Wilbur Curtis Primo Cappuccino PCGT3 User manual

Primo Cappuccino™3 Station

Dispensing System

USER GUIDE

READ AND SAVE THESE INSTRUCTIONS

NOTICE TO INSTALLER: Please leave this booklet with the machine.

øøøøø "

'$1$(5'30/5$07&3 'SFW/$

CONTENTS CL40

.H\)HDWXUHV6SHFLÀFDWLRQV6\VWHP5HTXLUHPHQWV..............................................................................................FS40

,PSRUWDQW6DIHJXDUGV............................................................................................................................................... IS2

,QVWDOODWLRQ,QVWUXFWLRQV*HQHUDO...............................................................................................................................II2

,QVWDOODWLRQ,QVWUXFWLRQV/HYHOLQJ:DWHU6XSSO\(OHFWULFDO....................................................................................II22

2SHUDWLQJ,QVWUXFWLRQV ............................................................................................................................................OI33

&OHDQLQJ,QVWUXFWLRQV*HQHUDO..............................................................................................................................CI19

&OHDQLQJ,QVWUXFWLRQV:KLSSHU3ODWH$VVHPEO\ ...................................................................................................CI20

3URJUDPPLQJ*XLGH ............................................................................................................................................. 3*

5RXJK,Q'UDZLQJ................................................................................................................................................. 5'

,OOXVWUDWHG3DUWV5HFRPPHQGHG3DUWV0DLQ&KDVVLV........................................................................................... ,3

,OOXVWUDWHG3DUWV5HFRPPHQGHG3DUWV7DQN$VVHPEO\6WDQGDUG ....................................................................... ,3

,OOXVWUDWHG3DUWV5HFRPPHQGHG3DUWV7DQN$VVHPEO\'XDO9ROWDJH ................................................................. ,3

,OOXVWUDWHG3DUWV5HFRPPHQGHG3DUWV7DQN$VVHPEO\([SRUW ........................................................................... ,3

(OHFWULFDO6FKHPDWLFV ............................................................................................................................................(6

7URXEOHVKRRWLQJ*XLGH*HQHUDO..........................................................................................................................7*

7URXEOHVKRRWLQJ*XLGH'XPS9DOYH&DOLEUDWLRQ.................................................................................................7*

(UURU&RGHV .............................................................................................................................................................(&

3URGXFW:DUUDQW\....................................................................................................................................................3:

Contact Information

Wilbur Curtis Co., Inc.

6913 Acco Street | Montebello, CA 90640 US

Phone: 323-837-2300 | Toll Free: 800-421-6150

'PSUIFMBUFTUTQFDJmDBUJPOTBOEJOGPSNBUJPOHPUPXXXXJMCVSDVSUJTDPN

5PMM'SFF].POEBZ'SJEBZA.M.- 4:00 P.M.PT

Email: [email protected]

%VFUPDPOUJOVFEQSPEVDUJNQSPWFNFOUUIFQSPEVDUTJMMVTUSBUFEQIPUPHSBQIFEJOUIJTHVJEFNBZWBSZTMJHIUMZGSPNUIFBDUVBMQSPEVDU

1$(5$0/5&/54-*45øø 021618NC

KEY FEATURES/SPECIFICATIONS/SYSTEM REQUIREMENTS FS40

Key Features

• G3 Digital Control Module - Provides precise control over all critical blending and dispensing functions.

• Pre-Dispense - Easy to use. Choose a size from small, medium or large by the touch of a button.

• Factory Pre-Set - For out-of-the-box operation.

• LCD Digital Display - Extra bright and easy to use.

• 4DSPMM5ISPVHI1SFDJTJPO1SPHSBNNJOH"EKVTUQPXEFSnPXJOJODSFNFOUTBOEXBUFSUFNQFSBUVSFGSPN¡'

UP¡'¡$UPDSFBUFUIFQFSGFDUIPUPSDPMECFWFSBHF

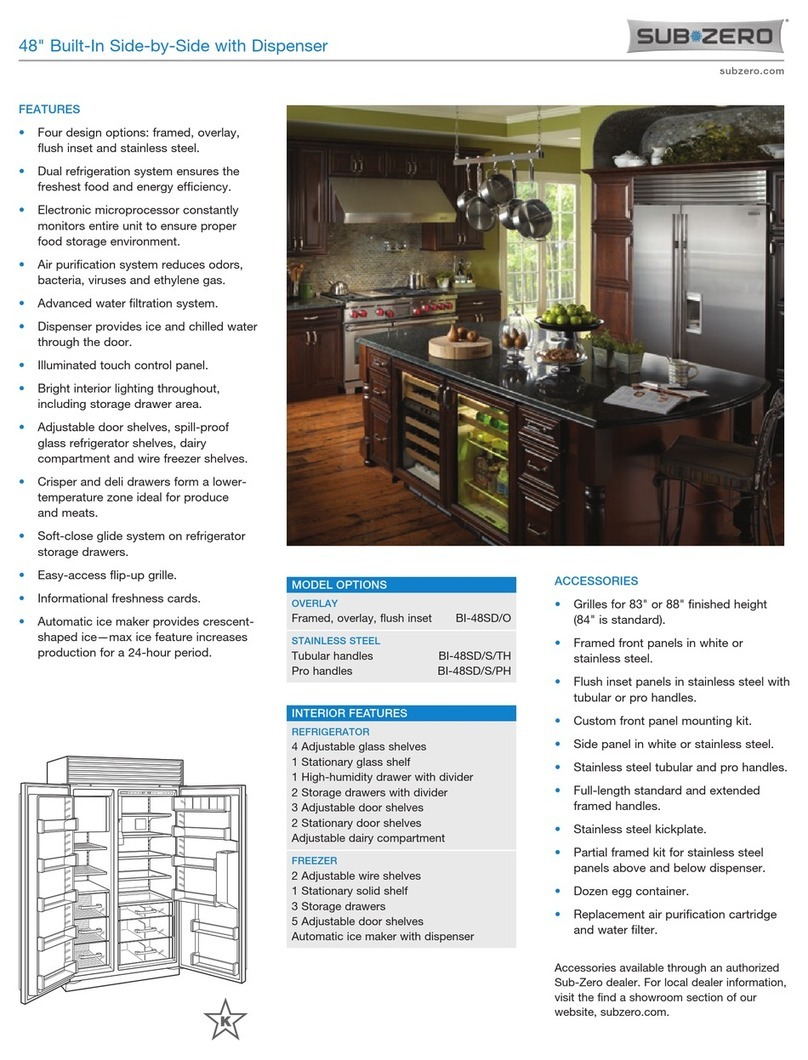

6SHFLÀFDWLRQV6HOHFWHG0RGHOV

(OHFWULFDO6XSSO\5HTXLUHPHQWV

02'(/ '(6&5,37,21 3+$6( 92/76 $036 +($7,1*&21),* :,5( :$776 +(57= &$3$&,7<

3&*7 3 Station 1 PH 120 V 15.0 A 1 x 1600 W 2W + G 1800 W 50/60 Hz 5.4 gal/hr

[20.4 l/hr]

3&*7'9 3 Station, dual voltage 1 PH 120/220 V 15.0/14.5 A 2 x 1600 W 2W/3W + G 1800/3000 W 50/60 Hz 5.4/10.7 gal/hr

[20.4/40.5 l/hr]

3&*7 3 Station with lift door 1 PH 120 V 15.0 A 1 x 1600 W 2W + G 1800 W 50/60 Hz 5.4 gal/hr

[20.4 l/hr]

3&*7 3 Station, pre-set dispense 1 PH 120 V 15.0 A 1 x 1600 W 2W + G 1800 W 50/60 Hz 5.4 gal/hr

[20.4 l/hr]

3&*7 3 Station with hot water faucet 1 PH 120 V 15.0 A 1 x 1600 W 2W + G 1800 W 50/60 Hz 5.4 gal/hr

[20.4 l/hr]

3&*7 3 Station, iced coffee 1 PH 120 V 15.0 A 1 x 1600 W 2W + G 1800 W 50/60 Hz 5.4 gal/hr

[20.4 l/hr]

(;3257

3&*7( 3 Station, export 1 PH 230 V 11.5 A 1 x 2000 W 2W + G 2650 W 50/60 Hz 10.9 gal/hr

[41.3 l/hr]

'LPHQVLRQV :DWHU6XSSO\5HTXLUHPHQWV

02'(/ +(,*+7 :,'7+ '(37+ 6+,3:(,*+7 6+,3&8%( :$7(5&211(&725 :$7(535(6685( 0,1)/2:5$7(

3&*7

34.78”

[88.3 cm]

14.25”

[36.2 cm]

24.54”

[62.3 cm]

125.0 lbs

[56.7 kg]

21.64 cu. ft.

[0.16 m3]µÁDUH

20 - 90 psi

[138 - 620 kPa]

1.0 gpm

[3.8 lpm]

3&*7'9

3&*7

3&*7

3&*7

3&*7

(;3257

3&*7( 34.78”

[88.3 cm]

14.25”

[36.2 cm]

24.54”

[62.3 cm]

125.0 lbs

[56.7 kg]

21.64 cu. ft.

[0.16 m3]µÁDUH

20 - 90 psi

[138 - 620 kPa]

1.0 gpm

[3.8 lpm]

PCGT3, KEY FEATURES/SPECS/SYSTEM REQUIREMENTS "

Following are the factory default settings for the Primo Cappuccino dispenser:

• 1PXEFS3BUJP• Water Temperature = ¡'¡$TUBOEBSEVOJUT

¡'¡$JDFEDBQQVDDJOPVOJUT

IMPORTANT SAFEGUARDS IS2

Symbols

This is the safety alert symbol. It is used to alert you to potential physical injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

DANGER - Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING - Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION - Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE - Indicates a situation which, if not avoided, could result in property damage.

IMPORTANT - Provides information and tips for proper operation.

SANITATION REQUIREMENTS

Important Safeguards/Conventions

WARNING:

• Make sure that this appliance is installed and grounded according to the INSTALLATION

*/4536$5*0/4CZRVBMJmFEQFSTPOOFMCFGPSFBUUFNQUJOHUPVTFJU'BJMVSFUPGPMMPXUIF*/45"--"5*0/

INSTRUCTIONS could result in personal injury or void the warranty.

• This appliance is designed for commercial use. Any service other than cleaning and preventive

maintenance should be performed by an authorized Wilbur Curtis service technician.

• 5PSFEVDFUIFSJTLPGmSFPSFMFDUSJDTIPDL%0/05PQFOUIFTFSWJDFQBOFMT5IFSFBSFOPVTFS

serviceable parts inside.

• Keep hands, arms and other items away from hot surfaces of the unit during operation.

• Clean the appliance and any dispensers completelyCFGPSFVTJOHUIFNGPSUIFmSTUUJNFBDDPSEJOHUP

the CLEANING INSTRUCTIONS. Clean them regularly as instructed in the CLEANING INSTRUCTIONS.

• Use this appliance only for its intended use, brewing/dispensing hot and/or cold beverages/water.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety. Children should

be supervised to ensure that they do not play with the appliance.

• Avoid spillage onto the power (mains) connector.

$0''&&5&"#3&8&34*.1035"/54"'&(6"3%44:.#0-4 (

WARNING - 5IJTQSPEVDUDBOFYQPTFZPVUPDIFNJDBMTJODMVEJOH"DSZMBNJEFBOE#JTQIFOPM"#1"

which are known to the State of California to cause cancer and birth defects or other reproductive harm.

'PSNPSFJOGPSNBUJPOWJTJUXXX18BSOJOHTDBHPW

IMPORTANT SAFEGUARDS IS2

$0''&&5&"#3&8&34*.1035"/54"'&(6"3%44:.#0-4 (

CE Requirements

• This appliance must be installed in locations where it can be overseen by trained personnel.

• 'PSQSPQFSPQFSBUJPOUIJTBQQMJBODFNVTUCFJOTUBMMFEXIFSFUIFUFNQFSBUVSFJTCFUXFFO¡$UP¡$

• "QQMJBODFTIBMMOPUCFUJMUFENPSFUIBO¡GPSTBGFPQFSBUJPO

• "OFMFDUSJDJBONVTUQSPWJEFFMFDUSJDBMTFSWJDFBTTQFDJmFEJODPOGPSNBODFXJUIBMMMPDBMBOEOBUJPOBMDPEFT

'PSTBGFVTFBOBMMQPMFEJTDPOOFDUJPONVTUCFJODPSQPSBUFEJOUPUIFmYFEXJSJOHJOBDDPSEBODFXJUIUIF

XJSJOHSVMFTPVUMJOFEJODMBVTFPG*&$GPSNFFUJOHUIFNJOJNVNFMFDUSJDBMTBGFUZPGUIJTTUBOEBSE

• This appliance must not be cleaned by water jet.

• 5IJTBQQMJBODFDBOCFVTFECZQFSTPOTBHFEGSPNZFBSTBOEBCPWFJGUIFZIBWFCFFOHJWFOTVQFSWJTJPOPS

instruction concerning use of the appliance in a safe way and if they understand the hazards involved.

• ,FFQUIFBQQMJBODFBOEJUTDPSEPVUPGSFBDIPGDIJMESFOBHFEMFTTUIBOZFBST

• "QQMJBODFTDBOCFVTFECZQFSTPOTZFBSTBOEBCPWFXJUISFEVDFEQIZTJDBMTFOTPSZPSNFOUBMDBQBCJMJUJFT

or lack of experience and knowledge if they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

• $IJMESFOVOEFSUIFBHFPGZFBSTTIPVMECFTVQFSWJTFEUPFOTVSFUIFZEPOPUQMBZXJUIUIFBQQMJBODF

• If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel

with a special cord available from the manufacturer or its authorized service personnel in order to avoid a

hazard.

• Machine must not be immersed for cleaning.

• $MFBOJOHBOEVTFSNBJOUFOBODFTIBMMOPUCFNBEFCZDIJMESFOVOMFTTUIFZBSFPMEFSUIBOZFBSTBOE

supervised.

• This appliance is intended to be used in household and similar applications such as:

oTUBGGLJUDIFOBSFBTJOTIPQTPGmDFTBOEPUIFSXPSLJOHFOWJSPONFOUT

oCZDMJFOUTJOIPUFMTNPUFMTBOEPUIFSSFTJEFOUJBMUZQFFOWJSPONFOUT

– bed and breakfast type environments.

• This appliance not intended to be used in applications such as:

– farm houses

• Access to the service areas permitted by Authorized Service personnel only.

• 5IF"8FJHIUFETPVOEQSFTTVSFMFWFMJTCFMPXE#"

INSTALLATION INSTRUCTIONS II2

Installation Instructions

Installation Requirements

• A secure surface capable of supporting the weight of the appliance.

• For units without an attached cord set: Appropriately sized, UL listed, grounding type power cable to meet

UIFFMFDUSJDBMTQFDJmDBUJPOTGPSUIFBQQMJBODF*GZPVIBWFRVFTUJPOTBCPVUUIFDPSSFDUDBCMFTJ[FBOEMFOHUI

DPOTVMUBRVBMJmFEJOTUBMMFS*GUIFBQQMJBODFXJMMCFIBSEXJSFEUPBKVODUJPOCPYUIFQPXFSDBCMFNVTUCFMPOH

enoughTPUIBUUIFVOJUDBOCFNPWFEGPSDMFBOJOHVOEFSOFBUI

• "HSPVOEFEFMFDUSJDBMDPOOFDUJPOUPBOFMFDUSJDBMDJSDVJUUIBUNFFUTUIFFMFDUSJDBMTQFDJmDBUJPOTPGUIF

appliance (see SPECIFICATIONS5IFDJSDVJUNVTUCFQSPUFDUFECZUIFBQQSPQSJBUFTJ[FEDJSDVJUCSFBLFS*G

ZPVBSFOPUDFSUBJOUIBUUIFFYJTUJOHDJSDVJUNFFUTUIFSFRVJSFNFOUTGPSZPVSVOJUDPOTVMUBMJDFOTFEFMFDUSJDJBO

• "XBUFSmMUSBUJPOTZTUFNJTSFRVJSFEUPNBJOUBJOUSPVCMFGSFFPQFSBUJPO8JMCVS$VSUJT$P*ODSFDPNNFOETB

8JMCVS$VSUJTBQQSPWFEXBUFSmMUFS4FFUIF$VSUJT&RVJQNFOU$BUBMPHGPSBGVMMMJOFPG8JMCVS$VSUJTBQQSPWFE

XBUFSmMUFST

• 1PUBCMFXBUFSTVQQMZMJOFDPOOFDUJPOGSPNUIFXBUFSmMUFSDBQBCMFPGTVQQMZJOHUIFNJOJNVNnPXSBUFSFRVJSFE

CZUIFTQFDJmDBUJPOT5IFXBUFSTVQQMZMJOFNVTUCFBCMFUPDPOOFDUUPUIFnBSFmUUJOHPOUIFCBDLPGUIF

VOJU4FFUIFSPECIFICATIONS section for the correct size. The water line should also be capable of being

DPOUSPMMFECZBTIVUPGGWBMWF%POPUDPOOFDUUIFXBUFSMJOFUPBTBEEMFWBMWFPSOFFEMFWBMWF

/4'*OUFSOBUJPOBMSFRVJSFTUIFGPMMPXJOHXBUFSDPOOFDUJPO

1 "RVJDLEJTDPOOFDUPSBEEJUJPOBMDPJMFEUVCJOHBUMFBTUUXPUJNFTUIFEFQUIPGUIFapplianceJTSFRVJSFE

TPUIBUJUDBOCFNPWFEGPSDMFBOJOHVOEFSOFBUI

2 5IJTFRVJQNFOUJTUPCFJOTUBMMFEXJUIBEFRVBUFCBDLnPXQSPUFDUJPOUPDPNQMZXJUIBQQMJDBCMF

federal, state and local codes.

8BUFSQJQFDPOOFDUJPOTBOEmYUVSFTEJSFDUMZDPOOFDUFEUPBQPUBCMFXBUFSTVQQMZTIBMMCFTJ[FE

installed and maintained in accordance with federal, state and local codes.

WARNING:*OTUBMMBUJPOJTUPCFQFSGPSNFEPOMZCZBRVBMJmFEJOTUBMMFS

WARNING: *NQSPQFS FMFDUSJDBM DPOOFDUJPO NBZ SFTVMU JO BO FMFDUSJD TIPDL IB[BSE 5IJT CSFXFS NVTU CF

properly grounded.

NOTICE:%0/05DPOOFDUUIJTCSFXFSUPBIPUXBUFSTVQQMZ5IFXBUFSJOMFUWBMWFJTOPUSBUFEGPSIPUXBUFS

%POPUFYDFFEUIFNBYJNVNXBUFSQSFTTVSFTUBUFEJOUIFSPECIFICATIONS section.

IMPORTANT:0CTFSWFBMMHPWFSOJOHDPEFTBOEPSEJOBODFT

#3&8&34(&/&3*$*/45"--"5*0/*/4536$5*0/4 %

5IF*OUFSOBUJPOBM1MVNCJOH$PEFPGUIF*OUFSOBUJPOBM$PEF$PVODJMBOEUIF'PPEBOE%SVH"ENJOJTUSBUJPO

'%"'PPE$PEFNBOVBMEJSFDUUIBUUIJTFRVJQNFOUNVTUCFJOTUBMMFEXJUIBEFRVBUFCBDLnPXQSFWFOUJPO

JODPNQMJBODFXJUIGFEFSBMTUBUFBOEMPDBMDPEFT'PSVOJUTJOTUBMMFEPVUTJEFPGUIF64"NBLFTVSFUIBU

the installation is in compliance with the applicable plumbing/sanitation code for your area.

INSTALLATION INSTRUCTIONS II22

Style may vary

Style may vary

Strain

relief

220 Volt

power

cable

Terminal

block

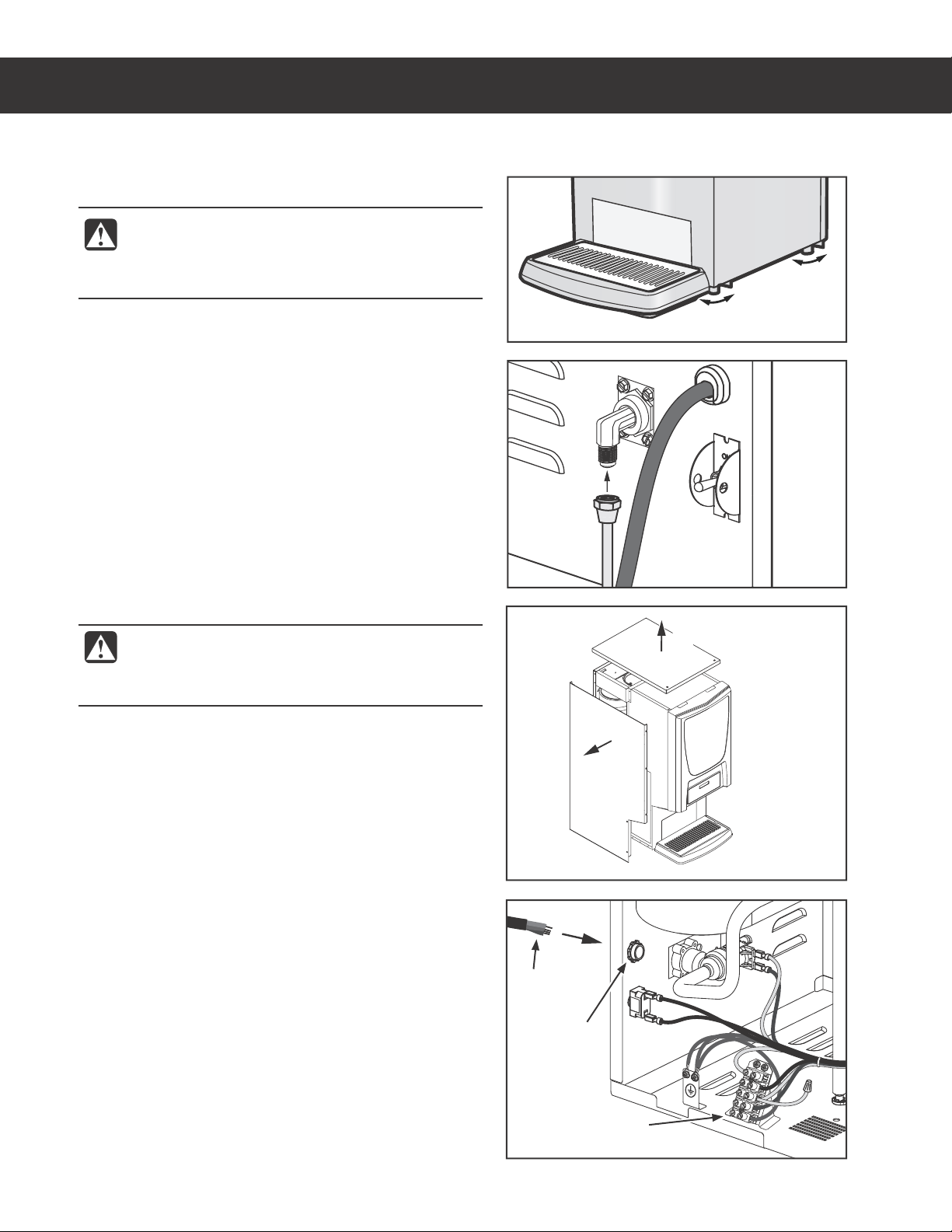

Installation

Leveling

1 Position the dispenser on the counter top. Level it left

to right and front to back by turning the bottom of the

legs.

Connect the Water Supply

2 Flush the water supply line prior to installation to

QVSHFBJSBOEEFCSJTGSPNUIFXBUFSmMUFSBOEUVCJOH

3 $POOFDUUIFXBUFSTVQQMZMJOFUPUIFnBSFmUUJOHPOUIF

back of the unit. Leave the water supply valve closed

until power is connected.

Connect the Wiring - Dual Voltage Units to be Operated

220-240 Volts Only

4 Remove the top cover and the left side panel to

expose the terminal block.

5 Disconnect and cap the jumper wire between the “C”

and “N” terminals on the terminal block.

6 Loosen the strain relief on the back panel.

7 Disconnect the 120 Volt power cable from the terminal

block and pull the cable out through the back.

8 Feed the end of the 220-240 Volt power cable through

the strain relief, into the unit.

9 Connect the wires on the power cable to the terminal

block inside.

10 Tighten the strain relief and replace the side and top

panels.

11 Connect the power cable wires to the terminals in the

junction box. See the ELECTRICAL SCHEMATIC for

the power supply requirements.

WARNING: Use the leveling legs to level the

dispenser only. Do not use them to adjust

dispenser height. Do not extend them higher

than necessary.

WARNING: Turn off power to the junction box at

the circuit breaker panel before connecting the

power cable to the dispenser. Lock out and tag

the circuit breaker.

1$(5&913*/45"--"5*0/*/4536$5*0/4ø 100318A

Back of unit

d

c

INSTALLATION INSTRUCTIONS II22

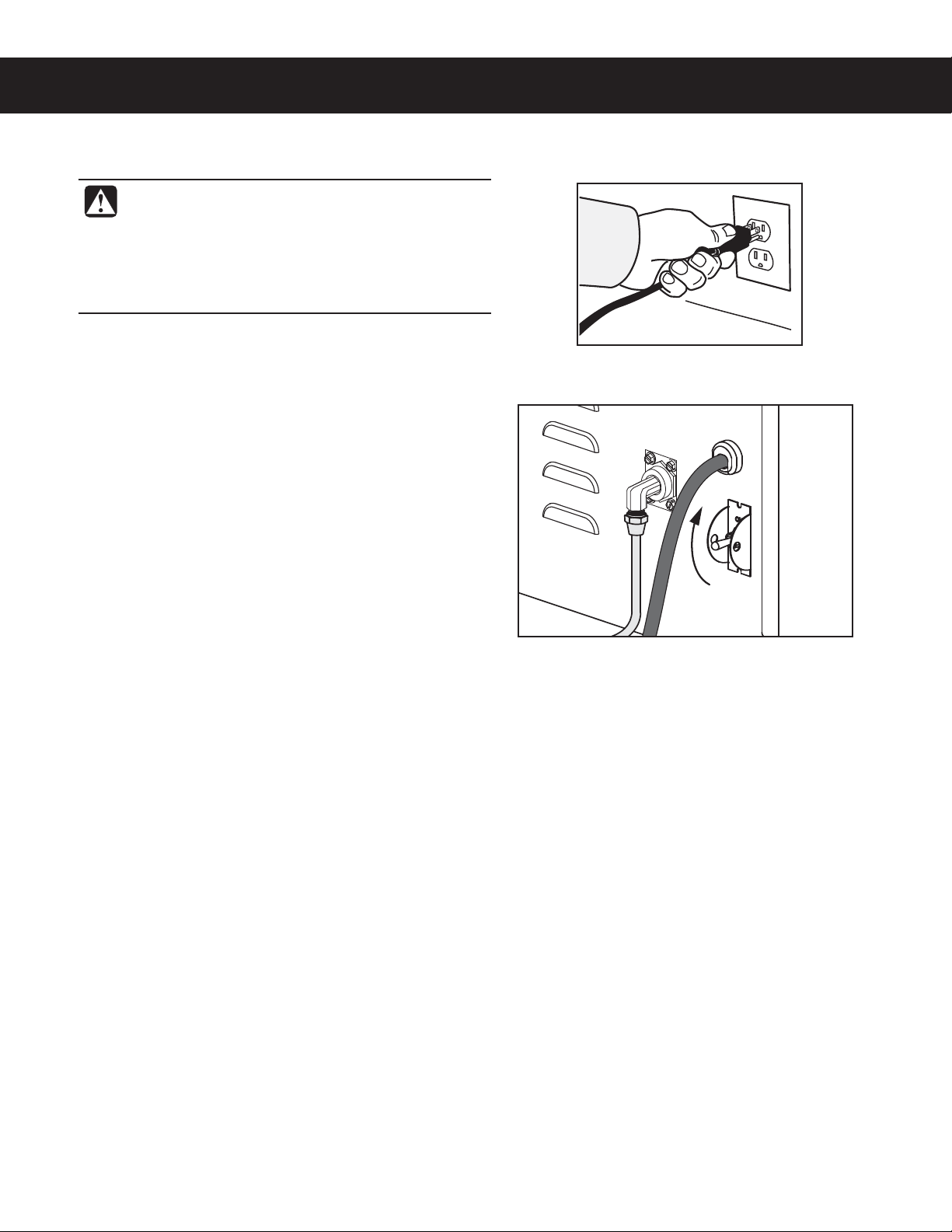

Connect the Power Cable - 120 Volt Units

12 Connect the power cord to the appropriate type of

electrical outlet.

Power Up the Unit

13 Turn on the water supply valve.

14 Make sure that the circuit breaker supplying power to

the dispenser is on.

15 Turn the toggle switch on the back of the dispenser to

UIF0/QPTJUJPO5IFXBUFSUBOLXJMMTUBSUUPmMM8IJMF

UIFUBOLJTmMMJOHJOTQFDUUIFXBUFSTVQQMZMJOFGPSMFBLT

16 8IFOUIFXBUFSMFWFMJOUIFUBOLSJTFTUPUIF

correct volume, the heating element(s) will turn on

automatically. Depending on the incoming water

UFNQFSBUVSFBOEUIFFMFDUSJDBMTQFDJmDBUJPOTUIFXBUFS

tank typically requires 1 hour to reach the factory set

PQFSBUJOHUFNQFSBUVSF8IFOUIFXBUFSIBTIFBUFE

“Ready to Dispense” should be on the display.

17 If the unit is equipped with a hot water faucet, before

VTJOHUIFVOJUGPSUIFmSTUUJNFEJTQFOTFPVODFTPG

hot water from the hot water faucet to help purge air

from the tubing inside the unit.

18 Dispense at least 12 ounces from each spout, to purge

any remaining air from the tubing. See OPERATING

INSTRUCTIONS. During initial dispensing, and

XIFOFWFSUIFmMUFSJTSFQMBDFEZPVNBZIFBSUIF

TPVOETPGBJSCFJOHQVSHFEGSPNUIFmMUFSUVCJOHBOE

water tank.

WARNING: Connect the power cord to the

appropriate type and size electrical outlet. If the

electrical outlet is not compatible with the power

cord, have it upgraded by a licensed electrician.

Do not modify the power plug. Do not use an

extension cord. Do not use a power cord/plug that

is damaged.

1$(5&913*/45"--"5*0/*/4536$5*0/4ø 100318A

OPERATING INSTRUCTIONS OI33

1$(501&3"5*/(*/4536$5*0/4øø "

Dispensing

2 Open the front panel. On

some models the panel

swings to the right, on others,

the panel swings up. Turn

the elbow on each canister

UPCFmMMFEVQXBSEUIFOMJGU

each canister up and out. Fill

with powdered cappuccino

product.

Reinstall each canister in the

same spot it was removed

from. Properly mate the

gear socket on the back of

each canister with the gear

inside the dispenser. Turn the

canister elbows downward

and close the door.

4 Place a cup under the spout

GPSUIFEFTJSFEnBWPS*GUIF

dispenser is set for iced

DPGGFFmMMUIFDVQXJUIJDF

mSTU

Preset Dispense Models:

5 Push and release the

dispensing button for the

EFTJSFEnBWPSBOEDVQ

size. Remove the cup when

QSPEVDUTUPQTnPXJOH

The unit should be ON.

$POmSNUIJTBUUIFSFBSUPHHMF

switch. “Ready to Dispense”

should be on the display.

Manual Dispense Models:

6 Push and hold the dispensing

CVUUPOGPSUIFEFTJSFEnBWPS

Release the button when the

cup is ¾ full. Remove the cup

XIFOQSPEVDUTUPQTnPXJOH

WARNING - TO AVOID SCALDING, AVOID SPLASHING. Keep body parts clear of the spout during

dispensing. Do not remove the cup during dispensing.

The G3 dispenser is factory preset for optimal performance.

d

d

e

5B5A

c

c

e

WARNING: HOT SURFACES - To avoid injury, allow the dispenser to cool before cleaning.

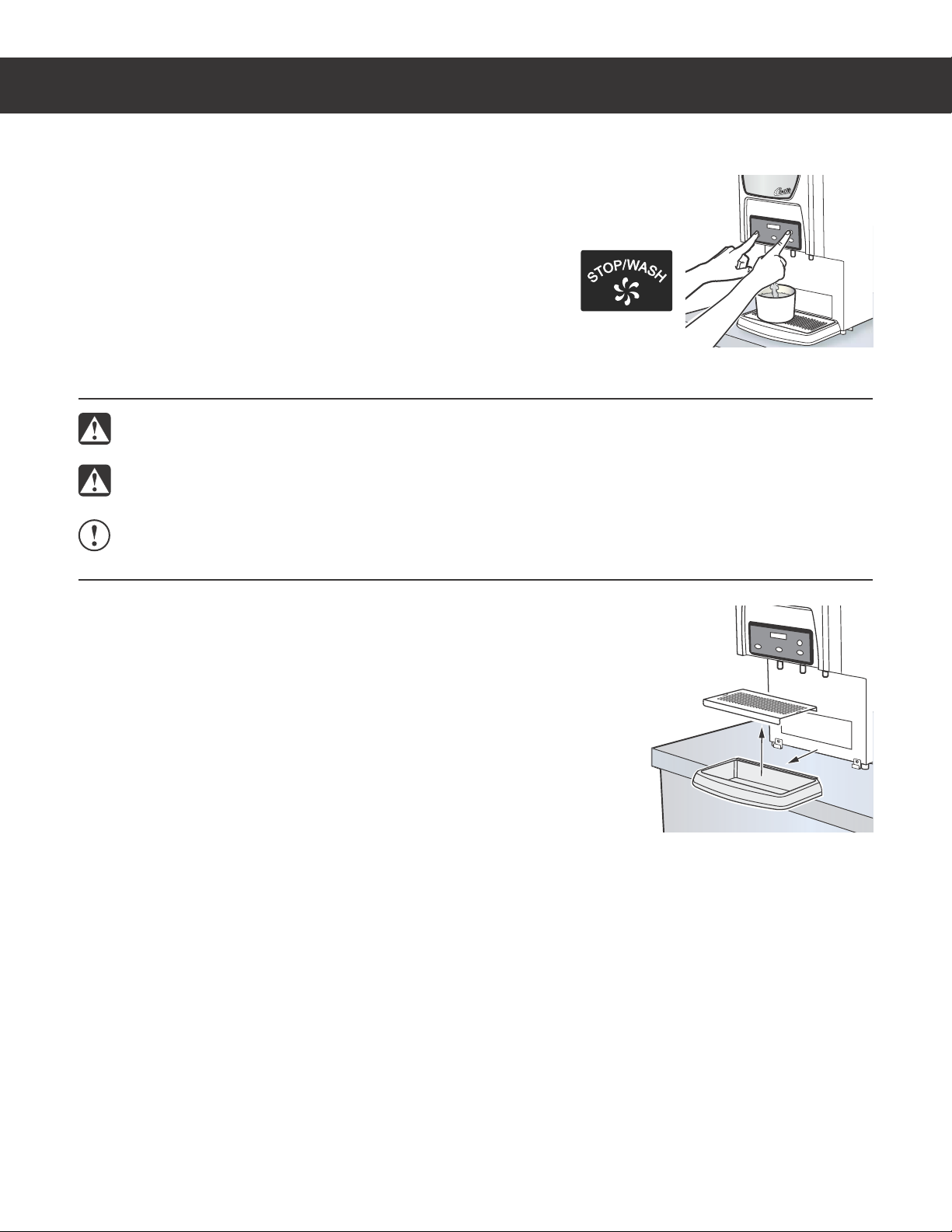

1 Make sure power is ON.

2 Place a container under the dispense spout to catch the rinse water.

3 3JOTFFBDInBWPSCZQSFTTJOHBOEIPMEJOHUIF8"4)CVUUPOXIJMF

BUUIFTBNFUJNFQSFTTJOHPOFPGUIF164)EJTQFOTJOHCVUUPOT

POUIFDPOUSPMQBOFM$POUJOVFIPMEJOHUIF8"4)CVUUPOVOUJMUIF

water running from the spout runs clear.

NOTICE - Do not use cleaning liquids, compounds or powders containing chlorine (bleach) or corrosives.

5IFTFQSPEVDUTQSPNPUFDPSSPTJPOBOEXJMMEBNBHFUIFmOJTIFT USE OF THESE PRODUCTS WILL VOID

THE WARRANTY.

CLEANING INSTRUCTIONS CI19

Cleaning the Exterior - Daily

Spout Cleaning - Every 3 or 4 Hours

41&$*"-5:%*41&/4&3$-&"/*/(*/4536$5*0/4 "

WARNING: DO NOT immerse the dispenser in water or any other liquid.

The dispenser should be OFF.5VSOUIFCSFXFSPGGCZnJQQJOHUIFSFBSUPHHMF

switch to the OFF position.

1 8JQFUIFFYUFSJPSEJTQFOTFSTVSGBDFTXJUIBEBNQDMPUIUPSFNPWFTQJMMTBOE

debris.

2 -JGUUIFESJQUSBZVQUPSFNPWF3FNPWFUIFMPVWFSFEHSJMMGSPNUIFESJQUSBZ

UIFOXBTIPVUUIFUSBZXJUIUIFEFUFSHFOUTPMVUJPO8BTIUIFMPVWFSFEHSJMM

then rinse both pieces with water and dry.

3 8JQFBOEDMFBOUIFEJTQFOTJOHBSFBXJUIUIFEFUFSHFOUTPMVUJPOUIFO

reinstall the drip tray.

11 Reassemble the cleaned whipper assembly parts into the unit in

reverse order.

CLEANING INSTRUCTIONS CI20

CAFEPC, PCGT WHIPPER ASSEMBLY, CLEANING INSTRUCTIONS 120517NC

Cleaning The Whipper Plate Assembly CAFEPC and PCGT Series - Weekly or As Needed

The dispenser should be OFF. Turn the dispenser off by

turning the rear toggle switch to the OFF position.

1 Remove the dispensing spout from the whipper

chamber. Clean the inside using a narrow brush.

2 Pull the upper mixing cup forward and twist it up and to

the left to separate it from the lower mixing cup.

3 To remove the lower mixing cup, pull it up and forward to

free it from the hot water inlet.

4 Take hold of the whipper chamber. Turn it clock-wise to

free it from the mounting plate.

5 Pull the whipper propeller off of the motor shaft.

6 Wash, rinse, sanitize and air dry the whipper assembly

parts using the 3-sink method. Wash in a mild solution of warm water

and dishwashing detergent, rinse in warm clean water and sanitize in

a commercial sanitizer suitable for food grade applications. Sanitize

according to the directions on the package. Air dry all parts.

7 Clean the motor shaft with a cloth and mild detergent before

removing the mounting plate.

8 Twist the mounting plate clockwise and pull it off of the motor shaft.

IMPORTANT - Do not remove the mounting pillars to remove the

mounting plate.

9 $MFBOUIFBSFBCFIJOEUIFNPVOUJOHQMBUFBOEUIFXBUFSJOMFUmUUJOH

10 Lubricate the center seal of the mounting plate with food grade

lubricant before reinstalling (See Figure 3).

CAUTION: When replacing the propeller, line up the “D” shaped

mark on the propeller with the “D” shape on the motor shaft. Failure

to line up the propeller properly will cause it to fuse with the shaft.

This condition is not covered under the warranty.

WASH

SANITIZE

RINSE

Spout

Whipping

chamber

Propeller

Mounting

pillar

Mounting

plate

Motor Shaft

Upper

mixing

cup

Hot water

inlet

Lower

mixing

cup

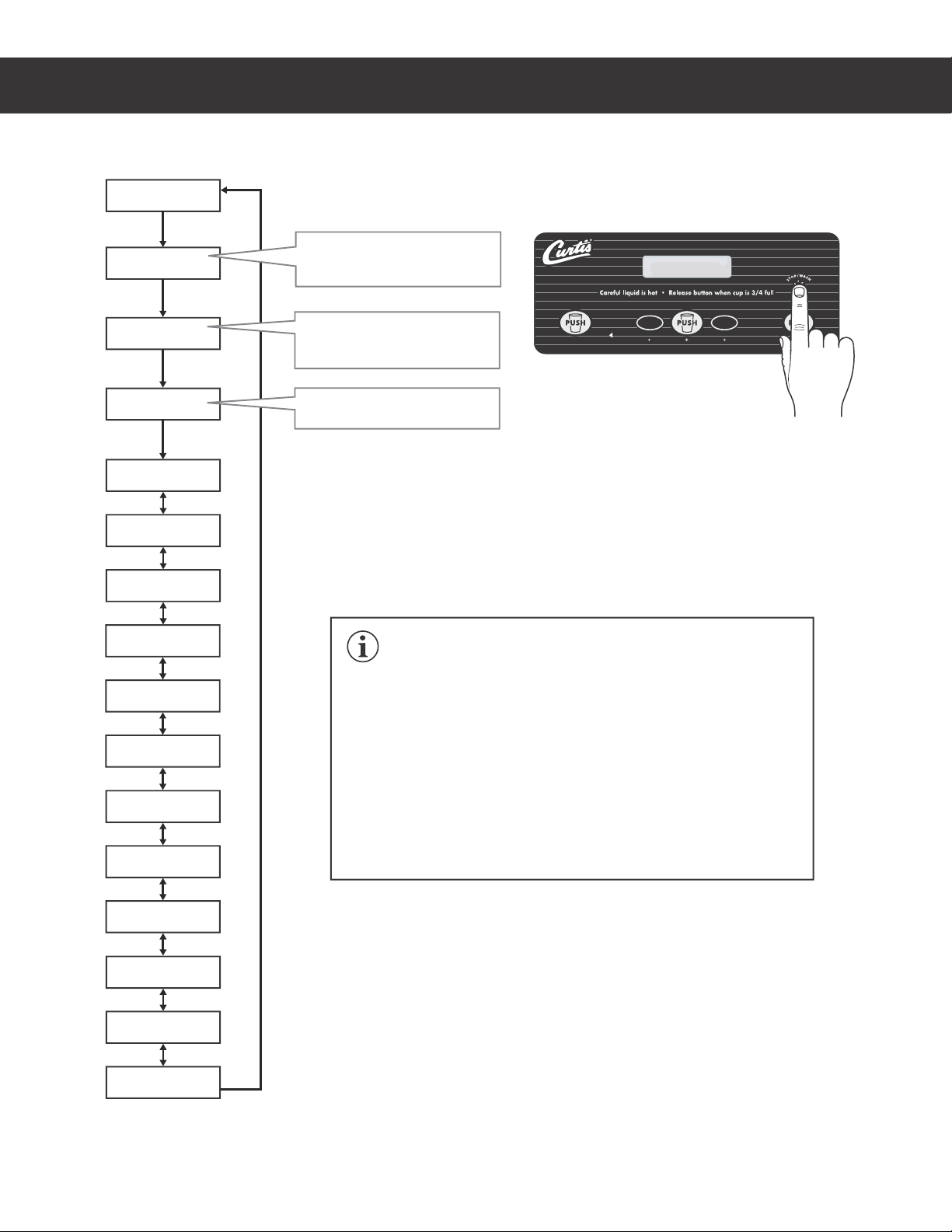

PROGRAMMING GUIDE PG12

With unit ON, press and hold

STOP/WASH button for 10

seconds.

While pressing STOP/WASH,

“Washing...Select Station”

appears on the display.

After 10 seconds, the

programming menu appears.

Label style and STOP/WASH

button location varies.

On PCGT6 models, the buttons

are located inside the front door.

1Not present on Pre-Set Dispense models

2Not present on PCGT6 series models.

1

1, 2

1, 2

1, 2

1, 2

CURTIS

Ready to Dispens

CURTIS

Ready to Dispens

Entering

Programming mode

Washing...

Select Station

To enter programming mode:

<Program Menus>

ÅSelect Æ

Manual Dispense

ÅSelect Æ

Dispense By Time

ÅSelect Æ

Temperature

ÅSelect Æ

Powder % Ratio

ÅSelect Æ

Dispense Odom.

ÅSelect Æ

Dispense Total

ÅSelect Æ

Service Call

ÅSelect Æ

Banner Name

ÅSelect Æ

Valve Calibrate

ÅSelect Æ

Model Select

ÅSelect Æ

Exit

ÅSelect Æ

Language

ÅSelect Æ

1$(5130(3"..*/((6*%&ø /$

IMPORTANT: All programming functions are performed with the

three center buttons.

The symbols below the buttons are:

Ż 4DSPMM61

~4&-&$5PS&/5&3UPTBWFOFXQBSBNFUFS

Ź4DSPMM%08/

Once you enter programming mode, press Żor Źto scroll UP or DOWN

through the various functions/features. Press ~4FMFDUUPNBLFDIBOHFT

to the function/feature displayed. Then press Żor Źto scroll through

the various available settings. See Programming Options for detailed

descriptions.

Programming Options

4FFUIFmSTUQBHFPGUIFPROGRAMMING GUIDE for instructions on how to access the programming menu.

To exit programming mode, press Źuntil EXIT appears on the display, then press ~.

Manual Dispense - All stations are set to Manual Dispense mode at the factory (except on Pre-Set Dispense

NPEFMT5IF.BOVBM%JTQFOTFQSPHSBNNJOHPQUJPOJTVTFEUPDIBOHFTUBUJPOTUIBUBSFTFUUP%JTQFOTF#Z

5JNFTFFCFMPXUP.BOVBM%JTQFOTFNPEF1SFTT~to access, then press the PUSH button for the station

to be set to Manual Dispense. “Saving Complete!” will appear on the display, then return to the programming

menu. Repeat the process to set other stations, if desired, or press Źto go to the next menu.

Dispense by Time - (default on Pre-Set Dispense Models) sets the unit

to dispense the amount of product by time rather than holding the button

until the desired amount is dispensed. Place a cup below the spout for

the desired station. Press ~to access. Press the PUSH button for the

TUBUJPOUPCFTFUUP%JTQFOTF#Z5JNF.BOVBM%JTQFOTFXJMMCFEJTBCMFE

GPSUIBUTUBUJPO5IFEJTQMBZXJMMSFBEi5P#FHJO1VTI164)w1VTIUIF

desired PUSH button. Hot water will start to dispense and the screen

will display “To Finish Push PUSH”. When the desired volume is reached

QVTIUIFCVUUPOBHBJO5IFEJTQMBZXJMMHPCBDLUPUIFQSPHSBNNJOHNFOV3FQFBUUIFQSPDFTTUPTFUPUIFS

stations if desired, or press Źto go to the next menu.

Temperature - TFUTUIFUFNQFSBUVSFPGUIFXBUFSIFMEJOUIFXBUFSUBOL5IFSBOHFJT'UP'¡$UP

¡$5IFSFDPNNFOEFEUFNQFSBUVSFGPSJDFEDPGGFFVOJUTJT¡'5IFSFDPNNFOEFEUFNQFSBUVSFGPSBMM

PUIFSVOJUTJT¡'¡$1SFTT~to access. Press Żor Źto choose the desired temperature. Then press

~to set and exit. Press Źto continue to the next menu.

Powder % Ratio - sets the ratio of product powder dispensed. The

higher the powder ratio, the richer the product dispensed. The factory

EFGBVMUTFUUJOHJT5IFSBOHFJTGSPNIPUXBUFSUP

HSBNTQFS1SFTT~to access. Press the PUSH button for the

desired station. Press Żor Źto increase or decrease the ratio, then

press ~to set and exit. Press Źto continue to the next menu.

Service Call - sets the service phone number that appears on the

display when the unit detects a SENSOR ERROR or WATER LEVEL

ERROR. Press ~to access. Press Żor Źto choose the number to be

changed. Then press ~repeatedly to change the number value. Press

Żor Źto choose the next number to change or choose ex and press ~

to exit. Repeat the process to set other stations, or press Źto go to the

next menu.

Banner Name - changes the banner name that appears on the display (the factory default is CURTIS/P

CBOOFSOBNFBQQFBSTXIFOBMMCMBOLTBSFFOUFSFE1SFTT~to access. Press Żor Źto choose the letter to

change. Then press ~repeatedly to change the letter. Press Żor Źto choose the next number to change or

choose ex and press ~to exit. Press Źto continue to the next menu.

Dispense Odom1, 2 - displays the total dispense cycles since the odometer was last reset. Press ~to access.

Press Żto exit or ~reset and exit. Press Źto continue to the next menu.

PROGRAMMING GUIDE PG12

1$(5130(3"..*/((6*%&ø /$

Default Settings Time Dispense Settings

Preset Dispense Models

Cup Size Time Setting

LARGE 25.5 Seconds

MEDIUM 16.5 Seconds

SMALL 12.5 Seconds

1Not present on Pre-Set Dispense models

2Not present on PCGT6 series models

% Ratio Grams*

10% 7 gm

20% 14 gm

30% 21 gm

40% 28 gm

50% 35 gm

60% 42 gm

70% 49 gm

80% 56 gm

90% 63 gm

100% 70 gm

*Approximate

PROGRAMMING GUIDE PG12

1$(5130(3"..*/((6*%&ø /$

Programming Options (cont.)

Dispense Total1, 2 - when accessed, displays the total dispense cycles on the unit. It cannot be reset. The

display returns to the previous screen automatically after a few seconds. Press Źto continue to the next

menu.

Language1, 2 - DIBOHFTUIFMBOHVBHFUIBUBQQFBSTPOUIFEJTQMBZUIFGBDUPSZEFGBVMUJT&OHMJTI1SFTT~

to access. Press Żor Źto choose the desired setting, then press ~to exit. Press Źto continue to the next

menu.

Valve Calibrate1-QPVSTXBUFSPOMZGSPNUIFTQPVUGPSTFDPOETUPBMMPXUIFEVNQWBMWFTUPCF

calibrated. See Dump Valve Calibration in the Troubleshooting Section for the complete dump valve calibration

procedure. Press ~to access. The bottom portion of the display will read “Select Station”. Place an empty

measuring cup under the dispensing spout for the valve to be calibrated. Press the PUSH button above the

DVQ8BUFSXJMMEJTQFOTFGPSTFDPOET1SFTT~UPNFBTVSFnPXSBUFGPSBEJGGFSFOUWBMWFPSQSFTTŹto

continue to the next menu.

Model Select1, 2 - changes the model number. The unit must be set to the proper model number for proper

operation. Press ~to access. Press Żor Źuntil the model number matching the model number label on the

unit appears, then press ~to exit. Press Źto continue to the next menu.

1Not present on Pre-Set Dispense models

2Not present on PCGT6 series models

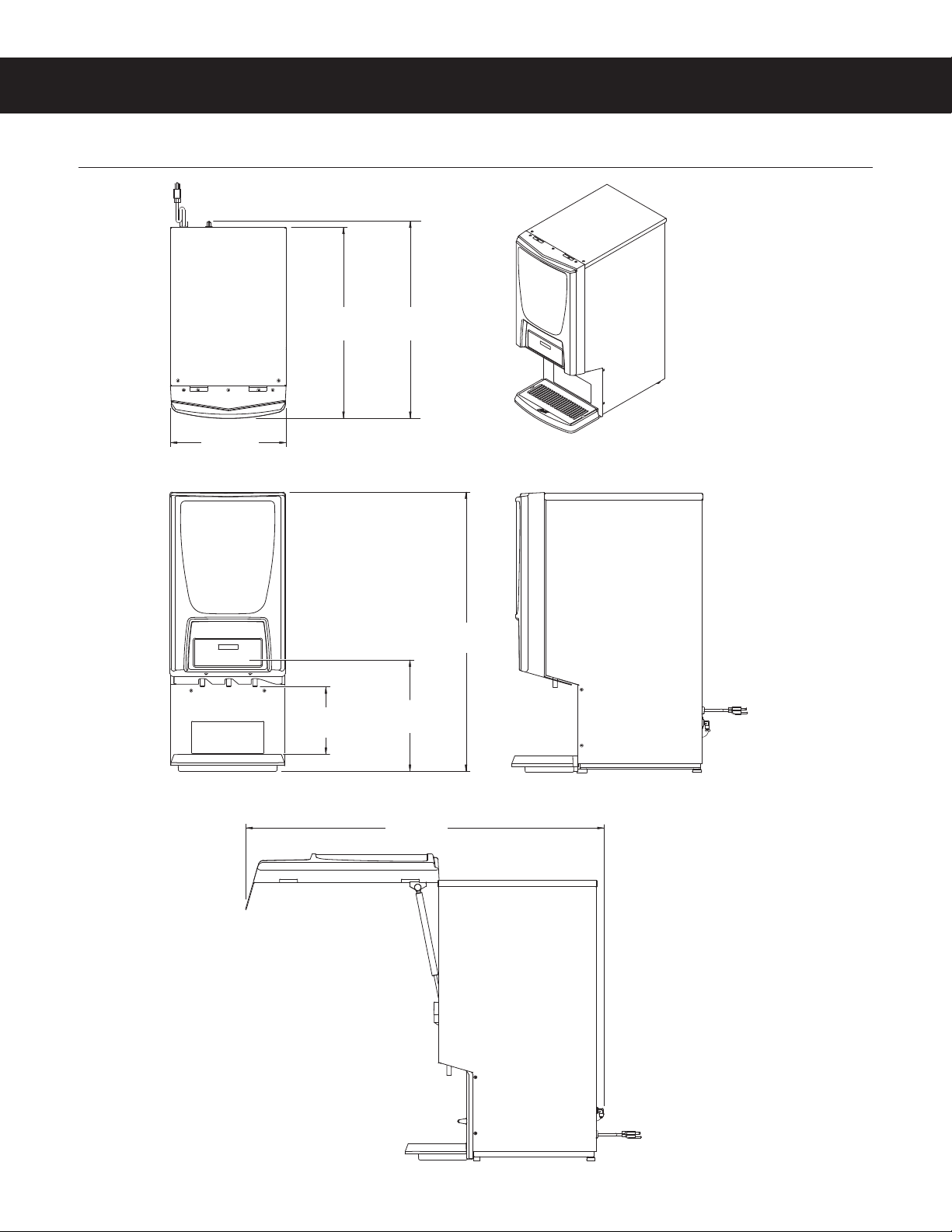

ROUGH-IN DRAWINGS RD46

PCGT3

PCGT3, ROUGH-IN DRAWING 061319B

14.25 in

[36.2 cm]

8.38 in1

[21.3 cm]

1CUP CLEARANCE

2DISPENCE BUTTON HEIGHT

13.94 in2

[35.5 cm]

34.78 in

[88.3 cm]

23.72 in

[60.2 cm]

24.54 in

[62.3 cm]

44.07 in

[111.9 cm]

LIFT DOOR

MODELS

ILLUSTRATED PARTS LIST IP75

PCGT3, ILLUSTRATED PARTS/RECOMMENDED PARTS 022519B

8

10

2

19C

2

14

13

19B

15

14

11

4

13

15

16

17

22

23

14

PCGT3300

PCGT3, PCGT3DV, PCGT3800

PCGT3700, PCGT3900, PCGT3E

MISCELLANEOUS

14

7

2

1A

1B 1D

20 10

21

19A

1C

20

8

8

6A

6B

6C

6D

9A

9B

9A

5

16

6A

6A

3A

3B

3C 3A

3A

12

PCGT3 - Door Assemblies - Exploded View

7

21

7

20

9A

21

ILLUSTRATED PARTS LIST IP75

PCGT3, ILLUSTRATED PARTS/RECOMMENDED PARTS 022519B

ITEM # PART # DESCRIPTION

1A CA-1184K1,2,4,6,7 KIT, DOOR ASSY PCGT3

(UNITS BUILT 08/01/11 AND LATER,

REPLACES CA-1172, CA-1101 & WC-37461)

1B CA-11581,2,4,6 DOOR/WINDOW SUPPORT PCGT3

(UNITS BUILT BEFORE 08/01/11)

1C CA-1184K13KIT, DOOR ASSY PCGT3300

(REPLACES CA-1172-101 & CA-1101)

1D CA-1184K25COVER, DOOR PCGT3800

(REPLACES CA-1172-102 & CA-1101)

2WC-39203 LABEL, SERVICING INSTRUCTIONS PC-

1/2/3/4D/CK-3D/HC-1D

3A CA-1109-011,2,3,5,7 FILM, CURTIS LOGO PCGT-3

3B CA-1148-014FILM, CURTIS LOGO PRE-DISPENSE PCGT3

3C CA-1144-016FILM, LIGHT BOX ICED COFFEE CURTIS

4 WC-380715LABEL, HOT WATER TLP/PC’s

5 WC-1705SWITCH, PUSHBUTTON-RED N.O. PCGT5 HOT

WATER KIT

6A WC-399581,2,3,5,6,7 LABEL, DOOR UCM PCGT3 CURTIS LOGO

(UNITS BUILT 08/01/11 AND LATER)

6B WC-397631,2,6 LABEL, UCM & DOOR PCGT3 CURTIS (UNITS

BUILT BEFORE 08/01/11)

6C WC-399774LABEL, UCM & OUTER PRE-SET DISPENSE

PCGT3 ADA (UNITS BUILT 08/01/11 AND

LATER)

6D WC-396184LABEL ASSY, UCM & DOOR PCGT3 WITH

PRE-SET DISPENSING CURTIS (UNITS BUILT

BEFORE 08/01/11)

7 CA-1176K* KIT, LAMP ASSY LED 120V 9W CAFEPC’s

ITEM # PART # DESCRIPTION

7 CA-1176K KIT, LAMP ASSY LED 120V 9W CAFEPC’s

Recommended Parts to Stock

ITEM # PART # DESCRIPTION

8CA-11011,2,4,6 WINDOW, FRONT CLEAR PCGT-3 (UNITS

BUILT BEFORE 08/01/11)

9A WC-7781,2,3,5,6,7 CONTROL MODULE, UCM 120V PCGTs

9B WC-7954CONTROL MODULE, UCM 120V EXPR/PCGT3

PRESET DISPENSE

10 CA-11351,2,4,5,6,7 LATCH ASSY, DOOR SIDE MOUNT PCGT’S/

CAFEPC’S/SD2’S

11 CA-10443BUMPER, BUTTON BLACK

12 WC-39350-02 LABEL, PANEL FLAVOR PCGT’S CURTIS

13 WC-49373GAS, SPRING 35LBS PCGT3300

14 WC-49333RECEPTACLE QUICK RELEASE GAS SPRING

15 WC-49313MOUNT, LOWER BALL STUD GAS SPRING

16 WC-49303MOUNT, UPPER BALL STUD GAS SPRING

17 WC-49353HINGE, ASSY DOOR PCGT5300

18 WC-134343HARNESS DOOR EXTENSION PCGT PCGT5300

(NOT SHOWN)

19A#CA-1184KDC1,2,4,6,7 KIT, DOOR COMPLETE PCGT3

(REPLACES WC-68165-101)

19B#CA-1184K1DC3KIT, DOOR COMPLETE PCGT3300

19C#CA-1184K2DC5KIT, DOOR COMPLETE PCGT3800

20 WC-4442 SCREW, 8-32x3/8 PH HD TRUSS BLACK

21 WC-4403 SCREW, 6-32x3/8 PHIL ROUND HD

22 WC-4468 SCREW, 8-32x5/8 PH HD TRUSS SS

23 WC-4426 SCREW, 8-32x3/8 PH HEAD TRUSS

ITEM # PART # DESCRIPTION

13 WC-4937 GAS, SPRING 35LBS PCGT3300

PCGT3 - Door Assemblies - Parts List

1PCGT3, 2PCGT3DV, 3PCGT3300, 4PCGT3700, 5PCGT3800, 6PCGT3900, 7PCGT3E

$OVRUHSODFHVÁRUHVFHQWDQGROGHUVW\OH/('OLJKWDVVHPEOLHVXVHGRQROGHUXQLWV

#&RPSOHWHGRRUDVVHPEOLHVLQFOXGHWKHSODVWLFIURQWDQGZLQGRZEXW'2127LQFOXGHWKH

8&0DQGOLJKWDVVHPEO\

ILLUSTRATED PARTS LIST IP75

PCGT3, ILLUSTRATED PARTS/RECOMMENDED PARTS 022519B

2

11A

4

5A

5B

6A

6B

11B

1A

1B

7

10

8

13

12

9

3A

3B

PCGT3 - Exterior - Exploded View

Door assemblies:

see previous pages

ILLUSTRATED PARTS LIST IP75

PCGT3, ILLUSTRATED PARTS/RECOMMENDED PARTS 022519B

ITEM # PART # DESCRIPTION

1A WC-581101,2,4,5,6,7 COVER, TOP PCGT3

1B WC-58110-1013COVER, TOP PCGT3300 FOR UNITS W/FRONT

LIFT DOOR

2 WC-68123 PANEL, SIDE LEFT PCGT3/5

3A WC-58351K1,2,3,4,6,7 KIT, ALCOVE PCGT3*

3B WC-58352K5KIT, ALCOVE PCGT3800*

4 WC-2401-P ELBOW 3/8 NPT X 1/4 FLARE PLTD

5A WC-681211,2,4,5,6,7 PANEL, SIDE RIGHT PCGT3/5

5B WC-68121-1013PANEL, SIDE RIGHT PCGT5300

6A WC-12001,2,3,4,5,6 CORD, 14/3 SJTO 6’ BLK W/PLUG

6B WC-1231-1027CORD, 2.5 mm² 90ºC 36A 450/750 V STRIPPED

W/FERRULES ONE END

ITEM # PART # DESCRIPTION

6 WC-1200 CORD, 14/3 SJTO 6’ BLK W/PLUG

Recommended Parts to Stock

ITEM # PART # DESCRIPTION

7 WC-3503 LEG, 3/8”-16 STUD SCREW BUMPER

8WC-68160 SCREEN, DRIP TRAY PCGT3

9CA-1160 DRIP, TRAY PLASTIC PCGT3

10 WC-3518 LEG, GLIDE 3/8”-16 STUD SCREW

11A WC-14081,3,4,5,6,7 CORD GRIP, 7/8” O.D.

11B WC-14122CORD GRIP, 3/4” FOR METAL CORD TO

.81”OD

12 WC-390503 LABEL, SPLASH PANEL CUP LOCATOR

PCGT3

13 WC-58274 RETAINER, DRIP TRAY PCGT6

ITEM # PART # DESCRIPTION

8 WC-68160 SCREEN, DRIP TRAY PCGT3

PCGT3 - Exterior - Parts List

1PCGT3, 2PCGT3DV, 3PCGT3300, 4PCGT3700, 5PCGT3800, 6PCGT3900, 7PCGT3E

,QFOXGHVODEHODQGGULSWUD\UHWDLQHUFOLSVLWHPVDQG

ILLUSTRATED PARTS/RECOMMENDED PARTS IP75

PCGT3, ILLUSTRATED PARTS/RECOMMENDED PARTS 022519B

15

4

5

6

8

7

23

37

38

13

PCGT3 - Interior Components - Exploded View

11

25

12

26

28

30

31

19A

19B

22

29

3A

3B

3C

2

32

33

10

34

27

21

1

39

36

24

9

17 35A

35B

20

14

Water tanks assemblies

- See section IP76 for single voltage models

- See section IP77 for dual voltage models

- See section IP80 for export models

18

This manual suits for next models

6

Table of contents

Popular Dispenser manuals by other brands

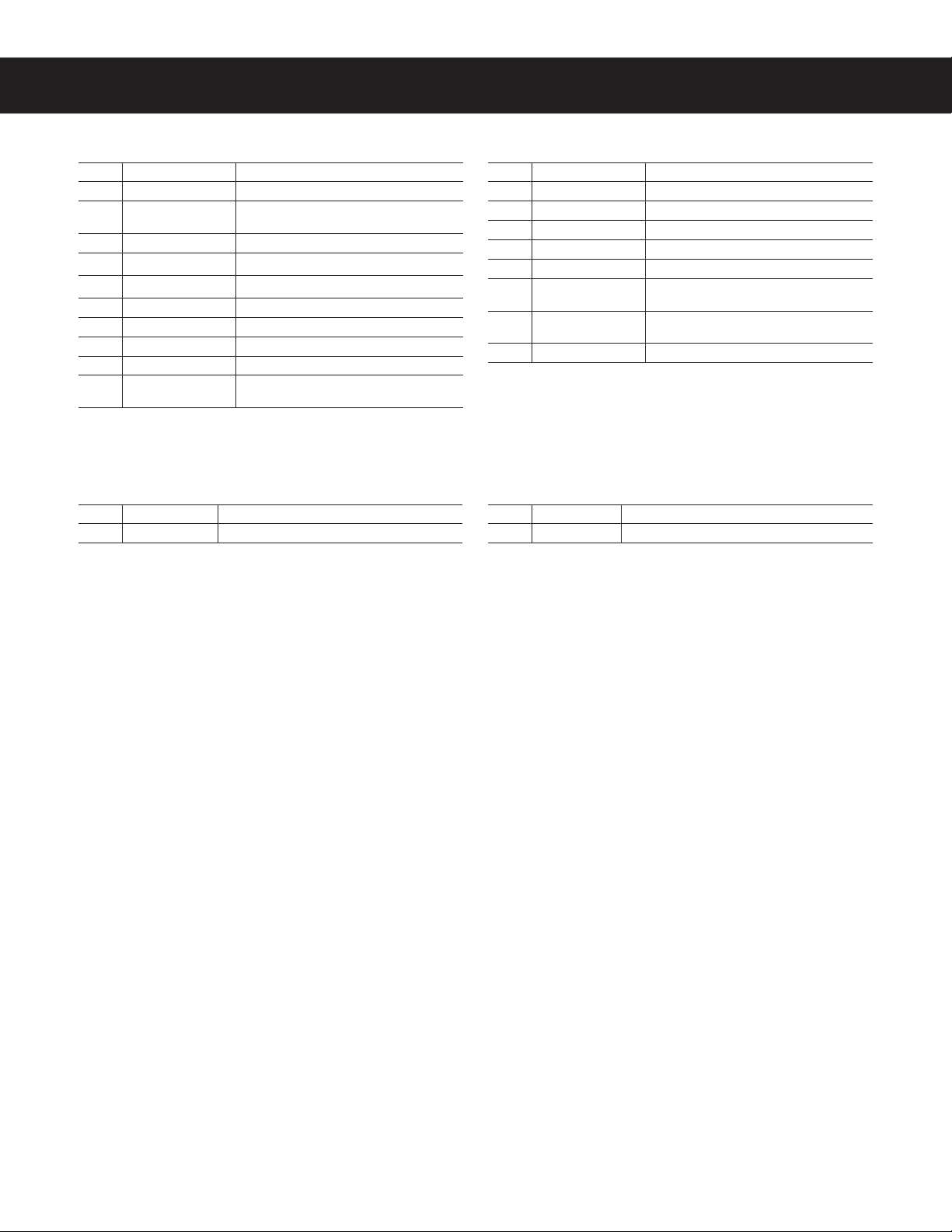

Sub-Zero

Sub-Zero BI-48SD Specifications

Royal Catering

Royal Catering RCSD-4 user manual

E-Pill

E-Pill MedSmart Voice Plus instruction manual

Gloria

Gloria CleanMaster PERFORMANCE CM 12 manual

Nordson

Nordson DispensGun user manual

AMERICAN SPECIALTIES

AMERICAN SPECIALTIES EZ FILL 0394 Series quick start guide