WELS-2230 ENVY SERIES

SINGLE STATION SOLID SURFACE LAVATORY SYSTEM INSTALLATION & OPERATION MANUAL

PAGE 9

© Rev. 3/2021

1.800.428.4065 TOLL FREE

| www.willoughby-ind.com

INSTALLATION INSTRUCTIONS

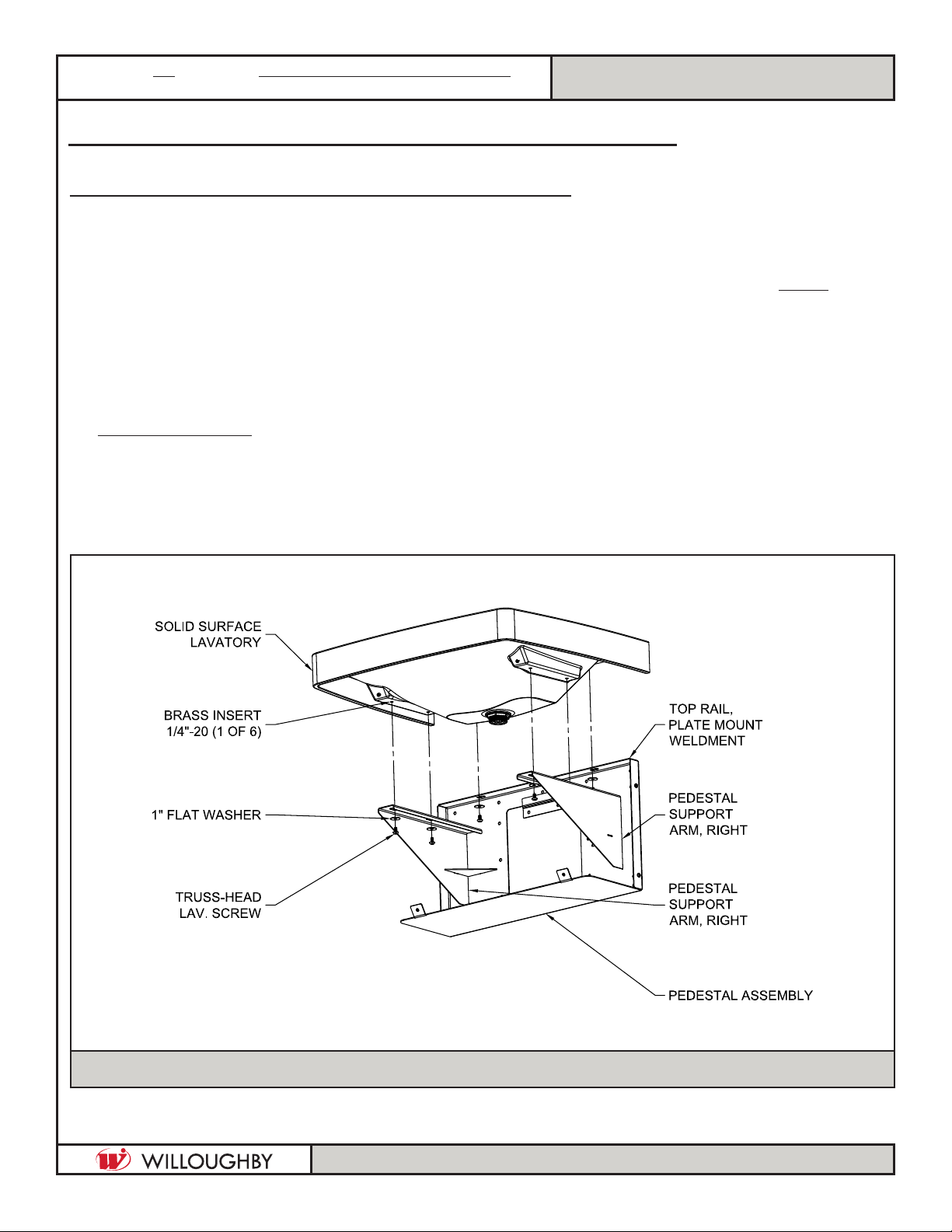

Step 1: Pedestal Mounting

Note: Wall anchoring hardware by others; use wall anchors appropriate for the wall type.

1. Unpack the Pedestal & remove the Security Screws holding the Shroud to Plate Mount Weldment.

2. Mount the 6” Z-clip to the wall as shown on the Rough-in Detail. Make sure adequate backing

exists to securely mount the Lavatory.

3. If not yet completed, install the supply and waste rough-ins appropriate to the installation.

Refer to the Rough-in Detail for backplate access hole measurements (all by others).

4. Lift the Plate Mount Weldment & place it into the Z-clip.

5. Level the Plate Mount Weldment, making sure that it remains ush to the wall, to mark and drill

holes for the wall anchors; the Plate Mount Weldment has (16) usable Ø3/8” mounting holes.

6. Re-check the Plate Mount Weldment is level front-to-back and side-to-side & secure the Pedestal

with anchors through the (16) mounting holes in the Plate Mount Weldment.

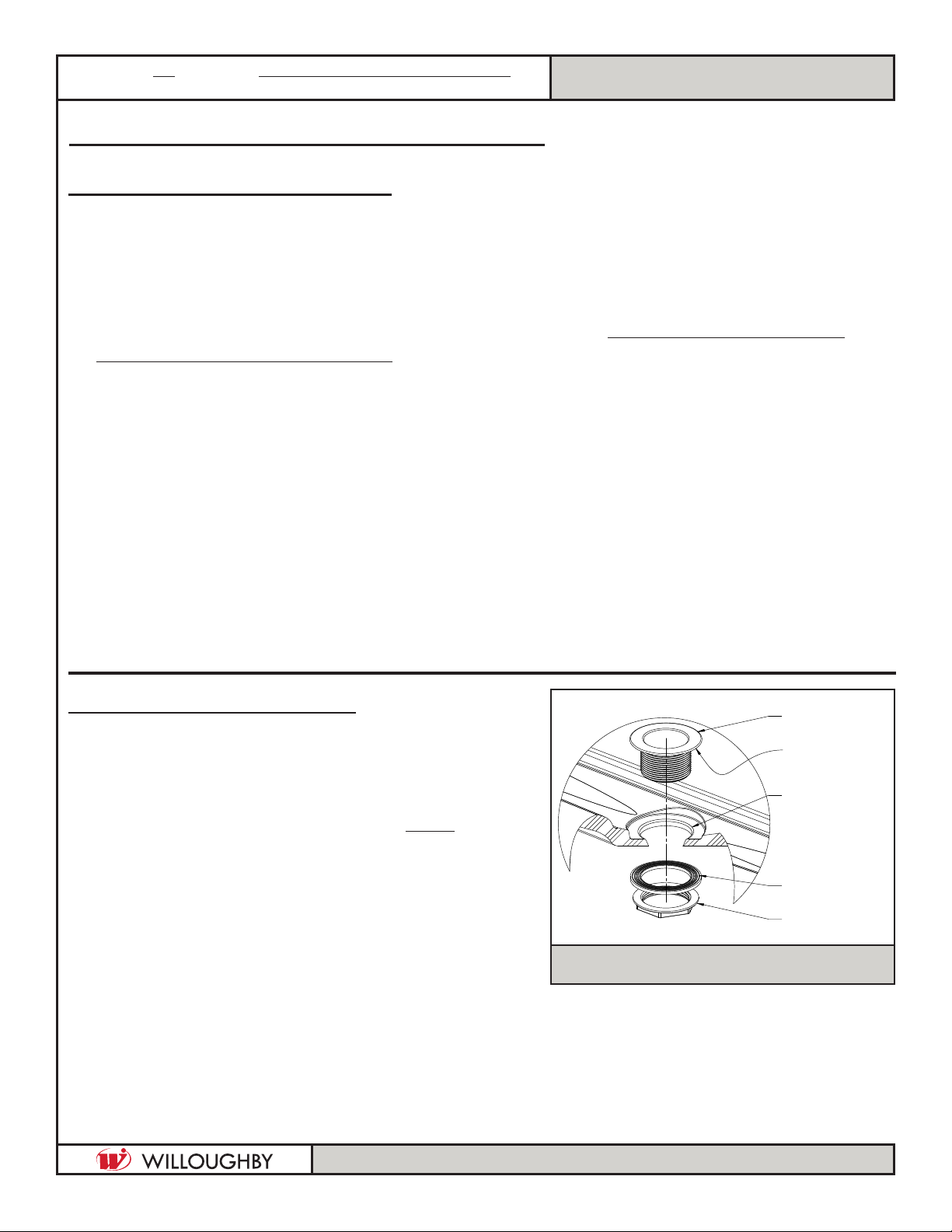

Step 2: Drain Assembly

1. Unpack the Solid Surface Lavatory, check condition.

2. Apply a small strand of plumbers putty on the

underside of the Drain Basket lip (SEE FIG. 1).

3. Insert the Drain Basket into the Lavatory drain hole.

4. Secure the Drain Basket in place:

Fit the Rubber Washer onto the Basket from the

underside of the Lavatory, then tighten the Locknut

onto the Basket, sandwiching the Washer against the

Lavatory.

Note: Over-tightening the Locknut can damage the

Lavatory and Drain Assembly.

APPLY PUTTY

DRAIN HOLE

DRAIN BASKET

LAVATORY

LOCKNUT

RUBBER

WASHER

FIG. 1- DRAIN INSTALLATION