INSTALLATION

US / M-SQ7 / October 2010 7

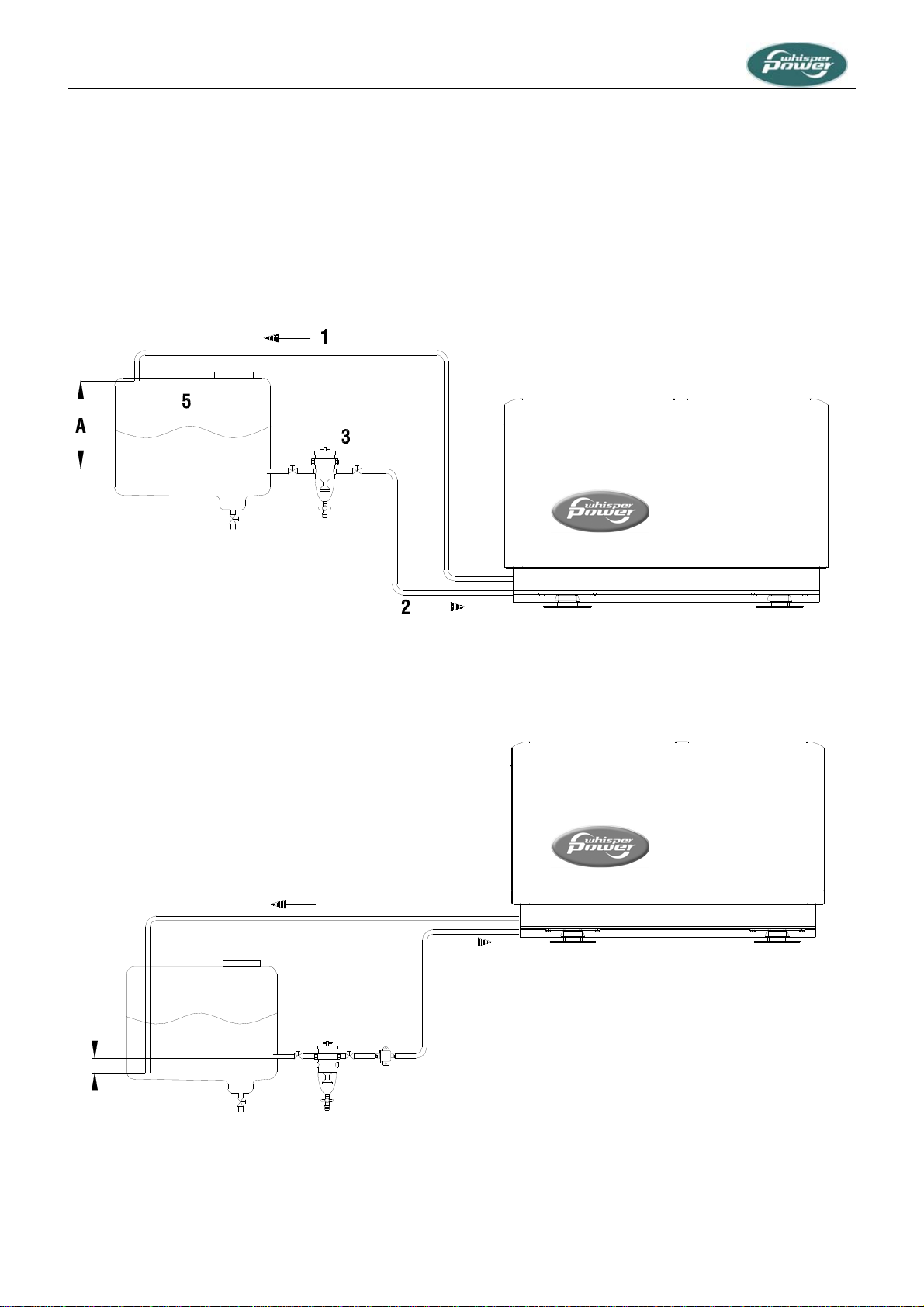

2 FUEL LIFT PUMP

The generating set itself is equipped with a fuel lift pump;

therefore the tank can be installed at a lower level than the

generating set. The maximum suction height is 1 m.

If the pump has to lift the fuel higher than one meter an

external fuel lift pump must be installed. The control board

is already prepared to connect an extra fuel pump.

3 FUEL PIPES

When the tank is above the generating set we recommend

ending the return line on the top of the tank.

When the return is on the top - in case of a leakage the

return line cannot overflow because of siphoning. One will

only need a fuel cock in the fuel supply line. When the tank

is below the generating set we recommend ending the

return line on the bottom of the tank (A) below the inlet of

the supply line.

Both supply and return fuel pipe lines should be

appropriate material and 5/16” (8 mm) outer diameter

tubing. The quality of the tubing of fuel pipes could be

submitted to local regulations depending on the application

of the vessel.

The fuel pipes can be plumbed to the flexible hoses which

are on the generating set and have a connection to fit to

5/16” (8 mm) pipe. This fuel lines fulfils CE standards and

are according to ISO 7840 A2.

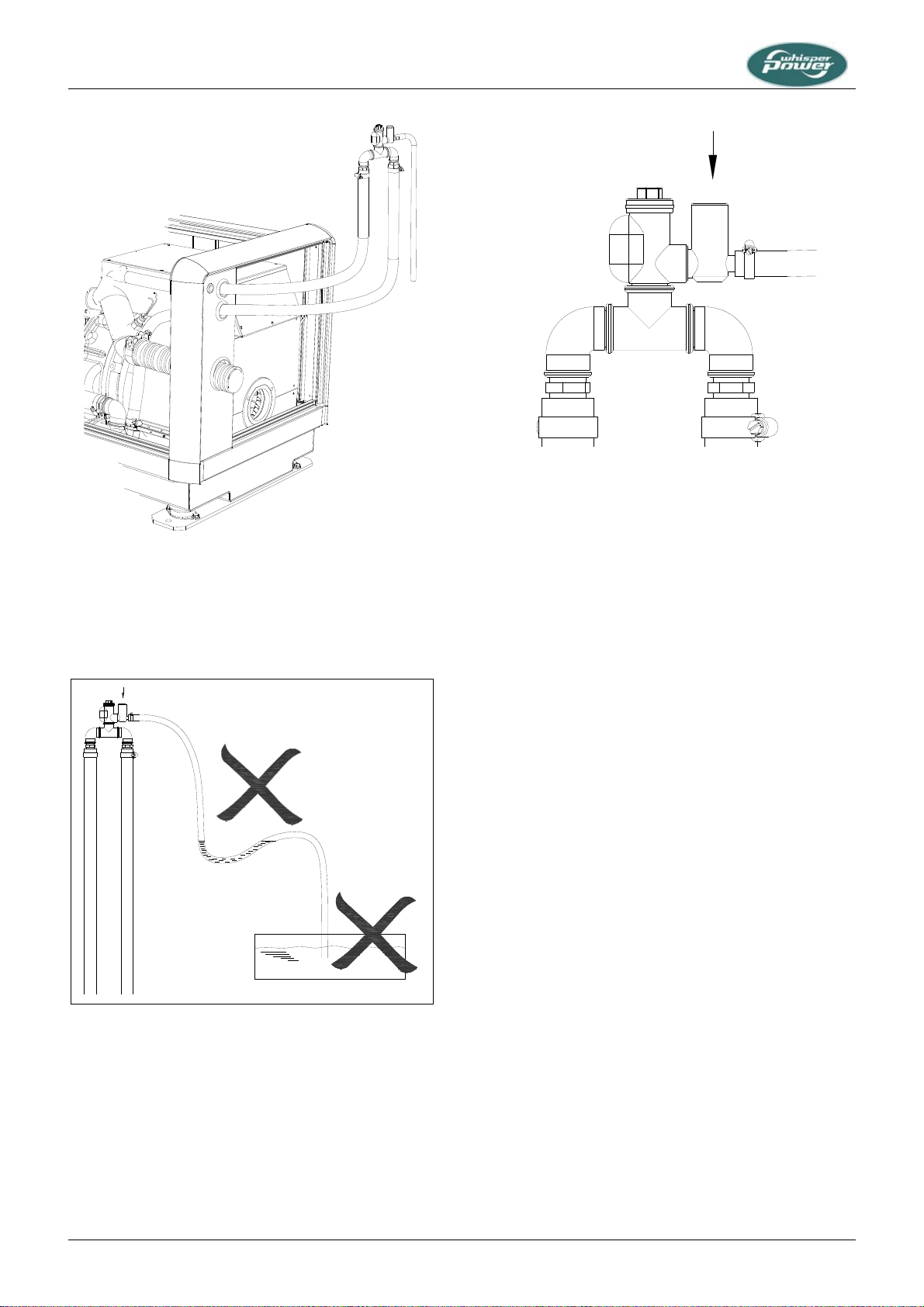

It is important to avoid bends in the pipes, as they could

trap air bubbles. The return pipe should never be

connected to the suction pipe. Other consumers of diesel

fuel, such as the propulsion engine and heaters, have to

be connected to separate suction and return pipes

4 FUEL FILTERS

A fine fuel filter is installed which requires maintenance.

WhisperPower advises to install an extra fuel filter/ water

fuel separator near the fuel tank.

Before starting your generating set for the first time follow

the fuel system bleeding procedure in the users manual.

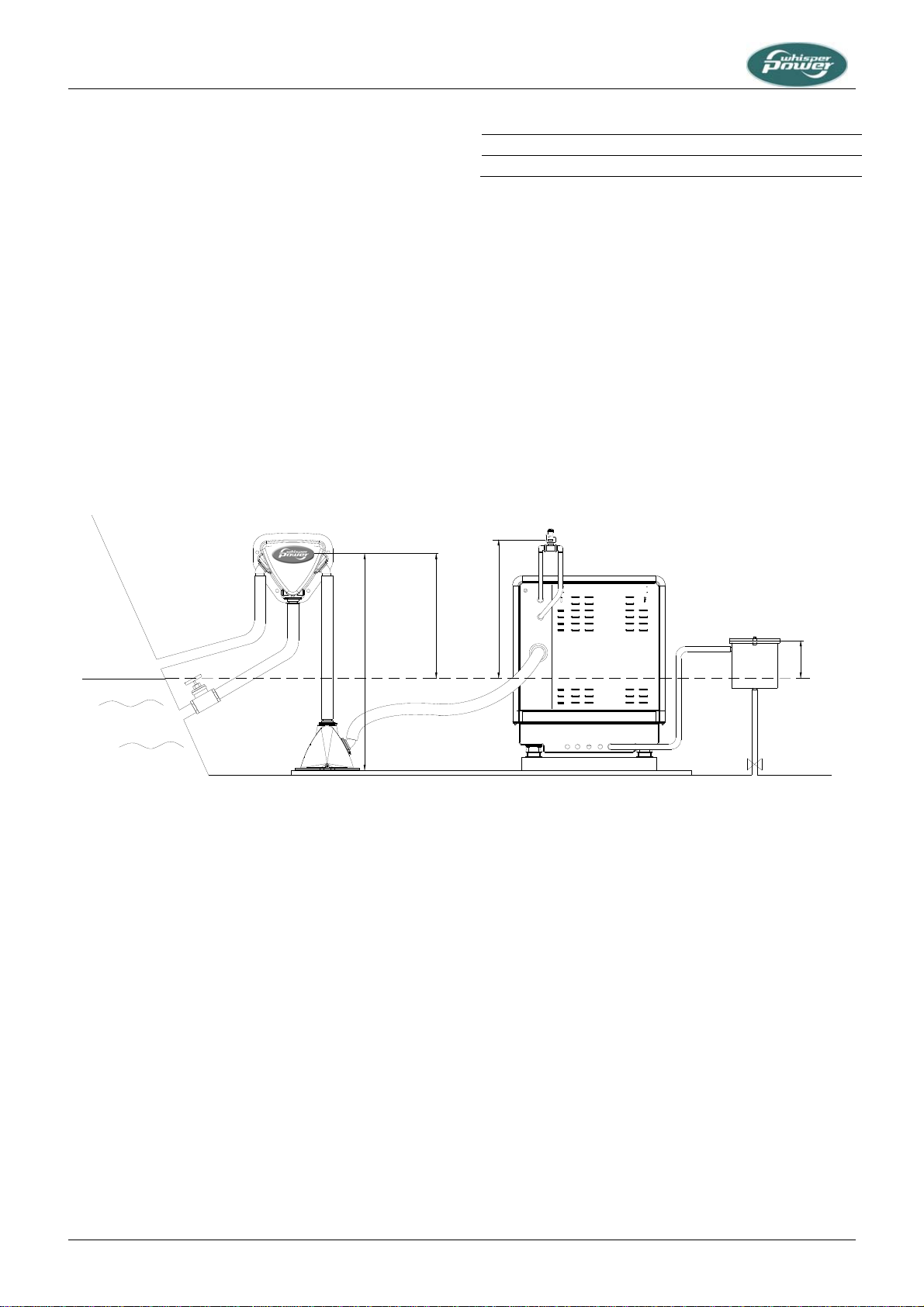

1.5.2 Cooling

Intercooling is based on a raw water pump, heat

exchanger and water-injected exhaust. Cooling liquid in

the internal cooling system is cooled in a heatexchanger

by outboard water (raw water or seawater). After the raw

water is warmed up in the heatexchanger it is dumped

overboard by injecting it in the exhaust.

The generating set should have its own sea water (coolant

water) inlet and should not be connected to any other

engine systems. A properly installed cooling system is

critical to keep engine temperatures within an acceptable

range. Ensure that the installation complies to the

following installation instructions.

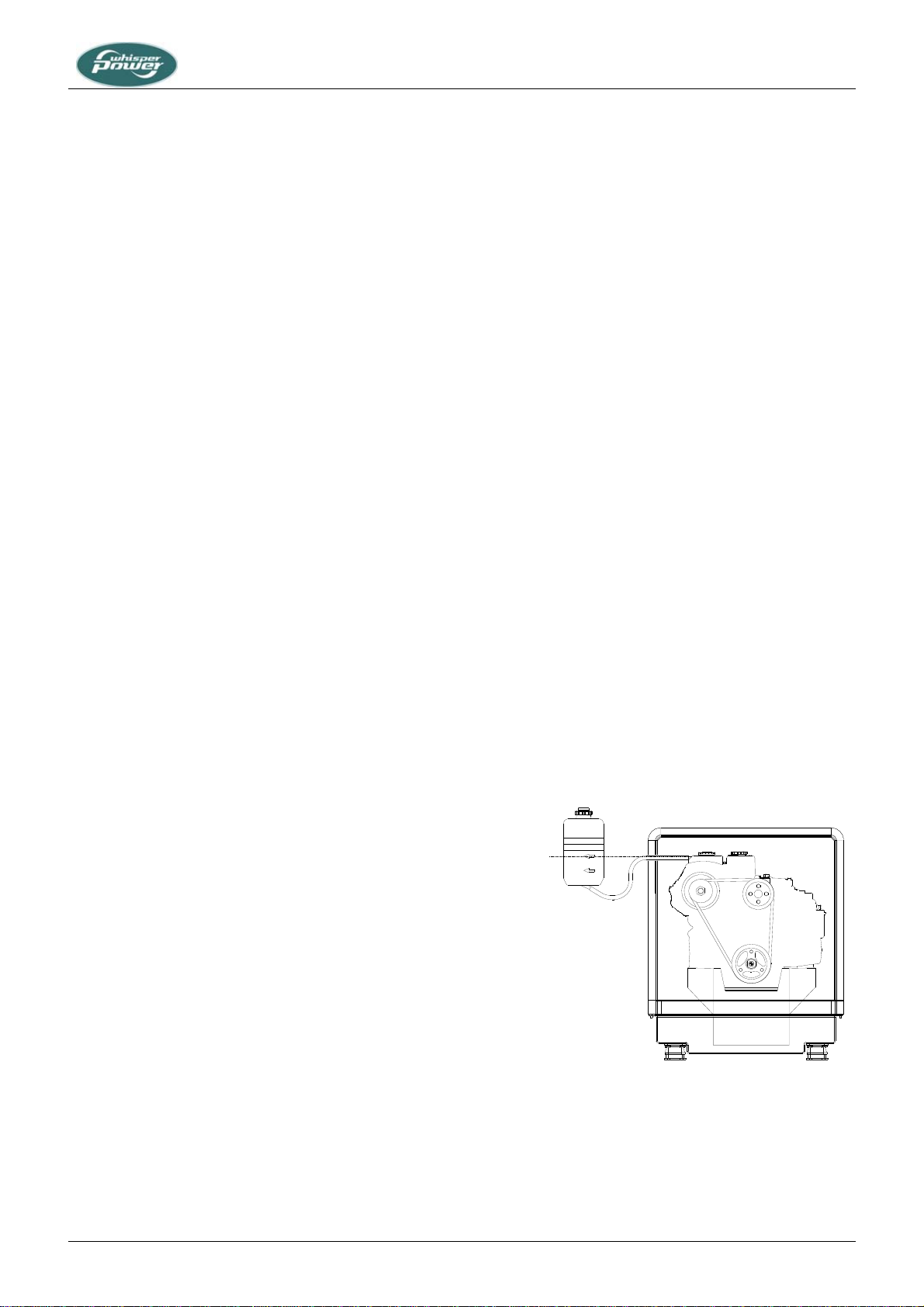

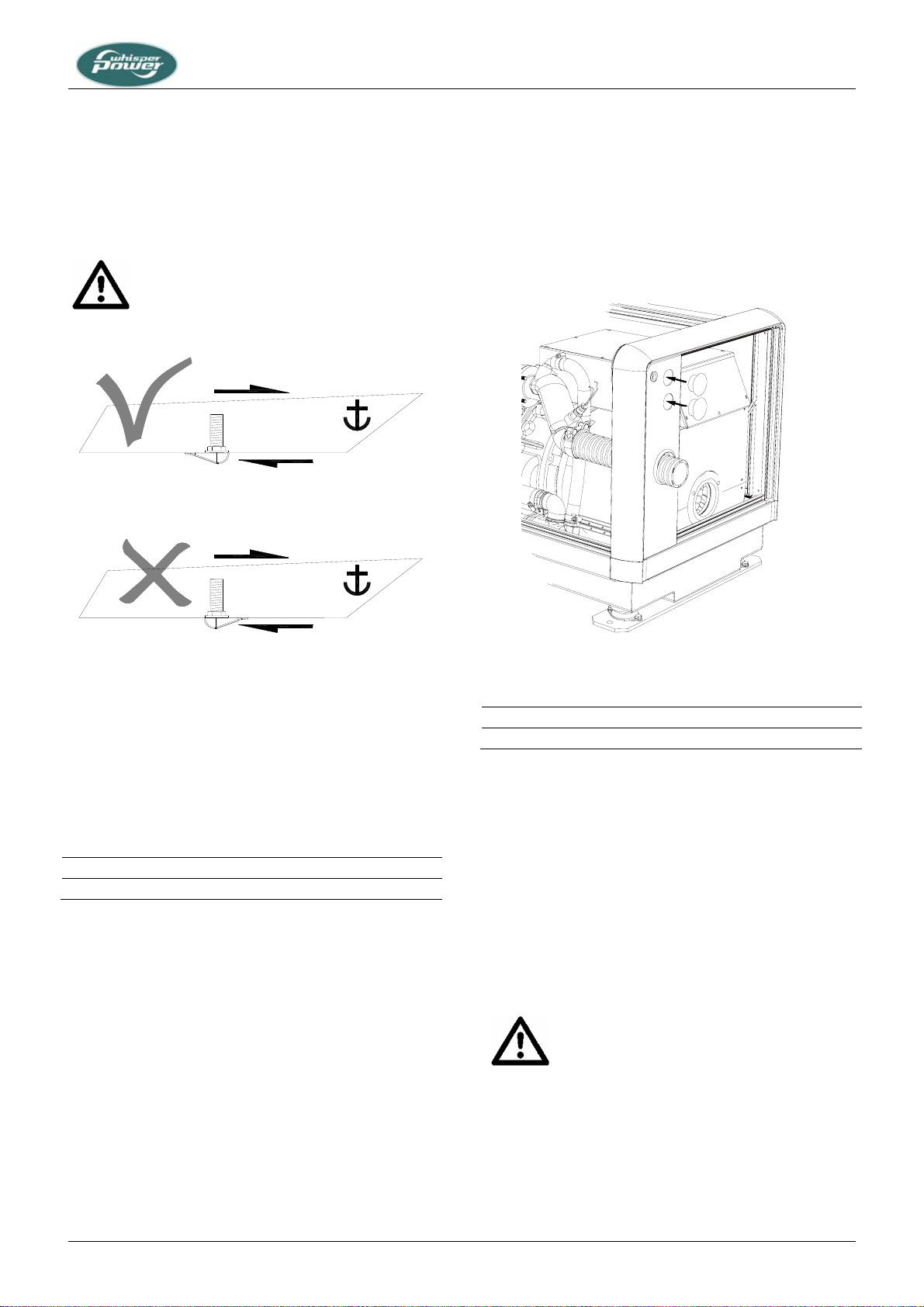

1 THE INTERNAL COOLING SYSTEM

The internal cooling system should be filled with cooling

liquid. (Refer to the users manual 2.5.12) When the engine

becomes hot the liquid expands and the system is

pressurised. After the pressure becomes too high the

release valve in the filling cap on the manifold opens and

the expanding liquid is pressed into the expansion tank

that is in the delivery. Also the air in the system that is

collected at the top of the manifold is released in this way.

When the liquid cools down there will be under-pressure.

Another valve opens and the liquid is sucked into the

manifold again. This system works only when there is

enough liquid initially. This has to be checked when

commissioning the generator set. By filling up the

expansion tank when necessary there will always be

enough liquid in the system. The hose that is in the

delivery has to be connected to the connection on the side

of the filling cap. This hose is made of heat resistant

plastic and is not sensitive for kinks.

MAX.

Fig.5: Expansion tank placement

The tank has to be placed close to the generator. When it

is mounted above the top of the manifold the liquid in the

tank will be drained when the cap on the manifold is taken

off. When keel cooling or radiator cooling is applied the

system will not be pressurised. A cap without release