Using The Whirlpool

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

3

USING THE WHIRLPOOL

ŸTo read and understand the information in this manual.

Operators using the whirlpool need:

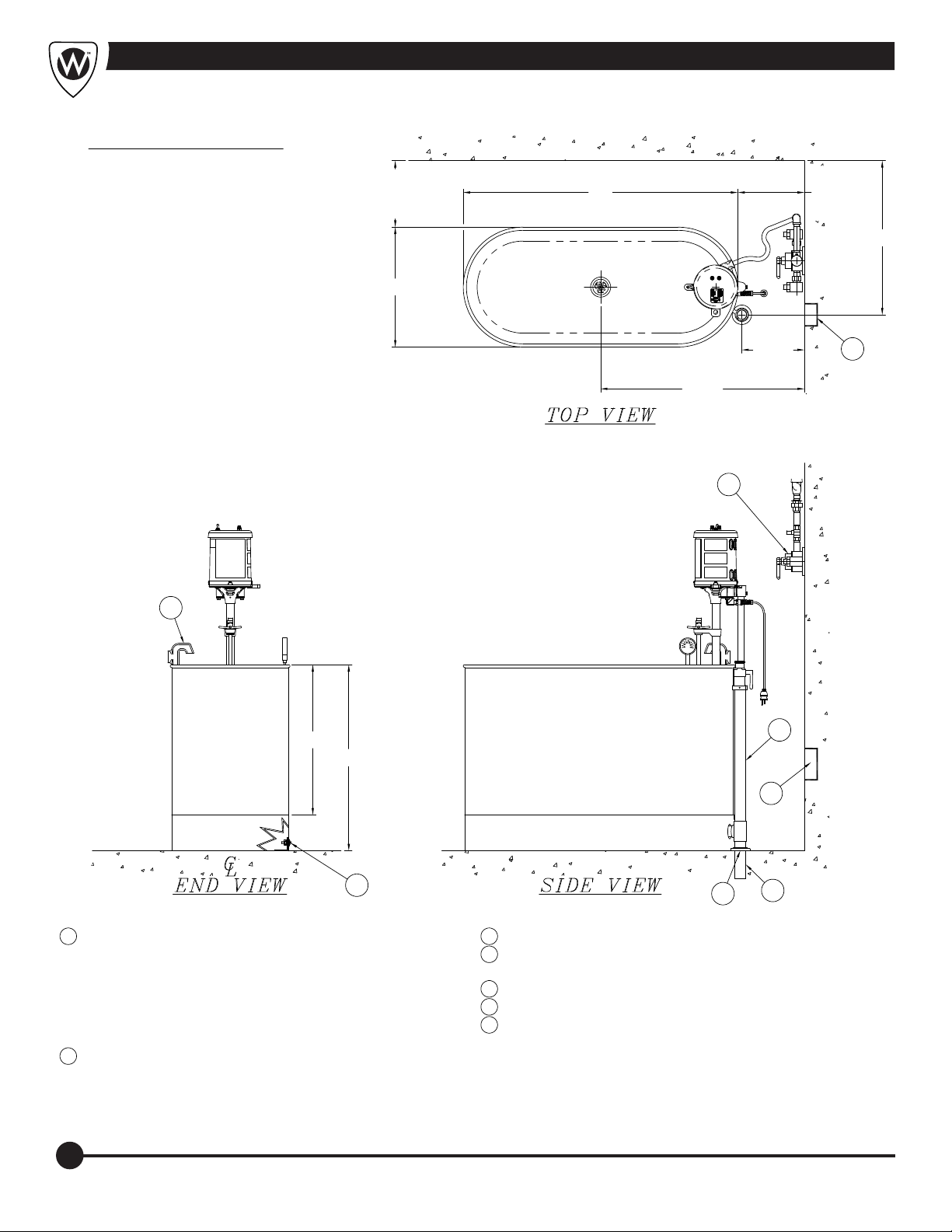

Before Placing the Whirlpool Tub and Turbine

Combination In Service:

ŸTo have a plumbing professional install the whirlpool as

instructed in page 4. A rough-in Installing the Whirlpool,

drawing is available to assist the installer. Contact

Whitehall Customer Service, bottom of page, for any

additional information not covered in this manual.

ŸConfirm that the whirlpool operates properly. See

Inspecting the Whirlpool , page 2.

ŸMedical advice is beyond the scope of this manual.

ŸIt is the operator’s responsibility to ensure safe

practices for the patient and themselves.

ŸThe whirlpool is for professional use only. A minimum of

one trained operator is required.

ŸTurbine precautions:

Ÿ Keep the area around the tub clear a minimum of 12"

(305mm) of clearance.

ŸThe trained operator must evaluate and verify that the

patient is suitable for hydrotherapy treatment before

beginning hydrotherapy with the whirlpool. See Patient

Evaluation, page 2.

ŸStay with patient at all times.

General Guidelines for Use:

Ÿ Cord plug is disconnect device. Always maintain clear

access to this connection after installation.

ŸFollow your state and local hydrotherapy procedures

and, if the patient has one, the physician's order for

treatment (see Patient Evaluation, page 2).

Plug the turbine cord only into a receptacle that is

voltage-matched, properly grounded and polarized.

Verify that the receptacle has GFCI protection.

Ÿ Keep patient hair, gown strings and other loose items

away from the impeller housing to avoid

entanglement and injury.

WARNING

!

Certain medical conditions are incompatible with

hydrotherapy. The trained operator is responsible for

determining each user's suitability for hydrotherapy

before beginning treatment.

Improper operation can cause injury. Operate the

whirlpool only as described in this manual.

Loose items such as gown straps or gauze can be

pulled into the turbine impeller and cause injury. Keep

loose items away from the turbine impeller housing.

An unattended patient can be injured. Stay with

patient at all times.

Important

Communicate with patient at all times. When the

turbine is used, tell the patient before starting or

stopping the turbine and before changing the water or

aeration level.

ŸAvoid prolonged contact with the motor cover, as

elevated temperatures can cause discomfort.

ŸRelative humidity 5 to 95% and atmospheric pressure sea

level to 3,000 meters during use.

ŸNormal Operating Conditions:

Temperature range between 50° and 93°F (10° and

35°C).

Transportation and Storage Conditions:

General Guidelines for Use: (Continued)

Ÿ Relative Humidity Range: 5 to 95%.

Ÿ Prior to unpacking, when new, tipping has no effect.

However, after assembly, the equipment should

remain upright, as tipping or inversion may cause

damage from components coming loose.

Ÿ Temperature Range should remain between 32° and

110°F (0° and 43°C)

Ÿ Room Atmospheric Pressure sea level to 3,000

meters.

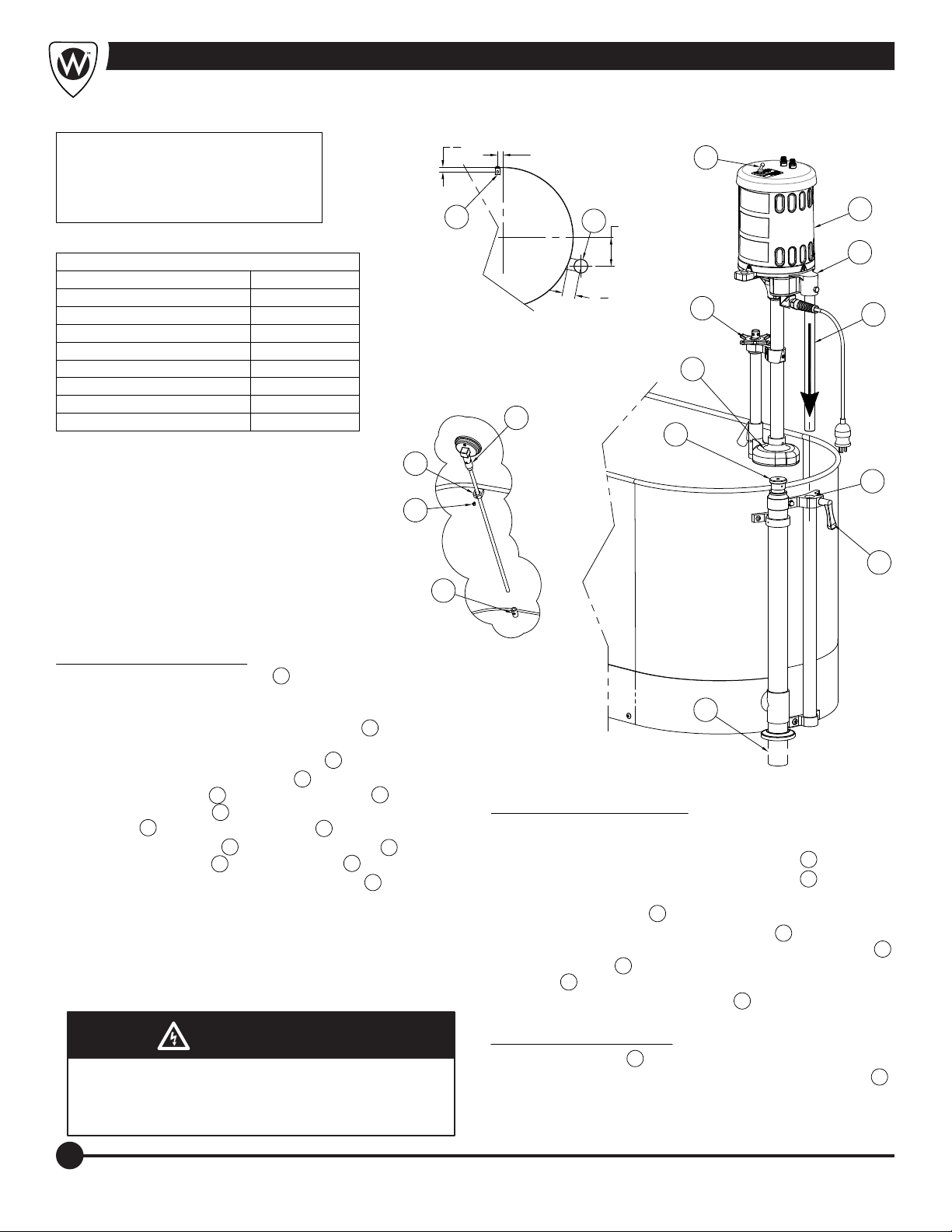

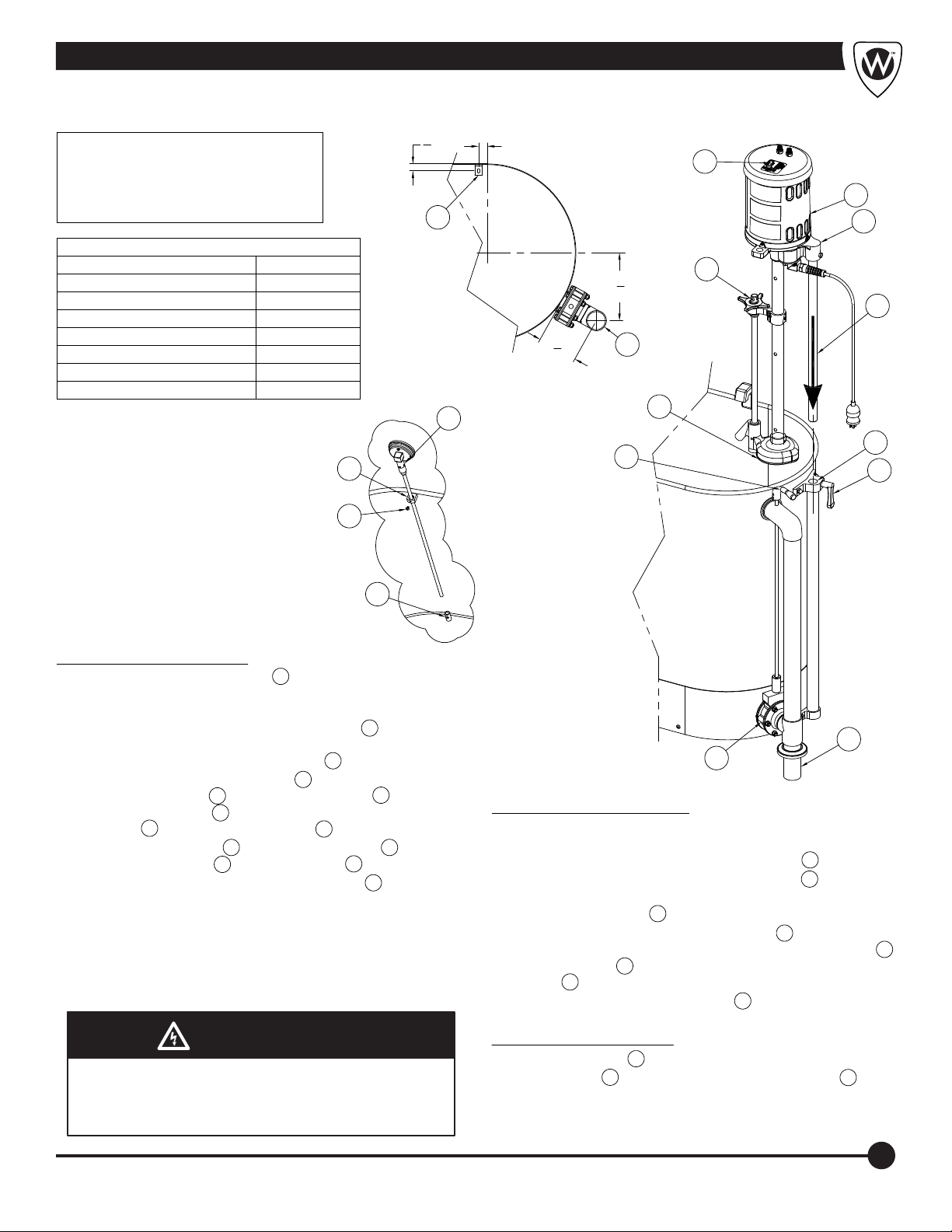

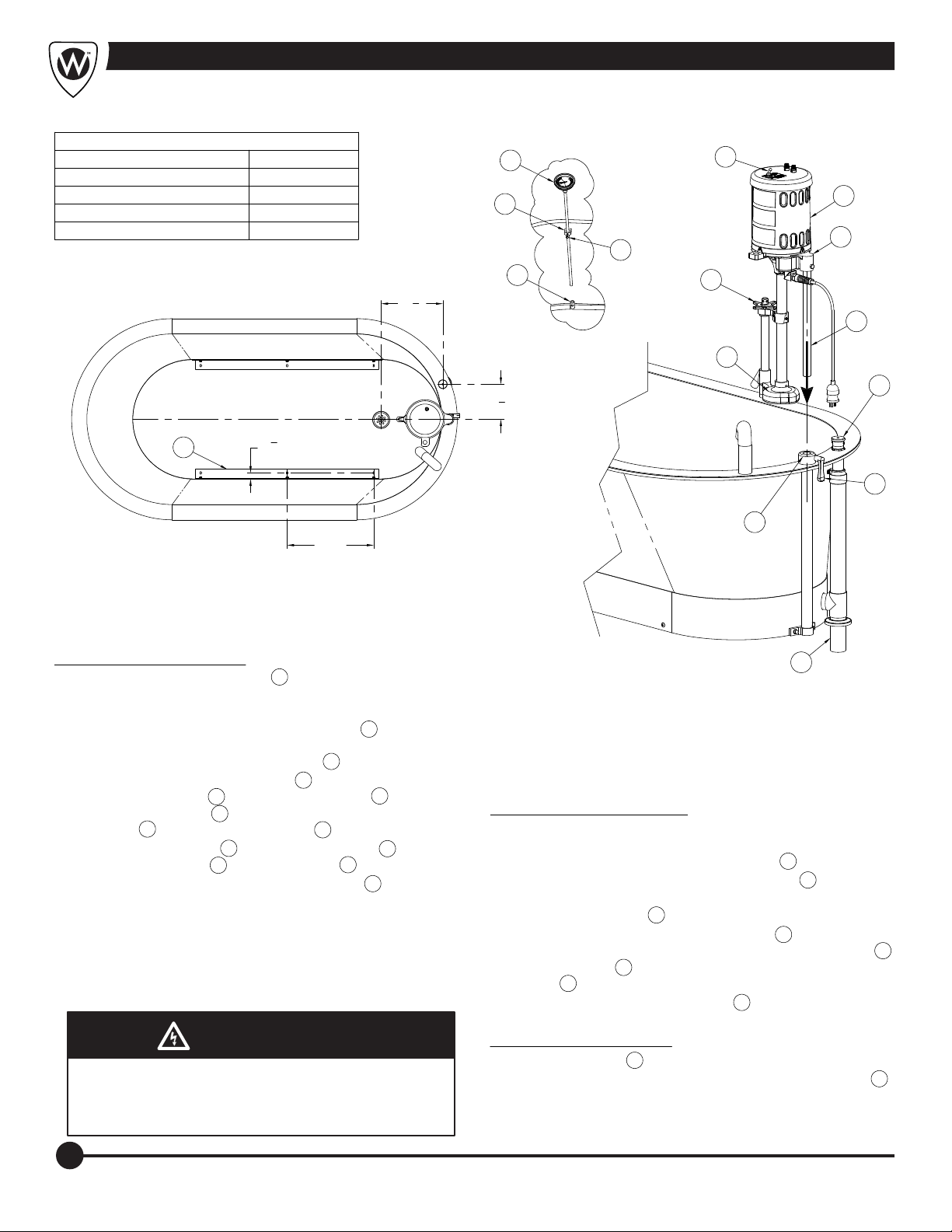

Device Intended Use:

Whitehall Whirlpool turbines are intended to provide

clinical, physical hydro-massage treatment within a fluid

medium, mounted in a tank of a size and shape as

deemed effective and determined by a medical

professional.