Wilbur Curtis Alpha McDonald's Fresh-Trac ALP3GT15A826 User manual

1

Model Included:

•ALP3GT15A826

3. Connecttheunittoelectricaloutletwithappropriateamperagerating(seeserialtagonmachine).

4. Oncepowerhasbeensuppliedtotheunit,ipthetoggleswitchtothe‘ON’position(locatedontherearoftheunit),thewatertankwill

begintoll.Whenthewaterlevelinthetankreachestheprobe,theheatingelement(s)willturnon.

5. Waterintheheatingtankwillrequireapproximatelyahalfhourbeforereachingoperatingtemperature(factorysettingof202°F).When

theunitreachesoperatingtemperature,itwilldisplay“READYTOBREW”.

BREWING INSTRUCTIONS

1.ThebrewershouldbeON.Conrmthisatthereartoggleswitch,thenpresstheON/OFFbutton.Ready-to-Brewshouldbedisplayed.

2.Placeanemptydecanteronwarmerplate.

3. Placeanewpaperlterintothebrewcone.

6. PresstheBREWbuttononthe

controlpaneltostartbrewing.

5. Slidethelledbrewconeintothe

railsonthecoffeebrewer.

4. Pourtheproperamountofground

coffeeintothebrewcone.

Wilbur Curtis Company, inC.

Service Manual – Alpha McDonald’s Fresh-Trac

ImportantSafeguards/Conventions

Thisapplianceisdesignedforcommercialuse.Anyservicingotherthancleaningandpreventivemaintenanceshouldbeperformedbyan

authorizedWilburCurtisservicetechnician.

•DoNOTimmersetheunitinwateroranyotherliquid

•Toreducetheriskofreorelectricshock,doNOTopenservicepanels.Nouserserviceablepartsinside.

•Keephandsandotheritemsawayfromhotsurfacesofunitduringoperation.

•Nevercleanwithscouringpowders,bleachorharshchemicals.

Symbols

WARNINGS–Tohelpavoidpersonalinjury

ImportantNotes/Cautions–fromthefactory

SanitationRequirements

TheCurtisAlphaG3isFactoryPre-SetandReadytoGo…RightfromtheBox.

Following are the Factory Settings for the Alpha Fresh-Trac:

•BrewTemperature=202°F

•BrewVolume=Settovesselrequirements(60oz).

System Requirements:

•WaterSource20–90PSI(minimumowrateof1GPM)

•Electrical:Seeattachedschematicforstandardmodelorvisitwww.wilburcurtis.comforyourmodel.

SETUP STEPS

1. Theunitshouldbelevel(lefttoright-fronttoback),onasecuresurface.

2. Connectthewaterlinetothewaterinletttingontherearoftheunit.Watervolumeowtothemachineshouldbeconsistent.Use

tubingsizedsufcientlytoprovideaminimumowrateof1gallonperminute.

NOTE:Awaterltrationsystemmustbeusedtohelpmaintaintrouble-freeoperation.Air must be purged from the cartridge prior to

connection to equipment.Inareaswithextremelyhardwater,wehighlyrecommendtheuseofaCurtisapprovedwaterlter.Forour

fulllineoflters,pleaselogontowww.wilburcurtis.com.

NSFInternationalrequiresthefollowingwaterconnection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) is required so that the unit can be moved

for cleaning.

2. Thisunitmustbeinstalledwithadequatebackowprotectiontocomplywithapplicablefederal,stateandlocalcodes.

3. Waterpipeconnectionsandxturesdirectlyconnectedtoaportablewatersupplyshallbesized,installedandmain-

tainedinaccordancewithfederal,state,andlocalcodes.

CAUTION: DO NOT

connect the unit to

hot water supply.

The inlet valve is not rated for

hot water.

CAUTION: Follow

this setup procedure

before attempting

to use this unit. Failure to

follow these instructions can

result in injury and/or void of

warranty.

ISO 9001:2008 REGISTERED

WILBURCURTISCO.,INC.

6913 West Acco Street

Montebello,CA90640-5403

For the latest information go to

www.wilburcurtis.com

Tel:800-421-6150

Fax:323-837-2410

CAUTION:

Equipment must be

installed to comply

with applicable federal, state,

and local plumbing/electrical

codes.

2

Brew Volume

Duringtheactualbrewcycle,a2-minutedripmodeisaddedtothebrewtime.Theprogrammedwaterlevelcompensatesforbacktobackbrewingto

allowforanincreaseofwatervolume.

Brew by Volume(Factorysetto60oz.)Presstoselect.DisplaywillnowshowPushSTARTToBegin...PresstheBREWbuttonthenhotwaterstarts

running,whendesiredvolumeisreachedpressBREWbuttonagaintostoptheow.Nowthevolumeisset.Pressingthe>buttonwilldisplaythenextmenu

feature,BrewbyTime.

Brew by Time(Factorysetto2min–17sec)Presstoselectandchangethebrewtime.Displaywillshowthecurrenttime.Bypressing<or>youcantoggle

betweenminutesandseconds,toexit(ex).Changethetimeorsetandexitbypressing.

Temperature(Factorysetto202°F)PresstoSelect.Press<or>tomovetodesiredtemperatureandthentoset.Temperatureisprogrammablefrom

170ºFto206ºF,in2-degreeincrements.

Energy Save Mode(FactorysettoOFF)PresstoSelect,<or>ON,OFForON140ºF,toset.WheninON,unitwillautomaticallyshutoff4hoursfrom

lastbrew.WhenfeatureisOFF,unitdoesnothavetheenergysavingmode.IntheON140ºFposition,temperaturegoesdownto140ºFifunithasnotbrewed

in4hours.Thisfeaturewillsaveenergybyloweringthetanktemperatureduringperiodsofnon-operation.

Brew Count Odom.Presstodisplaytotalgallonsbrewed.PressexorReset

Pre-Infusion(FactorysettoOFFDisabled)PresstoSelect.Currentsettinginsecondsisdisplayed<todecreaseorselect>toincrease(rangefromOFF

to10through60seconds);presstoset.

IfPre-infusionisselected(ON),ColdBrewLockissettowithin15ºFofsetpointandColdBrewLockdisappearsfromthelistofprogramselections.

WhenPre-infusionisON,PulseBrewdisappearsfromthelistofprogramselections.

Brew Count Total Presstoselect.Thisfeaturewilldisplaythetotalgallonsandtotalbrewcyclesonthebrewer.Itisreadonlyandcannotbereset.

EnterProgramMode

Turnoff(darkdisplay)bypressingON/OFFbutton(yellow).PressandholdBREWbutton(green)andthenpressandreleaseON/OFFbutton(yellow).

ContinueholdingBREWbutton.Displaywillread ,waituntil isdisplayedEnterthe4-digitaccesscode,thedigits1-4cor-

respondtothebuttons(seeillustrationbelow).

Thedefaultcodesetatthefactoryis1-2-3-4.Then willbedisplayed.

YourCurtisG3SystemisFactoryPre-SetforOptimumPerformance.

Afterconnectiontowaterandpower;thereartoggleswitchmustbeon.Youwillhearabeepsound,indicatingpowerisavailabletothecontroller.

Thecontroldisplays .PressON/OFFbuttonandthescreenwilldisplay .Afterthreeseconds, isdisplayed.

Waterwillllthetank(approximately2-3minutesdependingonwaterowrate).Whentheproperlevelisreached willappearonthescreen.Ittakesapproxi-

mately20minutestoreachsetpointtemperatureof202°F.

Controlwilldisplay whentemperaturereachesthesetpoint(202°F).Unitisnowreadytobrew.

<ALP3/4/5>

CURTIS

CURTIS CURTIS

FILLING

CURTIS

HEATING

ENTER CODE

– – – –

PROGRAM MENUS

< SELECT >

ENTERING PROGRAM

MODE

PROGRAM MENUS

Allprogrammingselectionsareperformedwiththethreecenterbuttons.

Thesymbolsbelowthebuttonsare:

ScrollLEFT

SELECTIONorENTERtosavenewparameter

ScrollRIGHT

3

Cold Brew Lock(Factorysetto15º)Presstoselect,<or>toselectdesiredsetting(CBL5or15),toset.

TheColdBrewLockfeatureallowsthebrewertobrewatthreedifferenttemperaturelevelsfromtheactualsetpoint.Therstsettingiswithin5degreesofset

point,nextiswithin15degreesofsetpointfortheReadytoBrewmessage,howeveritwillbrewatanytemperature.

Master ResetPresstodisplayAreYouSure?Then<forYes,>forNo.Brewerfactorydefaultsarethenreset.

Service Call(PhonenumberFactorysetto1-[800]000-0000x)Presstodisplaynumberandchangenumberor<tomoveplaceandEXtoexitwhen

completeThisnumberwillbedisplayedduringaHeatingsystemSENSORERRORorduringaWATERERROR.

Access Code(Factorysetto1-2-3-4)Presstodisplaynumberandchangenumber,(therangeis1to4)or<tomoveplaceandextoexitwhencomplete.

Banner Name(FactorysettoMcDONALD’S)Presstodisplaylettersandchangelettersor<tomoveplaceandEXtoexitwhencomplete.Thisfeature

allowsupto14letterstobeprogrammedforcompanynameorregionalname.ProgrammingallblanksdisablesBannerName.

Warmer Auto OFF(FactorysettoDisable)PresstoSelect.Press<or>tomovetodesiredtimeandthentoset.TimerrangeisOFF,2hours,3hours,

and4hours.

P-Maintenance(FactorysettoOFF)Presstoselect.Toturnon,press<or>setgallonsbrewed.TherangeisfromOffto3000gallons.Presstoexit.

Whenthenumberofbrewsreachesthesetamount,P-Maintenancewilldisplayonthescreen.

Beeper On/Off (FactorysettoON)PresstodisplayONorOFF.Pressingeither<or>totogglebetweenonandoff.Presstoset.

Pulse Brew(FactorysettoPulseD[1pulseof40secon,5secoff,2pulsesof40secon,5secoff]).Presstoselect,<or>toselectOFForoneofve

pulsepatterns(AtoE).

GuidelinesforPulseBrew:

Thisfeatureallowstuningofthecoffeeavor.ThepotlevelshouldalwaysbesetrstwiththisoptionOFF.Dependingonyourgrindproleandwatercondi-

tions,thevePulseBrewoptionshelp“tune”orchangethecoffeeavor.FilterPacktypecoffeestypicallyextractbetterwiththeAandBpulsesetting.Decaf-

feinatedcoffeestypicallyextractbetterwiththeBpulsesetting.High-YieldcoffeestypicallyextractbetterwiththeCpulsesetting.Ofcourse,anyoftheA,Bor

Csettingsmaybeusedtosuityourtasteprole.Therearetwoadditionalsettings(DandE)thatallowyoutomanuallysettheONTIMEpulsesandOFFTIME.

IfPulseBrewisselected(ON),ColdBrewLockissettowithin15ºFofsetpointandColdBrewLockdisappearsfromthelistofprogramselections.

WhenPulseBrewisON,Pre-infusiondisappearsfromthelistofprogramselections.

Display Brew Time(FactorysettoON).PresstodisplayONorOFF.Pressingeither<or>togglesbetweenonandoff.Presstoset.Whenon,this

featurewillappearwhenthebrewbuttonispressed.Thebrewtimewillcountdown.

Drip-Out Mode(Factorysetto1min)Presstoselect.Press>toincreasetime(toamaximumof5minutes)or<todecreasethetimeandturnOFF.Time

countsupin5secondincrements.Presstoset.

Display Messages(FactorysettoON)PresstoturnONorOFF.Themessagedisplayedis“RinseServerBeforeBrewing”.Thismessagewillalternate;

twosecondswithRinseServerBeforeBrewing,thenMcDONALD’S-READYwillappearforsixseconds..

Language(FactorysettoEnglish)Pressing<or>togglesbetweenEnglishandFrench.Presstoset.

Model Select(FactorysettoALPHA-3/4/5)Presstoselect,<or>toselectmodel.Theselectionsare:ALPHA-1,ALPHA-2,ALPHA-3/4/5,AirpotBrewer,

Thermo-Alpha(fortheD60GT).Presstoset.WhentheModelSelectfeatureischanged,allsettingsareresettothedefaultsofthenewlyselectedmodel.

ExitPresstoselect,exitsprogrammodeandreturnsunittooperation.

Warmer Temperature Control

TurnonbreweratthecontrolpanelON/OFFbutton.WarmerbuttonshouldbeOFF(LEDoff).PressandholddesiredWARMERbutton.Screenwilldisplaycur-

rentsettingin%ofpower.Press<or>toincreaseordecreasepowertowarmer(50%to100%in10%increments).Presstoset.

Tank Temperature Check

TurnonbreweratthecontrolpanelON/OFFbutton.Pressandhold3button(seeillustration,page2)for5seconds.WaterTemperaturewillbedisplayed.The

temperaturewillnotdisplaywhiletheunitisintheprocessofreheating.

NOTE:Alpha3GTONLY;whencheckingtanktemperature,rstmakesureREARwarmerisON(redLEDon)andthenpressbutton3for5secondsto

displaytanktemperature.

Brew Volume – Easy Access

Unitscanbeeasilyadjustedfromthefrontpanel.WrittenintothesoftwareontheAlphaG3UCM,isafeaturetoaccessthebrewvolumewithoutenteringthe

programmode.

Onanymulti-stationAlpha(ALP2/3/4/5/6GT):PressthecenterSelectbutton 2(seeillustration,page2)twice,withthesecondpressholddownthebuttonfor

aroundve[5]seconds.Thescreenwilldisplay pressing<or>willadjustthebrewvolumeupordown,±20oz,in1ounceincrements.

PROGRAM MENUS

4

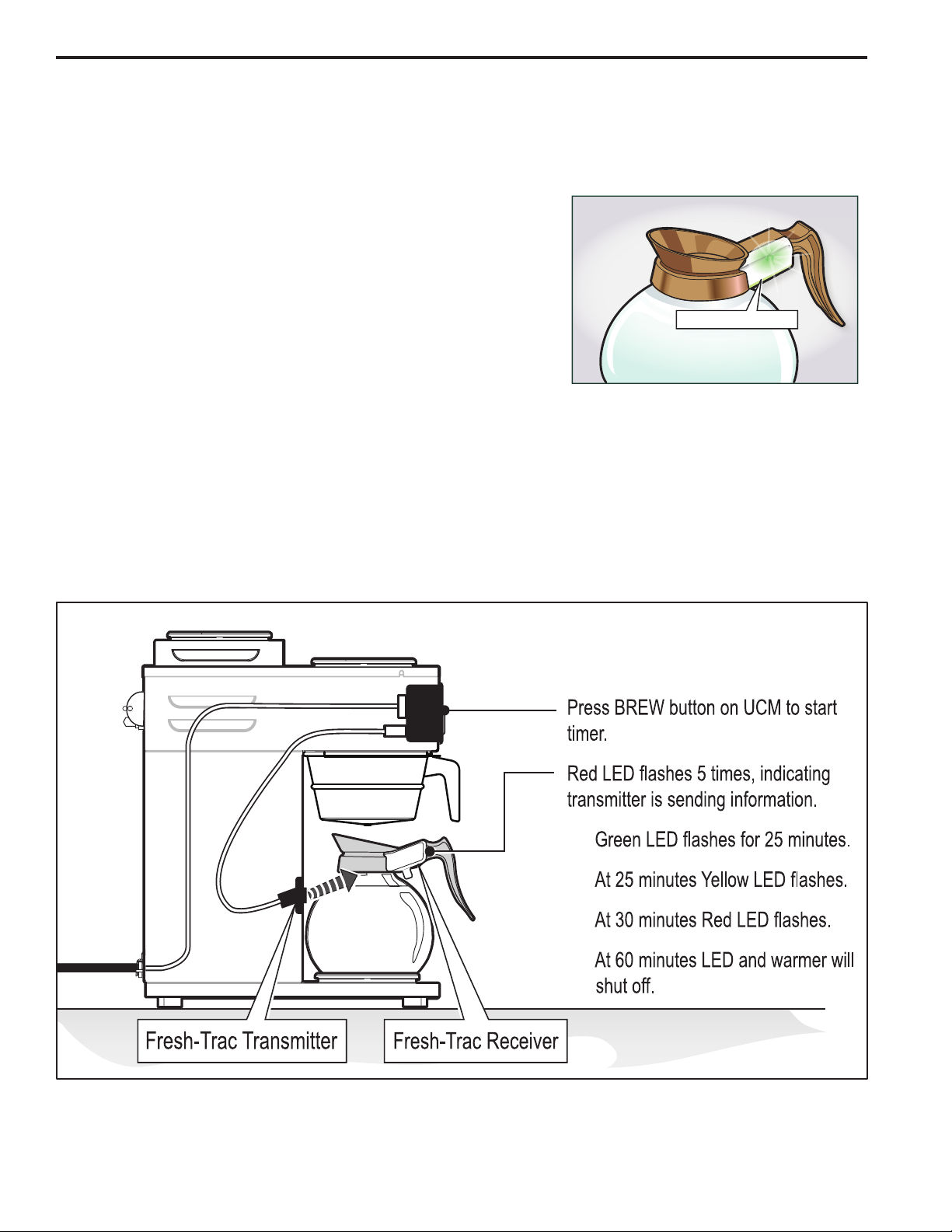

Fresh-Trac Transmitter

These instructions will explain the operation and maintenance of the Fresh-Trac coffee timer. This timer will

allow the user to track the freshness of coffee brewed into glass decanters. Fresh-Trac is only available

with Curtis Alpha G3 brewers. The Fresh-Trac decanter is dish-washer safe. The expected battery life in

the light unit is two years. The battery is not replaceable.

The Fresh-Trac timer uses 3 LEDs (Red, Yellow & Green), as a

visual time indicator.

The Red LED ashes 5 times at the beginning of the brew cycle

and the warmer plate will turn on.

The Green LED will ash every 10 to 20 seconds during the brew

cycle and continue until 25 minutes have elapsed.

At 25 minutes, the Yellow LED will ash every 3 to 5 seconds, for

5 minutes. This will continue for 5 minutes until 30 minutes has

elapsed.

At 30 minutes, the Red LED will ash every 3 to 5 seconds until 60 minutes have elapsed. The Red LED

indicates that the hold time has expired and any remaining coffee should be discarded.

All ashing LEDs will stop and the warmer will turn off completely after 60 minutes. A new brew cycle will

restart the Fresh-Trac timer.

FRESH-TRAC SYSTEM - OPERATION

INSTRUCTIONS

FRESH-TRAC TIMER

5

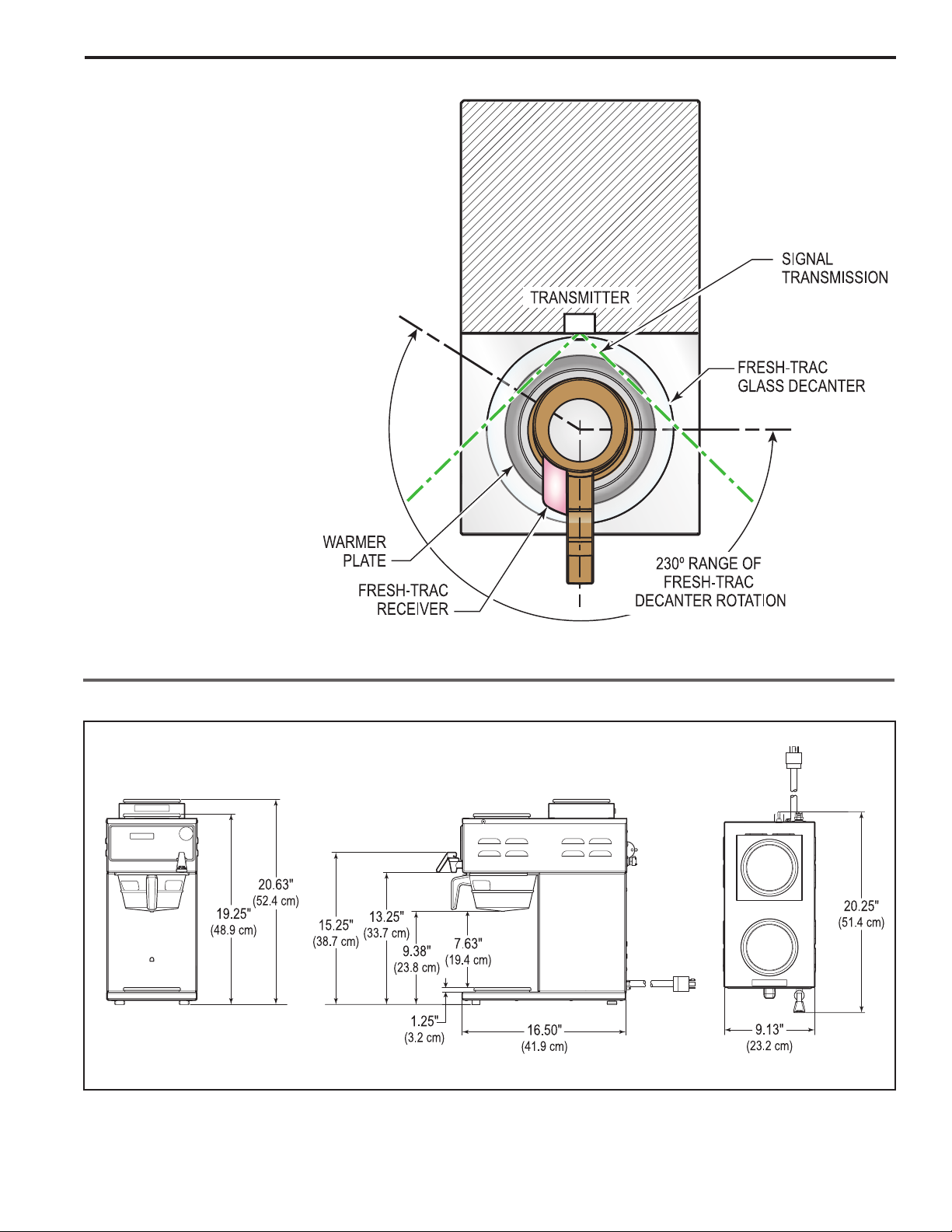

ROUGH-IN DRAWING

INSTRUCTIONS

FRESH-TRAC TIMER

TRANSMITTER RANGE

The most effective signal range of the Fresh-

Trac transmitter is 230º. This is shown as a

top view in the illustration.

6

ILLUSTRATED PARTS LIST

ALPHA G3

7

ILLUSTRATED PARTS LIST

ALPHA G3

ITEM№ PART№ DESCRIPTION

1 WC-6812 WARMER,ASSYTOPALP3GT

2 WC-13164 HARNESSASSY,WARMERALPGTUPPERWARMER

3 WC-889-101 VALVE,DUMPLEFT120V12W

4 WC-37379 KIT,SPRAYHEADFITTING

5. WC-774-108* CONTROLMODULE,FRESHTRACMCDONALDSALP

6 WC-390178 LABEL,UCMOVERLAYALP3GTWITHQRCODECURTISLOGO

7 WC-1809* FAUCET,PS/HSPSERIESHOTWATER1/2-20UNF

8 WC-5853-102 COVER,TOPHEATINGTANK

9 WC-43062* GASKET,TANKLID

10 WC-4320 O’RING,1/2”I.D.

11 WC-5502-01* KIT,PROBE,ASSYWATERLEVELW/HEXFITTING,O-RING&NUT

12 WC-4394 GUARD,SHOCKHEATINGELEMENT

13 WC-43055 GUARD,SHOCKRESETTHERMOSTAT

14 WC-1438-101* SENSOR,TEMPERATURETANK

15 WC-522* THERMOSTAT,HILIMITHEATERDPST277V-40A

16 WC-6267* TANK,COMPLETEALP-DS/G3220V

17 WC-2401 ELBOW,3/8NPTx1/4FLAREPLATED

18 WC-826L* VALVE,INLET1.15GPM120VAC10W

19 WC-8556* HEATSINKandTRIACASSY40A600V

20 WC-103* SWITCH,TOGGLEDPST25A125/250VACRESISTIVE

21 WC-13315-103 HARNESSCOMPLETEALPHAGTN-18

22 WC-5985 COVER,BACKCENTERWRAPD60GT/ALPTALL

23 WC-10002D TRANSMITTERASSY,D-STYLE(UNITSBUILTAFTER8/2012)

24 WC-29025 SPRAYHEAD,ASSYAFS-PURPLE

25 WC-972-102* WARMER,ASSYCOMPLETE100W120VW/TBNGSEALANT

26 WC-58056 COVER,BOTTOMALP3GT

27 WC-3518 LEG,3/8”-16X1/2”LGLIDE

28 WC-10011* RECEIVERASSEMBLY3LEDsFRESH-TRACMCDONALDSDECANTER

29 70517430303* DECANTER,GLASSCURTISFRESH-TRACREGBLACK

29A 70517430103* DECANTER,GLASSCURTISFRESH-TRACDECAFORANGE

30 WC-3503 LEG,3/8”-16STUDSCREWBUMPER

31 WC-3316* BREWCONEASSY,w/HANDLE7.1”DIA.

32 CR-10* FILTER,PAPERCOFFEE#5061000/PKG

33 WC-5310* TUBE,5/16IDX1/8WSILICONE

34 WC-922-04* KIT,ELEMENTHEATING3.5KW220VW/JAMNUTS&SILICONEWASHERS

*SUGGESTEDPARTSTOSTOCK

8

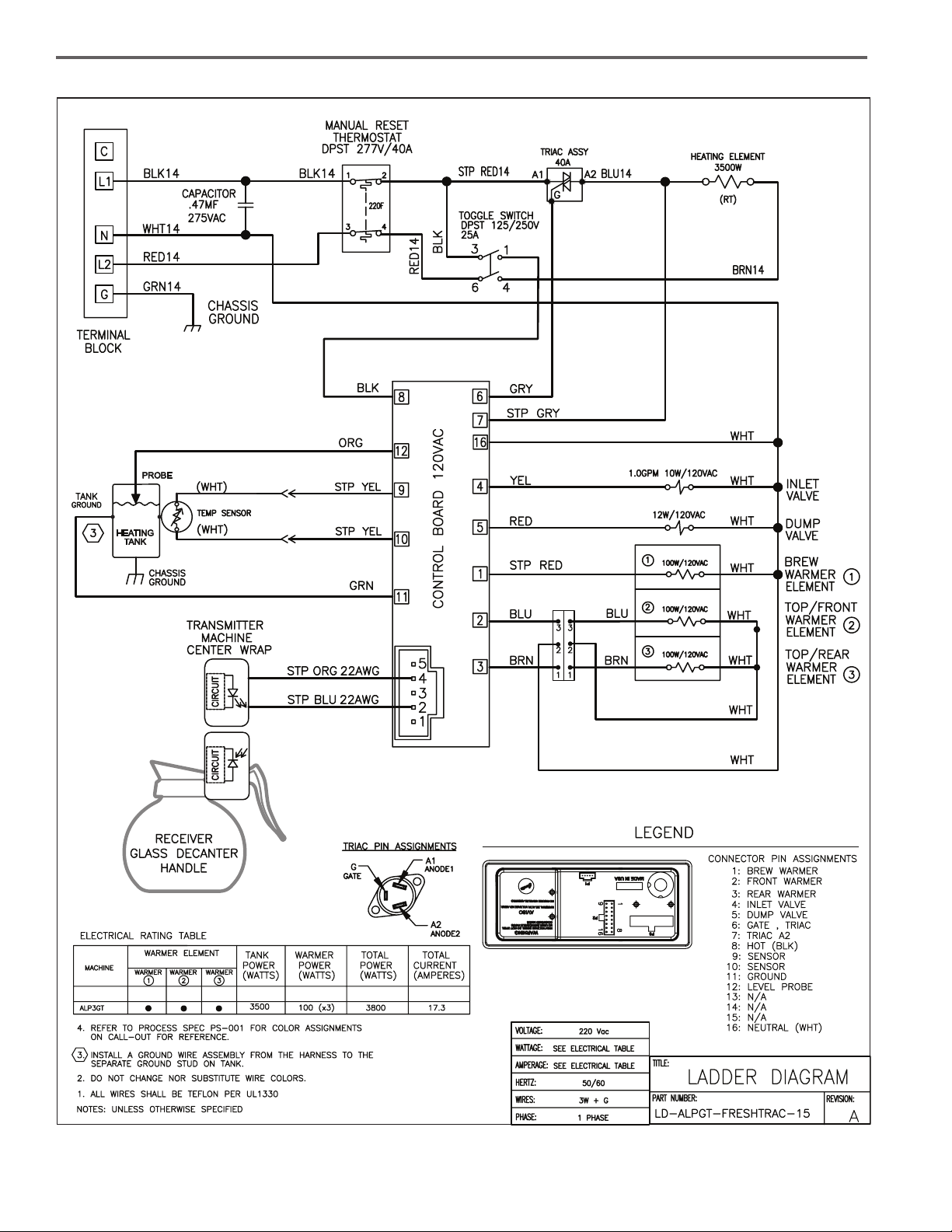

ELECTRICAL SCHEMATIC

9

CLEANING

1. Brewer (Exterior) Cleaning Instructions: Use KAY QSR Glass & Multi-Surface Cleaner solution

and a clean, sanitizer-soaked towel to remove soils from the exterior of coffee brewers.

2. Glass Coffee Pot Cleaning Instructions:

a. Remove lid from the decanter.

b. Place one Kay Beverage Equipment Cleaner tablet into the decanter and ll with hot water.

c. Allow to soak for 10 minutes. For heavy soil, use two Kay Beverage Equipment Cleaner

tablets.

d. Scrub the decanter and the lip at the neck of the decanter thoroughly with the curved coffee

pot brush.

e. Use the exible brush to scrub the lid and areas around and inside each inlet/outlet.

f. Discard the solution; then, rinse and sanitize the decanter at the 3-compartment sink.

g. Allow to air dry

3. Brew Basket Cleaning Instructions:

a. Turn coffee machine OFF.

b. Remove coffee pots and take to 3-compartment sink.

c. Remove brew basket and spray head tting.

d. Insert the short end of the deliming tool into each of the ve holes

in the spray head.

e. Ensure each hole is open and free of mineral deposits.

f. Insert the long end into the spray head tting.

g. Rotate to remove mineral deposits.

h. Insert deliming tool into hot water dispenser nozzle to remove any mineral deposits.

i. Take brew basket and spray head to 3-compartment sink. Wash, rinse, and sanitize for a

minimum of one minute; then, allow to air dry.

j. Spray a clean, sanitizer-soaked towel with Glass & Multi-Surface Cleaner Solution and use

to wipe the exterior of the coffee machine clean.

k. Then, wipe with a clean, sanitizer-soaked towel from the clean towel bucket.

l. For tough stains, dissolve one tablet of Beverage Equipment Cleaner in 1 gallon of hot 110-

120°F (43-49°C) water in a clean bucket.

m. Submerse brew baskets and parts in BEC solution and allow to soak for 10 minutes.

n. Remove items, rinse and sanitize for a minimum of one minute at the 3-compartment sink.

o. Allow to air dry.

10

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

Printed in U.S.A. 4/2014 F-3844 rev G

WILBUR CURTIS CO., INC.

6913AccoSt.,Montebello,CA90640-5403USA

Phone:800/421-6150 Fax:323-837-2410

TechnicalSupportPhone:800/995-0417(M-F5:30A-4:00PPST) E-Mail:[email protected]

Web Site: www.wilburcurtis.com

Product Warranty Information

The Wilbur Curtis Company certies that its products are free from defects in material and workmanship under normal

use. The following limited warranties and conditions apply:

3 Years, Parts and Labor, from Original Date of Purchase on digital control boards.

2 Years, Parts, from Original Date of Purchase on all other electrical components, ttings and tubing.

2 Years, Labor, from Original Date of Purchase on all electrical components, ttings and tubing.

Additionally, the Wilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds

of coffee, whichever comes rst. Stainless Steel components are warranted for two (2) years from date of purchase against leaking

or pitting and replacement parts are warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty

period of the equipment in which the component is installed.

All in-warranty service calls must have prior authorization. For Authorization, call the Technical Support Department at 1-800-995-

0417. Effective date of this policy is April 1, 2003.

Additional conditions may apply. Go to www.wilburcurtis.com to view the full product warranty information.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no responsibility for

substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company, Inc. The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The

warranty does not cover and is void under the following circumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all

local electrical, mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or uctuating

water ow rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature

adjustments are the responsibility of the equipment owner. The owner is responsible for proper cleaning and regular

maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be

made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for

variation in equipment operation due to excessive lime or local water conditions. The equipment must be maintained accord-

ing to the manufacturer’s recommendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0”

rings, gaskets, silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and

whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed

up under normal use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of

the owner. Charges incurred by delays, waiting time, or operating restrictions that hinder the service technician’s ability to

perform service is the responsibility of the owner of the equipment. This includes institutional and correctional facilities.

The Wilbur Curtis Company will allow up to 100 miles, round trip, per in-warranty service call.

RETURN MERCHANDISE AUTHORIZATION: All claims under this warranty must be submitted to the Wilbur Curtis Company

Technical Support Department prior to performing any repair work or return of this equipment to the factory. All returned equip-

ment must be repackaged properly in the original carton. No units will be accepted if they are damaged in transit due to improper

packaging. NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA

NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL. All in-warranty service calls must be performed by an

authorized service agent. Call the Wilbur Curtis Technical Support Department to nd an agent near you.

Table of contents

Other Wilbur Curtis Coffee Maker manuals