WARRANTY POLICY - Effecttive from 1st March 2010

Warranty applies to equipment manufactured by Williams

Refrigeration and equipment bearing the Williams name plate and

serial number identification tag.

We undertake, in conjunction with the supplying agent, distributor or

representative, to repair free of charge any such piece of equipment or

part thereof used which is found to be faulty in either materials or

workmanship.

Products Covered

A24 months Warranty from the original date of purchase is given to

the following Williams equipment:

Garnet / Sapphire / Zircon / Jade / Amber (stainless) /

Mobile Heated / Mobile Refrigerated.

Reach-in Blast Chillers / Reach-in Blast Chillers Freezers.

Opal / Emerald / Onyx / Aztra / Salad Counters.

Crystal Bakery Cabinets and Counters.

A12 months Warranty from the original date of purchase is given to

all other Williams equipment including:

All Modular Products (including Coldrooms).

Remote Systems (including Glycol).

Bottle Coolers.

Multidecks.

GEM Product Range.

Bottle Well / Meat Freezer Well.

Thermowell.

White Goods.

Non Standard Products.

Warranty Terms

The equipment has been installed correctly and has not been subject

to misuse or abuse but is functioning correctly.

The equipment was purchased by the authorised supplying distributor

direct from Williams Refrigeration and not through a wholesales or

other supplier whose warranty may be different.

The Warranty Policy shall be non-transferable.

Replacement of defective equipment can only be made with the

approval of Williams Refrigeration.

Any repair under warranty will only be carried out in its position of

operation or in a suitable location on the customer’s premises. If the

product has to be removed for security or any other reason, this will be

subject to additional charge (may include hydrocarbon charged

equipment).

Warranty work will be covered by Williams Refrigeration or by one of

its appointed agents between the hours of 8.00am and 5.30pm

Monday to Friday.

Exceptions to Standard Warranties

Second hand equipment.

The Standard Warranty is for Mainland GB only (does not cover

Marine equipment).

Any third party item(s) connected to the equipment that may affect

performance.

Components inlcuding gaskets, doors / drawers, handles, shelves,

trayslides, all internal fixings, plug and lead, connectors, the outer

shell, castors / legs, food probes, refrigerant and blockages as well

as consumable items such as (but not limited to) batteries, fuses,

light bulbs, printer cartridges, keys, glass and paper roll.

Any fault not reported within 10 working days of being discovered.

No claim shall exceed the original selling price.

Where equipment is manufactured to the customers’ own design,

Williams Refrigeration will not be liable for any non performance or

operation of the equipment as a result of a design fault.

The customer permits persons other than those authorised by

Williams Refrigeration to perform or effect repairs or adjustments to

the equipment.

Repairs are made using spare parts or replacements not of the

same make as those supplied originally as components of the

equipment unless authorised by Williams Refrigeration.

If authorised representatives of Williams Refrigeration are denied full

and free rights of access to the equipment for inspection during

normal business hours as previously stated.

The customer has not properly maintained the equipment or carried

out annual servicing, including cleaning the condenser, in

accordance with instructions, literature or directions issued

by Williams Refrigeration. (Operating Instructions are supplied with

all equipment but also available at www.williams-refrigeration.com).

The customer fails to observe commonly accepted operating

practices.

The customer uses or installs the equipment in such a way that it

exceeds its design envelope.

Call out and repair costs if no fault found or access denied.

The initial supply date shall apply to a replacement.

Equipment fails through misuse, abuse, accidental damage, power

surges or spikes, fire, flooding or acts of God.

Food and / or contents or the product ( including pharmaceutical).

Claim Procedure

If a customer wishes to make a claim under the terms of this

warranty, the following procedure should be observed:

Contact the supplying agent, representative or distributor.

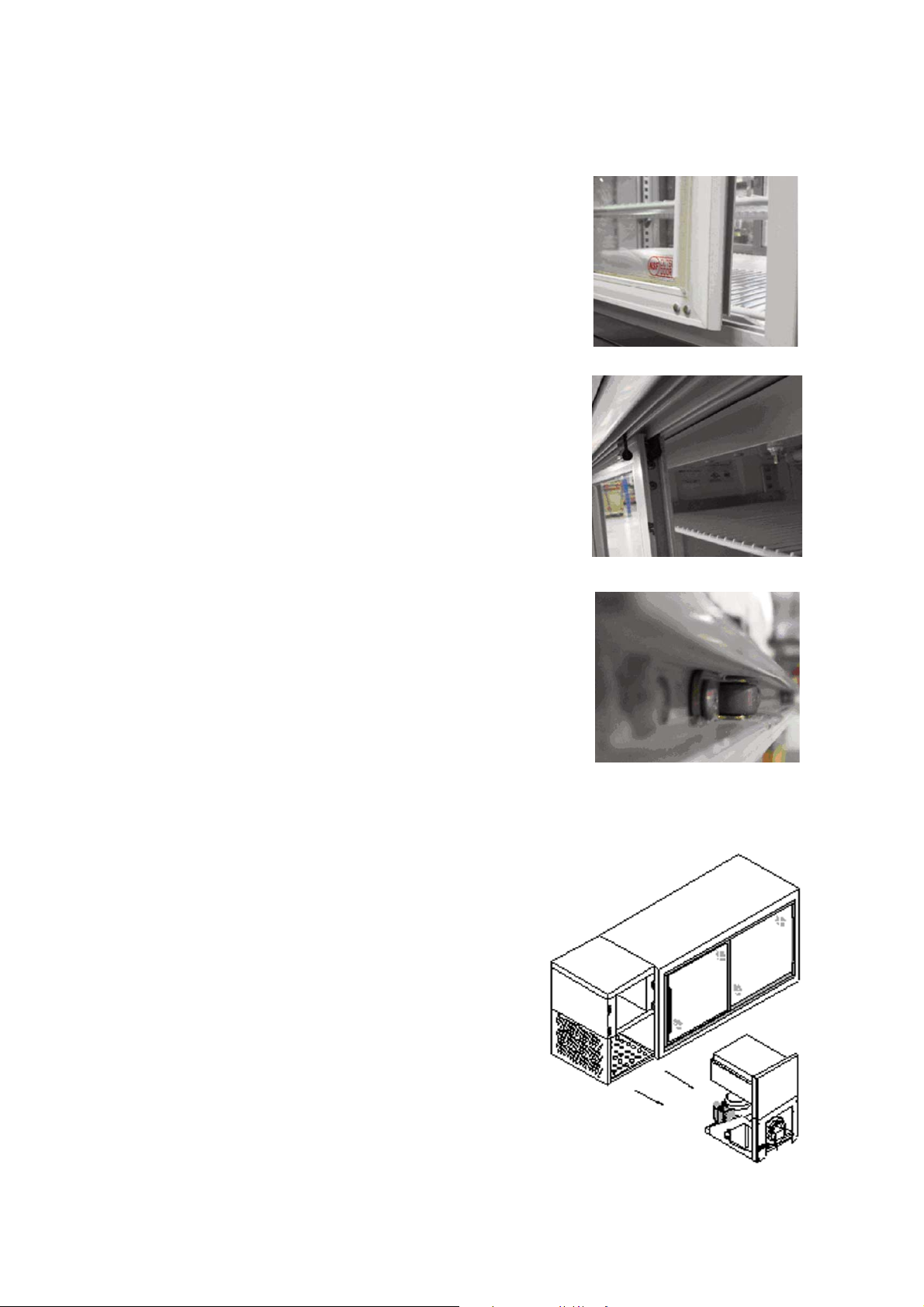

Quote the model, date of installation and serial number of the

cabinet. The serial number is located on the cabinet identification

plate inside the cabinet. It should also be recorded on the

operating instruction booklet supplied with the cabinet.

Note: contents risk and insurance responsibility remains at all times

with the customer.

A current list of main distributors is avilable on request.

Extended Warranty

Extended Warranty offers the opportunity to protect your equipment

(subject to conditions outlined) for an additional period of up to 5 years

inclusive of original warranty periods.

Should you require Extended Warranty, state on your order or notify

the Dealer or Williams Sales Manager at the time of purchase and they

will be able to arrange it for you.

To ensure your Extended Warranty Policy remains valid, at least one

maintenance / service visit per year must take place in years 2, 3, 4

and 5.

All - Inclusive Parts & Labour Warranty

An all inclusive 2 year Parts & Labour Warranty, subject to the

Warranty Policy terms, is available from your Williams Dealer. Contact

your delaer for further details.

This warranty does not affect your statutory rights.

March 2010