Wilbur Curtis Company STBA48026 User manual

Page 1

SETUP STEPS

NOTE: Some type of water ltration device must be used to maintain trouble-free operation.

In areas with extremely hard water, we suggest that a sedimentary, taste and odor lter be

installed. This will prolong the life of your brewing system and enhance tea quality.

1. Locate the brewer on a secure surface. Level it left to right and

front to back by rotating the feet on the 4 corners.

2. Connect a water line from the water lter to the brewer.

Plumb water lines. A 1/2” hose barb has been supplied for water

line connections. See page 3 for location.

Use tubing sized sufcient to provide a minimum of 3.0 gpm for the ambient INLET WATER

(2 places) and CHILLED WATER connections.

3. Connect the CO2 or compressed air line.

4. Connect the brewer to an electrical outlet with the appropriate

amperage rating (see serial tag on brewer).

continued...

Symbols:

WARNING/CAUTION – To advise about conditions that my result in property damage,

personal injury or death

IMPORTANT – Notes about proper operation

Sanitation requirements

Models covered

• STBA48026

Important Safeguards/Symbols

This appliance is designed for commercial use. Any servicing other than cleaning and routine

maintenance should be performed by an authorized Wilbur Curtis Co., Inc. service technician.

• DO NOT immerse the brewer in water or any other liquid.

• To reduce the risk of re or electric shock, DO NOT open service panels. There are no user

serviceable parts inside.

• Keep hands and other items away from hot areas of the brewer during operation.

• Never clean with scouring powders or harsh chemicals.

Following are the factory settings for the STBA48026 Iced Tea Brewing System:

• Brew Temperature = 200°F

• Brew Volume = Set to dispensing vessel requirements (2.2 liters)

Usually, there will never be a reason to change the programming on the system’s G3 series

controller. However, should you need to make slight adjustments to meet your brewing needs,

programming instructions are provided later in this manual.

System Requirements:

• Water source: 50 – 90 psi (minimum ow rate of 3.0 gpm)

• CO2/compressed air source: 50 psig max.

• Electrical: See schematic in this manual

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO., INC.

6913 Acco Street

Montebello, CA 90640

For the latest information go to

www.wilburcurtis.com

Phone: 800-421-6150

WARNING: Equipment

must be installed to

comply with applicable

federal, state, and local plumbing/

electrical codes having jurisdiction.

WARNING: Follow this

setup procedure before

attempting to use this

brewer. Failure to follow these

instructions can result in injury

and/or void of warranty.

IMPORTANT: After

setup, run a FULL

brew cycle. Place a

tea container to catch both hot

water from the brew basket and

dilution water from spout on the

front cover.

CAUTION: DO NOT

connect the brewer

to hot water. The inlet

valve is not rated for hot water.

WARNING: Use the

leveling legs to level the

brewer only. Do not use

them to adjust brewer height. Do not

extend them higher than necessary.

WARNING: The CO2/

compressed air input

pressure must not

exceed 50 psig.

Wilbur Curtis Co., inC.

Service Manual – McDonald’s Sweet Tea Brewer

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the brewer) is required so

that the brewer can be moved for cleaning underneath.

2. This equipment is to be installed with adequate back-ow protection to comply with applicable

federal, state and local codes.

3. Water pipe connections and xtures directly connected to a potable water supply shall be sized,

installed and maintained in accordance with federal, state and local codes.

Page 2

Wilbur Curtis Co., Inc.

SETUP STEPS (CONT.)

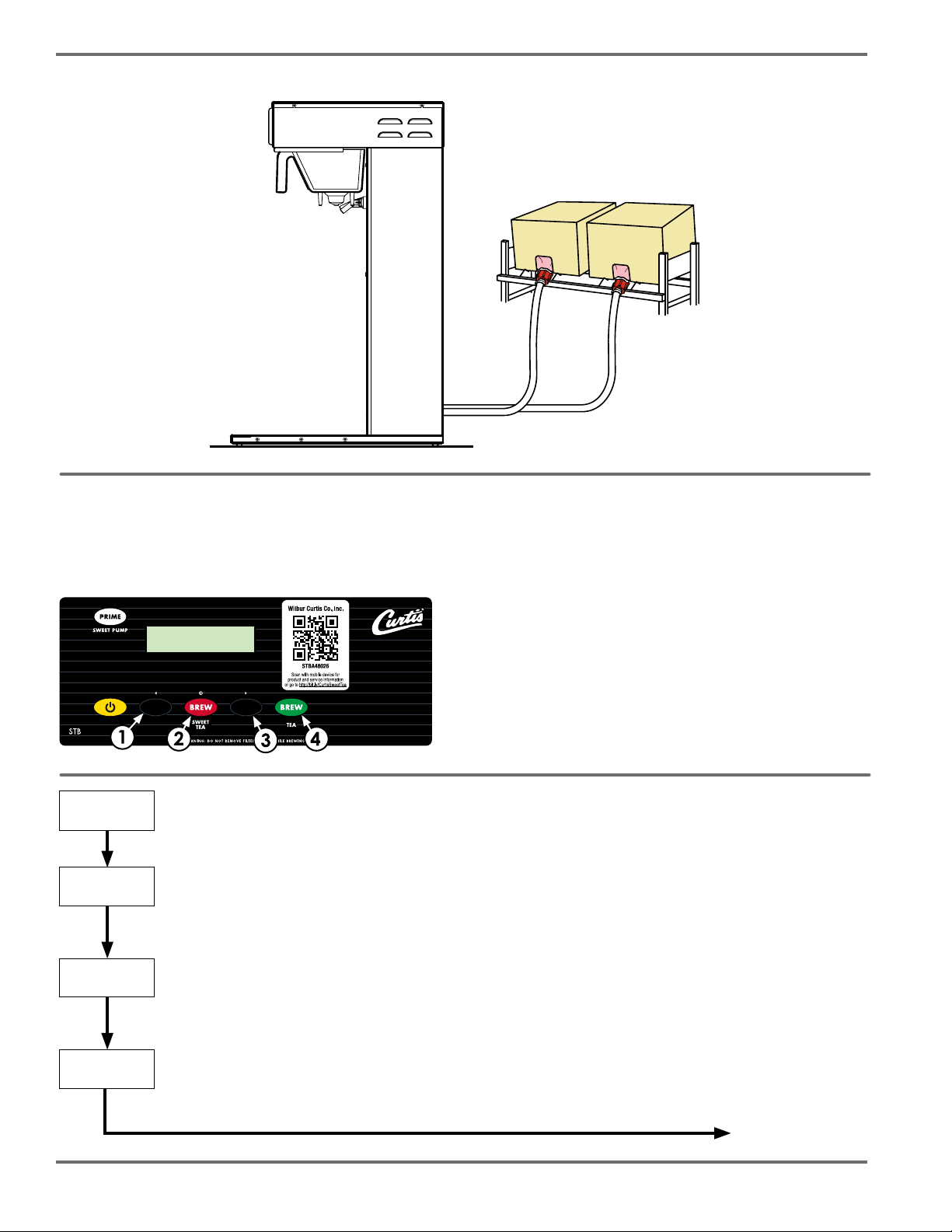

5. Connect two Bag-in-Box (BIB) sweeteners to the brewer sweetener supply hoses as instructed

on page 5. Connecting two bags allows the brewer to continue operating if one bag runs out.

6. Turn on the main power switch (toggle switch, behind the brewer). The heating tank will start to

ll. When the water level in the tank rises to the correct volume, the heating element will start

automatically. This eliminates the possibility of element burnout caused by heating with an empty tank.

7. Place a quart or larger container under the spout assembly. Press and hold the PRIME button

to draw the sweetener through the system. Release the PRIME button when sweetener begins

to ow out of the spout without any air bubbles (about 20 ounces).

8. The heating tank will require 20 to 30 minutes to reach operating temperature (200°F) indicated by Ready to Brew on the

display.

9. Enter programming mode on the universal control module (UCM) to choose the brewer operation mode (Model Select).

Turn off power at the ON/OFF (yellow) button. Press and hold the green BREW button (button 4, see diagram below). While

holding down the BREW button, press and release the ON/OFF button. Continue to hold the BREW button, until Entering

Programming Mode appears on the screen. Enter the access code when prompted (Enter Code). The default code is 1-2-3-4.

< Program Menus > will appear on the display.

10. Press button 3 (►) repeatedly until Model Select appears on the display. Press button 2 () to enter the Model Select sub-

menu. Press button 3 (►) repeatedly until the desired model appears on the display*. Press button 2 () to save and exit. The

UCM will reset.

* For iced coffee models, a different UCM label is required. Order Curtis kit # WC3423K.

IMPORTANT: The

sweetener must be

between 50°F and 120°F

(10°C and 49°C) for proper operation.

IMPORTANT: For proper

operation, the sweetener

pumps must be primed

before using for the rst time. After

initial priming, the pumps prime

automatically when sweetener bags

are replaced.

TEA BREWER

CONTAINER

TO CATCH

SWEETENER

SPOUT

ASSEMBLY

PRIME

BUTTON

Programming Buttons

<Program Menus >

Select

Page 3

Service Manual - STBA48026 Tea Brewer

11. Center an empty tea dispenser under the brew basket. Press the SWEET TEA BREW button to run one full brew cycle with the

brew basket empty (Ready to Brew must be on the display). This process will purge the hoses and valves of any remaining air.

Sweet Tea Brix Measurement Procedure

1. Brew a batch of sweet teat into a tea dispenser according to the brewing instructions on the following page.

2. Wait for Brewing to disappear from the display. Allow the tea to cool to room temperature.

3. Dispense a full cup of cooled tea from the dispenser into a clean, empty 16 ounce cup.

4. Use a refractometer to test the Brix level of the tea according to the refractometer manufacturer’s instructions. The reading

should be between 9.8 and 12.8 for regular sweet tea and between 11.8 and 14.8 for southern sweet tea.

5. Dispense a second full cup of tea into a separate, clean, empty 16 ounce cup from the same dispenser. Run the refractometer

test a second time to validate the results. The reading is considered accurate when the test is run twice on the two cups of tea

and the results are approximately the same. If the results vary, try running the two tests again.

6. If the Brix level is outside of specications, check the following:

A. Check to make sure that the sweetener BIB feed system is properly primed. Air bubbles in the system will affect the Brix

level.

B. Was a full brew cycle run to remove any additional air from the system?

C. Check to make sure that the tea dilution time is properly set for the model selected, 1:10 for regular sweet tea, 1:05 for

southern sweet tea.

D. Did you run the refractometer test twice to validate the results?

E. Does the water supply meet specications (3.0 gpm with a water pressure between 50 and 90 psi)?

All the above factors can affect the Brix measurement. If all of the above conditions have been met, and the Brix

measurement is out of specications, call technical support.

REAR PANEL CONNECTIONS

BACK PANEL

OF BREWER

MAIN POWER

SWITCH CO2/

COMPRESSED AIR

CONNECTION

CHILLED

WATER INLET

(DILUTION)

POWER CORD SWEETENER

SUPPLY HOSE

SWEETENER

SUPPLY HOSE

AMBIENT

WATER INLET

(TANK)

AMBIENT

WATER INLET

(BLEND)

Page 4

Wilbur Curtis Co., Inc.

IMPORTANT: The ow of tea may pause for up to 10 seconds during brewing. This is normal.

BREWING INSTRUCTIONS

WARNING: HOT LIQUID - TO AVOID SCALDING, AVOID SPLASHING. DO NOT REMOVE BREW BASKET WHILE “BREWING”

APPEARS ON THE DISPLAY.

1. If it is not on, make sure that the toggle switch on the back of the brewer is in the ON position, then press the ON/OFF (yellow)

button on the front panel. Ready to Brew must appear on the display.

2. Place a tea pouch in the brew

basket. 3. Slide the brew basket into the brew

rails. Push it all the way in until it

stops.

4. Place a tea container on the brew

deck. Select a BREW button and

press to start a brew cycle.

TEA TIPS

• Store tea bags in a dark, cool and dry place away from strong odors and moisture. Do not

refrigerate.

• Do not hold brewed tea overnight.

• Make sure your equipment is clean at all times. Clean tea brewing equipment at least once per

day.

• Sanitize equipment at least once per week.

• Do not let fresh-brewed iced tea sit at room temperature for more than 8 hours.

As with other food products, if you adhere to proper preparation, holding and sanitation procedures, fresh-brewed iced tea is a safe

beverage. The primary cause for high bacteria counts found in tea from food service businesses is related to excessive holding

times and/or poor cleaning and sanitizing procedures.

WARNING DO NOT

refrigerate unused

tea overnight for later

consumption.

STBA48026 - SWEET TEA

Your Curtis Sweet Tea Brewer is Factory Pre‑Set for Optimum Performance.

After connection to water and power; the rear toggle switch must be on. You will hear a beep sound, indicating power is available to the controller.

The control displays . Press ON/OFF (yellow) button and the screen will display . After three seconds, is

displayed.

Water will ll the tank (approximately 2-3 minutes depending on water ow rate). When the proper level is reached will appear on the

screen. It takes approximately 20 minutes to reach the set point temperature of 200°F.

The display will show when the temperature reaches the set point (200°F). The brewer is now ready to brew.

MCDONALD’S

Ready to Brew

MCDONALD’S MCDONALD’S

WC786108 REV. B

MCDONALD’S

Filling...

MCDONALD’S

Heating...

Page 5

Service Manual - STBA48026 Tea Brewer

The PRIME button is used to ll the sweetener hoses when the unit is rst installed or after servicing. The system

automatically rells the hoses when the BIB is changed.

When one of the boxes runs out of sweetener, the Change Sweetener message appears on the display. Replace the empty box as

soon as possible, as instructed below. After the Change Sweetener message appears, the brewer will allow for eight more batches

of sweet tea to be brewed before the Sweet Tea Lockout message appears. When this message appears, the brewer will not

allow sweet tea to be brewed (only unsweetened tea). Replace the BIB, then press PRIME to unlock the sweet tea function.

SWEETENER REPLACEMENT/CONNECTION PROCEDURE - BAG-IN-BOX (BIB)

Disconnecting an Empty BIB

1. Locate the empty BIB sweetener container (the lightest one).

2. Remove the QDC at the end of the brewer sweetener hose from

the empty BIB container.

Connecting a New BIB

3. Place the new BIB container on the rack and remove the

cardboard cover labeled OPEN HERE.

4. Twist and remove the shipping cap that covers the spout.

5. Thread the QDC on the brewer sweetener supply hose onto

the bag spout. During operation, make sure that the BIB is

in an inverted position, with the spout and connector pointed

downward. This allows for more complete use of the product

while the bag empties. See the Sweetener Schematic on page

6 for an example of proper sweetener connection.

6. Press PRIME to clear the Change Sweetener message.

Page 6

Wilbur Curtis Co., Inc.

All programming selections are performed with the three center

buttons. The symbols above the buttons are:

To exit: Pressing when Exit is displayed, exits program

mode and returns brewer to normal operation.

PROGRAMMING

ENTER PROGRAMMING MODE: Turn off power at the ON/OFF (yellow) button. Press and hold button 4 (see below), while you

press and release the ON/OFF button. Continue to hold button 4. First Entering Programming Mode will appear on the display,

then Enter Code will appear. Release button 4 and enter the 4-digit access code, the digits 1-4 correspond to the buttons in the

diagram below. The default code set at the factory is 1-2-3-4. < Program Menus > will be displayed.

Program Menus

Tea By Time

Tea By Volume

Tea Dilut. Delay

◄Scroll left (button 1)

SELECTION or ENTER to save new parameter (button 2)

►Scroll right (button 3)

Program Menus screen. Press ►button to show the next menu item.

Tea by Volume - Press to select. The display will read “Select Brew Button!”. Press the BREW button for which the

brew volume needs to be changed. “Press BREW to Start” will appear on the display. Press BREW again and hot water

will start dispensing. When the desired volume is reached, press the brew button again to stop the ow. The brew volume

has now been set.

Tea by Time - (factory defaults: SWEET TEA = 4 min. - 36 sec., SOUTHERN SWEET TEA = 4 min. - 36 sec.,

REGULAR TEA = 3 min. - 35 sec., ICED COFFEE = 4 min. - 43 sec.) Press to select. The display will read

“Select Brew Button!”. Press the BREW button for which the brew time needs to be changed. Press the ◄or ►

buttons to select minutes or seconds. Press to change the number of minutes or seconds (when ashing). To exit,

press ►until ex (exit) is ashing, then press .

Tea Dilution Delay - (factory defaults: SWEET TEA = 5 min., SOUTHERN SWEET TEA = 5 min., REGULAR TEA

= 30 sec., ICED COFFEE = 1 min.). Press to select. The display will read “Select Brew Button”. Press the BREW

button for which the dilution delay needs to be changed. Press the ◄or ►buttons to add or decrease time. Press

to set.

continued on next page

SWEETENER SCHEMATIC

TEA BREWER

(SIDE VIEW)

BAG IN BOX (BIB)

SWEETENERS

(2 PER BREWER)

SWEETENER

HOSES

Page 7

Service Manual - STBA48026 Tea Brewer

PROGRAM MENUS (CONT.)

Energy Save Mode

Brew Count Odom.

Brew Count Total

Cold Brew Lock

Tea Dilution Volume - Press to select. The display will read “Select Brew Button!”. The display will read “Press

BREW to Start”. Press the BREW button for which the dilution volume needs to be changed. Press BREW again and

hot water will start dispensing. When the desired volume is reached, press the brew button again to stop the ow. The

tea dilution volume has now been set.

Tea Dilution Time - (factory defaults*: SWEET TEA = 1 min. - 10 sec., SOUTHERN SWEET TEA = 1 min. - 05

sec., REGULAR TEA = 1 min. - 56 sec., ICED COFFEE = 1 min. - 18 sec.) Press to select. The display will

read “Select Brew Button!”. Press the BREW button for which the dilution time needs to be changed. Press the ◄or

►buttons to select minutes or seconds. Press to change the number of minutes or seconds (when ashing). To

exit, press ►until ex (exit) is ashing, then press .

Tea Drip Out - (factory defaults: SWEET TEA = 4 min., SOUTHERN SWEET TEA = 4 min., REGULAR TEA = 3

min., ICED COFFEE = 3 min.) Press to select. The display will read “Select Brew Button!”. Press the BREW

button for which the Drip-Out needs to be changed. Press the ◄or ►buttons to add or decrease time. Press

to set.

Sweetener Count - (factory default: SWEET TEA = 42, SOUTHERN SWEET TEA = 50) Press to select. Press

the SWEET TEA BREW button. Press the ◄or ►buttons to increase or decrease the count. Press to set.

Blend Time - (factory default: 13 sec.) Press to select. Press the SWEET TEA BREW button. Press the ◄or

►buttons to select seconds. Press to change the number of seconds (when ashing). To exit, press ►until

ex (exit) is ashing, then press . NOTE: Minutes are not programmable.

Prime Sweetener Pump - Performs the same function as the PRIME button on the front of the control panel. Press

and hold to prime both sweetener pumps. Turns each sweetener pump on for 3 seconds alternately. Alternates

back and fourth between both pumps until is released. Be sure to have a quart or larger container under the

spout during the priming process.

Prime On/Off - (factory default: On) Press to select. Press ◄or ►to change between On and Off, then

press to set. Enables/disables the PRIME button.

Temperature - (factory default: 200ºF) Press to select. Press ◄or ►to increase or decrease the

temperature, then press to set.

Energy Save Mode - (factory default: Off) Press to select. Press ◄or ►to change between On, Off or On-

140ºF, then press to set. When set to On, the brewer will automatically shut off 4 hours from the last brew. When

the feature is Off, the brewer does not use the energy saving feature. In the On-140ºF position, the temperature goes

down to 140ºF if the brewer has not brewed in 4 hours. This saves energy by lowering the tank temperature during

periods of non-operation.

Brew Count Odometer -(resettable) Press to display the total brew cycles. Press to reset, or press the

button below ex to exit without resetting.

Brew Count Total - (not resettable)

Press to select (display returns to previous display after 5 seconds). Shows the total gallons and total number of

brew cycles on the brewer.

Cold Brew Lock - (factory default: 5ºF) Press to select. Press ◄or ►to select the desired setting (5ºF,

15ºF or Off). Press to set. The cold brew lock feature allows the brewer to brew at three different temperature

levels from the actual set point. The rst setting is within 5 degrees of the set point, next is within 15 degrees of the

set point, Off is within 30 degrees of the set point for the Ready to Brew message, however the brewer will brew at

any temperature.

* Sweet tea and southern sweet tea only.

Prime On/Off

Temperature

Tea Dilut. Time

Tea Dilut. Volume

Tea Drip-Out

Sweetener

Count*

Blend Time*

Prime Sweet

Pump*

continued on next page

Page 8

Wilbur Curtis Co., Inc.

PROGRAM MENUS (CONT.)

Model Select

Displ. Brew Time

Exit

Master Reset Press to display Are You Sure? Then press ◄for yes, or ►for no. When master reset is

used, all of the menu selections in the control module are reset to the factory defaults.

Service Call (phone number factory set to [800] 000-0000) Press to display the phone number. Press ◄or ►

to select each number to change, then press to change the number. To exit, press ►until ex is ashing, then

press . The phone number entered will be displayed during a heating system Sensor Erroror during a Water

Error.

Access Code (factory default is 1-2-3-4) Press ◄or ►to select each number to change, then press to

change the number. Each number can be changed from 1 to 4. To exit, press ►until ex is ashing, then press .

Banner Name (factory default: MCDONALD’S) Press to display the letters. Press ◄or ►to select each

letter to change, then press to change the letter. Up to 14 letters may be programmed. If all blanks are selected,

no banner name will be displayed. The banner name is displayed 5 seconds on and off. To exit, press ►until ex is

ashing, then press .

P-Maintenance (factory default: Off) Sets the number of gallons brewed before P-Maintenance is indicated.

Press to select. Press ◄or ►to adjust from Off to 3000 gallons. Press to exit and save setting.

Beeper On/Off (factory default: On) Press to display the current setting. Pressing either ◄or ►switches

between on and off. Press to set.

Display Brew Time (factory default: On)

Press to display the current setting. Press ◄or ►to toggle between On and Off. When On, the brew time

is displayed and counts down during the brew cycle. When Off, only the word Brewing is displayed during brewing.

Press to exit and save.

Model Select (factory default: STANDARD SWT TEA)

Press to select. Press ◄or ►to choose from STANDARD SWT TEA, SOUTHERN SWT TEA, ICE COF/

SWT TEA, ICE COF/STHN TEA. Press to set. IMPORTANT:

Exit

Press to select, exits program mode and returns the brewer to normal operation.

Beeper On/Off

Master Reset

Service Call

Access Code

Banner Name

P-Maintenance

Page 9

Service Manual - STBA48026 Tea Brewer

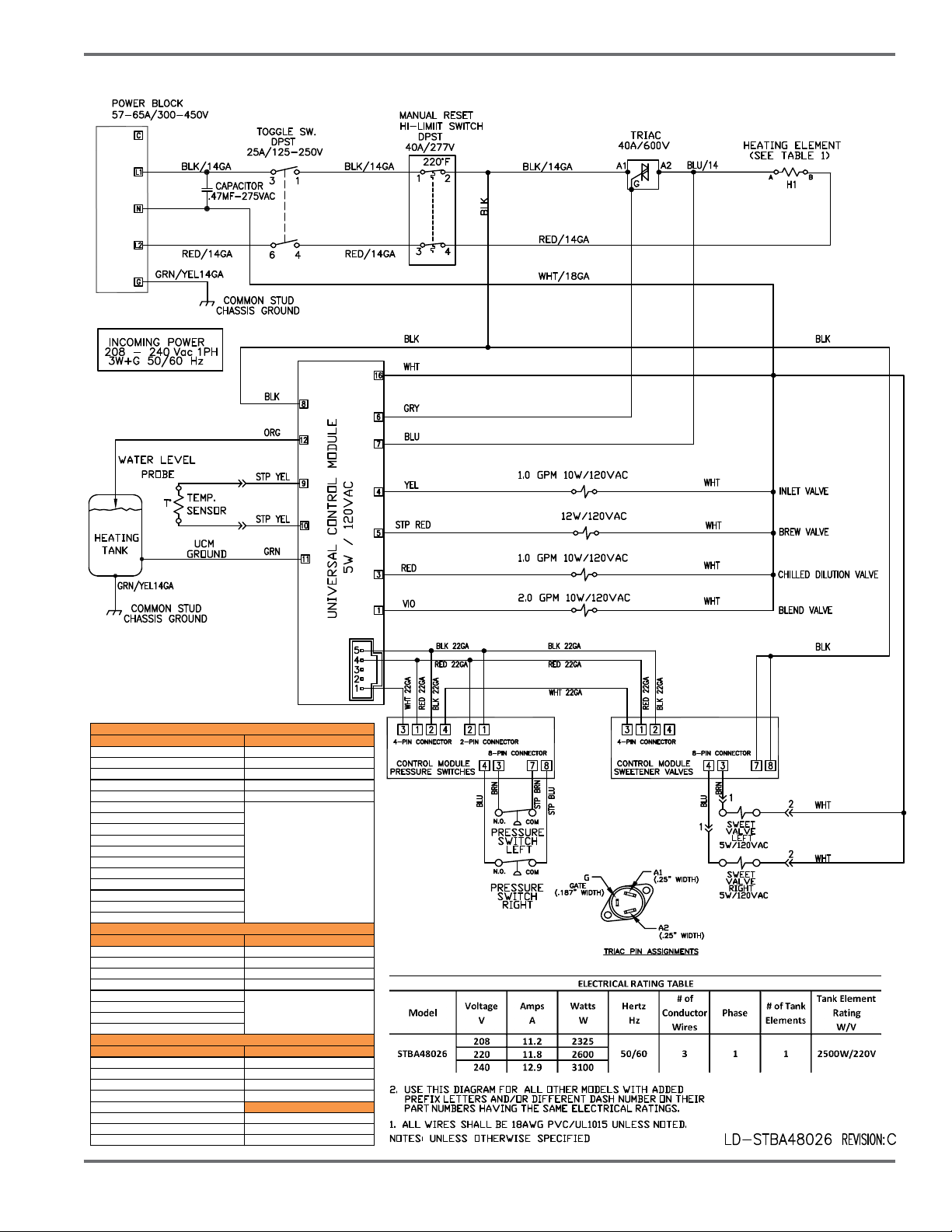

ELECTRICAL SCHEMATIC

PIN ASSIGNMENTS (16-PIN) PIN ASSIGNMENTS (5-PIN)

tsriFnoitacinumoC_ataD:10NIPEVLAVDNELB:10NIP

desUtoN:20NIPDESUTON:20NIP

PIN 03: CHILLED DILUTI ON VALVE PIN 03: Not Used

PIN 04: INLET VALVE / TANK PIN 04: Vdd +5Vdc

)nommoC_cigoL(-ssV:50NIPEVLAVWERB:50NIP

PIN 06: TRIAC GATE

PIN 07: TRIAC A2

PIN 08: 120Vac HOT

PIN 09: TEMP SENSOR

PIN 10: TEMP SENSOR

PIN 11: UCM GROUND

PIN 12: WATER LEVEL PROBE

PIN 13: NOT USED

PIN 14: NOT USED

PIN 15: NOT USED

PIN 16: 120Vac NEUTRAL

PIN ASSIGNMENTS (8-PIN) PIN ASSIGNMENTS (4-PIN)

cdV5+ddV:10NIPDESUTON:10NIP

)nommoC_cigoL(-ssV:20NIPDESUTON:20NIP

PIN 03: SWEETENER VALVE LEFT PIN 03: Data_Comunication First

PIN 04: SWEETENER VALVE RIGHT PIN 04: Data_Comunication Next

PIN 05: NOT USED

PIN 06: NOT USED

PIN 07: 120Vac INPUT LEFT

PIN 08: 120Vac INPUT RIGHT

PIN ASSIGNMENTS (8-PIN) PIN ASSIGNMENTS (4-PIN)

cdV5+ddV:10NIPDES

UTON:10NIP

)nommoC_cigoL(-ssV:20NIPDESUTON:20NIP

PIN 03: PRESSURE SWITCH LEFT (N.O.) PIN 03: Data_Comunication First

PIN 04: PRESSURE SWITCH RIGHT (N.O.) PIN 04: Data_Comunication Next

PIN 05: NOT USED PIN ASSIGNMENTS (2-PIN)

)nommoC_cigoL(-ssV:10NIPDESUTON:60NIP

PIN 07: PRESSURE SWITCH RI GHT (COM) PIN 02: Vdd +5Vdc

PIN 08: PRESSURE SWIT CH RIGHT (COM)

CONTROL MODULE UCM

CONTROL MODULE SWEETENER VALVES

CONTROL MODULE PRESSURE SWITCHES

Page 10

Wilbur Curtis Co., Inc.

CAUTION: DO NOT

use undiluted bleach

or chlorine.

WARNING: Electric

Shock Hazard

Disconnect electrical

power before removing

access panels.

WARNING: Scald

and Burn Hazard

Allow water and

brewer to cool before

disassembly.

Daily Cleaning

1. Wipe any spills, dust or debris from the exterior surfaces with a damp cloth. The outside

surfaces of the brewer should be cleaned with stainless steel polish only, to prevent

scratches.

2. Clean the spray head and domed area around the spray head with a mild detergent and

warm water solution. Scrub well to remove residue. Rinse with clear water. Dry with a clean

cloth.

3. Remove and thoroughly clean and sanitize the entire plastic brew basket, the four legs and

the basket orice using a mild detergent solution and hot water. Dry it before use or put it

through a dishwasher cleaning cycle, then dry before use.

4. Wash the tea container. Clean the container and the top cover with a detergent solution.

TEA BREWER

CLEANING

SWEET TEA MIXING

SYSTEM CLEANING

AND SANITIZING

LIQUID LEVEL

PROBE

Weekly Cleaning and Sanitizing

Use a concentrated cleaning solution to simplify the cleaning procedure. This procedure requires

a one gallon bucket of cleaning solution of warm water and a granulated concentrated sanitizer/

cleaner, diluted as specied by the manufacturer in a one gallon bucket of clean warm water

(maximum 120ºF).

1. Make sure the brewer is on and the water supply is hooked up.

2. Remove both quick disconnect connectors (QDCs) from the tea sweetener bag-in-box

(BIB) product bags.

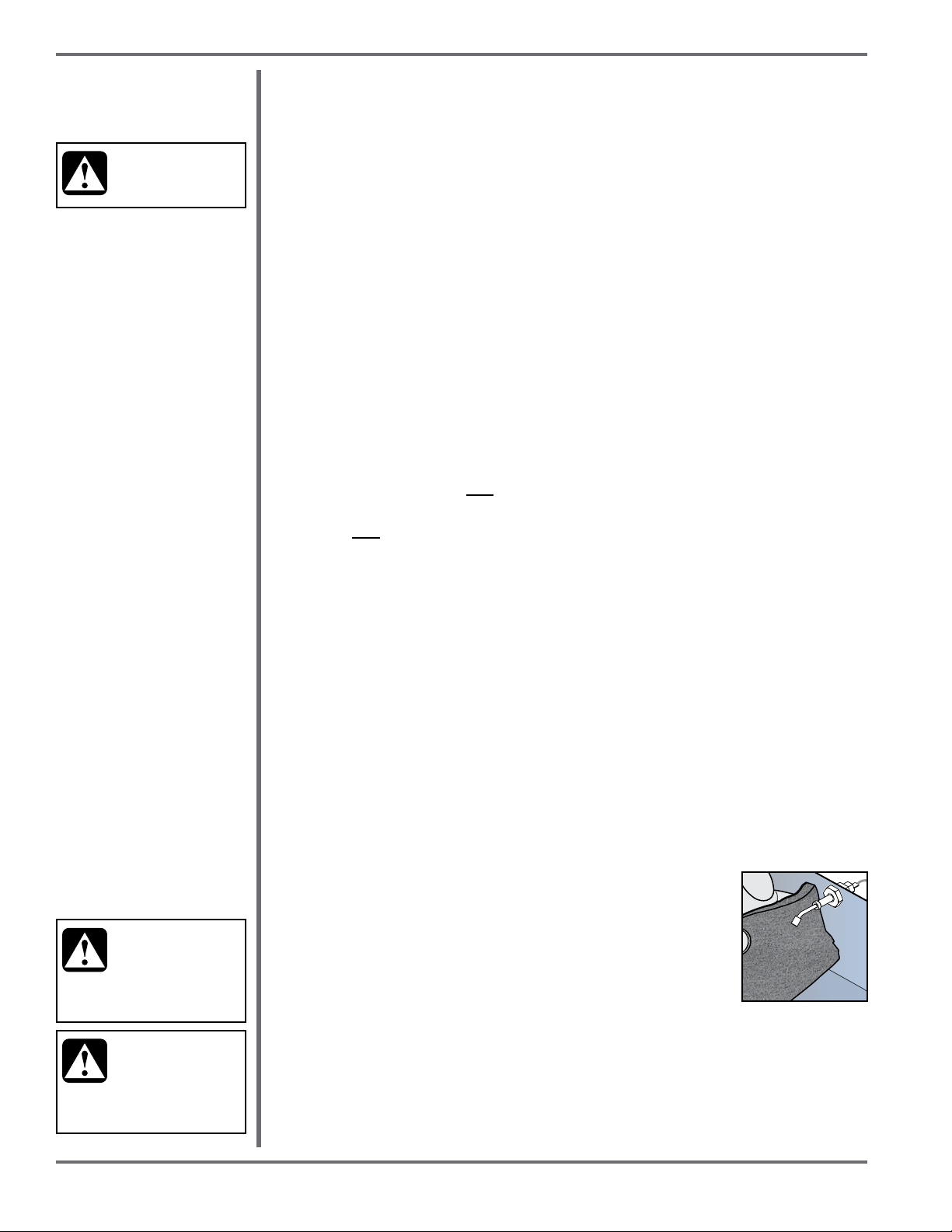

3. Attach male hose ttings to both QDCs. IMPORTANT: The cleaning process will not work

without both male hose ttings attached. See the diagram on the following page.

4. Immerse both QDCs, with male hose ttings attached in the bucket of cleaning solution.

5. Place an empty tea container on the brew deck and an empty brew basket below the spray

head.

6. Press and hold the PRIME button to draw the cleaner through the system. Release the

PRIME button when there is about 2 inches of cleaning solution in the bottom of the bucket

under the brew basket.

7. Allow the brewer to sit for the amount of time specied by the sanitizer/cleaner manufacturer

with the cleaning solution in the sweetener hoses/lines before ushing the cleaning solution.

8. Flush the system by lling a one gallon container with clean hot water (no cleaning solution).

Immerse BOTH quick disconnect connectors, with male hose ttings attached, in the bucket

of hot water. Press and hold the PRIME button to draw the hot water through hoses until all

the cleaning solution has been ushed from the system.

9. Discard solution that poured into the container under the brew basket.

10. Remove the QDCs from the hot water and remove the male hose ttings.

11. Reconnect both QDCs to the BIB sweetener bags.

12. Use the PRIME button to prime both sweetener lines.

The cleaning interval for the probe is determined by the user or the service

technician, based on water conditions. Use of a water lter and the type

of water lter used impacts the service interval. The service interval can

be from one month to several years, based on water conditions. However,

replacing the probe is preferred to cleaning it.

1. Unplug the power cord and shut off the water supply.

2. Remove the top cover of the brewer. Locate the water tank and

remove the top cover. Make sure the tank and water inside have

cooled before proceeding to the following steps.

3. Drain the tank to a level about 3” below the tip of the probe.

4. Clean the tip of the probe using a Scotch-Brite™ scuff pad.

5. If a white residue is still visible on the probe, remove the probe and soak it in vinegar or a

scale removing chemical. Repeat this step until the probe is clean.

Page 11

Service Manual - STBA48026 Tea Brewer

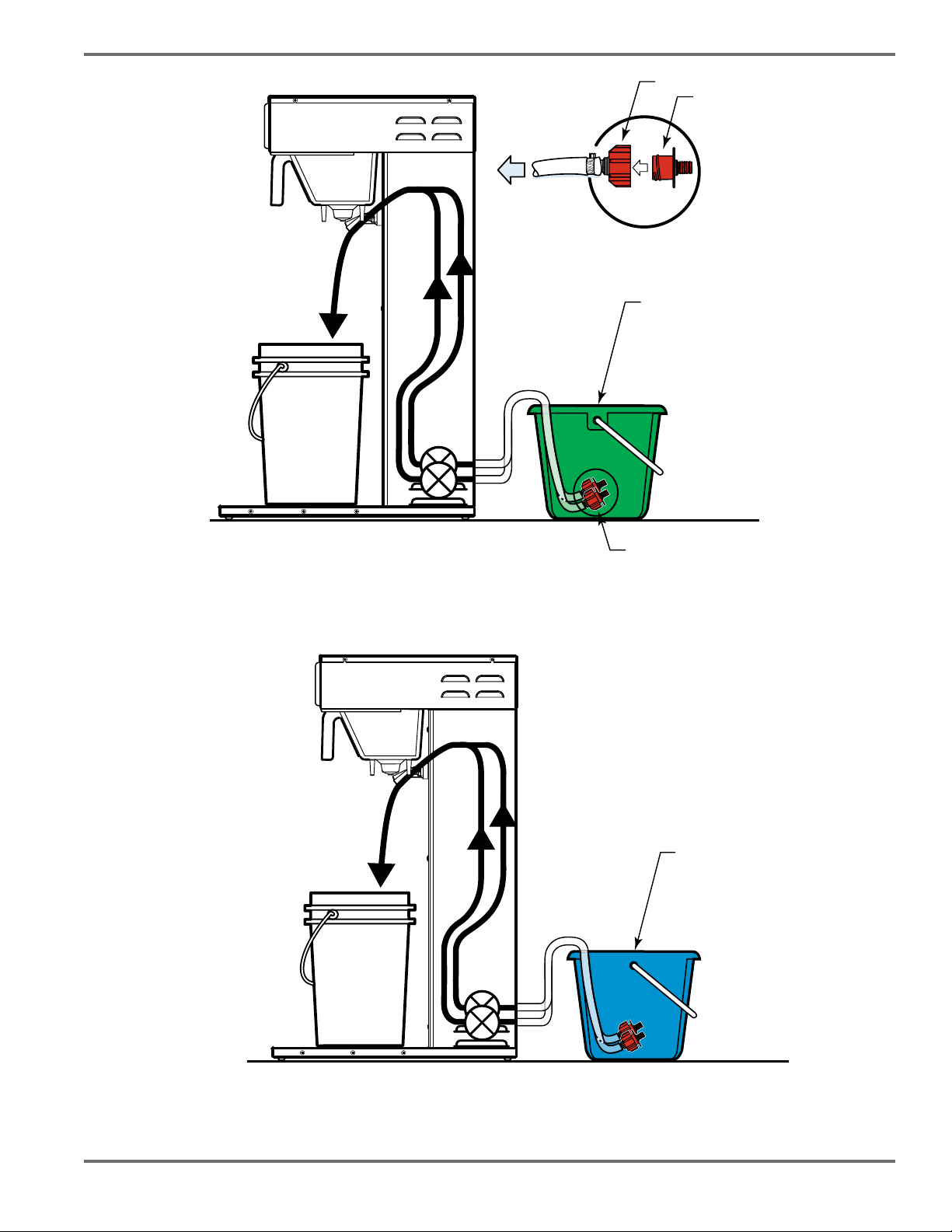

WEEKLY CLEANING AND SANITIZING - DIAGRAM 1

WEEKLY CLEANING AND SANITIZING - DIAGRAM 2

TEA BREWER

TO

SWEETENER

PUMP

MALE HOSE

FITTING

QDC

SWEETENER

PUMPS

FIGURE 1

SEE FIGURE 1

CONTAINER

TO CATCH

USED

CLEANER

MIX CLEANER

IN 1 GAL HOT

WATER

BREW

BASKET

SWEETENER

PUMPS

HOT RINSE

WATER

TEA BREWER

CONTAINER

TO CATCH

USED

CLEANER

BREW

BASKET

Page 12

Wilbur Curtis Co., Inc.

12

14

5

13

16

7

6

6

9

8

24

10

15

15

2

21

2x

3x

3

28

418 19 20

25

27

26

17

22

1

23

EXPLODED VIEW - MAIN CHASSIS

Page 13

Service Manual - STBA48026 Tea Brewer

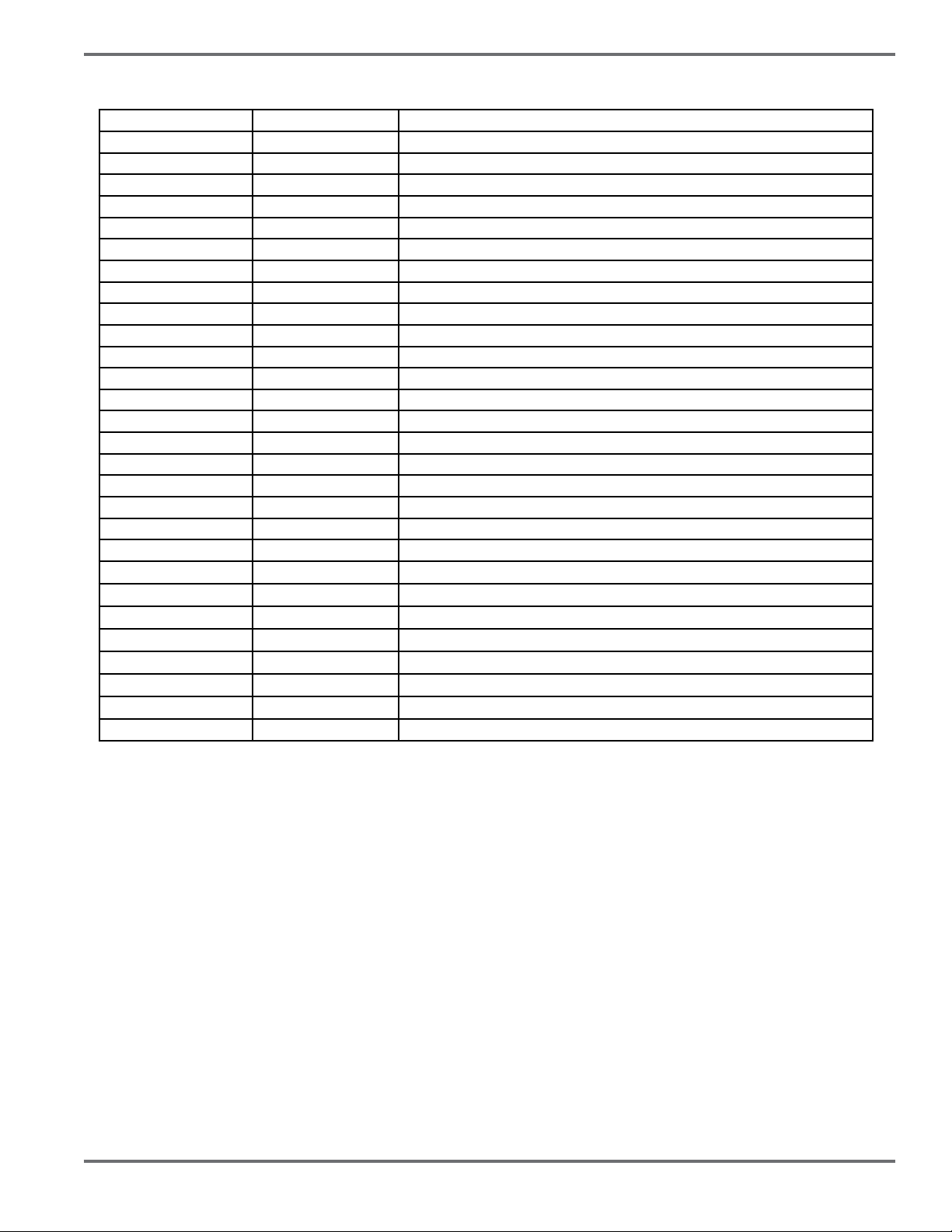

PARTS LIST - MAIN CHASSIS

ITEM PART # DESCRIPTION

1aWC-61702 RISER ASSY, SHORT TEA DISEPNSR STBA48026

2 WC-66100 SPOUT ASSY, DILUTION/SWEETENER PLASTIC

3 WC-889 VALVE, DUMP LEFT 120V 12W ALPHA’S/D1000/GEM-12/TLP

4 WC-2977-01 FITTING ASSY, SPRAYHEAD W/O-RING (INCLUDES NUT)

5bWC-29025 SPRAYHEAD, PURPLE ADVANCE FLOW (INCLUDES O-RING AND NUT)

6bWC-826L VALVE, INLET 1 GPM 120V 10W ALP/AP/TLP GREY BODY

7bWC-847 VALVE, INLET 2 GPM 120V-10W GEN USE BROWN BODY

8 WC-29117 FITTING, STRAIGHT 1/2” BARB X 3/8” NPT MALE ST./STL.

9 WC-8661 CONNECTOR, LANCER RED 3/8” BARB 1/4” I.D. SWEETENER BAG

10 WC-10024K KIT, CONTROL MODULE, SWEETENER VALVES

11 WC-10025K KIT, CONTROL MODULE, PRESSURE SWITCHES

12bWC-8556 HEATSINK, ASSY DV ALPDS/D500AP TCTD/PTTD

13 WC-103 SWITCH, TOGGLE NON-LIT DPST 25A 125/250VAC RESISTIVE

14 WC-1226 CORD, 600V 12/4, 6’ W/NEMA PLUG LOCKING L14-20P

15 WC-43059 CLAMP, HOSE SNAP NYLON .616/.707

16 WC-3503 LEG, 3/8”-16 STUD SCREW BUMPER

17 WC-3518 LEG, GLIDE 3/8”-16 STUD SCREW

18bWC-5310 TUBE, 5/16 ID X 1/8W SILICONE GEN USE

19bWC-53145 TUBING, .25” ID X .438” OD BRAIDED PVC STBA48026

20bWC-53114 TUBING, .375” ID X .625” OD BRAIDED SILICONE 60 DUROMETER

21a, b WC-5231 COMPOUND SILICONE, 5 OZ

22 WC-61979K KIT, BOTTOM COVER W/INSERTS

23 WC-58017-106 COVER, FRONT STB MCD

24 WC-43134 O’RING, .426 X 9/16 O.D X .07 0 WALL EDPM TCTS

25 WC-43113 WASHER, .5 ID X .88 OD INTERNAL LOCK STL

26 WC-29118 FITTING, STRAIGHT 1/4” BARB X 1/4” MALE FLARE BRASS

27 WC-2712 ADAPTER, ¼ FLARE FEMALE X 1/4 NPT MALE

28 WC-4320 O’RING, ½” I.D.

aItem sold separately

bRecommended parts to stock

Page 14

Wilbur Curtis Co., Inc.

EXPLODED VIEW - CONTROL PANEL

PARTS LIST - CONTROL PANEL

ITEM PART # DESCRIPTION

1 WC-67101 BRACKET, UCM MOUNT ALPHA-GT D500GT/GTH/D1000GT, GEMINI GT

2 WC-29044 SLEEVE, OVERFLOW ASSY GEN USE

3 WC-786-108 CONTROL MODULE, UCM 120V MCD SWEET TEA BREWER

4 WC-13486 HARNESS, ASSY COMPLETE MCD SWEET TEA

5A WC-390274 LABEL, UCM OVERLAY STB MCDONALD’S

5B WC-390275 LABEL, UCM OVERLAY STB ICED COFFEE MCDONALD’S

6 14287 BREW CONE, NON-METAL McDONALDS

7 WC-58117 COVER, TOP ALPGT/D500GT/D60GT TLP/TCTS/CBS/GEMSS

8 WC-3423 BREW CONE ASSY,MCD ICED COFFEE W/SPLASH POCKET/IC CLIP

9 WC-3423K KIT, (1) WC-3423, (1)WC-390275 (1 ) Bx GEM-6-101 (INCLUDES ITEMS 5B AND 8)

10 WC-3423K-101 KIT,(1)WC-3423,(1)BX GEM-6-101 (INCLUDES ITEM 8 AND 500 FILTERS [NOT SHOWN])

1

3

2

4

5A 5B

7

6

8

Page 15

Service Manual - STBA48026 Tea Brewer

EXPLODED VIEW - SYRUP PUMPS

PARTS LIST - SYRUP PUMPS

ITEM PART # DESCRIPTION

1A WC-1067K-L KIT, PUMP ASSY LEFT STBA48026

1B WC-1067K-R KIT, PUMP ASSY RIGHT STBA48026 (NOT SHOWN)

2 WC-29107 FITTING, Y-BARB 3/8” x 3/8” x 3/8” KYNAR (NOT SHOWN)

3 WC-29100 FITTING, ELBOW 1/4” BARB X 1/8 “ NPT W/ 1/6” BLEED HOLE BRSS

4 WC-29106 FITTING, TEE 1/4” BARB X 1/4” BARB X 1/4” BARB BRASS (NOT SHOWN)

5 WC-1070 SWITCH, PRESSURE (TEC MARK #TBS3000A)

6 WC-1071K KIT, VALVE ASSY SWEETENER W/CONNECTORS & FITTINGS

7 WC-43036 CLAMP, TUBING 10.3-12.8mm SS OETIKER STBA48026

8 WC-43059 CLAMP, HOSE SNAP NYLON .616/.707

9 WC-29099 FITTING, 3/8” BARB X 1/8”NPT STRAIGHT SS

10 WC-29097 FITTING, 1/8” NPT X 1.29” LG. STRAIGHT SS PUMP OUTLET

11 WC-43154 O’RING, .362” I.D. X .103” C.S BUNA-N (2-1110)

6

1A

3

9

11

10

5

7

8

Page 16

Wilbur Curtis Co., Inc.

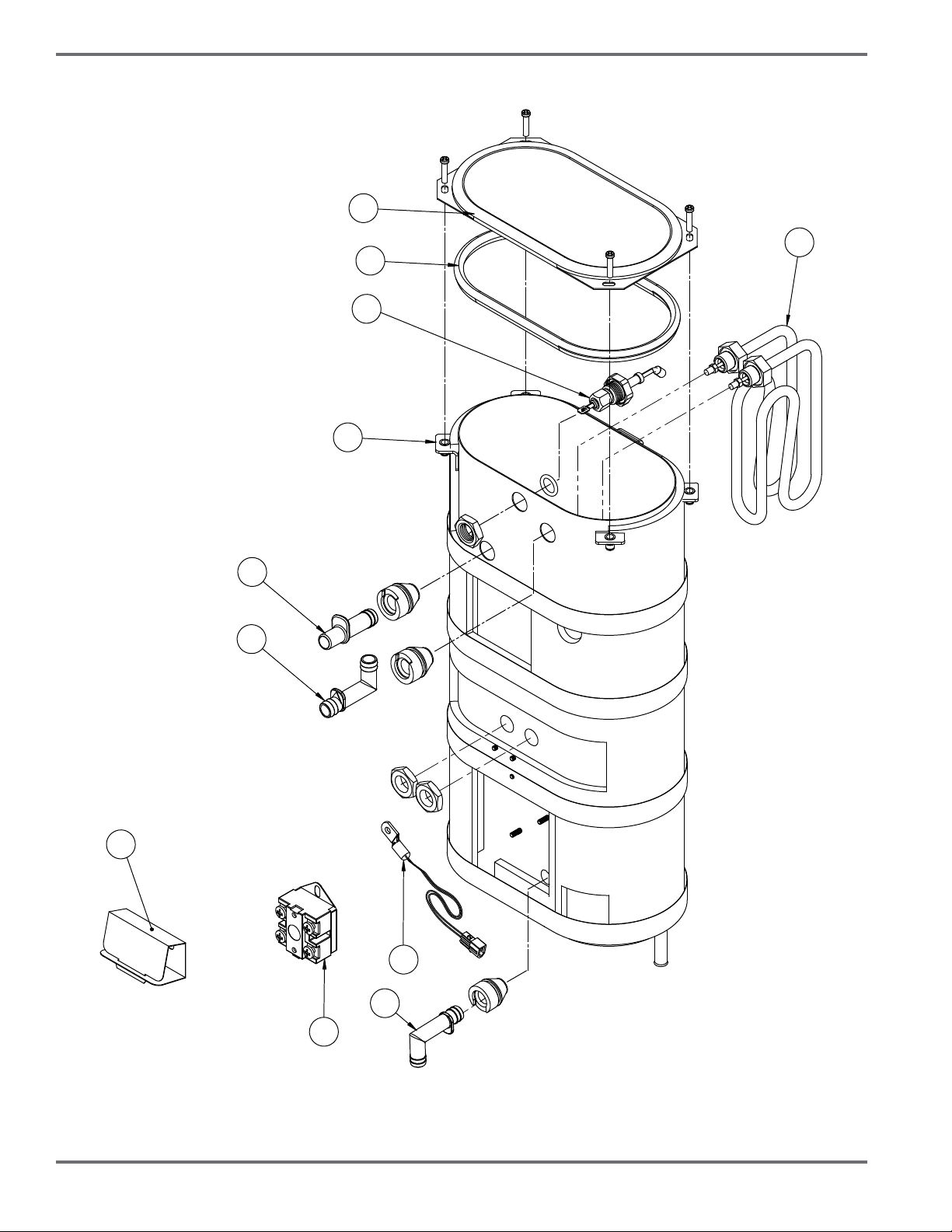

EXPLODED VIEW - TANK ASSEMBLY

6

5

9

10

8

7

11

1

2

3

4

Page 17

Service Manual - STBA48026 Tea Brewer

PARTS LIST - TANK ASSEMBLY

ITEM PART # DESCRIPTION

1 WC-62108-35 TANK ASSY, COMPLETE 2500 WATT-220VAC 1.63 GAL

2 WC-5527K KIT, PROBE WATER LEVEL O-RING & NUT

3 WC-37266 KIT, FITTING TANK OVERFLOW (INCLUDES BUSHING)

4 WC-37317 KIT, STRAIGHT FITTING & BUSHNG 8mm GEN USE

5 WC-43062 GASKET, TANK LID

6 WC-5853-102 COVER, TOP HEATING TANK GEN USE

7 WC-522 THERMOSTAT, HI LIMIT HEATER CONTROL DPST 277V 40A

8 WC-1438-101 SENSOR, TEMPERATURE TANK

9 WC-4394 GUARD, SHOCK/HEATING ELEMENT FOR SINGLE HEATING ELEMENT

10 WC-37365 KIT, FITTING TANK INLET (INCLUDES BUSHING)

11 WC-934-04 KIT, ELEMENT HEATING 2.5KW 220V W/JAM NUT & SILICONE WASHERS

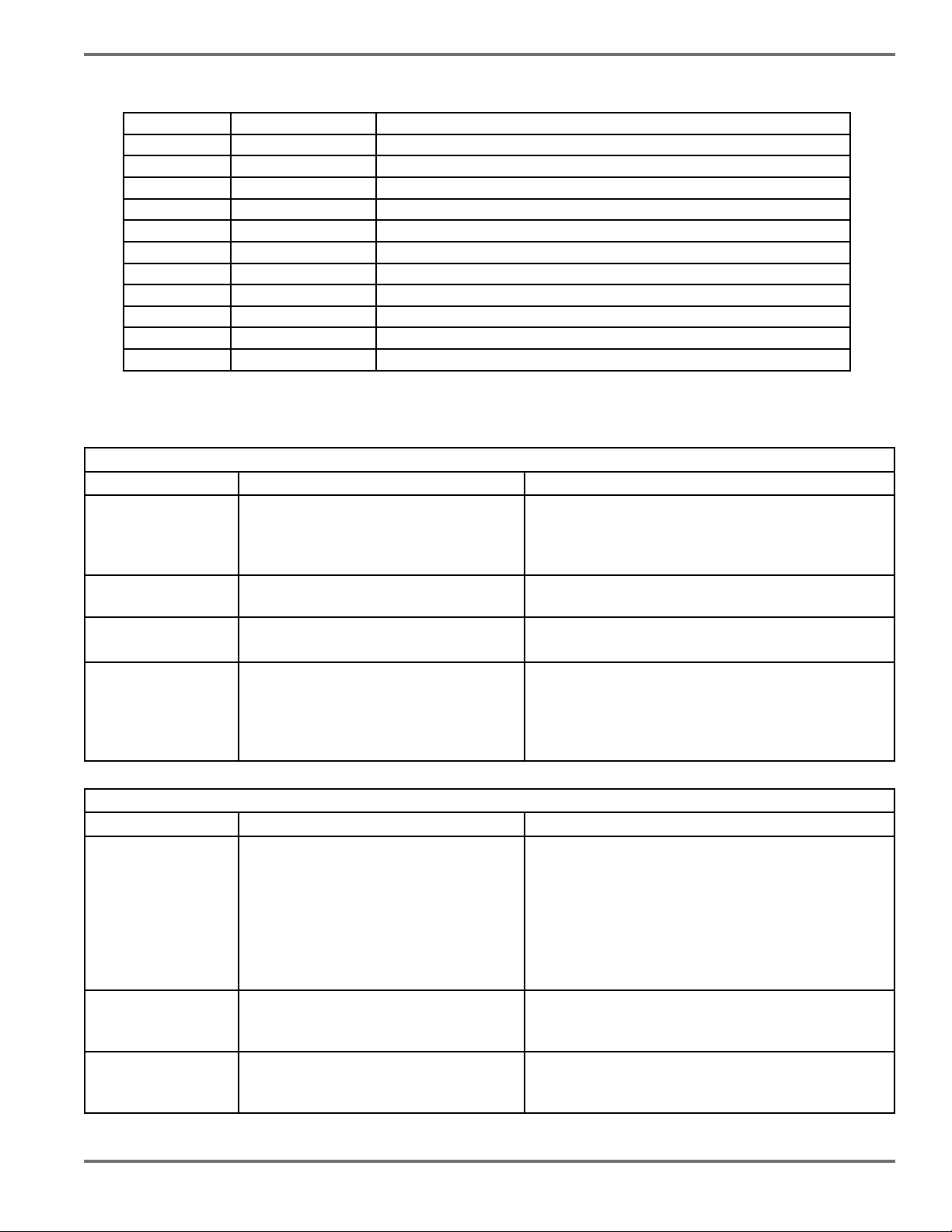

ERROR CODES - STOPS BREWING

ERROR MESSAGE DESCRIPTION CAUSE

Water Level Error

1-(800)-000-0000 Fill run error/

Overow

The water inlet valve has either been open for more

than 10 minutes on the initial tank ll or has been

open for more than 30 seconds in normal

operation.

Sensor Error

1-(800)-000-0000 Open Probe Break in the temperature thermistor circuit.

Over Temp. Error

1-(800)-000-0000 Excess Temperature The sensor is reading that temperature in the

heating tank has risen above 210ºF.

SweetTea Lockout

Change Sweetener

Press Prime Aftr

Changing Sweetnr

Sweetener BIBs were

not changed

The sweetener BIBs were not changed when the

“Change Sweetener” message appeared and eight

brews were performed. Change the sweetener

BIBs, press PRIME and message clears. Each

message displays for about four seconds.

NOTIFICATIONS - ALLOWS BREWING

MESSAGE DESCRIPTION CAUSE

MCDONALD’S

Change Sweetener

Press Prime Aftr

Changing Sweetnr

One of the

Sweetener BIBs is

empty

One of the sweetener BIBs is empty and has run

out of product. With this message on, you are

able to make only eight brews before changing the

BIB. Once it is changed and PRIME is pressed,

message clears. If you don’t change the

BIB, after eight brews brewer is locked out for

sweet tea. Each message displays for about four

seconds.

L-“L” in lower left hand corner of the LCD display

represents the left side sweetener bag is active,

displayed during brewing.

R - “R” in lower right hand corner of the LCD display

represents the right side sweetener bag is active,

displayed during brewing.

ERROR CODES/NOTIFICATIONS - CONTROL PANEL

Page 18

Wilbur Curtis Co., Inc.

This page intentionally left blank

Page 19

Service Manual - STBA48026 Tea Brewer

This page intentionally left blank

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

Printed in U.S.A. 07/2016 F-4026 Rev E

Wilbur Curtis Co., Inc.

6913 Acco Street, Montebello, CA 90640-5403 U.S.A.

Phone: 800-421-6150 │ Fax: 323-837-2410 │ Technical Support Phone: 800-995-0417 (M-F 5:30 a.m. - 4:00 p.m. PST) │ Email: [email protected] │ www.wilburcurtis.com

ECN 17458 RevE 07/13/16 @ 11.6

Table of contents

Other Wilbur Curtis Company Kitchen Appliance manuals