Wilbur Curtis CB User manual

1

Important Safeguards/Conventions

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance should be performed by an

authorized service technician.

•DoNOTimmersetheunitinwateroranyotherliquid

•Toreducetheriskofreorelectricshock,doNOTopentoporfrontpanel.Nouserserviceablepartsinside.

•Keephandsandotheritemsawayfromhotpartsofunitduringoperation.

•Nevercleanwithscouringpowders,bleachorharshchemicals.

Symbols

WARNINGS–Tohelpavoidpersonalinjury

ImportantNotes/Cautions–fromthefactory

SanitationRequirements

YourCurtisComboBrewerisFactoryPre-SetandReadytoGo…RightoutoftheBox.

FollowingaretheFactorySettingsforyourCoffee/TeaBrewingSystem:

•BrewTemperature=204°F

•BrewVolume=Settodispensingvesselrequirements(2.2liters)

GenerallytherewillneverbeareasontochangetheG3/GoldCupSeriesdefaultsettings.However,shouldyouneedtomakeslight

adjustmentstomeetyourbrewingneeds,programminginstructionsareprovidedlaterinthismanual.

SystemRequirements:

•WaterSource20–90PSI.Minimumowrateof½gpm(1gpmpreferredowrate).

•Electrical:Seeattachedschematicforstandardmodelorvisitwww.wilburcurtis.comforyourmodel.

Equipmenttobeinstalledtocomplywithapplicablefederal,state,orlocalplumbing/electricalcodeshavingjurisdiction.

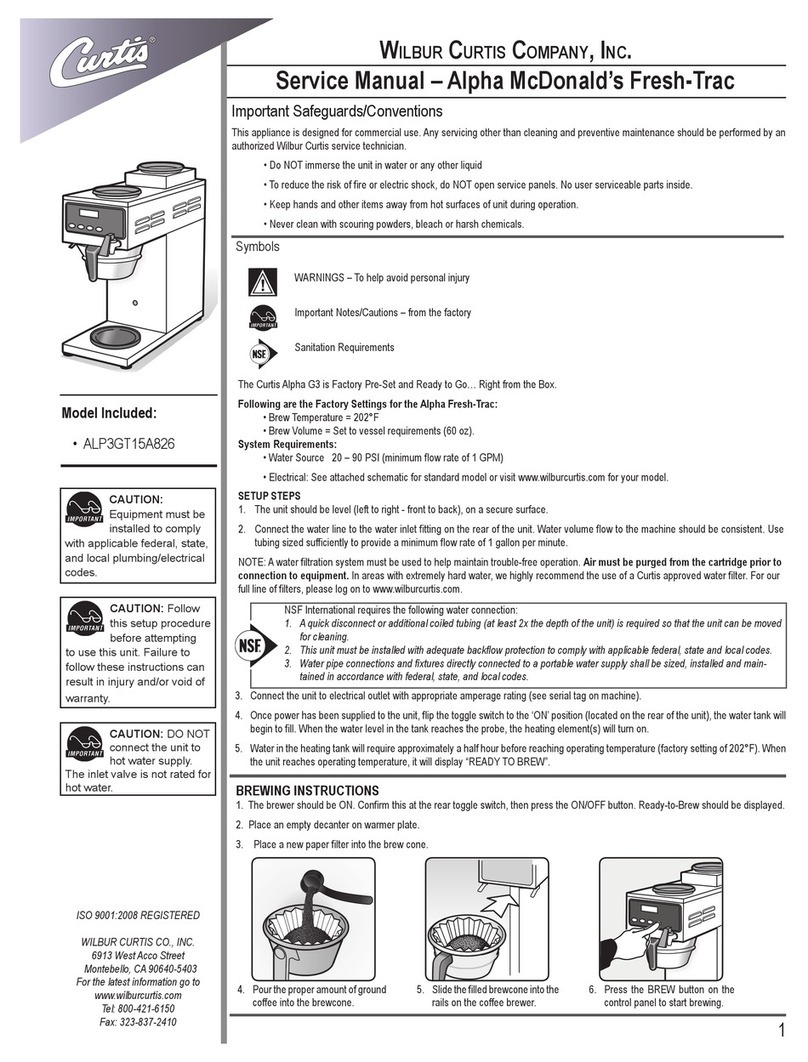

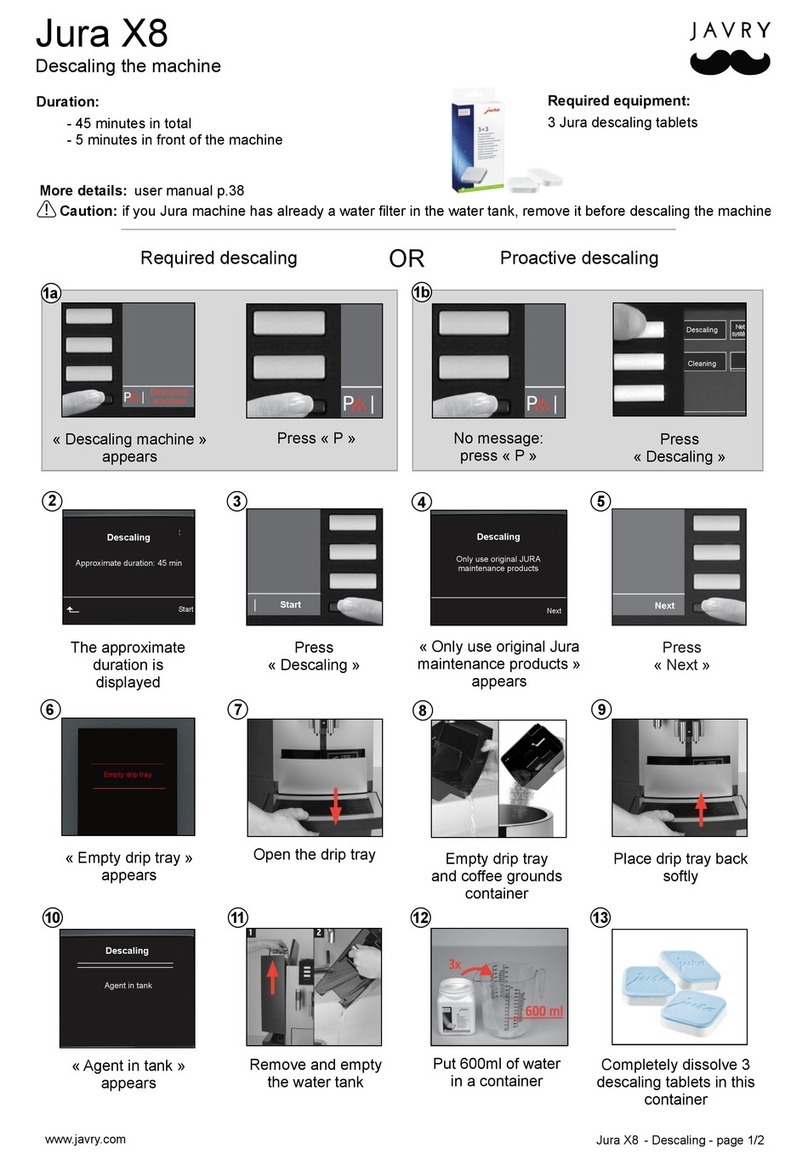

SETUP STEPS

Theunitshouldbelevel(lefttorightandfronttoback)andlocatedonasolidcountertop.Connectawaterlinefromthewaterltertothe

brewer.

NOTE:Awaterltrationsystemmustbeusedtohelpmaintaintrouble-freeoperation.Air must be purged from the

cartridge prior to connection to equipment.Inareaswithextremelyhardwater,wehighlyrecommendtheuseofaCurtis

approvedwaterlter.Forourfulllineoflters,pleaselogontowww.wilburcurtis.com.

1.A1/4”Flarehasbeensuppliedforwaterlineconnection.Usetubingsizedsufcientlytoprovideaminimumof½gpm(1gpmis

preferred).

2.Connecttheunittoanappropriateelectricalpowercircuit.

3.Turnonthetoggle(STANDBY/ON)switchbehindtheunit.Theheatingtankwillstarttoll.Whenthewaterlevelinthetankrises

tothecorrectvolume,theheatingelementwillenergizeautomatically.WiththeG3/GoldCupSeriesthereisnodangerofelement

burnoutduetoanunlledheatingtank.

4.Theheatingtankwillrequire20to30minutestoreachoperatingtemperature(204°F)asindicatedbytheREADY-TO-BREW

LCDreadout.

5.Important:RunonefullTEAbrewcyclerst,beforerunningacoffeebrewcycletopurgewaterlinesandvalvesofair.Five

secondsofpulsingdilutionwateratthebeginningofeachTEAbrewcycleisnormalpre-programmedoperatingbehavior.

NSFInternationalrequiresthefollowingwaterconnection:

1.Aquickdisconnectoradditionalcoiledtubing(atleast2xthedepthoftheunit)sothatthemachinecanbemovedforcleaning

underneath the unit.

2.Thisequipmentistobeinstalledwithadequatebackowprotectiontocomplywithapplicablefederal,stateandlocalcodes..

3.Waterpipeconnectionsandxturesdirectlyconnectedtoapotablewatersupplyshallbesized,installedandmaintainedin

accordancewithfederal,state,andlocalcodes.

CAUTION:Pleaseuse

this setup procedure

before attempting to use

thisbrewer.Failuretofollowthe

instructionscanresultininjuryorthe

voidingofthewarranty.

CAUTION:DONOT

connectthisbrewertohot

water.Theinletvalveis

notratedforhotwater.

IMPORTANT:After

setup,runafullTEA

cyclerstbeforerunning

aCOFFEEcycle.Placeanempty

teacontainertocatchbothhotwater

fromthebrewconeanddilution

waterfromspoutonthefrontcover.

Models:

•CB

•CBP

WARNINGHOTLIQUID,

Scaldingmayoccur.

Avoid splashing.

4. Pourground

coffee into

brewcone

marked

COFFEE

6.Pressthe

COFFEE

Brewbutton.

5. Position

lledbrew

cone into

brewrails.

BREWING INSTRUCTIONS – COFFEE

1.Ready-to-BrewshouldbedisplayedontheUCMscreen.

2.Makesurethatthefoldingairpotdeckisintheproperpositiontoaccommodateyourairpot.Placeaclean,emptyairpotonthedeck.

3. Placeanewpaperlterintothebrewcone.

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO WWW.WILBURCURTIS.COM

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO., INC.

6913 West Acco Street

Montebello, CA 90640-5403

For the latest information go to

www.wilburcurtis.com

Tel: 800-421-6150

Fax: 323-837-2410

ServiceManual–CB&CBP

Wilbur Curtis Co., inC.

2

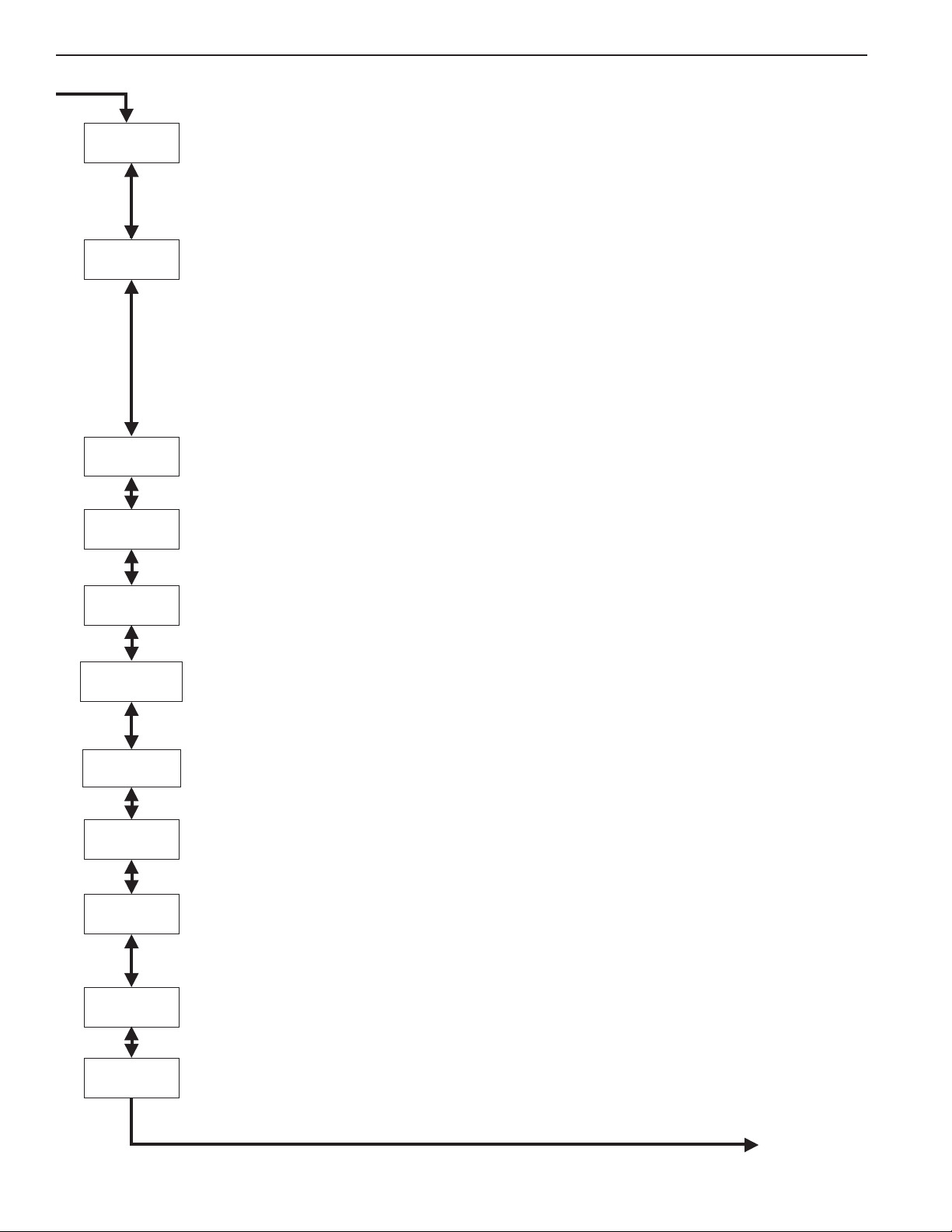

Program Menus

Tea Recipes

ProgramMenus

ContinuedonPage3

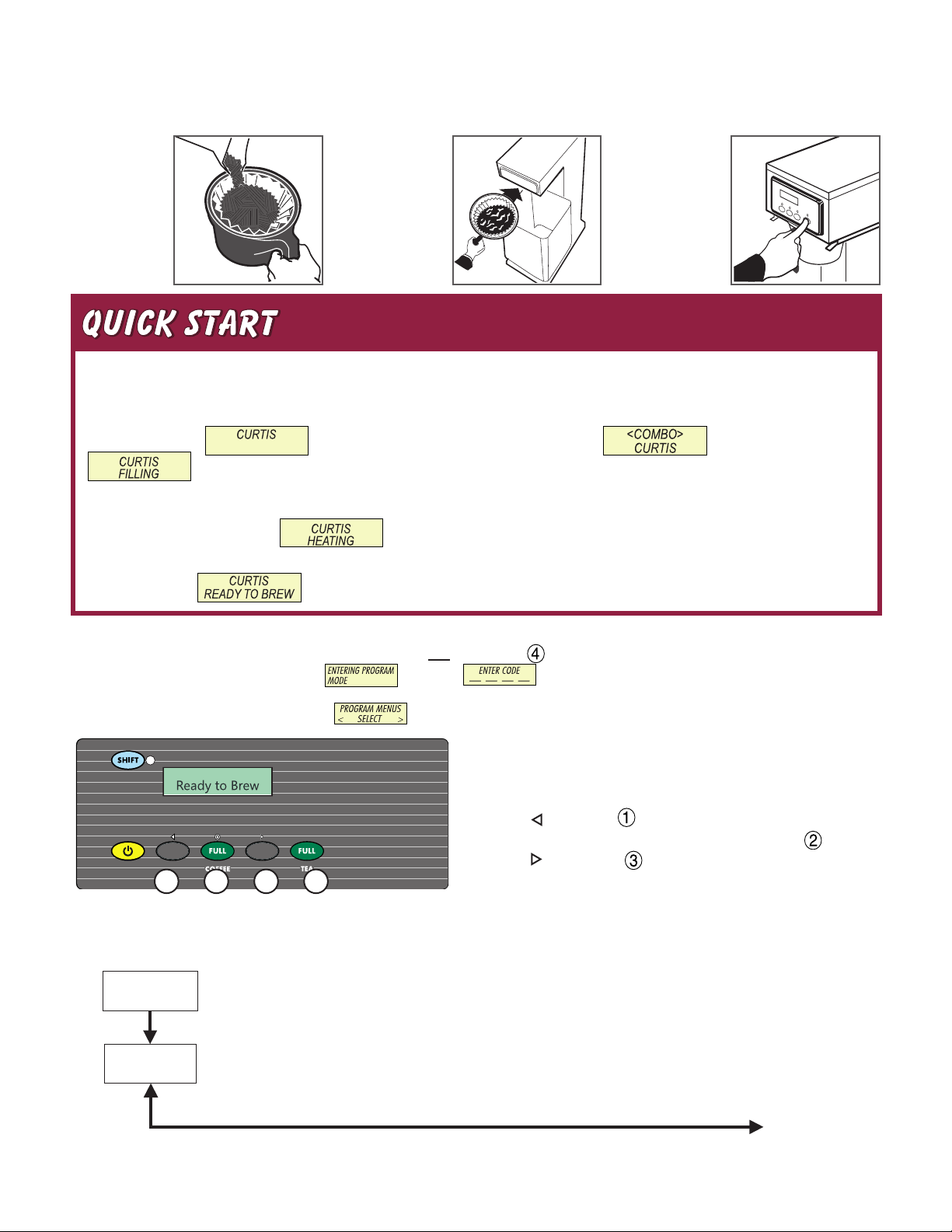

Your Curtis G3/Gold Cup Series is Factory Pre-Set for Optimum Performance.

Afterconnectiontowaterandpower;thereartoggleswitchmustbeon.Youwillhearabeepsound,indicatingpowerisavailabletothe

controller.

Thecontroldisplays .PressON/OFFbuttonandthescreenwilldisplay .Afterthreeseconds,

is displayed.

Thetheheatingtankwillllinapproximatelytwotothreeminutes,dependingonwaterowrate.

Whentheproperlevelisreached willappearonthescreen.Ittakesapproximately20minutestoreachsetpointtem-

peratureof204°F.

Controlwilldisplay whentemperaturereachesthesetpoint(204°F).Unitisnowreadytobrew.

Brewing Instructions – Tea

1. BrewershouldbeON(Conrmatreartoggleswitch,thenpressON/OFFbutton)andReady-to-Brewdisplayed.

2. Makesuredeckisfoldeddownandteacontainerisinplace.

3. Placelterin

brewbasket.

Pourteainto

basketmarked

ICEDTEA.

4. Slidebrew

cone into rails.

Placetea

container under

brewcone.

Programming

Turnoff(darkdisplay)bypressingON/OFFbutton(yellow).PressandholdBREWbutton4(green)andthenpressandreleaseON/OFFbutton(yellow).

ContinueholdingBREWbutton.Displaywillread ,waituntil isdisplayedEnterthe4-digitaccesscode,thedigits1-4corre-

spondtothebuttons(seeillustrationbelow).

Thedefaultcodesetatthefactoryis1-2-3-4.Then willbedisplayed.

Allprogrammingselectionsareperformedwiththethreecenterbuttons.

Thesymbolsbelowthebuttonsare:

ScrollLEFT

SELECTIONorENTERtosavenewparameter

ScrollRIGHT

431 2

SelectingBrewbyVolumeorBrewbyTimedependsonwhetheryouknowyourbrewtimebeforestarting.

FromProgram Menuspress>displaywillnowshowthenextfeature.

Tea Recipes (Factorysetting,Standard–PurpleFull,Standard–PurpleHalf)

PresstoSelect.Press<or>totogglebetweenStandard-Gray,Standard-Purple,Tropical-Gray,Tropical-

Purple,76/308-Grayand76/308-Purple.Setandexitprogrammingbypressing.

5. Pressthe

teabrew

button to begin

brewingtea.

3

TeaDilut.Volume

TeaDilut.Time

TeaDilut.Delay

TeaByVolume

TeaByTime

Tea by Volume

ScrolluntilBrewbyVolumeisdisplayed.PresstoSelect.ThedisplaywillreadSelectBrewButton!Oncethedesired

brewbuttonisselected(COFFEEorTEA),thedisplaywillreadPressBREWtoStart0:00Time.PresstheFULLBREW

buttonandhotwaterstartsdispensing.Whenthedesiredvolumeisreached,pressFULLBREWagaintostoptheow.

Thebrewvolumehasnowbeenset(HALFBREWwillalwaysbehalfoftheFULLBREWvolume).WhenEXITisdis-

played,Presstoselectandexittheprogrammingmode.Pressing>buttonwilldisplaythesubsequentmenufeatures.

Tea by Time:(Factorysetto5:52FullBrew,2:56HalfBrew)PresstoSelect.Press<or>toincreaseordecrease

time.TeabyTimehasarangeof0:00to9:59(Incrementsareminutesandseconds).TheHALFBREWbuttonwillbeset

athalfthebrewtime.

Dilution Delay: (Factorysetto30secFullBrew,30secHalfBrew)PresstoSelect.Press<or>totogglebetween

Standard-Gray(30sec),Standard-Purple(30sec),Tropical-Gray(9min),Tropical-Purple(9min),76/308-Gray(4min)

and76/308-Purple(4min).Rangeisfrom0seconds,1minuteto10minutes.

Dilution Volume:PresstoSelect,DisplaywillnowshowPushSTARTToBegin...PresstheBREWbuttonthenwater

startsrunning,whendesiredvolumeisreachedpressBREWbuttonagaintostoptheow.Nowthevolumehasbeenset.

Pressing>buttonwilldisplaythesubsequentmenufeatures.

Dilution Time: (Factorysetto4:05Full,2:02Half)PresstoSelect.Press<or>totogglebetweenStandard-Gray

(4min-5sec),Standard-Purple(4min-5sec),Tropical-Gray(4min-26sec),Tropical-Purple(4min-26sec),76/308-Gray

(4min-55sec)and76/308-Purple(4min-55sec).DilutionTimeisfrom30secto9min,59sec.

Tea Dilution Stir: (FactorysettoStandard–PurpleOn).

PresstoSelect,press<or>forachoiceofStandard-Gray:On,Standard-Purple:On,Tropical-Gray-Off,Tropical-

Purple-Off,76/308-Gray-Offand76/308-Purple-Off.DilutionStirappliesonlytotheDilutioncycle,bypulsingthedilution

time45secondson,5secondsoff.

Tea Pulse Brew (FactorysettoOFF).

PresstoSelect,press<or>tochooseON/OFForD(manualprogramming).Dwillgiveyouapulsingsprayof1-20

pulsesonandoffat5secondincrements,dependingonthetotaltimesetforbrew(seeTeabyTime).

Tea Fast Brew(FactorysettoOFF).

PresstoSelect,press<or>tochooseONorOFF.SelectingONwillstarthotwatersprayinginthebrewconerst

andthen1minutelaterthedilutionwaterwillstarttoow.

Tea Half Batch(FactorysettoON)

WhenthisfeatureisON,ahalfbatchbuttononthecontrolpanelactivates.PresstodisplayONorOFF.Pressing<or

>willchangethisfeatureofforon.

Tea Drip-out (FactorysettoOFF)

PresstoSelect.Press<or>tomovetodesiredtime.SettingsareOFF,5secondsto15minutes(in5secondincre-

ments).PresstoSelecttime.

Coffee by Volume: (Factorysetto60ozFullBrew,30ozHalfBrew)PresstoSelect,DisplaywillnowshowPush

STARTToBegin...PresstheFULLBREWbuttonthenhotwaterstartsrunning,whendesiredvolumeisreachedpress

FULLBREWbuttonagaintostoptheow.Nowthevolumehasbeenset(HALFBREWwillalwaysbehalfoftheFULL

BREWvolume).

Coffee by Time(Factorysetto2:25FullBrew,1:12HalfBrew).

PresstoSelecttochangethebrewtime.Displaywillnowshowthecurrenttime.Bypressing<or>youcantoggle

backandforthfromminutestosecondstoexit(ex).Changethetimeorsetandexitbypressing.

TeaDilutionStir

TeaPulseBrew

TeaFastBrew

Continued on Page 4

TeaHalf-Batch

TeaDrip-out

CoffeeByTime

CoffeeByVolume

Program Menus

4

Pre-Infusion(FactorysettoOFF)

PresstoSelect.Currentsettinginsecondsisdisplayed<todecreaseorselect>toincrease(rangefromOFFto10

through60seconds),to set.

IfPre-infusionisselected(ON),ColdBrewLockissettoDelta1within5ºFofsetpointandColdBrewLockdisappears

fromthelistofprogramselections.WhenPre-infusionisON,PulseBrewdisappearsfromthelistofprogramselections.

Pulse Brew (FactorysettingOFF)

Presstoselect,<or>toselectOFForoneofvepulsepatterns(AtoE).

GuidelinesforPulseBrew:

Thisfeatureallowstuningofthecoffeeavor.ThisoptionshouldonlybeusedwiththestandardGrayorPurpleAFS

sprayheads.ThepotlevelshouldalwaysbesetrstwiththisoptionOFF.Dependingonyourgrindproleandwater

conditions,thethreePulseBrewoptionshelp“tune”orchangethecoffeeavor.FilterPacktypecoffeestypicallyextract

betterwiththeAandBpulsesetting.DecafcoffeestypicallyextractbetterwiththeBpulsesetting.High-Yieldcoffeestypi-

callyextractbetterwiththeCpulsesetting.Ofcourse,anyoftheA,BorCsettingsmaybeusedtosuityourtasteprole.

SettingsDandEaremanualpulsecounts.IfPulseBrewisselected(ON),ColdBrewLockissettoDelta1within5ºFof

setpointandColdBrewLockdisappearsfromthelistofprogramselections.

WhenPulseBrewisON,Pre-infusiondisappearsfromthelistofprogramselections.

Coffee Drip-out (Factorysetto2minutes)

PresstoSelect.Press<or>tomovetodesiredtime.SettingsareOFF,1,2,3,4and5minutes.PresstoSelect

time.

Safety Sw On/Off (FactorysettoOFF)

Presstodisplay.Pressing<or>willturnthisfeatureofforon.

Temperature(Factorysetto204°F)

PresstoSelect.Press<or>tomovetodesiredtemperatureandthento set. Temperature is programmable from

170ºFto208ºFin2-degreeincrements.

Energy Save Mode(FactorysettoOFF)

PresstoSelect,<or>ON,OFForON140ºF,toset.WheninON,unitwillautomaticallyshutoff4hoursfrom

lastbrew.WhenfeatureisOFF,unitdoesnothavetheenergysavingmode.

IntheON140ºFposition,temperaturegoesdownto140ºF,ifunithasnotbrewedin4hours.Thisfeaturewillsave

energybymaintainingalowertemperatureinthetankinperiodsofnon-operation.

Brew Count Odom

Presstodisplaytotalbrewcycles.PressexorReset

Brew Count Total

PresstoSelect,Showstotalgallonsandtotalbrewcyclesontheunit.Cannotbereset.

Cold Brew Lock ...(Factorysetto5º)

Presstoselect,<or>toselectdesiredsetting(CBL5,15orOFF),to set.

TheColdBrewLockfeatureallowsthebrewertobrewatthreedifferenttemperaturelevelsfromtheactualsetpoint.The

rstsettingiswithin5degreesofsetpoint,nextiswithin15degreesofsetpoint,OFFiswithin30degreesofsetpointfor

theReadytoBrewmessage,however,itwillbrewatanytemperature.

Master Reset

PresstodisplayAreYouSure?

Then<forYes,>forNo.Whenreset,thebrewerresumesbacktothefactorydefaults.

Service Call(PhonenumberFactorysetto1-800-000-0000)

Presstodisplaynumberandchangenumberor<tomoveplaceandEXtoexitwhencomplete.Thisnumberwillbe

displayedduringaHeatingsystemSENSORERRORorduringaWATERERROR.

EnergySaveMode

Coffee

Drip-out

Temperature

ServiceCall

MasterReset

ColdBrewLock

BrewCountOdom

BrewCountTotal

Continued on Page 5

SafetySWOn/Off

CoffeePre-infusion

CoffeePulseBrew

Program Menus

5

BeeperOn/Off

P-Maintenance

BannerName

AccessCode

Access Code (Factorysetto1-2-3-4)

Presstodisplaynumberandchangenumber,(thenumbercanbechanged1to4)or<tomoveplaceandextoexit

whencomplete.

Banner Name(FactorysettoCurtis)

Presstodisplaylettersandchangelettersor<tomoveplaceandEXtoexitwhencomplete

Thisfeatureallowsupto14letterstobeprogrammedforcompanynameorregionalname.Programmingallblanks

disablesBannerName.Ifprogrammed,BannerNameisdisplayedevery5sec.onandoff.

P-Maintenance(FactorysettoOFF)

PresstoSelect,SetgallonsbrewedtoindicateP-Maintenance.Press<or>toadjustfromOffto3000gallons.Press

toexit.

Beeper On/Off (FactorysettoON)

PresstodisplayONorOFF.Pressingeither<or>togglesbetweenonandoff.toset.WhenON,thisfeatureallows

you to hear a short beep each time a button is pressed.

Quality Timer(FactorysettoOFF)

PresstoSelect,OFForON,or0to10hoursin5secondincrements.Anaudiblealarmsoundswhentimehasexpired;

atthesametime,thescreenwillashoffandonwiththewords“BrewFreshTea”.Thisfeatureisformodelsbuiltafter

1/2015).

Displ. Brew Time (FactorysettoON)

PresstodisplayONorOFF.Pressingeither<or>togglesbetweenonandoff.

Displ. Messages (FactorysettoON)

PresstodisplayONorOFF.Pressingeither<or>togglesbetweenonandoff.Whenon,thisfeaturedisplays“Rinse

ServerBeforeBrewing”alternately,with“ReadytoBrew”.

Model Select(FactorysettoCOMBO)

PresstoSelect.Pressing<or>willlistmodelsavailable:TEA/IC-1BATCH,TEA/IC-2BATCH,TEA/IC-3BATCH,TEA/

IC-4BATCH,TEA-SWEET,DUAL-DILUTION,DUAL-SWEET,COMBO,COMBO/IC,COMBO-SWEET.Pressto select

andexit.

Exit

Presstoselect,exitsprogrammodeandreturnsunittooperation.Pressing>returnsyoutoBrewByVolume.

Exit

Displ.BrewTime

Displ.Messages

QualityTimer

ModelSelect

Program Menus

Error Message

WiththeG3/GoldCupSeriesbrewers,therearethreeerrormessagesthatcanappearonthescreentoadvisetheuserofamalfunction.Ifoneof

theseerrormessagesappear,thebrewerwilllockupandstopfunctioninguntiltheerroriscorrected.Anerrormessagewilloccurunderthefollowing

conditions:

1.Waterlevelllerrororoverow.Thiserrormessageoccurswhentheinletvalvesolenoidhasbeenonformore

than10minutes.Thiserrormessagealsooccurswhenthevalveisrellingthetankduringabrewcycleformore

than1½minutes.

2.Watertemperaturecontrolsystemerror.Anopenprobeorabreakinthetemperaturecontrolcircuitisdetected.

This error message indicates there is an overheating problem. The sensor is reading that temperature in the heat-

ingtankhasrisenabove210ºF.

3.Usuallythescreenwilldisplayaservicecallphonenumber.Onceamalfunctioniscorrected,theerrormessage

mustbecleared.Toresetthecontrolpanelandreturntonormaloperation,pressthebutton for 5 seconds.

6

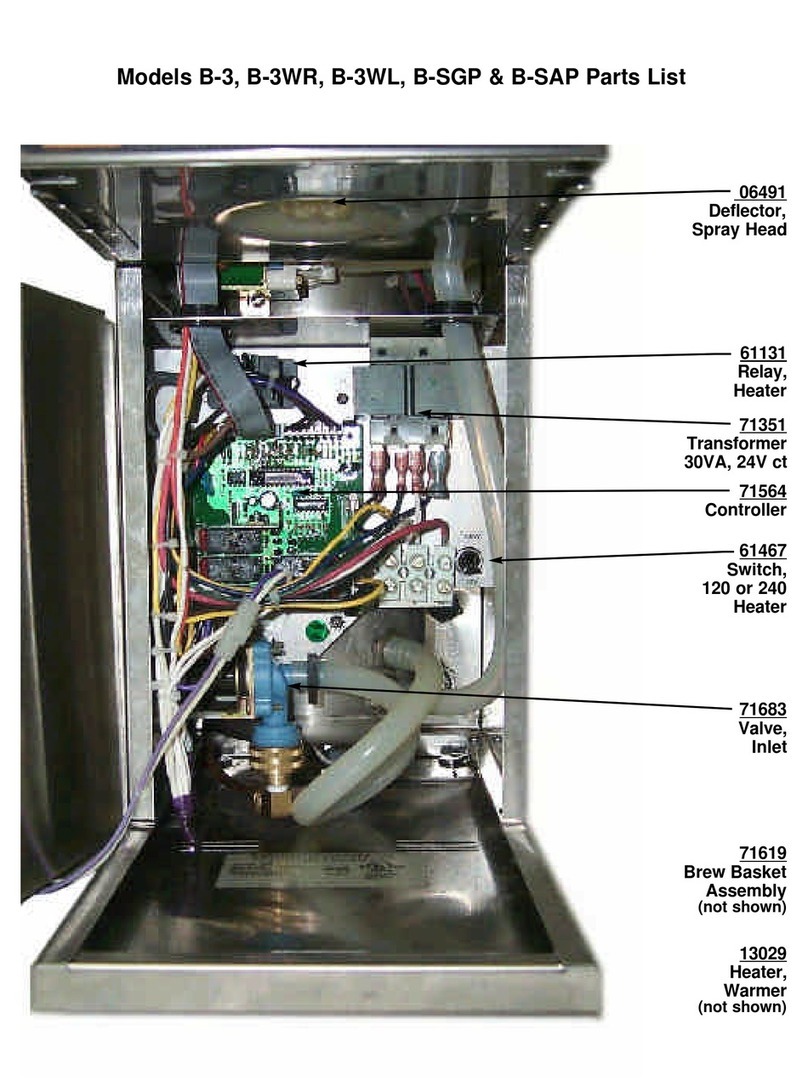

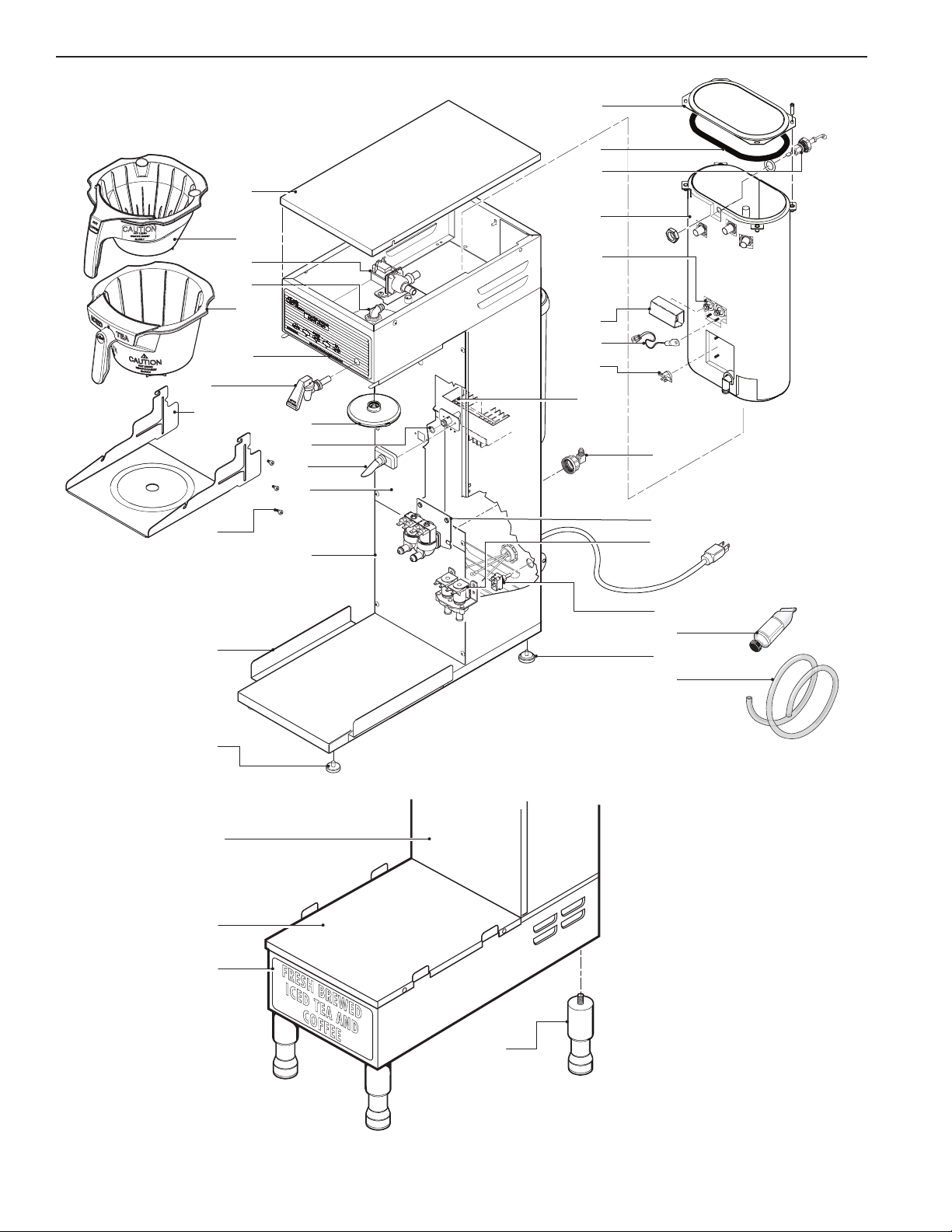

10

9

11

14

14A

13

29

29A

15

27

16

28

1

5

2

3

5A

4

18

19

22

21

23

24

25

26

8

6

7

30

31

14B

32

33

34

12

12A

Illustrated Parts

7

37

42

38

36

39

40

41

1

2

2A

3

4

4A

4B

5

5A

6

7

8

9

10

11

12

12A

13

14

14A

15

15A

16

18

19

21

21A

WC-58117

WC-889*

WC-860

WC-2977-101K*

WC-37184*

WC-390162

WC-37418

WC-3417

WC-3398*

WC-61709*

WC-4538

WC-1809

WC-43134

WC-29025*

WC-66079

WC-8556*

WC-6193-0

WC-37255

WC-61716-101

WC-61717-101

WC-102*

WC-103

WC-3518*

WC-5853-102

WC-43062*

WC-6277

WC-6290-101

COVER,TOPBREWER

VALVE,DUMPLEFT120V12W

VALVE,DUMPLEFT220V12W(EXPORTONLY)

KIT,FITTINGSPRAYHEADPLASTIC

KIT,LABEL&UCMCBSCURTIS

LABEL,UCMOVERLAYCBP/CBSCURTISLOGO

KIT,UCM&LABELCBS/CBP220V(EXPORT)

BREWCONE,ASSYW/SPLASHPOCKETBROWNCOFFEE

BREWCONE,ASSYSTDTEANON-METALW/BLUGUARD

SHELF,SSCBS

SCREW,SHOULDER8-32X.25x3/16LGTHRDS.S.

FAUCET,HOTWATER

O’RING,.426X9/16O.DX.070WALLEDPMTCTS

SPRAYHEAD,PURPLEADVANCEFLOW

SPOUTASSY,DILUTIONPLASTIC

HEATSINKASSYDV

TRIAC,40A600V

KIT,DUALVALVEWATERINLET

COVER,FRONTTOPCBS

COVER,FRONTBOTTOMNOSWITCHHOLE

SWITCH,TOGGLENON-LITSPST15A125VacRESISTIVE

SWITCH,TOGGLEDPST25A125/250VACRSTV(EXPORT)

LEG,GLIDE3/8”-16STUDSCREW

COVER,TOPHEATINGTANKGENUSE

GASKET,TANKLID

TANKASSY,COMPLETETEABREWER

TANK,COMPLETEW/WC-934-01ELMNT(EXPORTONLY)

DESCRIPTIONPART№ITEM№

22

23

23A

24

25

26

26A

27

28

29

29A

30

31

32

33

34

35

36

36A

36B

36C

37

38

39

40

41

42

WC-5527K*

WC-904-04*

WC-934-04

WC-4394

WC-1438-101*

WC-523*

WC-522

WC-5231*

WC-5310*

WC-895-105

WC-878-102

WC-8531

WC-3503*

WC-85008

WC-39550

WC-3528

WC-3763*

TCO308A000

TCO417A000

TCO419A000

TCO421A000

WC-5683

WC-38471

WC-1803

WC-3707*

WC-1805*

WC-37260*

KIT,PROBEWATERLEVELO-RING&NUT

ELEMENT,HEATING1.6KW120VW/JAMNUTS

KIT,HEATINGELEMENT2.5KW220V(EXPORTONLY)

SHOCKGUARD,HEATINGELEMENT

SENSOR,TEMPERATURETANK

THERMOSTAT,MANUALRESET120/220V25A220ºFMAX

THERMOSTAT,HILIMITDPST277V40A(EXPORTONLY)

COMPOUNDSILICONE5OZ

TUBING,5/16”IDX1/8”WSILICONE

VALVE,INLETDUAL120V10W2GPMX.5GPM

VALVE,INLETDUAL220V1.0GPM5GPMDLTN(EXPORT)

RAIL,BASETCTD

LEG,3/8”-16STUDSCREWBUMPER

SUPPORT,DECKEXTENDEDSS(CBPONLY)

LABEL,BOTTOMCPB

LEG,4”ADJUST3/8-16THRDITAL-STYLE(CBPONLY)

KIT,VALVEREPAIRUSEONWC-889(NOTSHOWN)

TEACONTAINEROVAL3GAL8½”(INCLDW/PTTBRWR)

TEACONTAINEROVAL4GAL17”(SOLDSEPARATELY)

TEACONTAINEROVAL4GAL19”(SOLDSEPARATELY)

TEACONTAINEROVAL4GAL21”(SOLDSEPARATELY)

LIDASSY,TCO

LABEL,FRONTTCOICEDTEAGENERIC

FAUCET,SPB

KIT,REPAIRSPBFAUCET

SEATCUP,FAUCETS’

KIT,FAUCETW/ADAPTERCOMPLETE

*Recommendedpartstostock

DESCRIPTIONPART№ITEM№

Parts List

Illustrated Parts List

TCOTeaServer

8

4

1

2

10

7

8

9

53

6

1

2

3

4

5

6

7

8

9

10

WC-56052

WC-38471

WC-1803

WC-37260

WC-3707

WC-1805

WC-38163

WC-5686

WC-3531

WC-3289

LID,BREWTHROUGHASSY

LABEL,FRONTTCNGENERIC

FAUCET,SPB

KIT,FAUCETW/ADAPTERCMPLT

KIT,REPAIRSPBFAUCET

SEATCUP,FAUCETS’

LABEL,CURTISSWPCLR/WHT

DRIPTRAY,OCTAGONSTYLE

LEG,PLASTICGLIDETCN

HANDLE,GASKET

DESCRIPTIONPART№ITEM№

Illustrated Parts List

TCNTeaServer

Tea Tips

1. Storeteabagsinadark,coolanddryplaceawayfromstrongodorsandmoisture.Donotrefrigerate.

2. Neverholdnishedbrewedteaformorethaneighthoursatroomtemperature.Discardanyunusedteaaftereighthours

3. Brewonlyenoughteathatyoureasonablyexpecttosellwithinafewhours.

4. Toprotectteaavorandtoavoidbacterialcontaminationandgrowth,cleanandsanitizeteabrewing,storageanddispensingequipmentatleast

once a day.

WARNINGDONOTrefrigerateunusedteaovernightforlaterconsumption.

9

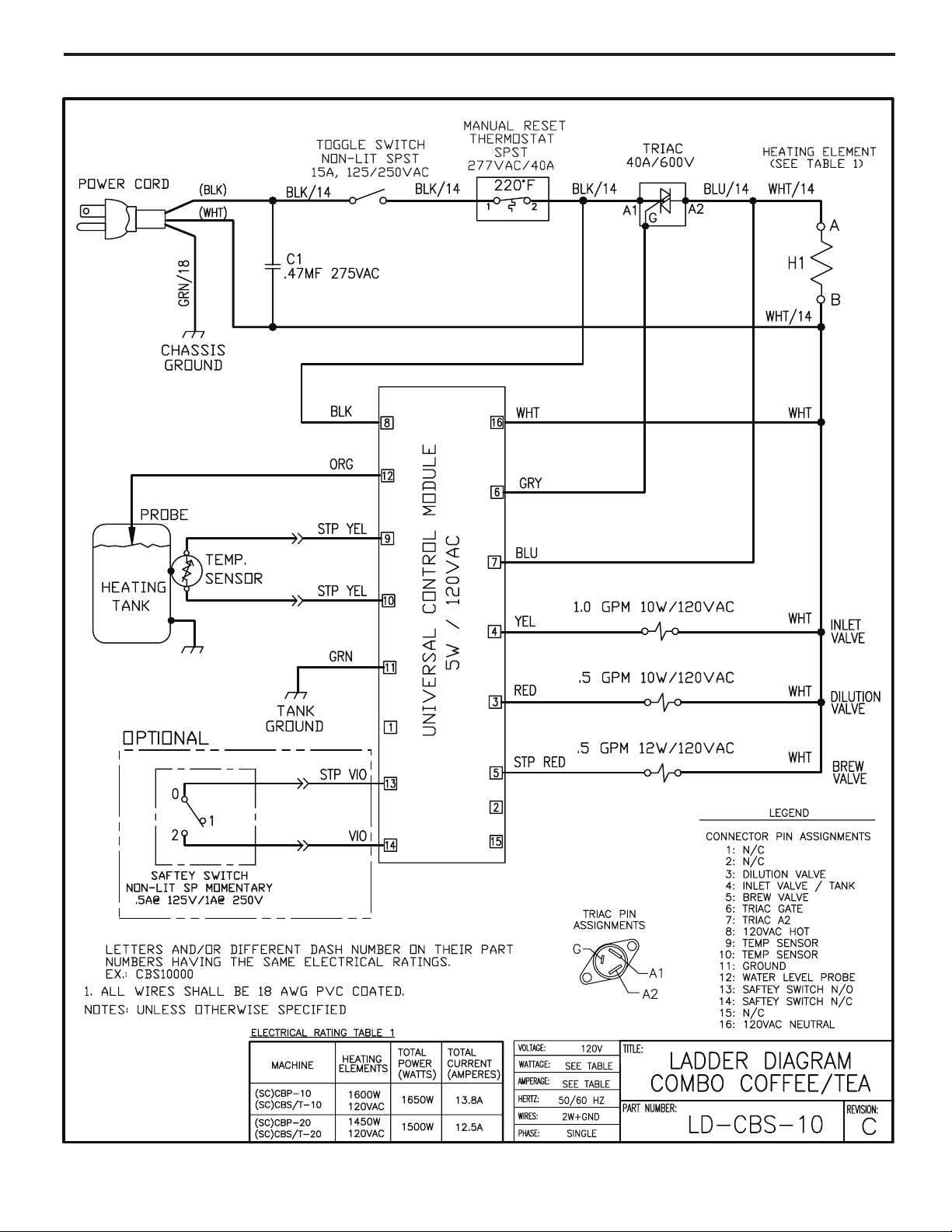

Electrical Schematic

10

Cleaning the Brewer

Regularcleaningandpreventivemaintenanceisessentialtokeepyourcoffeebrewerlookingandworkinglikenew.

CAUTION –Donotusecleansers,bleachliquids,powdersoranyothersubstancecontainingchlorine.Theseproductspromotecorro-

sionandwillpitthestainlesssteel.USEOFTHESEPRODUCTSWILLVOIDTHEWARRANTY.

1. Wipeexteriorsurfaceswithamoistcloth,removingspillsanddebris.

2. Slidethebrewconeoutandcleanit.Cleanthesprayheadareawithamoistcleancloth.

3. Rinseanddrythebrewcone.

4. Rubastainlesssteelpolishontheoutsidesurfacestoprotectthebrewer.

Cleaning the Tea Containers

1.Washtheteacontainerandtopcover.Useadetergentsolutionandasoftbristledbrushtocleaninsidethecontainer.Wipetheexterior

surfaceswithaspongeanddetergentsolution.Rinsethoroughly.

2.Cleanthefaucetassembly.Unscrewthehandleassemblyfromthefaucetandremove.Cleanthefaucetshankwithagageglassbrush

(circularbristle)bypushingthebrushthroughtheshank.Usingthesamebrushcleanthefaucetbodyinletandoutlet.Cleanthefaucet

cap and silicone seat cup.

3.Afterthecleaning,placetheparts(sprayhead,brewconeandbasketandfaucetparts)rinsethepartsinhotwatertoremovetracesof

detergent.

Rough-In Drawing

11

To Sanitize the Disassembled Parts:

Wear rubber gloves for protection.

1.Placethecleanedpartsintoasink.

2. ImmersethemincommercialBarTabs/Sani-TabssanitizingsolutionThesolutionmustbewarm(75°F.)Allowthepartssoakinthesanitizerforat

least one minute.

3. Removethepartsfromthesanitizerandairdry.

4.Aftercleaning,sanitizinganddrying,assemblethepartstakenfromtheteacontainer.

Cleaning Airpots:

1. Inacontainer,mixamilddetergentsolutionforcleaningyourairpots.

2. Discardanyoldcoffeefromtheairpot.

2. Wipetheexteriorsurfaceswithaspongemoistenedwiththedetergentsolution,removingwater

spots and coffee.

3. Removeandcleanthesyphontube/funnelwithadetergentsolution.

3. Cleaninsidetheairpotswithaspongebrushsoakedindetergentsolution.

4. Aneasywaytocleanremovemineraldepositsfromthebrewconeandairpot,istousecoffee

equipmentcleaningtablets.

a.Placeatabletintothebrewcone.

b.Placetheairpotontothebrewdeckandopenthelid.

c.StartacoffeebrewcyclebypressingtheBrewbuttononthecontrolpanel.

d.Oncethebrewcyclehasnished,allowthecleaningsolutiontositintheairpotfora

minute.Discardtheusedcleanerfromtheairpot.

e.Rinsetheairpotandbrewconewithrunningwater.Boththebrewconeandairpotshouldbe

clean and ready to use.

Airpot Precautions:

Donotimmerseairpotsinwater.

Donotplaceindishwasher.

Donotuseharshpowdersorcleanserscontainingchlorine.

Donotuseawirebrushorpotscourtocleaninsideliner.

Liquid Level Probe

Cleaningintervalsfortheprobearetobedeterminedbytheuserortheservicetech,basedonwaterconditions.Theuseofwaterlters,orthetype

ofwaterlterthatisbeingusedcanimpacttheserviceinterval.Intervalscanbefromonemonthtoseveralyears,however,replacingratherthan

cleaning the probe is preferable.

WARNING:Electricshockhazard.Disconnectelectricalpowerbeforeremovingaccesspanels.

CAUTION: ScaldingandBurnhazard.Hotwaterandhotsurfaces.Allowunittocoolbeforeworking.

1. Unplugthepowercordandshutoffthewaterline.

2. Removethetopcoveroftheteabrewer.Locatetheheatingtankandremovethetopcover.

3. Drainthetanktoalevelabout3”belowthetipoftheprobe.

4. Allowsometimefortheheatingtankandliquidlevelprobetocooldownbeforeproceeding.

5. CleanthetipoftheprobeusingaScotch-Brite™ scuff pad.

6. Ifawhiteresidueisstillvisibleontheprobe,removetheprobeandsoakitinvinegarorascaleremoving

chemical. Repeat this step until the probe is clean.

EDR9267.1/9/15@8º.revNC

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

Printed in U.S.A. 1/2015 F-4011 Rev NC

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Web Site: www.wilburcurtis.com

ProductWarrantyInformation

TheWilburCurtisCo.,Inc.certiesthatitsproductsarefreefromdefectsinmaterialandworkmanshipundernormaluse.Thefollowinglimitedwar-

rantiesandconditionsapply:

3 Years,PartsandLabor,fromOriginalDateofPurchaseondigitalcontrolboards.

2 Years,Parts,fromOriginalDateofPurchaseonallotherelectricalcomponents,ttingsandtubing.

1 Year,Labor,fromOriginalDateofPurchaseonallelectricalcomponents,ttingsandtubing.

Additionally,theWilburCurtisCo.,Inc.warrantsitsGrindingBurrsforForty(40)monthsfromdateofpurchaseor40,000poundsofcoffee,whichever

comesrst.StainlessSteelcomponentsarewarrantedfortwo(2)yearsfromdateofpurchaseagainstleakingorpittingandreplacementpartsarewar-

rantedforninety(90)daysfromdateofpurchaseorfortheremainderofthelimitedwarrantyperiodoftheequipmentinwhichthecomponentisinstalled.

Allin-warrantyservicecallsmusthavepriorauthorization.ForAuthorization,calltheTechnicalSupportDepartmentat1-800-995-0417.Effectivedate

ofthispolicyisApril1,2003.

Additionalconditionsmayapply.Gotowww.wilburcurtis.comtoviewthefullproductwarrantyinformation.

CONDITIONS & EXCEPTIONS

Thewarrantycoversoriginalequipmentattimeofpurchaseonly.TheWilburCurtisCo.,Inc.,assumesnoresponsibilityforsubstitutereplacementparts

installedonCurtisequipmentthathavenotbeenpurchasedfromWilburCurtisCo.,Inc.TheWilburCurtisCo.,Inc.willnotacceptanyresponsibilityif

thefollowingconditionsarenotmet.Thewarrantydoesnotcoverandisvoidunderthefollowingcircumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or uctuating water ow rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the respon-

sibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for variation in

equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s recom-

mendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets,

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by delays,

waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner of the equipment.

This includes institutional and correctional facilities. The Wilbur Curtis Co., Inc. will allow up to 100 miles, round trip, per in-warranty service call.

RETURN MERCHANDISE AUTHORIZATION:AllclaimsunderthiswarrantymustbesubmittedtotheWilburCurtisCo.,Inc.TechnicalSupport

Departmentpriortoperforminganyrepairworkorreturnofthisequipmenttothefactory.Allreturnedequipmentmustberepackagedproperlyinthe

originalcarton.Nounitswillbeacceptediftheyaredamagedintransitduetoimproperpackaging.NO UNITS OR PARTS WILL BE ACCEPTED

WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LA-

BEL. Allin-warrantyservicecallsmustbeperformedbyanauthorizedserviceagent.CalltheWilburCurtisTechnicalSupportDepartmenttondan

agent near you.

This manual suits for next models

1

Table of contents

Other Wilbur Curtis Coffee Maker manuals