GENEREX SYSTEMS Computervertriebsgesellschaft mbH - www generex de - 2

GENEREX Systems Inc - www generex us

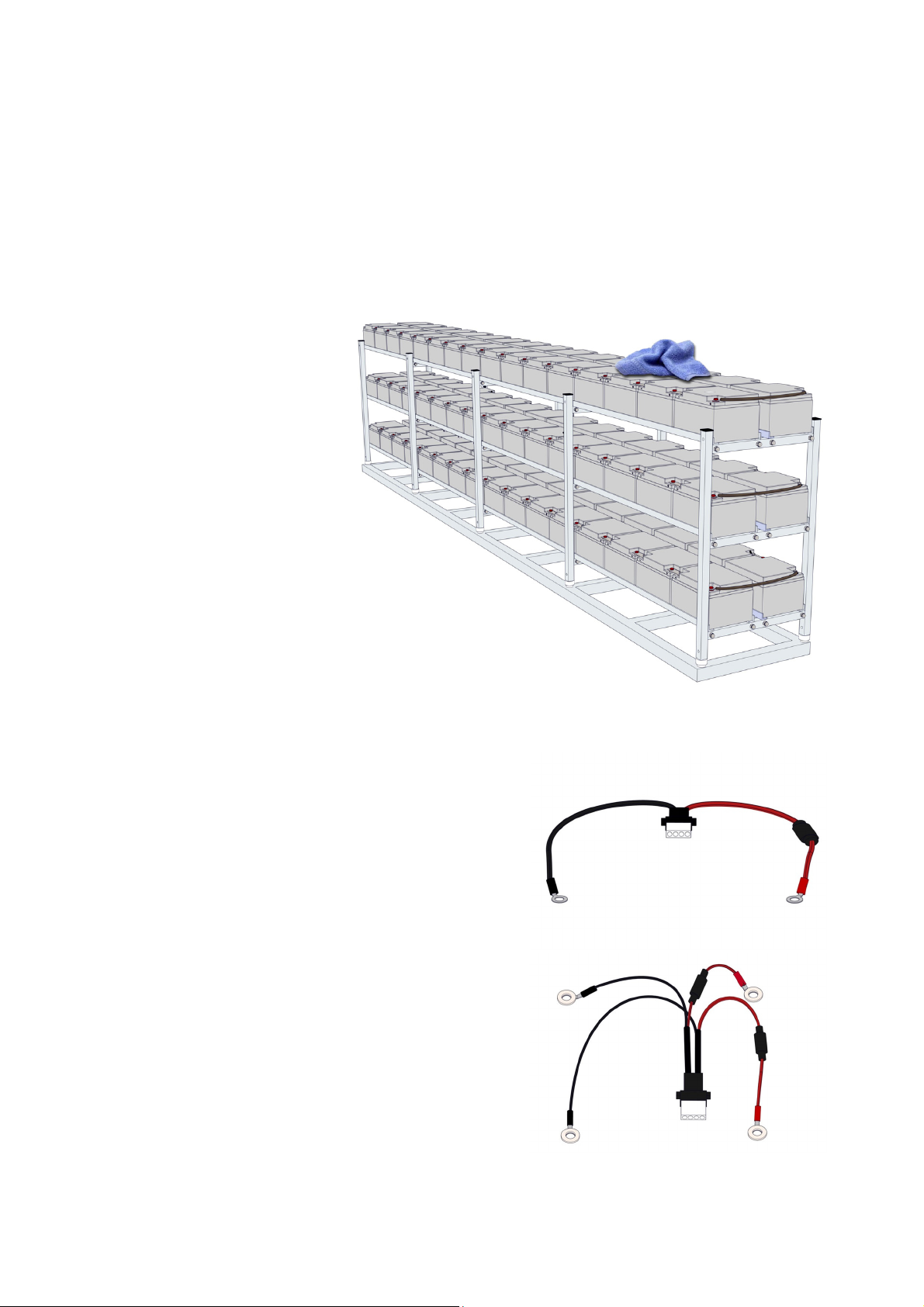

General Safet Precautions - Working with Batteries

For further information refer to the battery makers instructions for installation, maintenance, and operation of their

battery products

Improper use of the products described in this manual may lead to personal injury and/or

property damage GENEREX is not liable for injuries or damages that result from improper

handling these products

Risks associated with improper use include: explosion, fire, and short circuits Attention!

Battery terminals are always live, so never place metal objects or tools on top of the batter-

ies Battery electrolyte solutions are highly corrosive Should you observe leaks of electro-

lyte from a battery, be aware that these fluids are harmful to both eyes and skin

Installation, maintenance, and repair of batteries and battery equipment should be per-

formed only by trained specialists (or personnel authorized by battery manufacturers to

perform such services) Persons who have not been trained in battery safety or the proper

handling of batteries (or who have not been authorized to work on them) must not handle

batteries

Observe the following regulations (IEEE standards USA onl ):

ZVEI publication "Instructions for the Safe Handling of Electrolyte for Lead-acid Ac-

cumulators "

ZVEI publication "Safety Data Sheet on Accumulator Acid (Diluted Sulfu-ric Acid) "

VDE 0510 Part 2: 2001-12, in accordance with EN 50272-2:2001: "Safety Re-

quirements for Secondary Batteries and Battery Installations - Part 2: Stationary

Batteries"

IEEE Standard 450-2002: "Recommended Practice for Maintenance, Testing and

Replacement of Vented Lead Acid Batteries for Stationary Application "

IEEE Standard 1188-2005: “Recommended Practice for Maintenance, Testing and

Replacement of Valve Regulated Lead Acid Batteries for Stationary Application "

IEEE Standard 1375-1998: "Guide for Protection of Stationary Battery Systems

Observe also the following safety rules:

1. Ensure that all electrical loads and power supplies/charging devices

(including separators, fuses, and switches) are switched off. This must be car-

ried out b qualified personnel.

2 Remove all wrist watches, rings, chains, jewelry and other metal objects before

working with batteries

3 Use insulated tools only

4 Wear insulating rubber gloves and rubber shoes

5 Never place tools or metal components on top of the batteries

6 Make sure that the battery or batteries are not mistakenly grounded (The conse-

quences of an accidental or incorrect connec-tion can be mitigated reduced by ter-

minating the ground connection ) If the system is grounded, terminate the connec-

tion Touching a grounded batter b mistake can result in severe electric

shock.

7 Before establishing connections, make sure to verify polarity (Better one too many

times than one too few )

8 Filled lead-acid batteries contain highly explosive gas (hydrogen/air mixture) Never

smoke, handle open flames or create sparks near the batteries. Always avoid

electrostatic discharge; wear cotton clothing and ground yourself if necessary

9 Wear the appropriate safety clothing and equipment