is valid.

This is exactly the same rigorous process that your

furnace went through before it left the factory originally.

Why Do Furnaces Require Periodic

Temperature Recalibration?

There are several reasons why furnaces require periodic

QC checking and recalibration:

Effluents given off by the materials fired in the furnace

can deposit on the platinum/palladium thermocouple and

in some cases, chemically react with the noble metals,

thereby affecting the temperature sensed.

Oxide layers can build up on the thermocouple

through many cycles of vacuum, then exposure to

air and chemically react with the noble metals in the

thermocouple.

Prolonged high heat exposure can eventually crystallize

the noble metals making them brittle and inhibiting the

buildup of charge on each leg. The millivolts given off by

a thermocouple to register temperature accumulate all

along the heat exposed legs of the thermocouple, not just

at the tip.

The heater wire also becomes brittle and scaly along its

surface after extended usage. This can affect the infrared

spectrum irradiated by the heater and redirect the angle

which the photons emitted by the heater such that the

ones striking the thermocouple are more diffused and

therefore create less charge buildup in the thermocouple,

affecting the calibration.

How It Works - What’s it doing in there?

The thermocouple in the Special Firing Tray monitors the

furnace activity and reports its accumulated charge back to

the Instrument Box. The Instrument Box filters the electrical

noise inherent with very low level signals in the microvolt to

millivolt range. The cleaned-up signal is then sent to a pre-

amplifier with a built in digital filter to further boost the signal

and clean it up some more. Finally, the signal is presented

to a 24 bit Analog to Digital Converter (ADC) for conversion

into digital ones and zeros to be transmitted to the furnace

computer. There is also a local “ambient” temperature

sensor inside the Instrument Box which monitors the “cold

junction” temperature at the point where the thermocouple

alloys transition into the electronics. This cold junction

temperature sensor output is automatically used by the

computer inside the Instrument Box to correct any

measurement errors as the reference signal from the

SpecialFiring Tray makes its way back to the furnace.

Once the digital reference value from the Special Firing

Tray is received back in the furnace computer its value is

compared to the internal furnace thermocouple and the

sign (relative over-firing or under-firing) and the magnitude

of the difference are stored permanently in the furnace

computer.

After the calibration process is complete, every time

the furnace temperature is commanded to a specific

temperature, the furnace computer looks at the target

temperature, determines which calibration value is

appropriate for that target value, and either adds or

subtracts the stored calibration correction value in order to

produce the accurate temperature desired, all in real-time.

1