Wieland podis CON User guide

Other manuals for podis CON

1

This manual suits for next models

1

Table of contents

Other Wieland Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

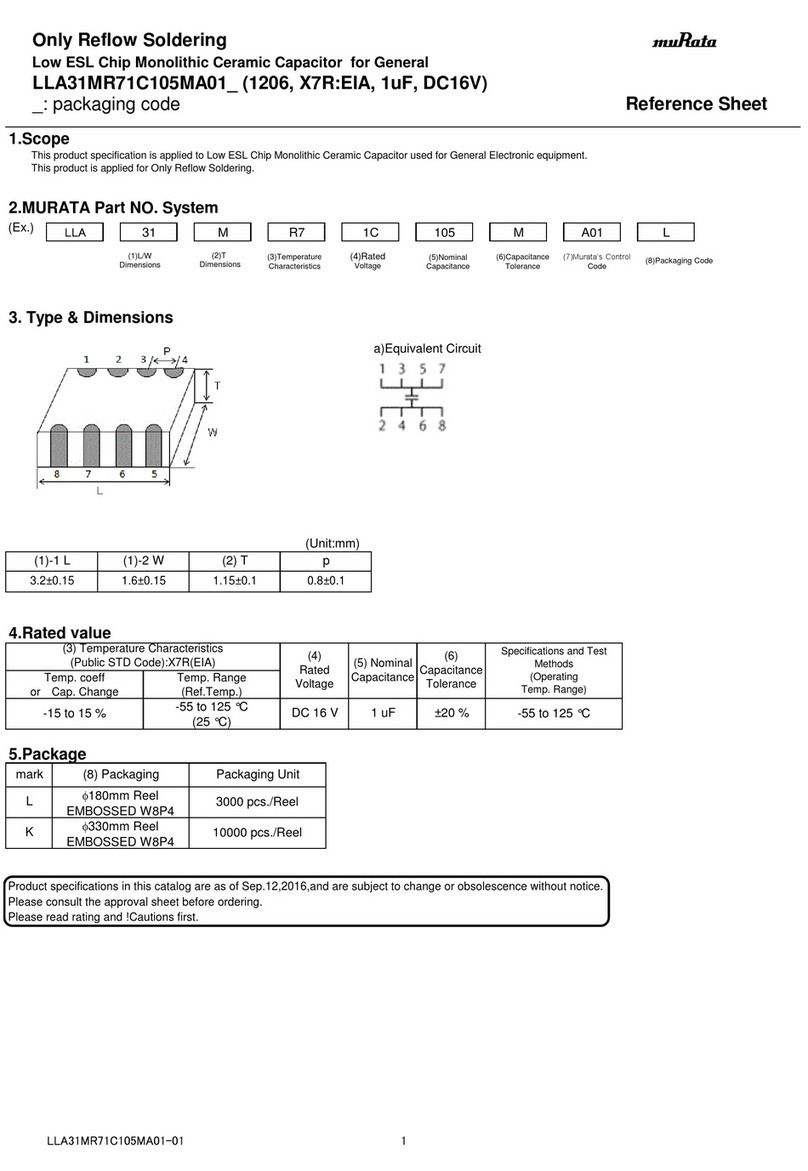

Murata

Murata LLA31MR71C105MA01 Series Reference sheet

Keysight Technologies

Keysight Technologies Ixia XGS12 Assembly guide

HALE

HALE FoamLogix 1.7AHP Description, Installation and Operation Manual

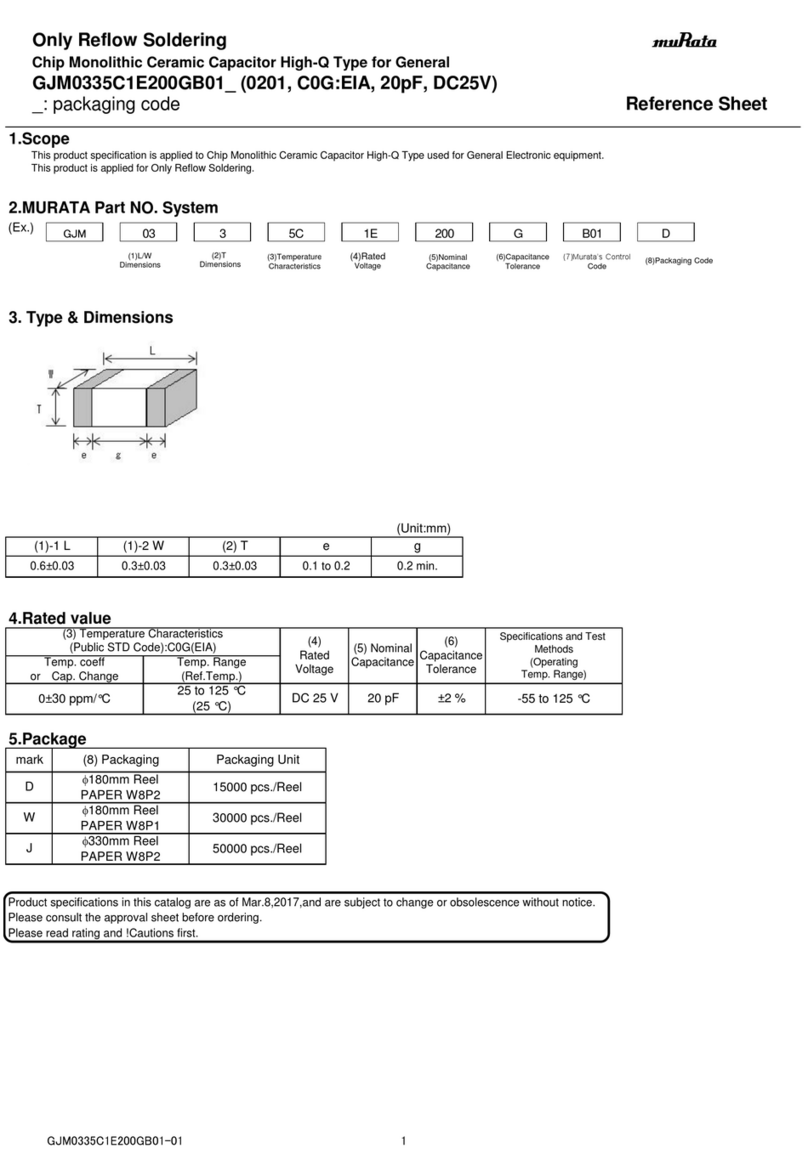

Murata

Murata GJM0335C1E200GB01 Series Reference sheet

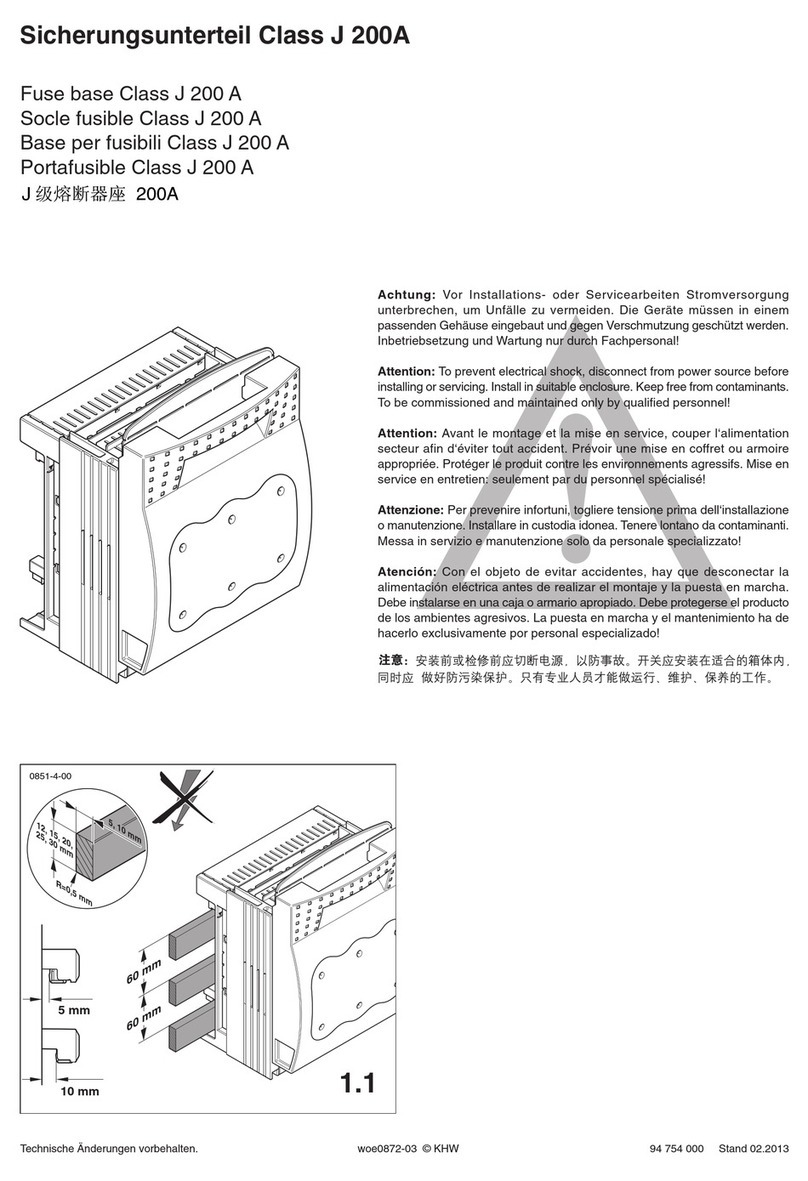

Wöhner

Wöhner QUADRON 60Classic manual

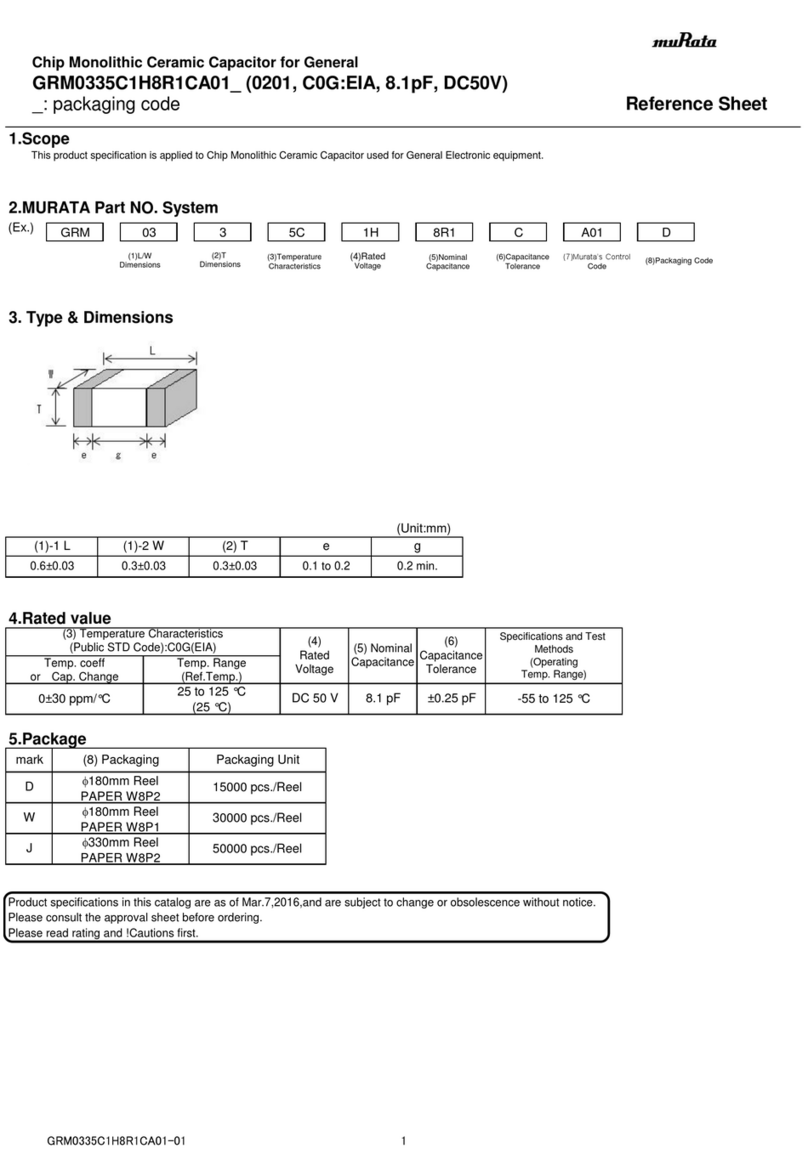

Murata

Murata GRM0335C1H8R1CA01 Series Reference sheet

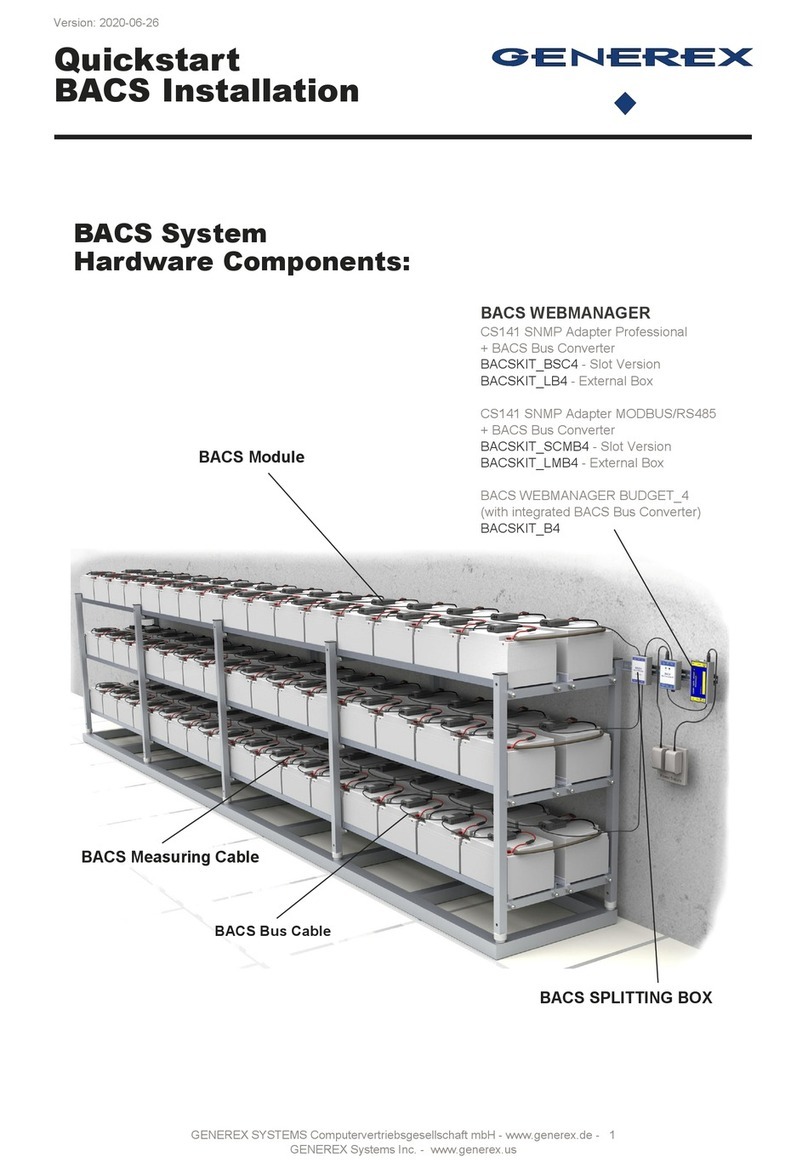

Generex

Generex BACS System quick start guide

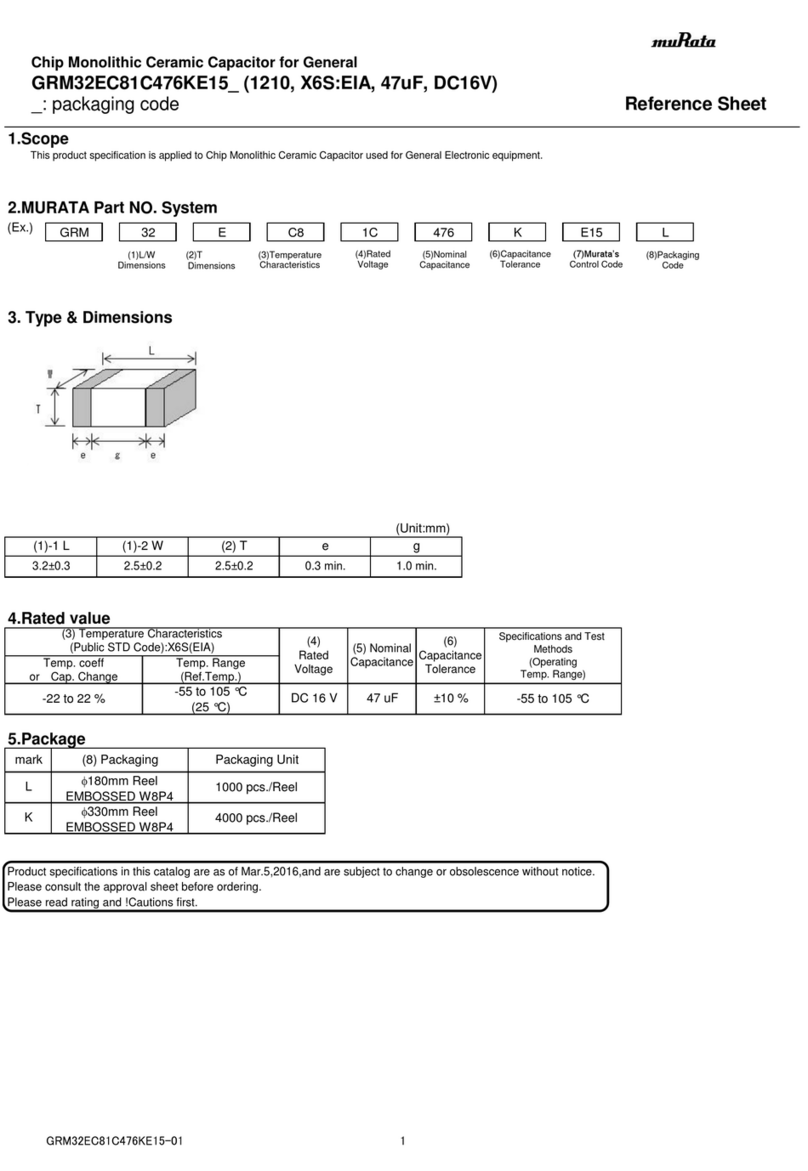

Murata

Murata GRM32EC81C476KE15 Series Reference sheet

Taga Harmony

Taga Harmony PC Series instruction manual

Murata

Murata GRM185R60J225KE26 Series Reference sheet

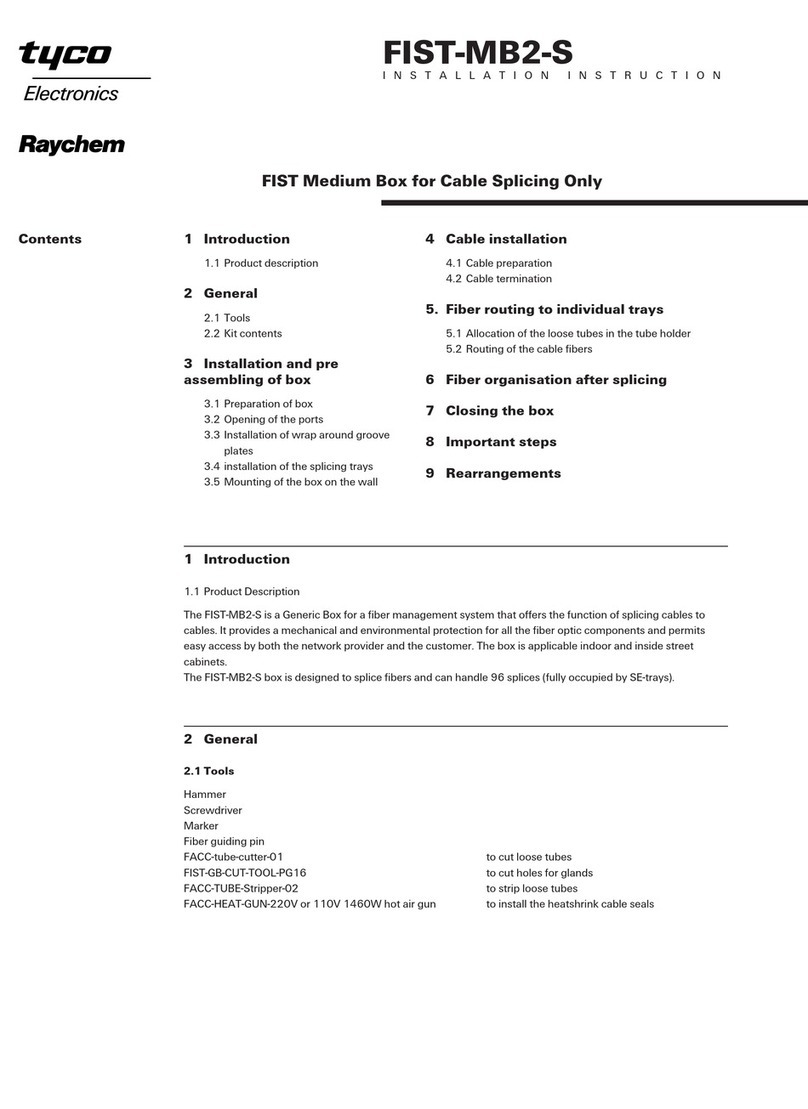

Tyco Electronics

Tyco Electronics Raychem FIST-MB2-S Installation instruction

Eaton

Eaton PT 10 instruction manual

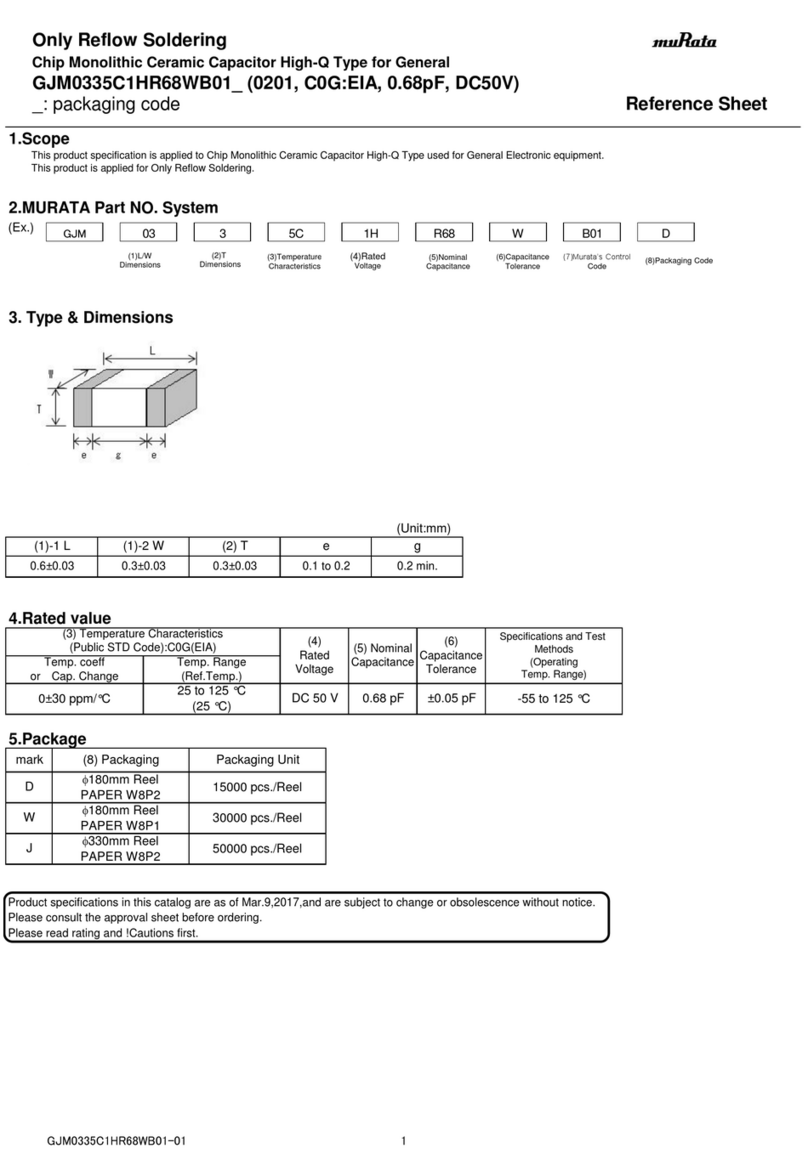

Murata

Murata GJM0335C1HR68WB01 Series Reference sheet

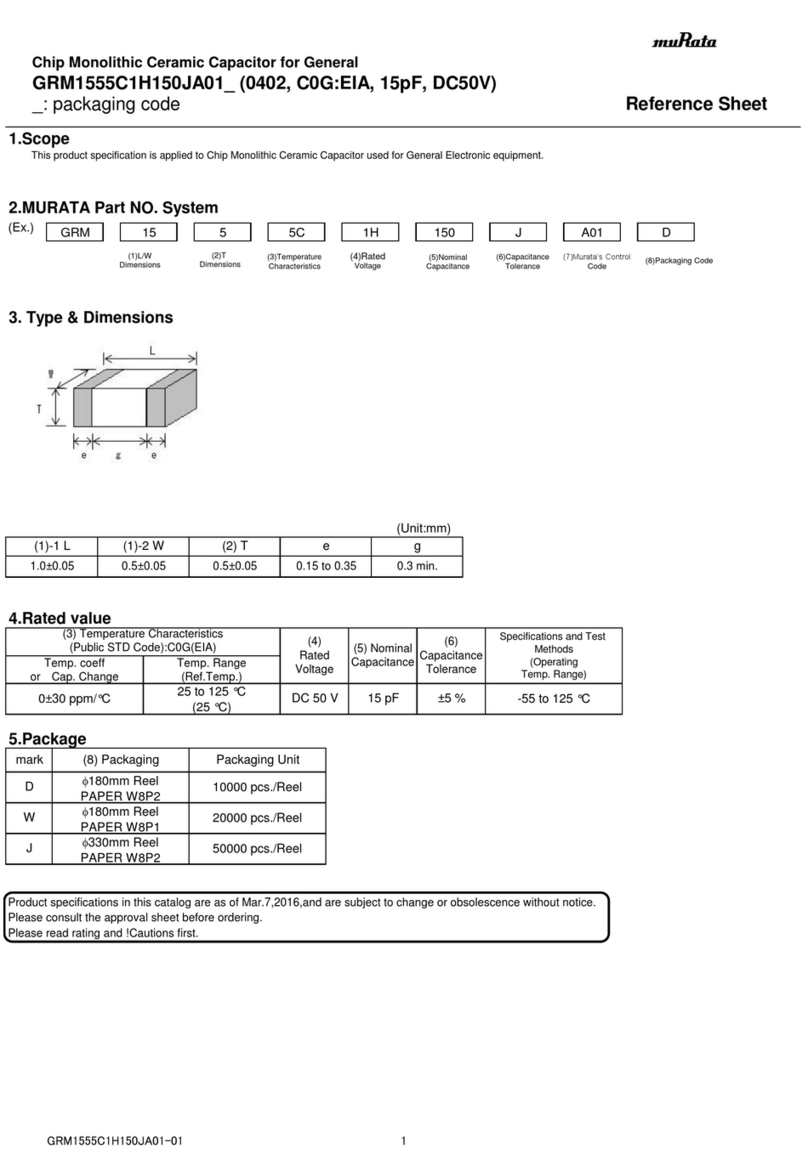

Murata

Murata GRM1555C1H150JA01 Series Reference sheet

Murata

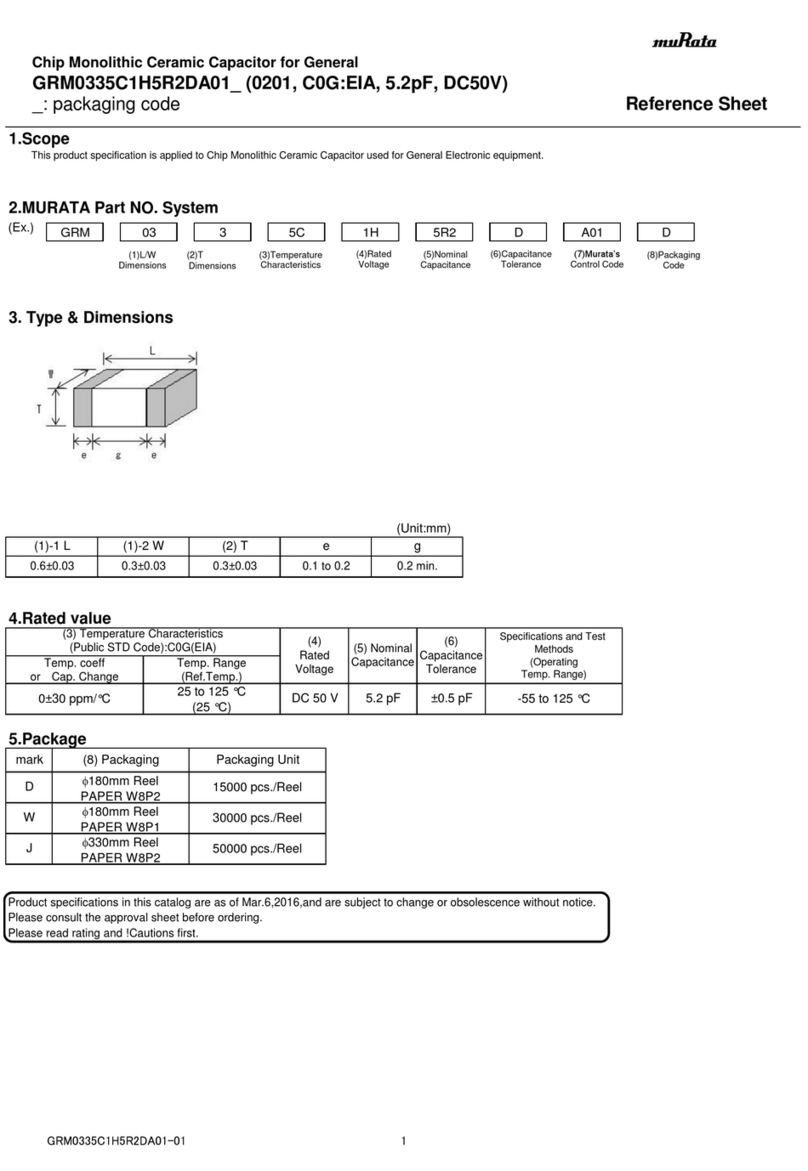

Murata GRM0335C1H5R2DA01 Series Reference sheet

Murata

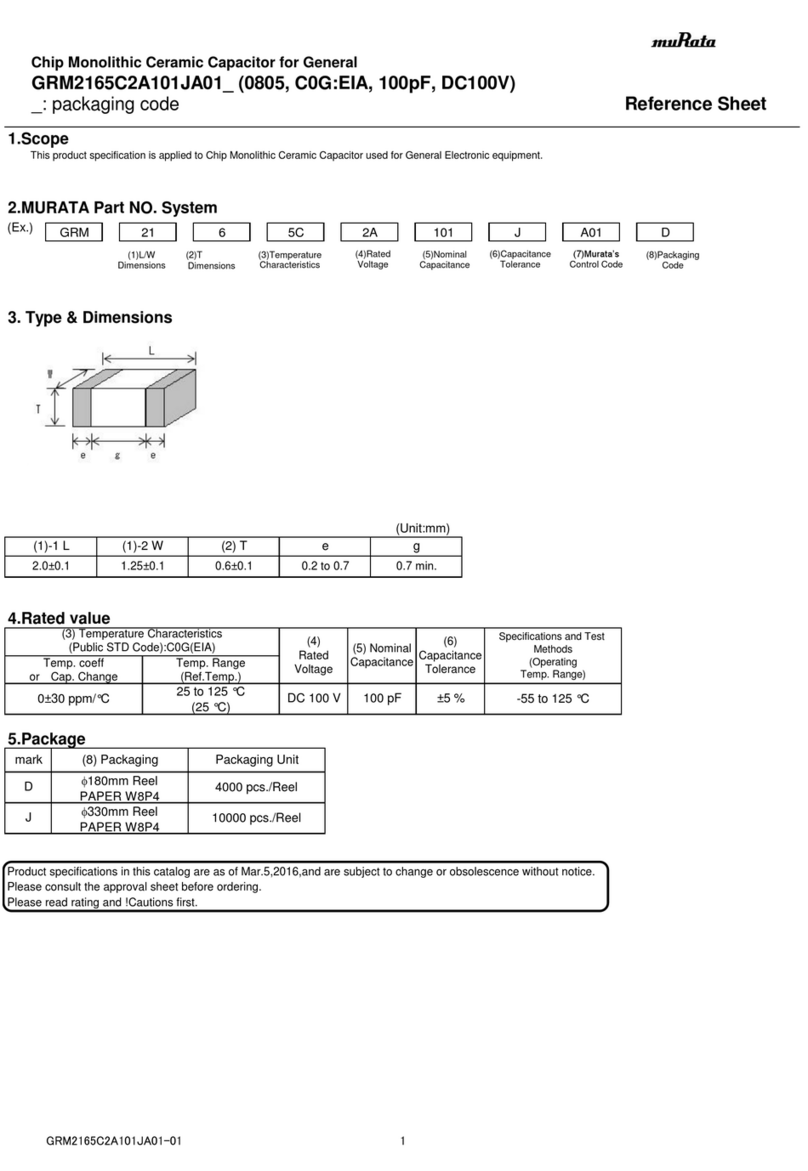

Murata GRM2165C2A101JA01 Series Reference sheet

Murata

Murata GRM188R71E104MA01 Series Reference sheet

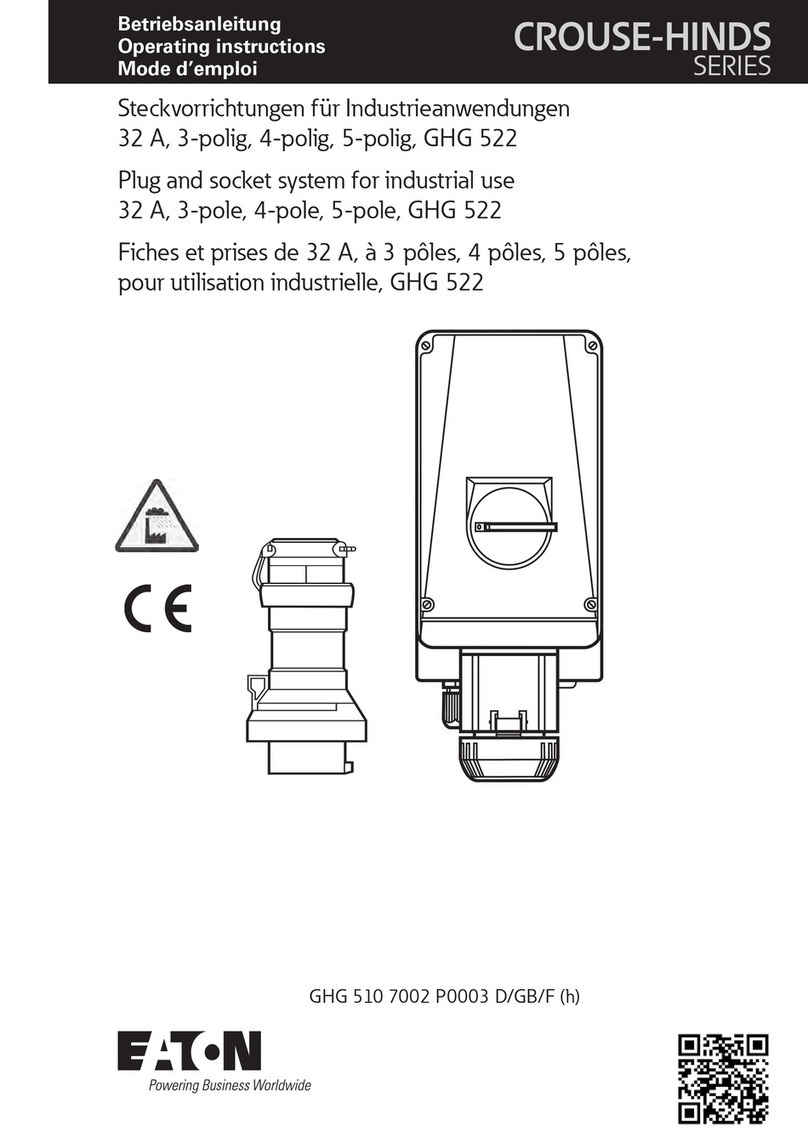

Eaton

Eaton Crouse-hinds series operating instructions