4

9. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never overfill the fuel tank. Fill tank to no

more than 1/2 inch below bottom of filler neck

to provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. move machine to another

area. Wait 5 minutes before starting the

engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark or

pilot light as on a water heater, space heater,

furnace, clothes dryer or other gas

appliances.

j. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Before starting this machine, review the “Safety

Instructions”.Failure to follow these rules may

result in serious injury to the operator or

bystanders.

2. Never leave this machine unattended with the

engine running.

3. Do not operate machine while under the influence

of alcohol, drugs, or medication.

4. Never allow anyone to operate this machine

without proper instruction.

5. Always operate this machine with all safety

equipment in place and working. Make sure all

controls are properly adjusted for safe operation.

6. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

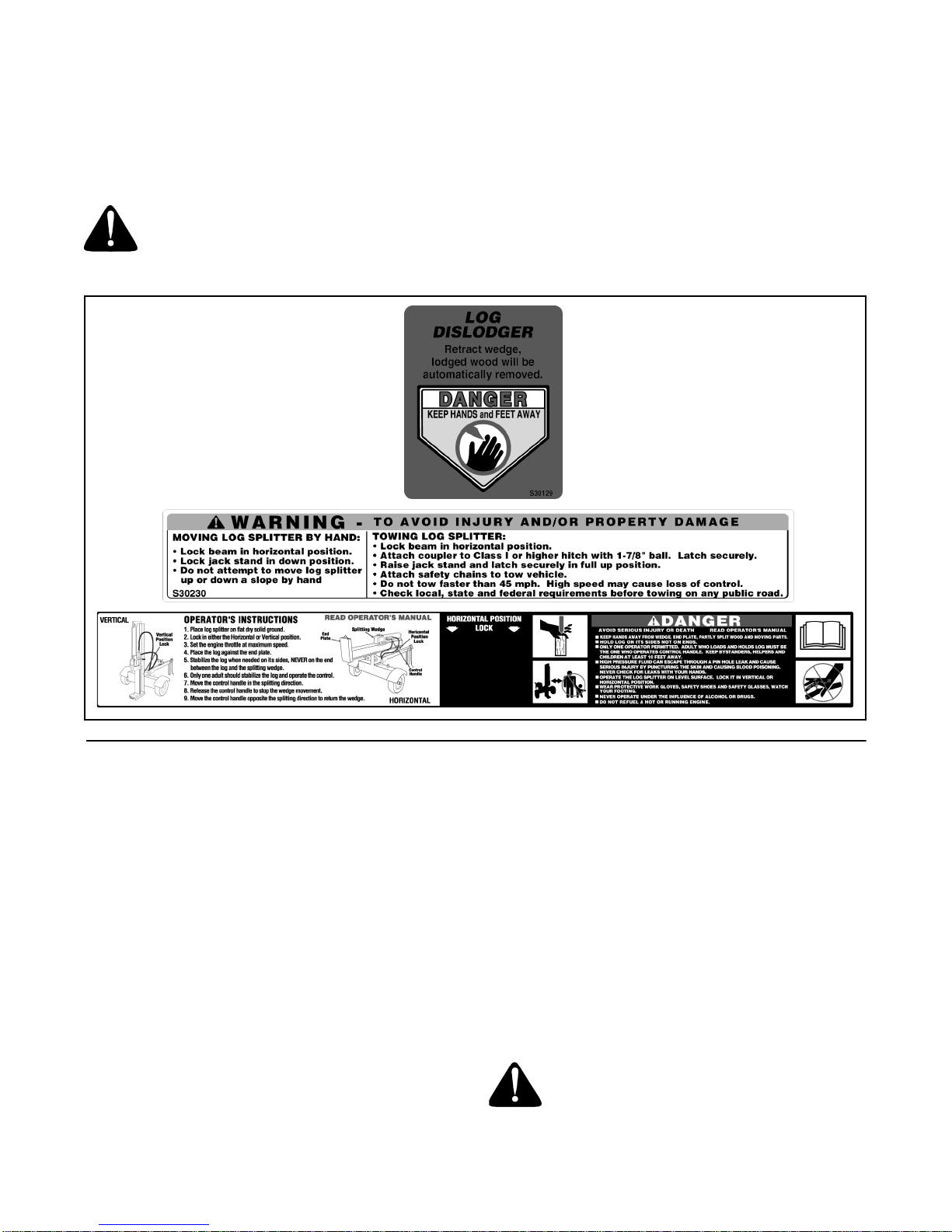

7. When loading a log, always place your hands on

the sides of the log, not on the ends, and never use

your foot to help stabilize a log. Failure to do so,

may result in crushed or amputated fingers, toes,

hand, or foot.

8. Use only your hand to operate the controls.

9. Never attempt to split more than one log at a time

unless the ram has fully extended and a second log

is needed to complete the separation of the first log.

10. For logs which are not cut square, the least square

end and the longest portion of the log should be

placed toward the beam and wedge, and the

square end placed toward the end plate.

11. When splitting in the vertical position, stabilize the

log before moving the control. Split as follows:

a. Place log on the end plate and turn until it

leans against the beam and is stable.

b. Whensplittingextralargeorunevenlogs,the

log must be stabilized with wooden shims or

split wood between the log and the end plate

or ground.

12. Always keep fingers away from any cracks that

open in the log while splitting. They can quickly

close and pinch or amputate your fingers.

13. Keep your work area clean. Immediately remove

split wood around the machine so that you do not

stumble over it.

14. Never move this machine while the engine is

running.

15. This machine should not be towed on any street,

highway or public road without checking the

existing federal, state, or local vehicle

requirements. Any licensing or modifications such

as taillights, etc., needed to comply, is the sole

responsibility of the purchaser. If a “Statement of

Origin”is required in your state, see your local

dealer.

16. See the towing section in this manual for proper

towing instructions once all federal, local, or state

requirements are met.

MAINTENANCE AND STORAGE

1. Stop the engine, disconnect the spark plug and

ground it against the engine before cleaning, or

inspecting the machine.

2. Stop the engine and relieve hydraulic system

pressure before repairing or adjusting fittings,

hoses, tubing, or other system components.

3. To prevent fires, clean debris and chaff from the

engine and muffler areas. If the engine is equipped

with a spark arrester muffler, clean and inspect it

regularly according to manufacturers instructions.

Replace if damaged.

4. Periodically check that all nuts and bolts, hose

clamps, and hydraulic fittings are tight to be sure

equipment is in safe working condition.

5. Check all safety guards and shields to be sure they

are in the proper position. Never operate with

safety guards, shields, or other protective features

removed.

6. Thepressurereliefvalveispresetatthefactory.Do

not adjust the valve.

7. Never attempt to move this machine over hilly or

uneven terrain without a tow vehicle or adequate

help.