1

English

Table of contents

1. TO THE USER ...................................................................................................................................................................... 2

1.1 INTRODUCTION ...................................................................................................................................................................... 2

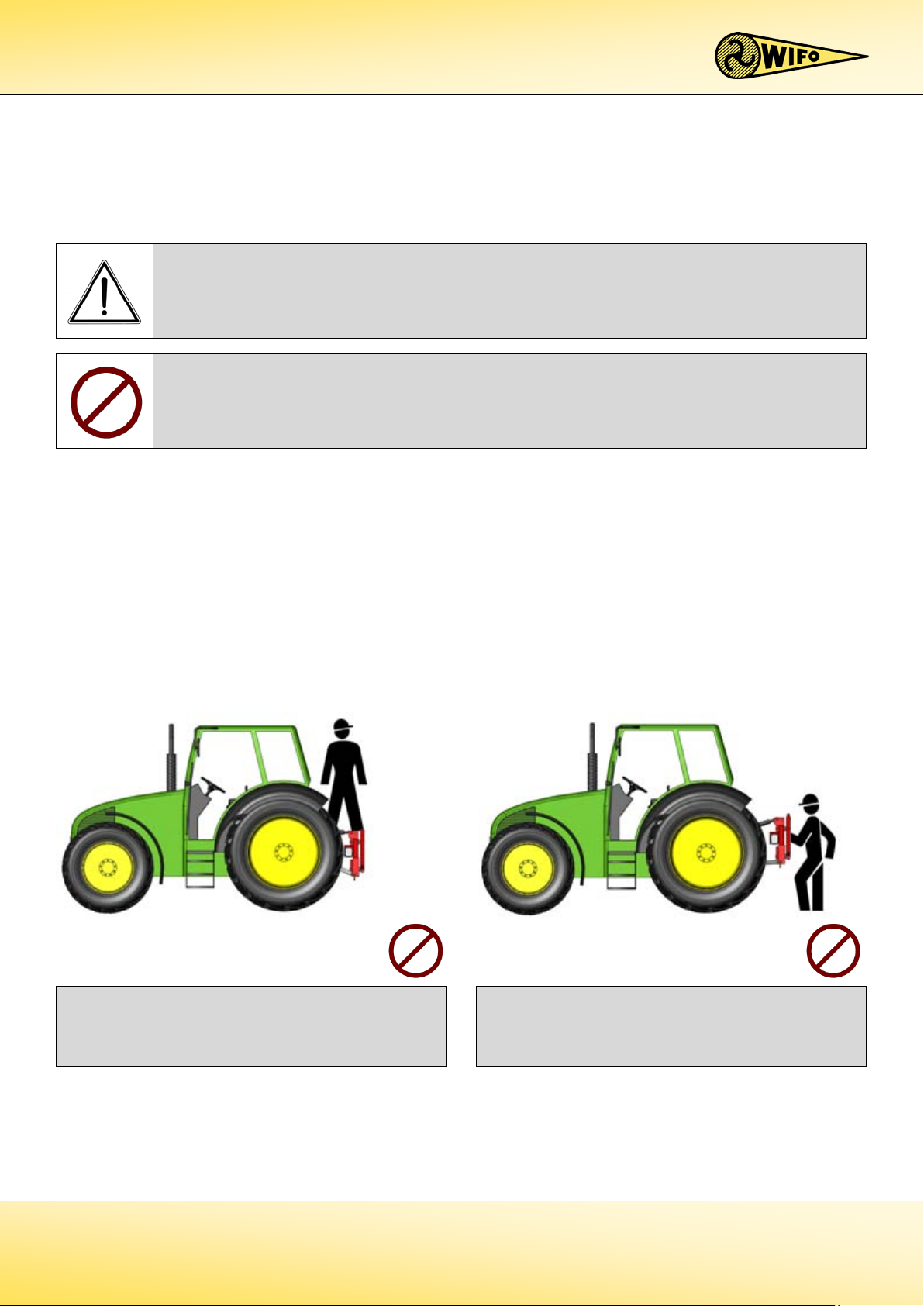

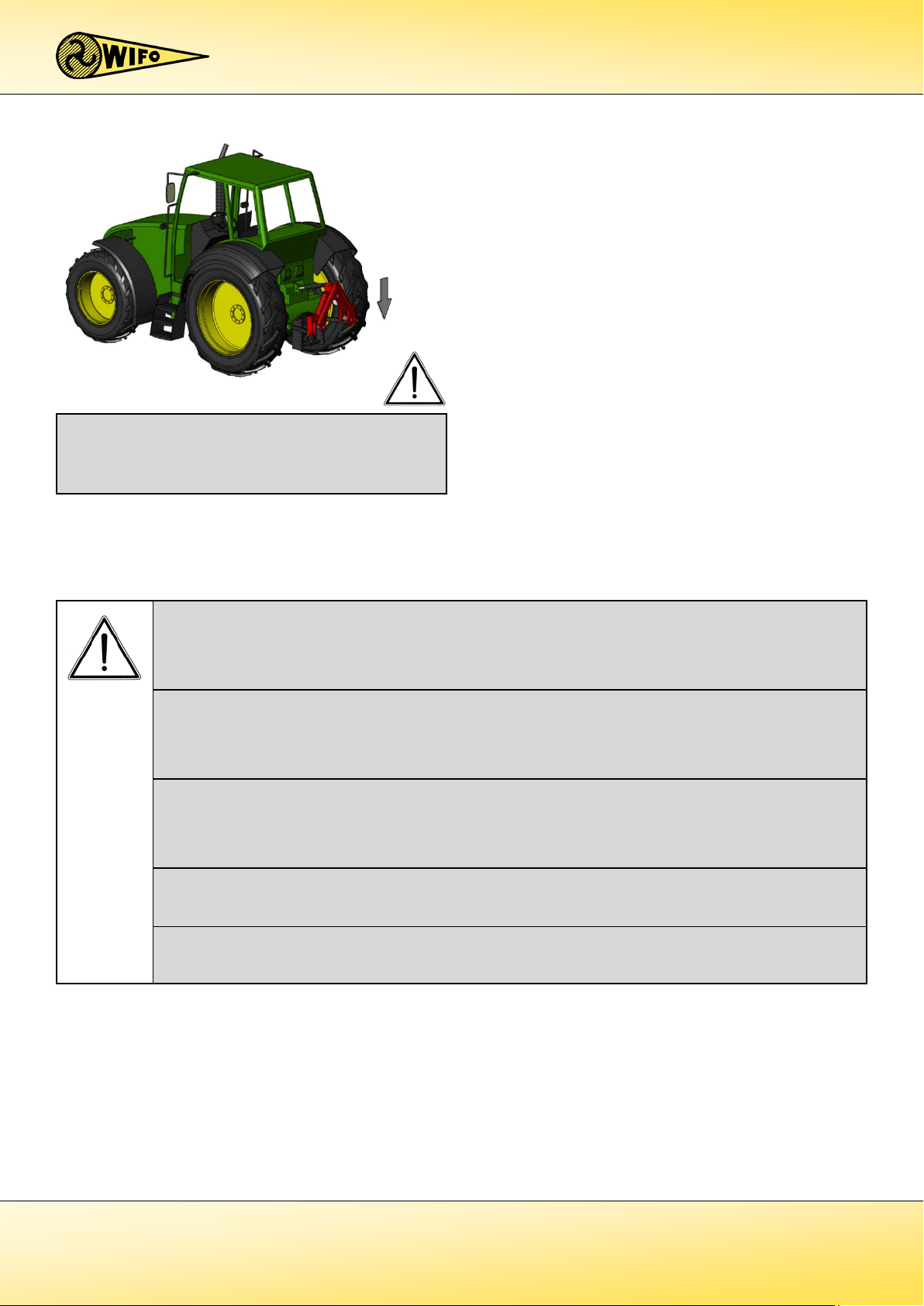

1.2 SAFETY PRECAUTIONS AND WARNINGS........................................................................................................................................ 3

1.2.1 Safety regulations..................................................................................................................................................... 3

1.2.2 Safety stickers and warning signs............................................................................................................................. 5

1.2.3 Placement of the safety stickers on the machine ..................................................................................................... 5

1.3 PURPOSE OF USE .................................................................................................................................................................... 6

1.4 LIABILITY............................................................................................................................................................................... 7

1.5 WARRANTY ........................................................................................................................................................................... 7

2. TECHNICAL DETAILS........................................................................................................................................................... 8

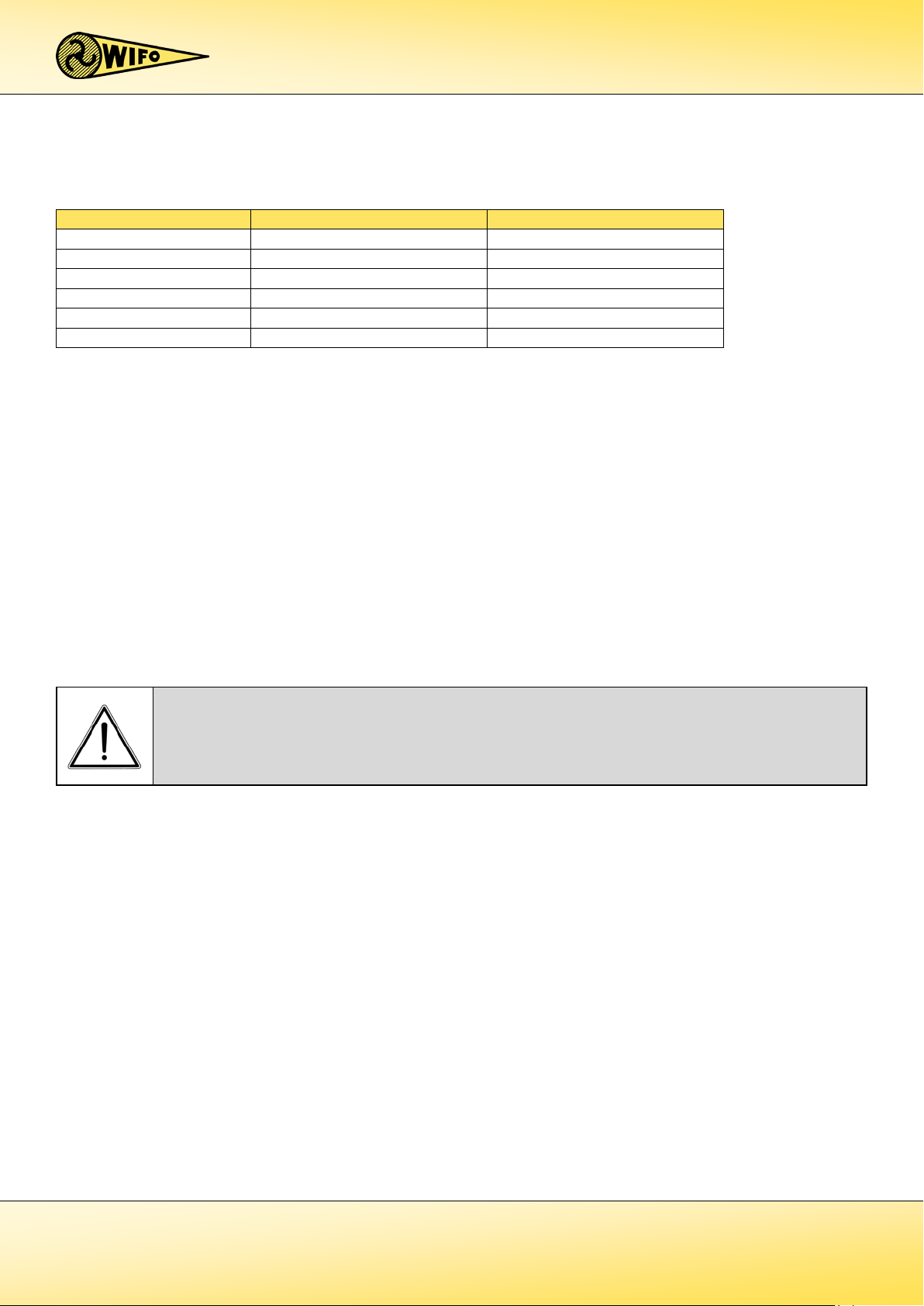

2.1 GENERAL TECHNICAL DATA...................................................................................................................................................... 8

2.2 WI-5000-T ......................................................................................................................................................................... 9

2.2.1 Parts list........................................................................................................................................................................ 9

2.2.2 Commencement of operation WI-5000-T.................................................................................................................... 10

2.3 WI-5000-TS ..................................................................................................................................................................... 11

2.3.1 Parts list...................................................................................................................................................................... 11

2.3.2 Commencement of operation WI-5000-TS.................................................................................................................. 12

2.4 ACCESSORIES/OPTIONAL EXTRAS.............................................................................................................................................. 13

2.4.1 Extension triangle for WI-5000-T/WI-5000-TS ........................................................................................................... 13

2.5 REPLACEMENT COMPONENTS.................................................................................................................................................. 13

3. FAULTS AND MAINTENANCE ........................................................................................................................................... 14

3.1 TROUBLESHOOTING.............................................................................................................................................................. 14

3.2 WORK TO BE CARRIED OUT BY THE USER ................................................................................................................................... 15

3.2.1 Calibrating the weighing equipment for WI-5000-T ............................................................................................... 15

3.2.2 Calibrating the weighing equipment for WI-5000-TS ............................................................................................. 16

3.2.3 Circuit testing weighing pins for WI-5000-T/WI-5000-TS ....................................................................................... 17

3.3 WORK TO BE CARRIED OUT BY A COMPETENT WELDER/MECHANIC ................................................................................................. 18

3.3.1 Instructions for welding an extension triangle to a machine...................................................................................... 18

3.3.2 Instructions for replacing a weighing pin.................................................................................................................... 18