WIA Weldmatic 180s CP17 User manual

Other WIA Welding System manuals

WIA

WIA VORTEX AD15VRADl5-0 User manual

WIA

WIA Weldmatic CP127-2 User manual

WIA

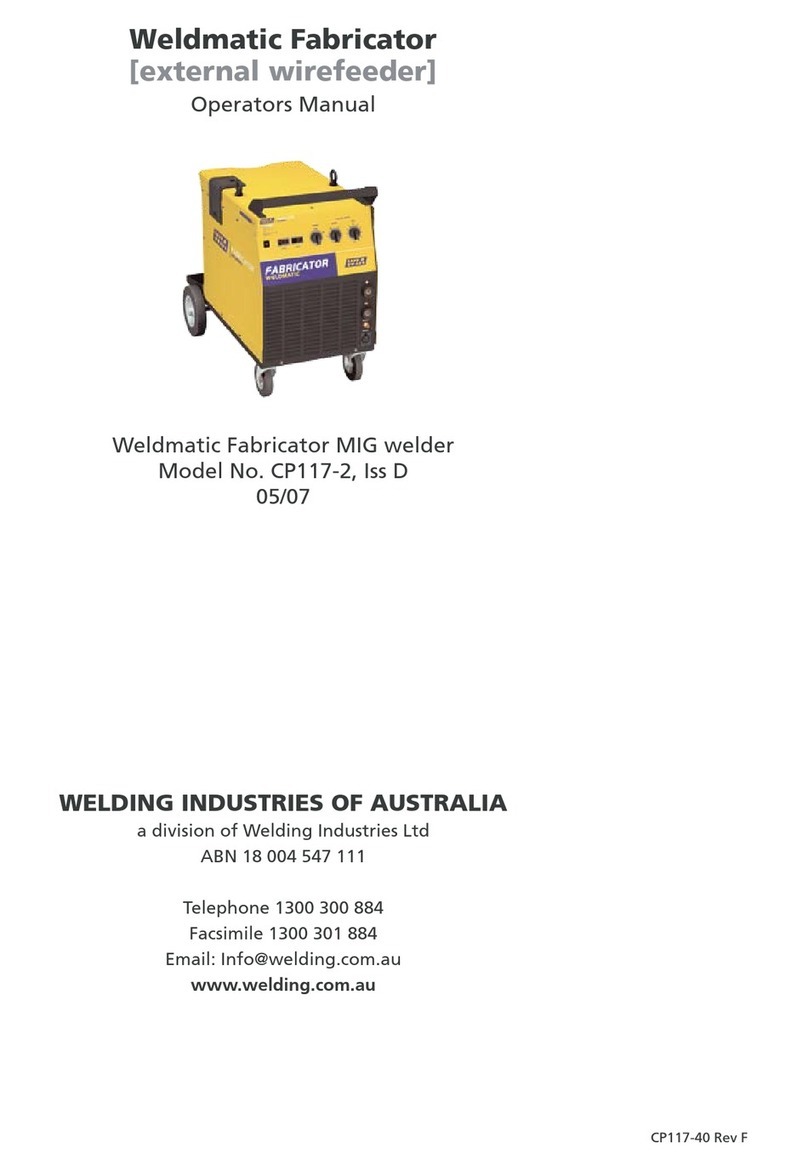

WIA CP117-2 User manual

WIA

WIA weldmatic 350i CP139-2 User manual

WIA

WIA Weldmatic 270 CP132-2 User manual

WIA

WIA Weldmatic 205S User manual

WIA

WIA Weldmatic 396 User manual

WIA

WIA Weldarc 180i User manual

WIA

WIA Weldmatic 200i MIG User manual

WIA

WIA UTILITY UTAC13-0 User manual

WIA

WIA TIGARC 140DC MC86-0 User manual

WIA

WIA MC105-0 User manual

WIA

WIA Weldmatic 150 User manual

WIA

WIA CP149-1 User manual

WIA

WIA Weldmatic 190 User manual

WIA

WIA WELDARC 400 User manual

WIA

WIA MC115-0 User manual

WIA

WIA WELDMATIC 180 User manual

WIA

WIA Weldmatic Fabricator P135-2 User manual

WIA

WIA WELDMATIC 200+ User manual

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual