WELDMATIC

205s

MANUAL

Page

3

SAFEN

Before this equipment

is

put into operation. the SAFEPRACTICES section at the

back of the manual must be read completely

.

This will help to avoid possible injury

due

to

misuseor improperwelding applications

.

CONTENTS

Sec.1 Introduction

........................................

P.4

Sec.2

....................................

Receiving

..........................................

P.4

Sec.3

.................................

Specifications

.......................................

P.5

Sec.4

.........................

Power SourceControls

...............................

P.6

Sec5

...................................

Installation

.........................................

P.7

Sec.6

......................

NormalWeldingSequence

.............................

P.10

Sec.7

.......................

BasicWelding Information

.............................

P.10

..................................

Sec.8

...........................

General Maintenance

.................................

P

.

13

Sec.9

..............................

Trouble Shooting

....................................

P.13

Sec.10

..........................

Service Information

..................................

P

.

14

Sec

.

11

................................

..PartsLists

..........................................

P

.

18

Sec.12

..............................

Safe Practices

.......................................

P.23

FIGURES

Fig.1

..........................

Power SourceControls

...............................

P.6

Fig.2

...................

Remote WirefeederConnection

.........................

P.8

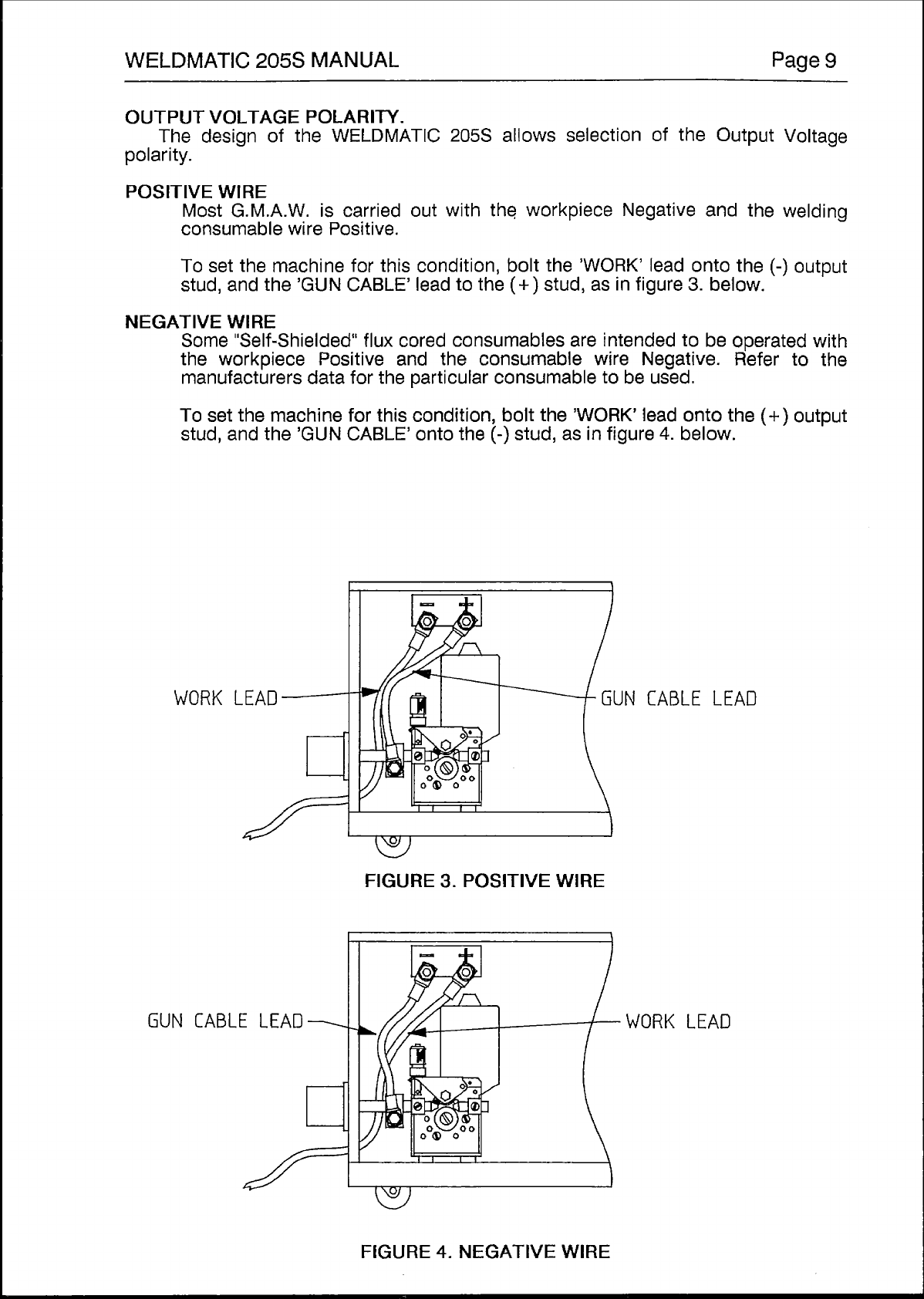

Fig.3

.........................

PositiveWire Connection

..............................

P.9

Fig.6

....................................

‘Bad’Weld

.........................................

P.12

Fig.7

...................................

Gun Position

........................................

P.12

Fig.8

................................

Circuit Diagram

......................................

P.15

Fig.9

.........................

Dual

SCR

ControlBoard

..............................

P

.

16

Fig.l2

..........................

GunCableAssembly

.................................

P.20

Fig.13

..........................

Wire DriveAssembly

.................................

P.21

Fig.14

...........................

Remote Wirefeeder

...................................

P.22

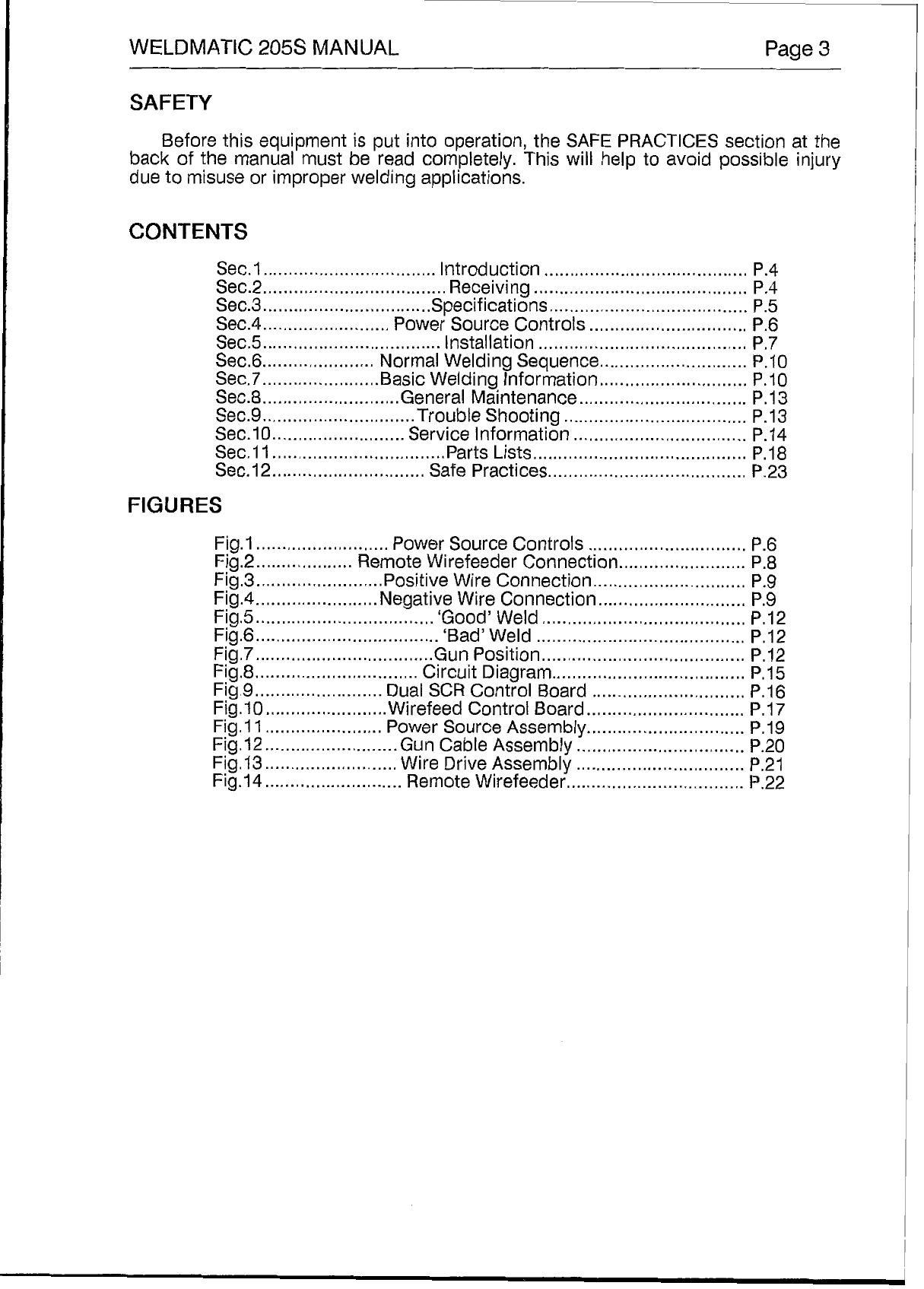

Fig.4

........................

Negative WireConnection

.............................

P.9

Fig.5

...................................

‘Good’

Weld

........................................

P.12

Fig.10

........................

WirefeedControl Board

...............................

P.17

Fig

.

1

1

.......................

Power Source

Assembly

...............................

P.19