Operating instructions Soyer Bolzenschweißtechnik 3

Contents

1General information.............................................................................................................. 5

1.1 Validity of the operating instructions ...................................................................................... 5

1.2 Declarations of conformity...................................................................................................... 5

1.3 Manufacturer.......................................................................................................................... 7

1.4 Instruction, training................................................................................................................. 7

1.5 Standards and directives........................................................................................................ 7

2Important safety instructions............................................................................................... 8

2.1 Warning signs used................................................................................................................ 8

2.2 General safety instructions..................................................................................................... 9

2.3 Personal protection equipment ............................................................................................ 12

2.4 Intended use of the stud welding device.............................................................................. 13

2.4.1 Incorrect use.................................................................................................................... 13

2.5 Intended use of the stud welding guns ................................................................................ 13

2.5.1 Incorrect use.................................................................................................................... 13

2.6 Operating company prerequisites........................................................................................ 14

2.6.1 Prerequisites for personnel.............................................................................................. 14

3Transport.............................................................................................................................. 15

4Storage, shutdown.............................................................................................................. 15

5Disposal ............................................................................................................................... 15

6Description of BMS-9(V) stud welding devices................................................................ 16

6.1 Type differentiation............................................................................................................... 16

6.2 Working method................................................................................................................... 16

6.2.1 Product features............................................................................................................... 16

6.2.2 Capacitor discharge stud welding.................................................................................... 17

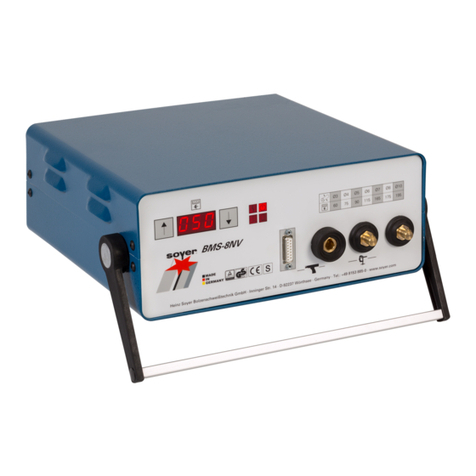

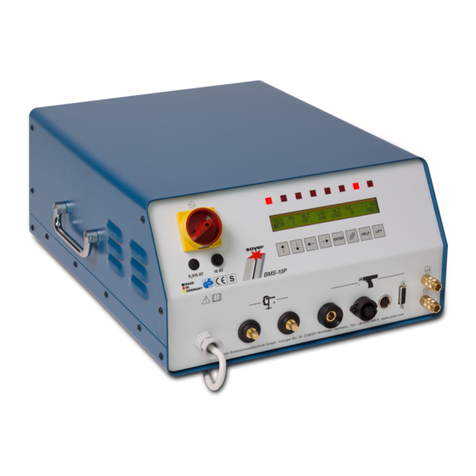

6.3 Overview of the controls....................................................................................................... 18

6.3.1 Displaying the operating states........................................................................................ 19

6.4 Technical data for BMS-9(V) stud welding device............................................................... 20

6.5 Permitted stud welding guns................................................................................................ 21

6.6 Cleaning of the stud welding device .................................................................................... 22

7Description of the PS-9 and PS-9K stud welding guns................................................... 23

7.1 Type differentiation............................................................................................................... 24

7.2 Meaning of the LED ring displays ........................................................................................ 24

7.3 Technical data for PS-9(K) stud welding guns..................................................................... 25

7.4 Cleaning of the stud welding gun......................................................................................... 26

8Description of the PS-1K stud welding gun..................................................................... 27

8.1 Technical data for PS-1K stud welding gun......................................................................... 28

8.2 Cleaning of the stud welding gun......................................................................................... 29

9Description of the stud chuck............................................................................................ 30

9.1 Non-adjustable stud chucks................................................................................................. 30

9.2 Adjusting and installing adjustable stud chucks................................................................... 32

10 Setup and connection......................................................................................................... 35

10.1 Requirements for the installation location............................................................................ 35