CONTENTS

2 M-GV/2, M-GV/3, M-GV/3+, M-GV 8, M-GV 10, M-GV 12 and M-GV 15 May 2018 EN

CONTENTS

1 INTRODUCTION .......................................................................................................................................................................... 4

1.1 General ................................................................................................................................................................................. 4

1.2 Service and maintenance ..................................................................................................................................................... 4

1.3 Guarantee ............................................................................................................................................................................. 4

1.4 Liability ................................................................................................................................................................................. 5

1.5 Identification ........................................................................................................................................................................ 5

1.5.1 General .............................................................................................................................................................. 5

1.5.2 Identification plate ............................................................................................................................................. 5

2 GENERAL INFORMATION ............................................................................................................................................................ 6

2.1 Safety .................................................................................................................................................................................... 6

2.1.1 General .............................................................................................................................................................. 6

2.1.1 Warnings and symbols ....................................................................................................................................... 6

2.1.2 Scope of regulations .......................................................................................................................................... 6

2.1.4 Maintenance & repair ........................................................................................................................................ 6

2.1.5 Electrical safety .................................................................................................................................................. 6

2.1.6 Installation ......................................................................................................................................................... 6

2.1.7 Operation ........................................................................................................................................................... 6

2.1.8 Fire and explosion .............................................................................................................................................. 7

2.1.9 Dangerous substances ....................................................................................................................................... 7

2.1.10 Warning regarding life support applications ..................................................................................................... 7

2.2 Transport, lifting and storage ............................................................................................................................................... 7

2.3 Features ................................................................................................................................................................................ 7

2.3.1 General .............................................................................................................................................................. 7

2.3.2 Construction ...................................................................................................................................................... 7

2.3.3 Control ............................................................................................................................................................... 8

2.3.4 Installation ......................................................................................................................................................... 8

2.3.5 Documentation .................................................................................................................................................. 8

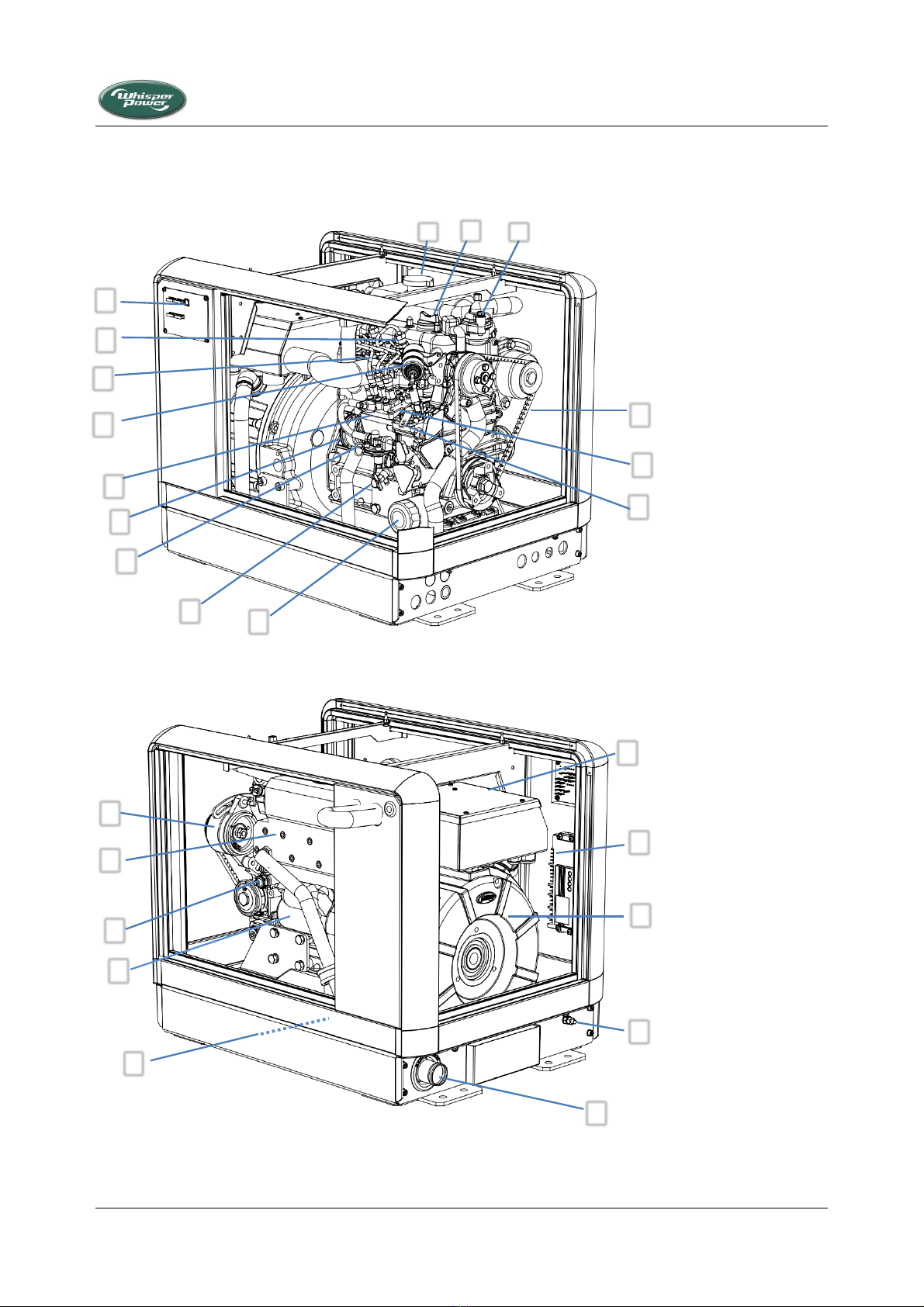

2.4 Main components to identify ............................................................................................................................................... 9

2.4.1 M-GV/2 and M-GV 8, M-GV/3 and M-GV 10 ..................................................................................................... 9

2.4.2 M-GV/3+, M-GV 12 and M-GV 15 .................................................................................................................... 10

3 TECHNICAL INFORMATION ....................................................................................................................................................... 11

3.1 Explanation of functional parts .......................................................................................................................................... 11

3.1.1 Control system ................................................................................................................................................. 11

3.1.2 AC Permanent Magnet Alternator ................................................................................................................... 11

3.1.3 Engine .............................................................................................................................................................. 11

3.1.4 Starter battery charging ................................................................................................................................... 11

3.1.5 Alarms and shut-down ..................................................................................................................................... 11

3.1.6 Control ............................................................................................................................................................. 11

3.1.7 Remote control panel ...................................................................................................................................... 11

3.1.8 Fuel .................................................................................................................................................................. 11

3.1.9 Biodiesel........................................................................................................................................................... 12

3.1.10 Lubricating oil .................................................................................................................................................. 12

3.1.12 Cooling liquid ................................................................................................................................................... 12

3.2 Technical data .................................................................................................................................................................... 13

4 OPERATION .............................................................................................................................................................................. 15

4.1 General ............................................................................................................................................................................... 15

4.2 Programmable speed ......................................................................................................................................................... 15

4.3 Operating instructions ........................................................................................................................................................ 15

4.3.1 Daily check of oil level ...................................................................................................................................... 15

4.3.2 Summarized operating instructions (daily use) ............................................................................................... 15

4.3.3 Extended operating instructions ...................................................................................................................... 15

5 MAINTENANCE ......................................................................................................................................................................... 17

5.1 Maintenance intervals ........................................................................................................................................................ 17

5.2 Alternator ........................................................................................................................................................................... 17

5.3 Engine ................................................................................................................................................................................. 17

5.3.1 Preliminary instructions ................................................................................................................................... 17

5.3.2 Bleeding the fuel lines...................................................................................................................................... 17

5.4 Regular maintenance.......................................................................................................................................................... 17

5.4.1 General precautions ........................................................................................................................................ 17

5.4.2 Servicing after break-in .................................................................................................................................... 18