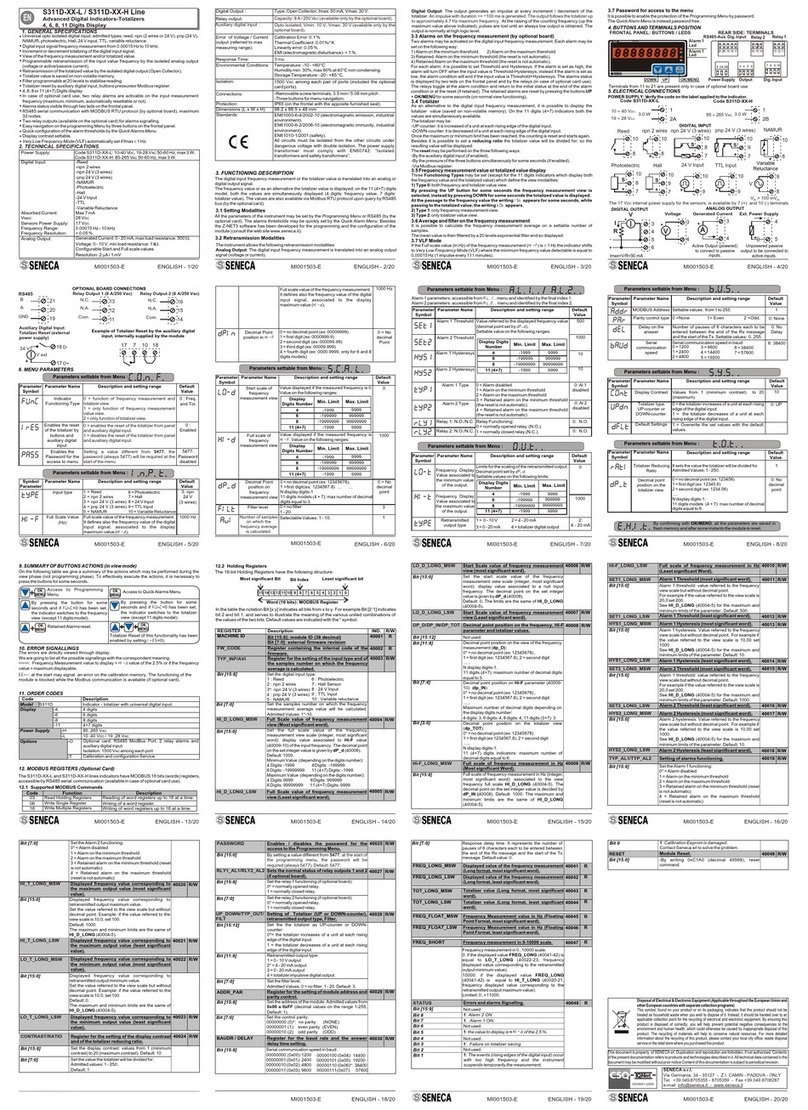

MI00614-1-EN INSTALLATION MANUAL 3/8

CERTIFICATIONS

INSULATION

ENVIRONMENTAL

CONDITIONS

Temperature: -25°C ÷ +65°C

Humidity: 30% ÷ 90% non condensing.

Storage temperature: -30°C÷ + 85°C

Degree of protection: IP20

ASSEMBLY DIN rail 35mm IEC EN60715, wall or panel with screws.

CONNECTIONS Screw terminals 5 mm, 7.5 mm and 3.5 mm pitch (RS485), cable with section <2.5 mm2

POWER SUPPLY Voltage: 90 ÷ 264Vac @ 50 ÷ 60Hz, max absorption: 2.5W @ 4VA (only R203-H)

Voltage: 10 ÷ 30Vdc, max absorption: 2.5W @ 24VA (only R203-L)

COMMUNICATION

PORTS

RS485: Baud rate: 1200 ÷ 115200 baud (for further information see the user manual).

Ethernet ports 2 (model R203-2); 1 (model R203-1)

VOLTAGE

INPUT

Voltage Up to 600 Vac, frequency 45 ÷ 65Hz

Minimum voltage 5 V (F.S. 150 Vac); 20 V (F.S. 600 Vac)

ANALOGUE

INPUT TA / TA

(mV)

Current input

Current input for TA: 1 ÷ 5A full scale.

Voltage input (mV) for TA with voltage or Rogowski output: up to 333 mV full

scale.

Base prec. (*) Network frequency: 50 ÷ 60 Hz. Voltmeter: 0.2%

Ammeter: 0.2%, wattmeter: 0.5%

(*) See the user manual for the error limits.

ROGOWSKI

ANALOGUE

INPUT

Class / base

prec. (*)

Network frequency: 50 ÷ 60 Hz. Voltmeter: 0.5%

Ammeter: 0.5%, wattmeter: 1%

Rogowski

supplied by

Seneca

• 100 mV correspond to 1000 A @ 50 Hz (sinusoidal)

• 120 mV correspond to 1000 A @ 60 Hz (sinusoidal)

Maximum measurable current: 3kA @ 50 Hz; 2.5kA @ 60Hz

Precision after calibration: ± 1 % (see chapter “Rogowski sensor”)

Linearity: ± 0.2 %

(*) Accuracy is guaranteed in the ranges: CosΦ > 0.5; Vrms: 40 ÷ 600 Vac; Irms: 5 - 100% Rogowski current (error due to

external Rogowski sensors excluded). See the user manual for the error limits.

ANALOGUE

OUTPUT

Voltage: 0÷ 10Vdc, minimum load resistance: 2kΩ

Current: 0 ÷ 20 mA, max. load resistance: 500Ω

Transmission error: 0.1% of maximum eld

Response time: 1 s (10% ÷ 90%)

Temperature drift: 100 ppm/K

DIGITAL

INPUT For the technical specications, see the electrical connection diagrams on page 5

DIGITAL

OUTPUT For the technical specications, see the electrical connection diagrams on page 5

COUNTERS

Number of counters: 2 at 32 bit, maximum speed: 5 KHz

INSTALLATION

CATEGORY

Category ⅡI (up to 600 V) in a direct connection (only R203-H)

Category ⅡI (up to 300 V) in a direct connection (only R203-L)

TECHNICAL SPECIFICATIONS

ETH1 ETH2

PWR RS485

DIGITAL

I/O

ANALOG

INPUT

ANALOG

OUTPUT

ETH1 ETH2

PWR RS485

DIGITAL

I/O

ANALOG

INPUT

ANALOG

OUTPUT

R203-X-L

*: Rated withstand voltage

KEY:

R203-X-H