Whirlpool® and Maytag® Dryer niii

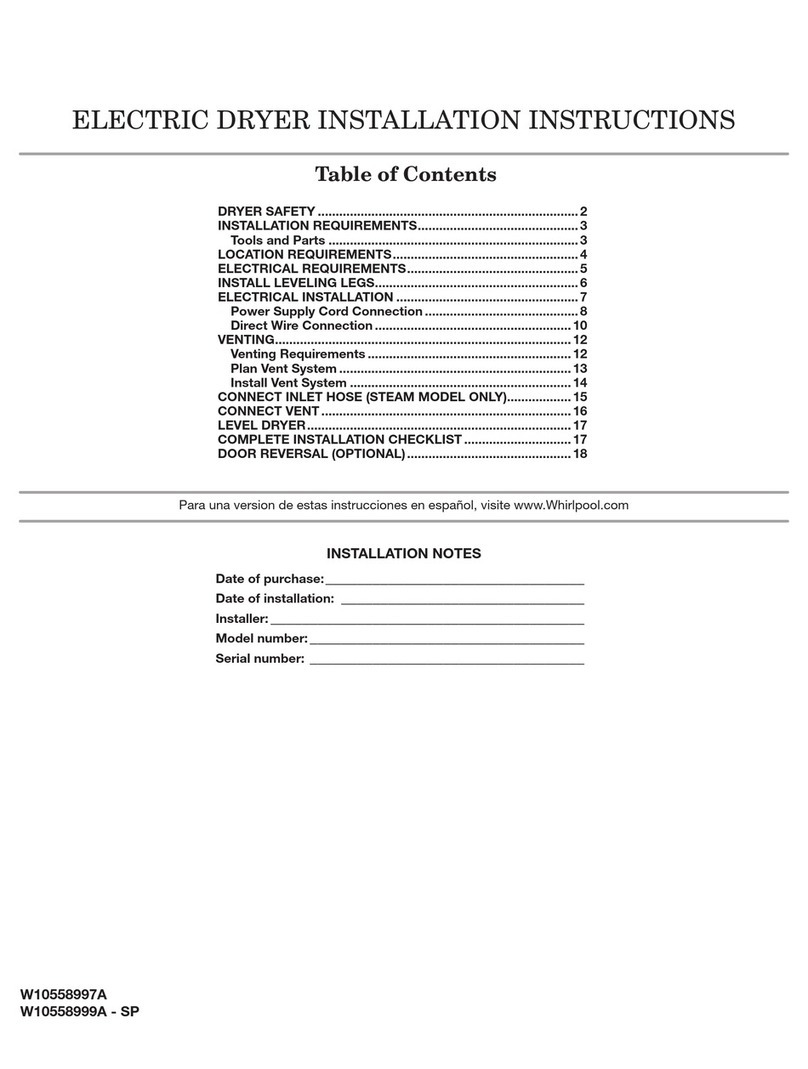

TABLE OF CONTENTS

Whirlpool® and Maytag® Dryer

SECTION 1: GENERAL INFORMATION........................................................................

DRYER SAFETY ..................................................................................................................................

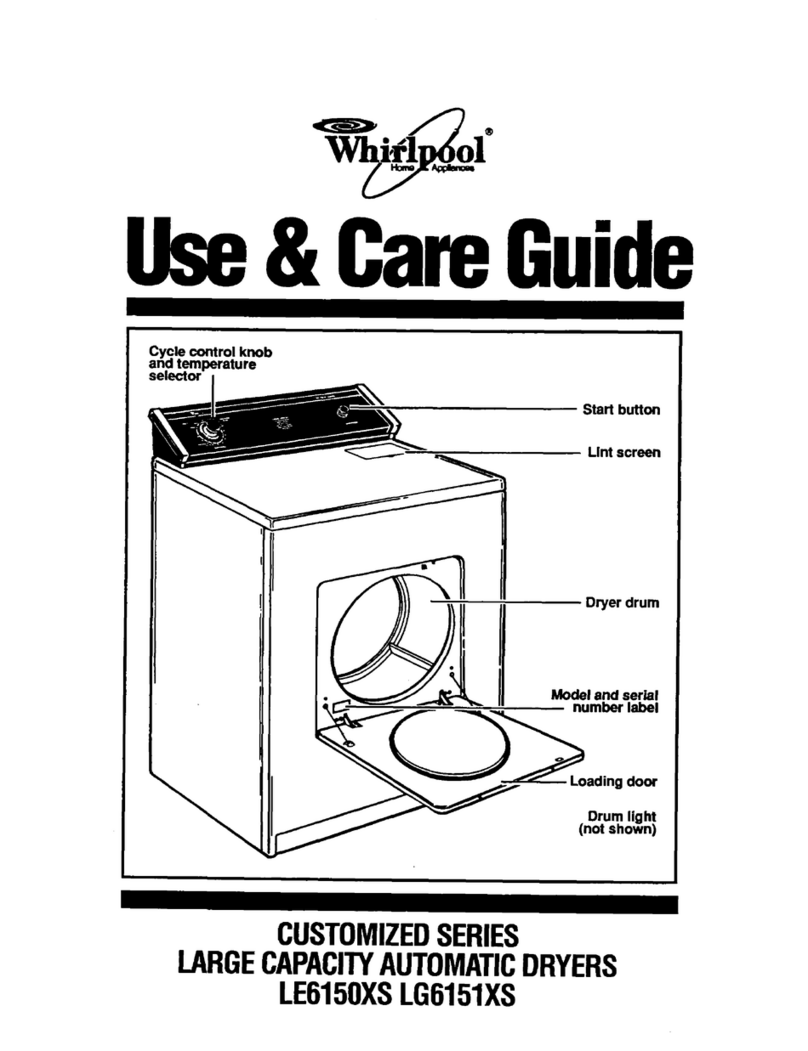

PRODUCT SPECIFICATIONS...............................................................................................................

MODEL AND SERIAL NUMBER LOCATION........................................................................................

MODEL NOMENCLATURE .................................................................................................................

TECH SHEET LOCATION.....................................................................................................................

...............................................

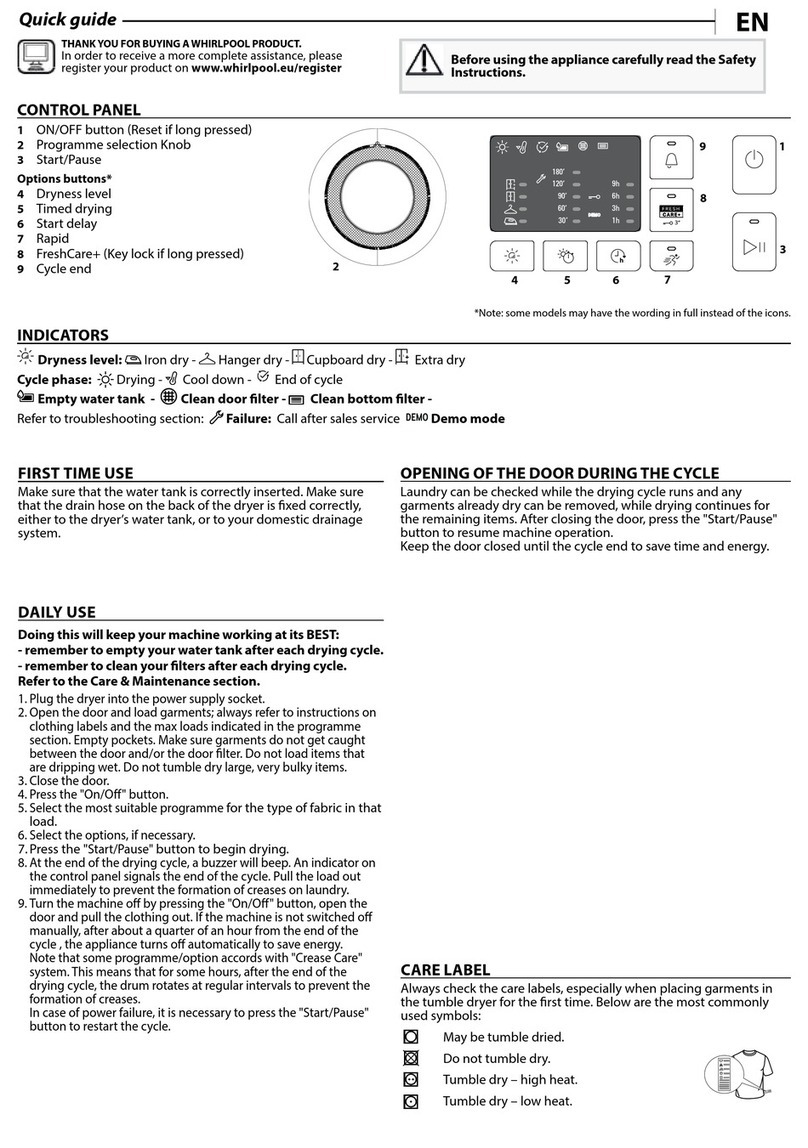

SAFETY ..............................................................................................................................................

SERVICE GUIDE .................................................................................................................................

ACTIVATING SERVICE MODE ............................................................................................................

SERVICE MODE FUNCTION...............................................................................................................

SENSOR FEEDBACK FUNCTION CHART ............................................................................................

SERVICE DIAGNOSTICS CHART.........................................................................................................

FAULTS AND ERROR CODES..............................................................................................................

TROUBLESHOOTING GUIDE .............................................................................................................

...........................................................................

SAFETY ..............................................................................................................................................

......................................................................

TROUBLESHOOTING TESTS...............................................................................................................

TROUBLESHOOTING GUIDE FOR CONNECTED DRYER.....................................................................

STRIP CIRCUITS.................................................................................................................................

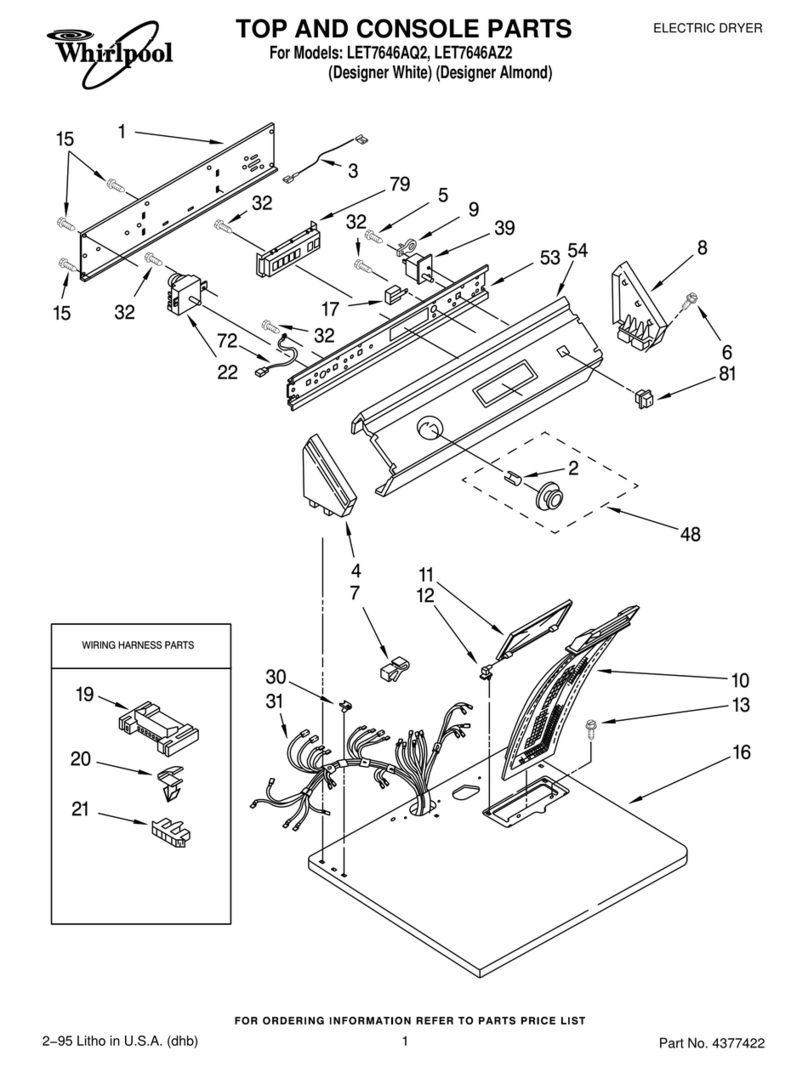

WIRING DIAGRAMS..........................................................................................................................

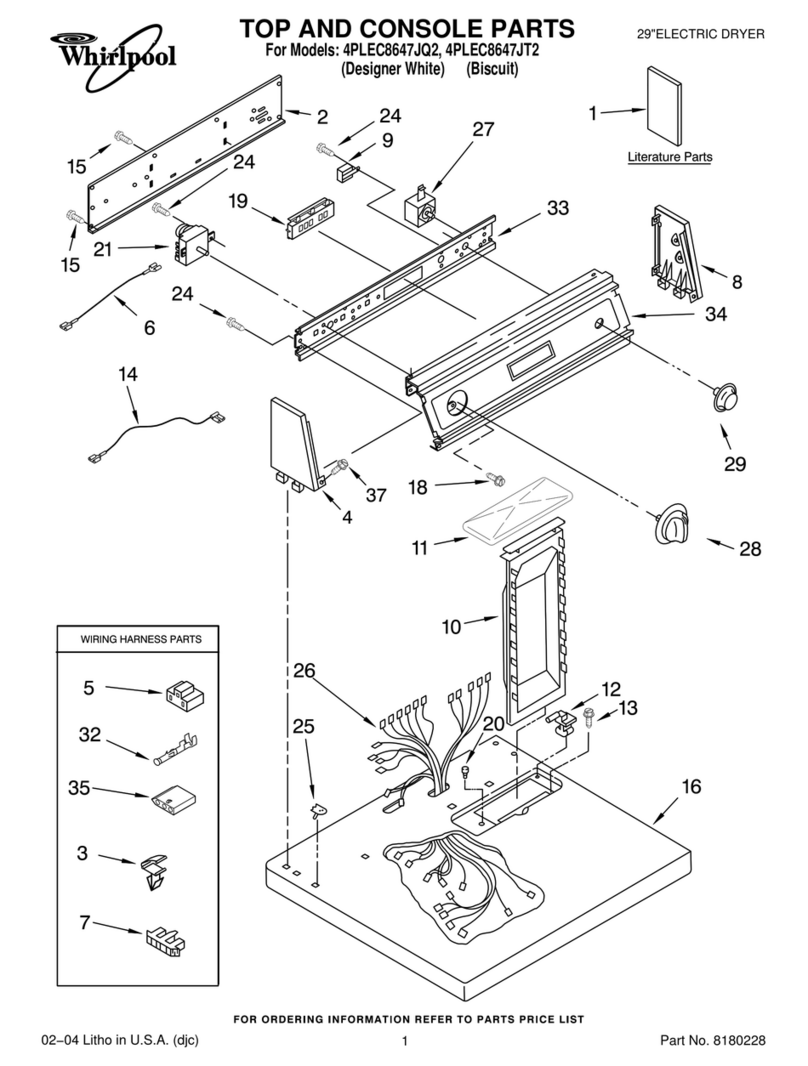

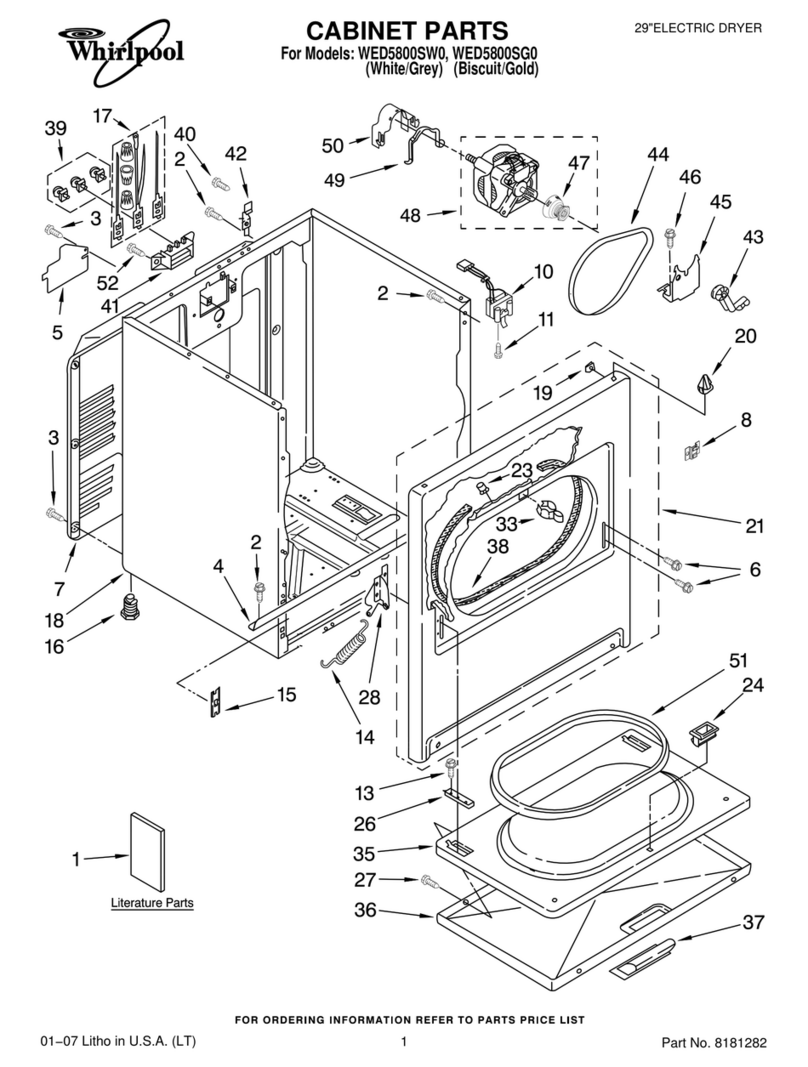

COMPONENT LOCATIONS.................................................................................................................

SECTION 4: COMPONENT ACCESS .............................................................................

REMOVING THE DOOR ASSEMBLY ...................................................................................................

....................................................

........................................................................

REMOVING THE FRONT PANEL AND DOOR SWITCH .......................................................................

REMOVING THE DRUM LIGHT AND MOISTURE SENSOR.................................................................

REMOVING THE BELT, DRUM, AND ROLLERS...................................................................................

REMOVING THE DRIVE MOTOR........................................................................................................

REMOVING THE THERMAL FUSE AND OUTLET THERMISTOR.........................................................

REMOVING THE HEATER, HIGH LIMIT THERMOSTAT, AND THERMAL CUTOFF

................................................................................................................

..........................................................................................

..........................................

......................................................................