WHITEHALL MANUFACTURING • P.O. BOX 3527 • City of Industry, CA 91744-0527 U.S.A Phone (800)

782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

Instructions for Operation and Care of Dickson Paraffin Baths

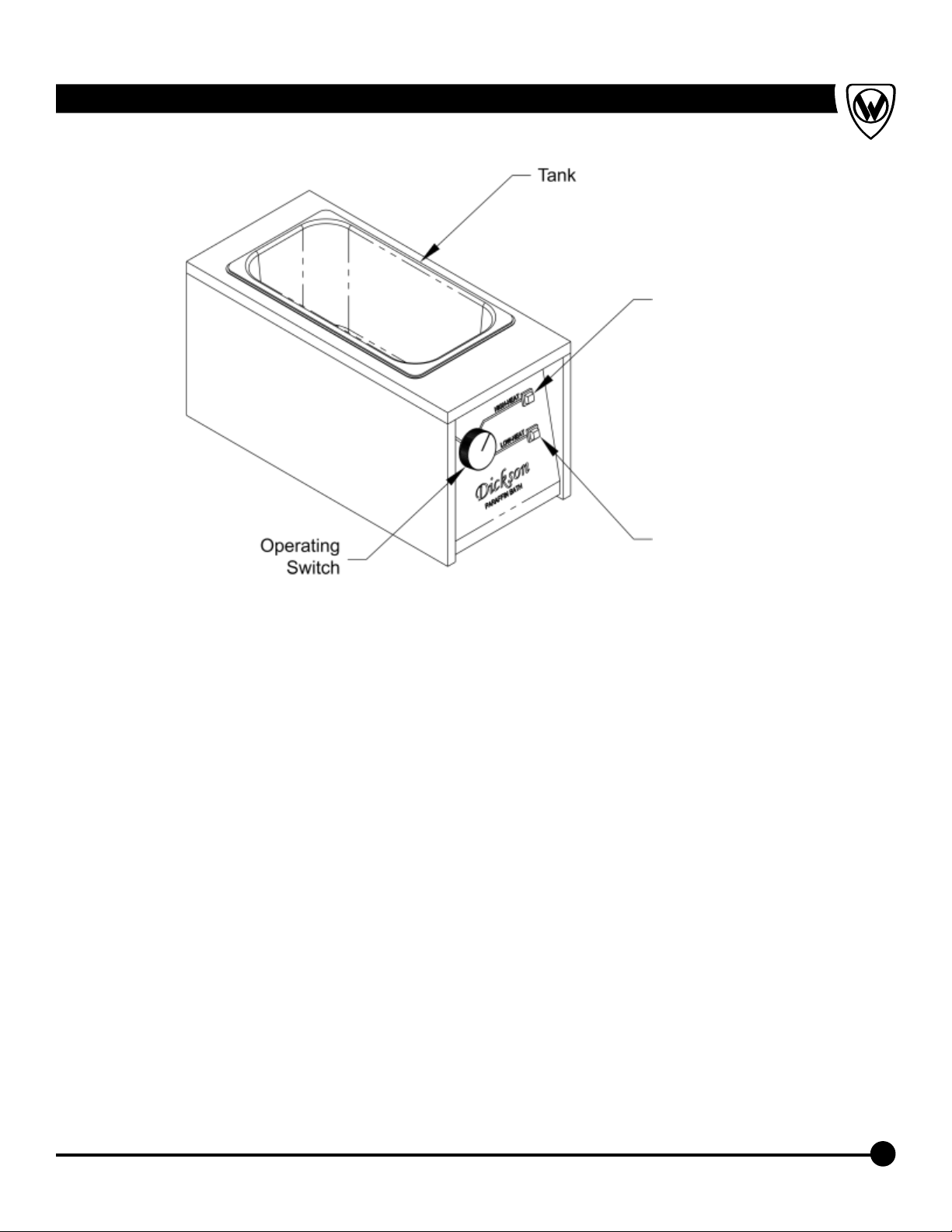

DIRECTIONS FOR OPERATING

Remove Plexiglass Slat from inside unit. Place the

paraffin in the bath. Plug the bath into outlet of 115 volt

50/60 cycle alternating current. There is no power switch

so the unit will be on once plugged in. Turn the knob

clockwise to the high heat position on Model PB-101 to

activate the highheat circuit (the high heat circuit will stay

in operation until the circuit is manually switched off). On

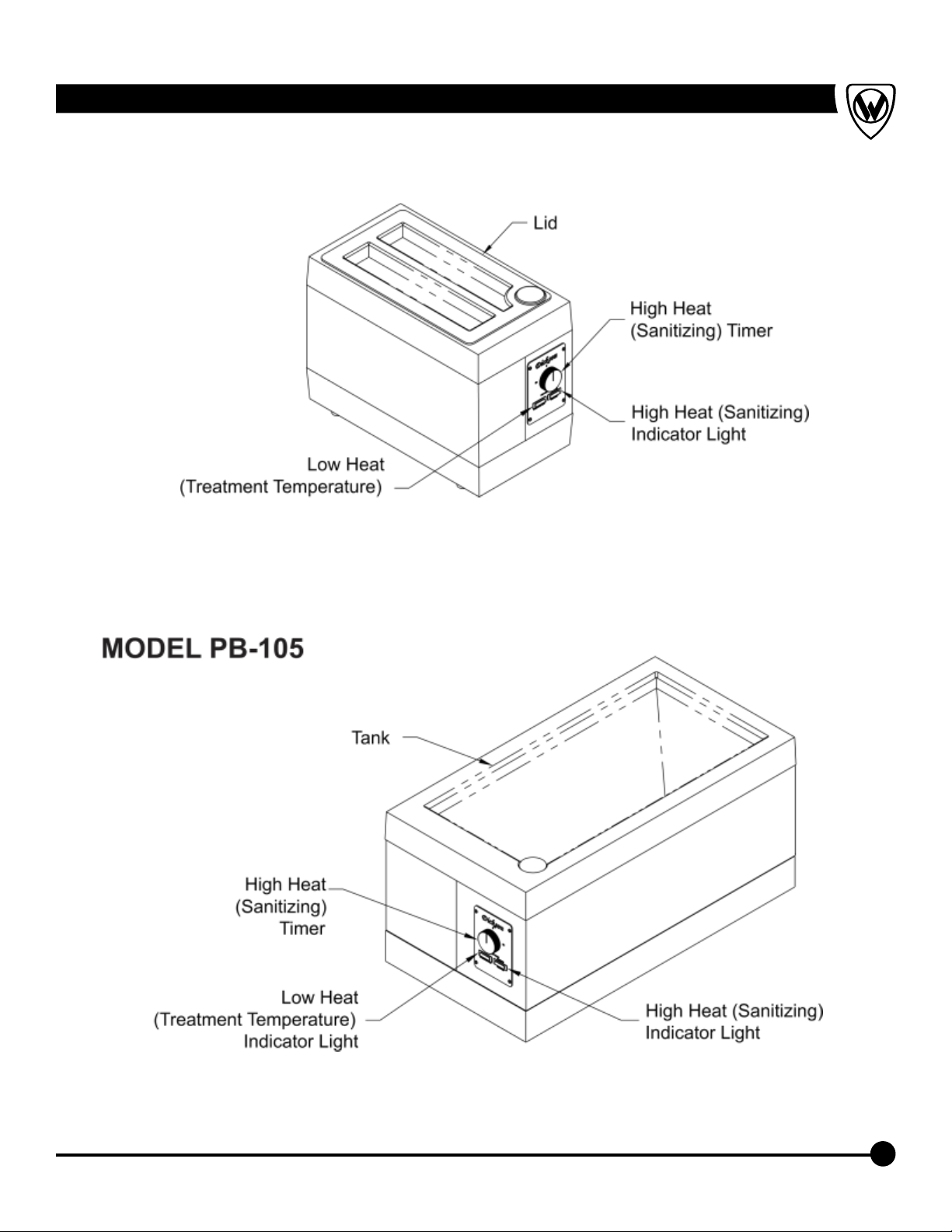

models PB-104, PB-105 and PB-107, rotate the timer

switch to activate the timed hi-heat circuit for the full 55

minutes. To rapidly melt the paraffin it may be desirable

to activate the hi-heat circuit a second time. In any event,

when the time switch returns to “0” the hi-heat circuit is

broken and the bath automatically will begin to operate

on the maintenance circuit. Therefore, after the timer

returns to “0”, allow the bath to cool until the treatment

temperature of 126°F (52.2°C) is reached and

maintained. The high heat warming light will go off as

treatment temperature is approached.

** CAUTION! Do not rely on the light alone to

determine whether the Dickson Paraffin Bath is at

operating temperature –ALWAYS CHECK THAT THE

PROVIDED THERMOMETER READS A SAFE

OPERATING TEMPERATURE, 126° to 132°F (52.2° to

55.6°C) BEFORE SUBMERGING ANY APPENDAGES

IN THE WAX!

** ATTENTION ! Ne vous fiez pas seulement au

voyant pour déterminer si le bain de paraffine

Dickson est à la bonne température - TOUJOURS

VÉRIFIER QUE LA TEMPÉRATURE PRISE AVEC LE

THERMOMÈTRE

FOURNI EST LA BONNE TEMPÉRATURE DE

FONCTIONNEMENT, soit de 52,2 à 55,6C (126 à 132F)

AVANT D'IMMERGER TOUT APPENDICE DANS LA

CIRE !

Keep the unit connected to the electrical outlet. The

maintenance circuit, independent of the high-heat

circuit, is controlled by a close differential thermo-switch

set to automaticallykeep the bath liquid at a temperature

of 126°F (52.2°C). The DICKSON Bath precisely

maintains this temperature. This insures the quickest

possible “glove” to be formed.

If a higher temperature is required for an individual patient,

turn on the high heat knob until the thermometer shows the

desired temperature. As a rule, with the high-heat knob

switched on and the bath covered, the temperature will rise

1°F (0.55°C) per minute.

The high heat indicator light will go on when the

temperature of the bath is anywhere in the range of 140 to

150°F (54.4 to 65.5 °C) and above. This light indicates

when the bath is coming up to sanitizing temperature.

DO NOT USE INDICATOR LIGHT TO DETERMINE

OPERATING TEMPERATURE! ALWAYS VERIFY

OPERATING TEMPERATURE WITH THE PROVIDED

THERMOMETER.

NE PAS UTILISER LE VOYANT POUR DÉTERMINER

LA TEMPÉRATURE DE FONCTIONNEMENT !

TOUJOURS VÉRIFIER LA TEMPÉRATURE DE

FONCTIONNEMENT À L'AIDE DU THERMOMÈTRE

FOURNI.

It is recommended the Paraffin Bath be connected to

electric current day and night. It will then be ready for use

at any time.

The temperature of the paraffin will not rise above 212°F

(100°C) at any time. Again, on all DICKSON models, there

is a safety limit switch on the melting element. Thus the

powerful melting element is safety circuited by both the

cutout switch and the timer mechanism. As an added

precaution the maintenance element, which in itself is not

powerful enough to overheat the bath is also limited by a

cut-out switch.

If it is necessary to disconnect the bath from the electrical

circuit at night, the temperature of the paraffin solution will

drop approximately 25 to 30°F (13.8 to 16.5°C). By turning

the high-heat switch on in the morning for about 30

minutes the proper treatment temperature will again be

achieved.

BE SURE THAT THERE IS PARAFFIN IN THE TANK BEFORE OPERATING UNIT.

OPERATION WITH AN EMPTY TANK MAY CAUSE THE HEATING ELEMENTS TO BURN

OUT.

S'ASSURER QU'IL Y A DE LA PARAFFINE DANS LE RÉSERVOIR AVANT DE DÉMARRER

L'APPAREIL. FAIRE FONCTIONNER L'APPAREIL AVEC UN RÉSERVOIR VIDE PEUT

BRÛLER LES ÉLÉMENTS CHAUFFANTS.