WELDMATIC

305

MANUAL

Page

3

SAFETY

Beforethis equipment

is

put into operation. theSafe Practicessectionat the back

of

the manualmust be read completely

.

Thiswill help to avoid possibleinjury due to

misuseor improper welding applications

.

CONTENTS

Sec.1 Introduction

........................................

P.4

Sec.2

....................................

Receiving

..........................................

P.4

Sec.3

.................................

Specifications

.......................................

P.5

Sec.4

.........................

Power SourceControls

...............................

P.6

Sec5

...................................

Installation

.........................................

P.7

Sec.7

.......................

BasicWelding Information

.............................

P.ll

..................................

Sec.6

......................

NormalWelding Sequence

.............................

P.11

Sec.8

...........................

GeneralMaintenance

.................................

P.14

Sec9

..............................

Trouble Shooting

....................................

P.14

Sec.10

..........................

Service Information

..................................

P.15

Sec.11

..................................

PartsLists

..........................................

P.18

Sec.12

..............................

Safe Practices

.......................................

P.24

FIGURES

Fig.1

..........................

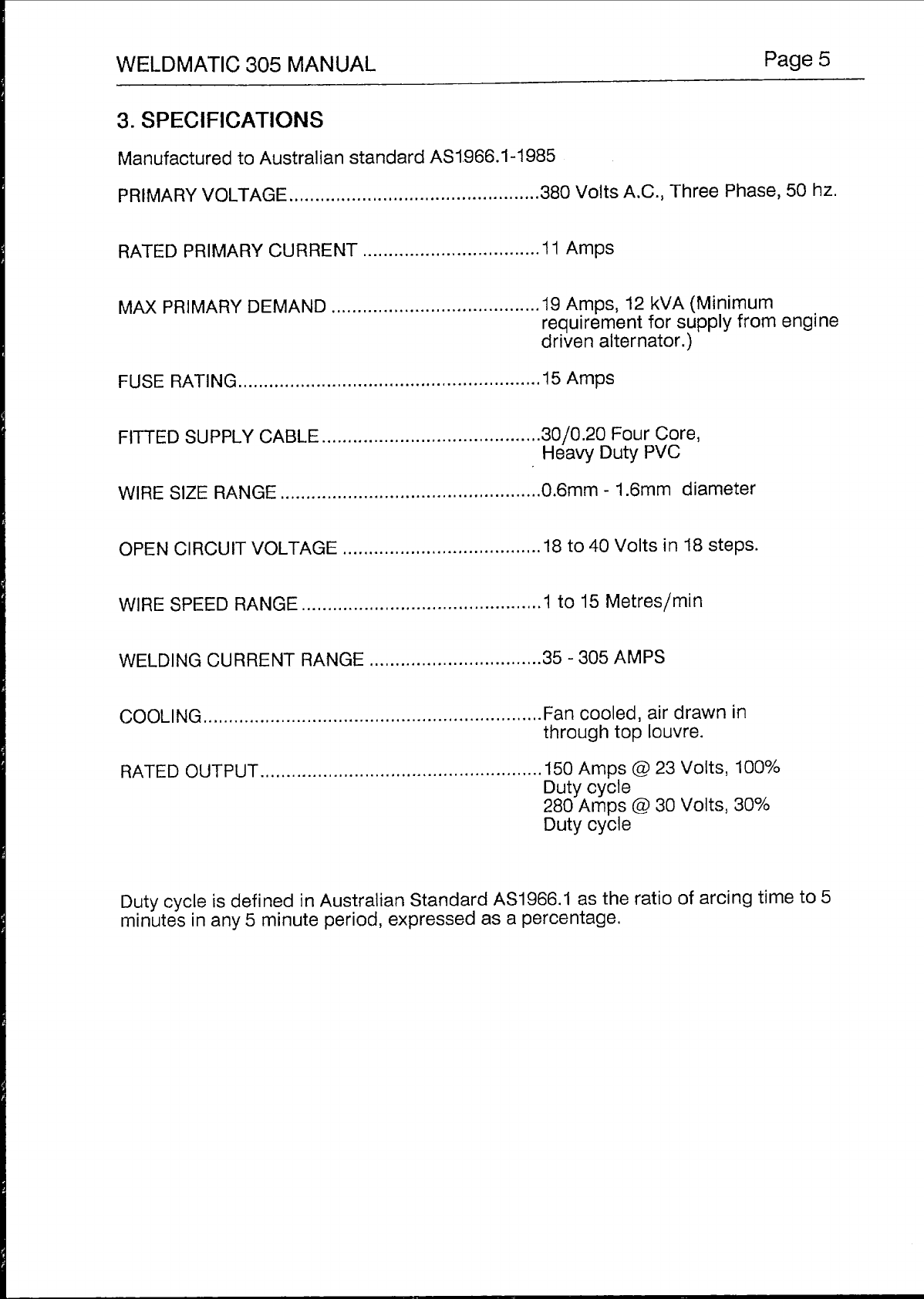

Power Source Controls

...............................

P.6

Fig.2

......................

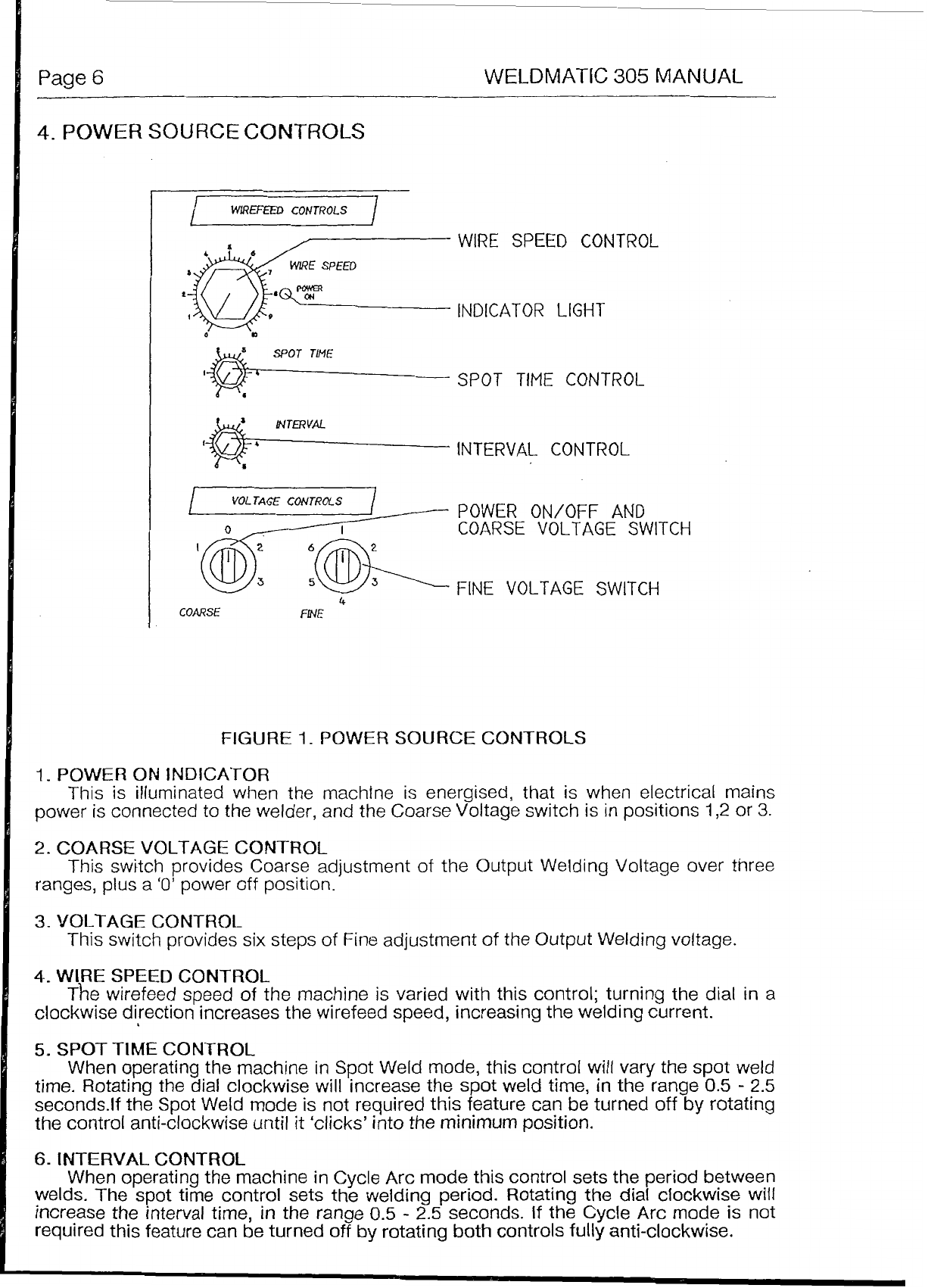

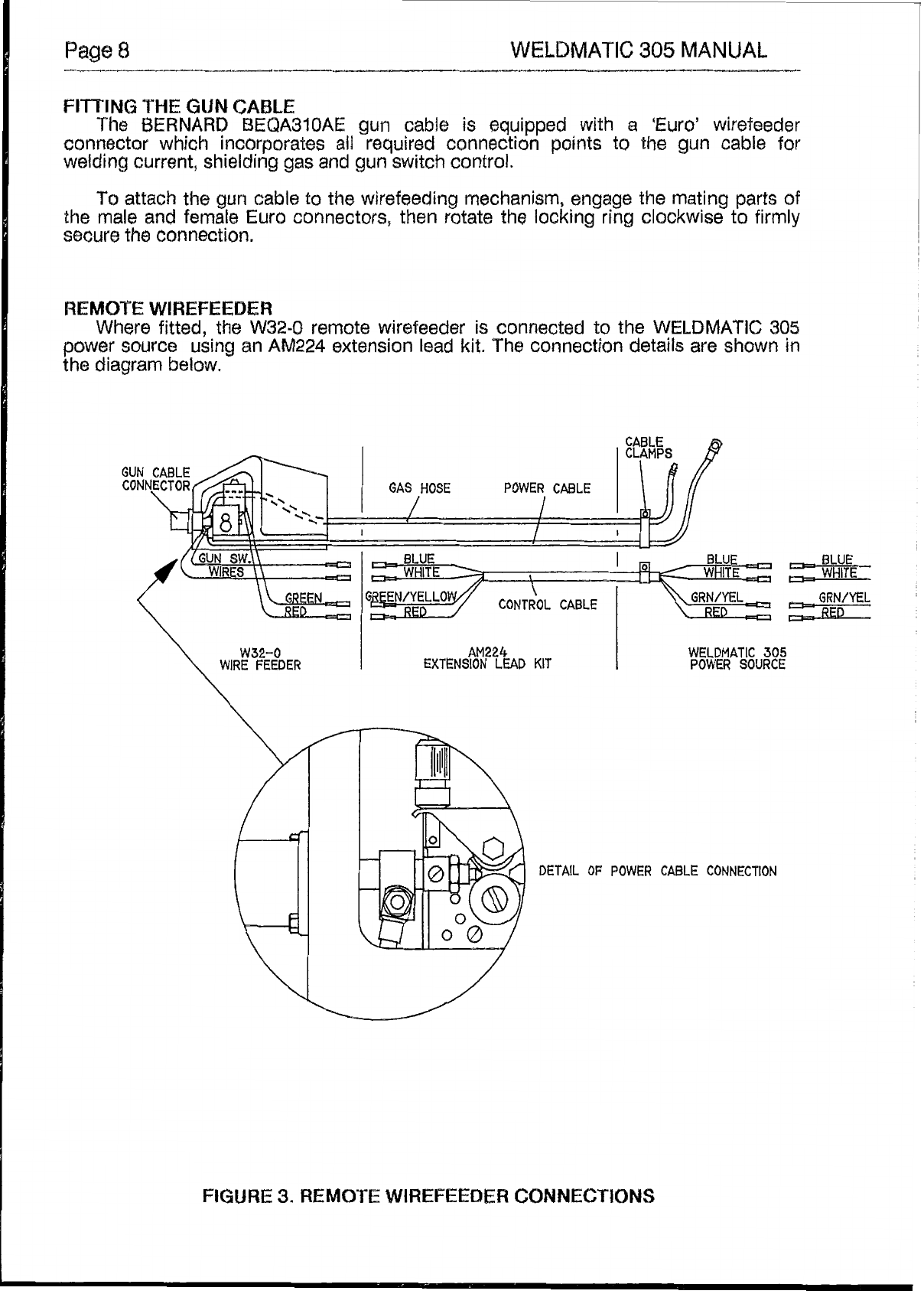

Connection ofSupplyCable

...........................

P.7

Fig.3

...................

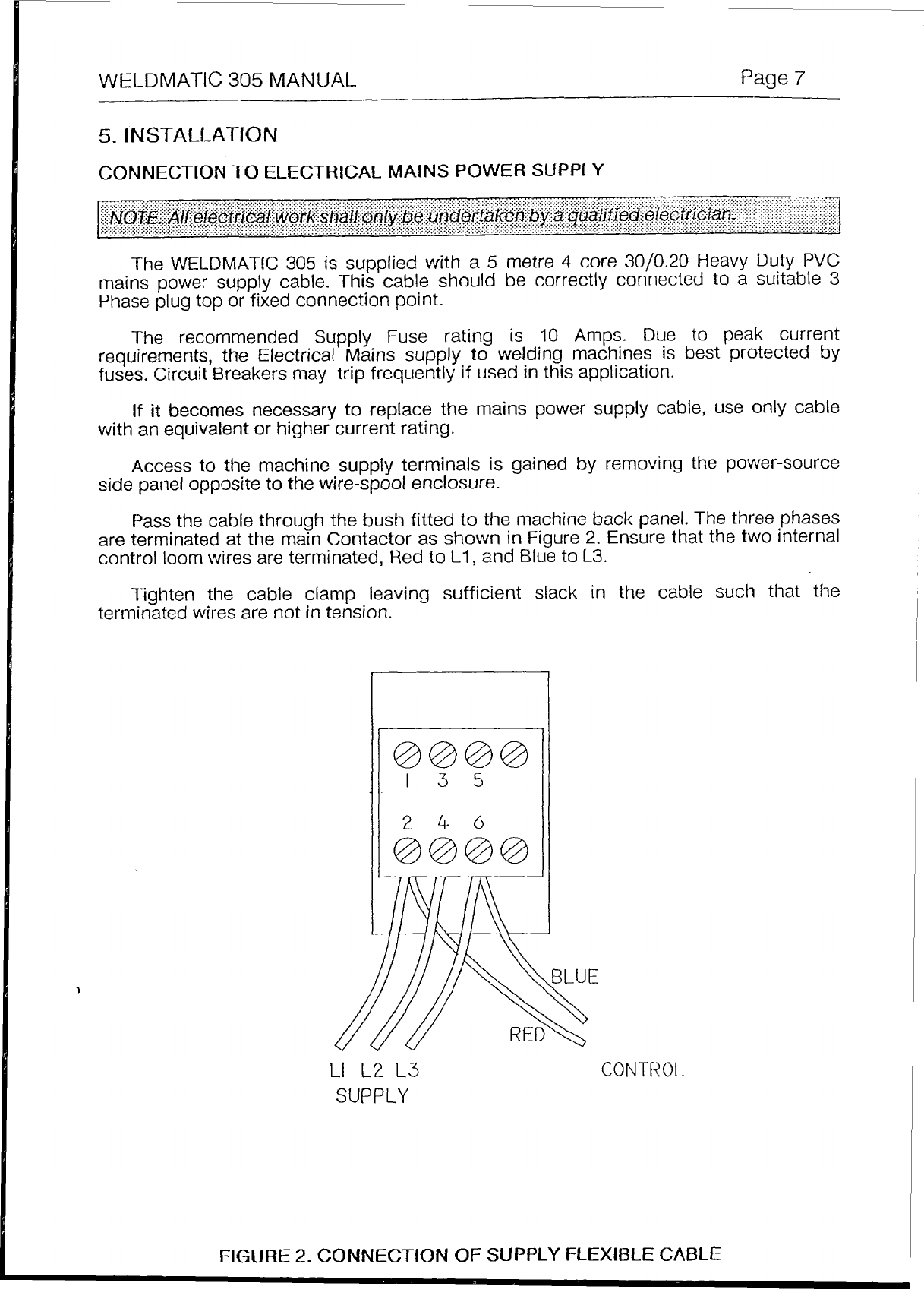

RemoteWirefeeder Connection

.........................

P.9

Fig.4

.........................

PositiveWire Connection

..............................

P.10

Fig.6

...................................

"Good"Weld

........................................

P

.

13

Fig.7

....................................

"Bad"

Weld

.........................................

P.13

Fig.8

...................................

Gun Position

........................................

P.13

Fig.9

................................

Circuit Diagram

......................................

P.16

Fig.10

........................

Wirefeed Control Board

...............................

P.17

Fig.13

..........................

Gun

CableAssembly

.................................

P.21

Fig.14

..........................

Wire DriveAssembly

.................................

P.22

Fig.15

...........................

Remote

Wirefeeder

...................................

P.23

Fig5

........................

NegativeWire Connection

.............................

P.10

Fig.1

1

.......................

Power Source Assembly

...............................

P

.

19

Fig.12

..........

Power Source Ass'y (RemoteWirefeeder)

.................

P.20