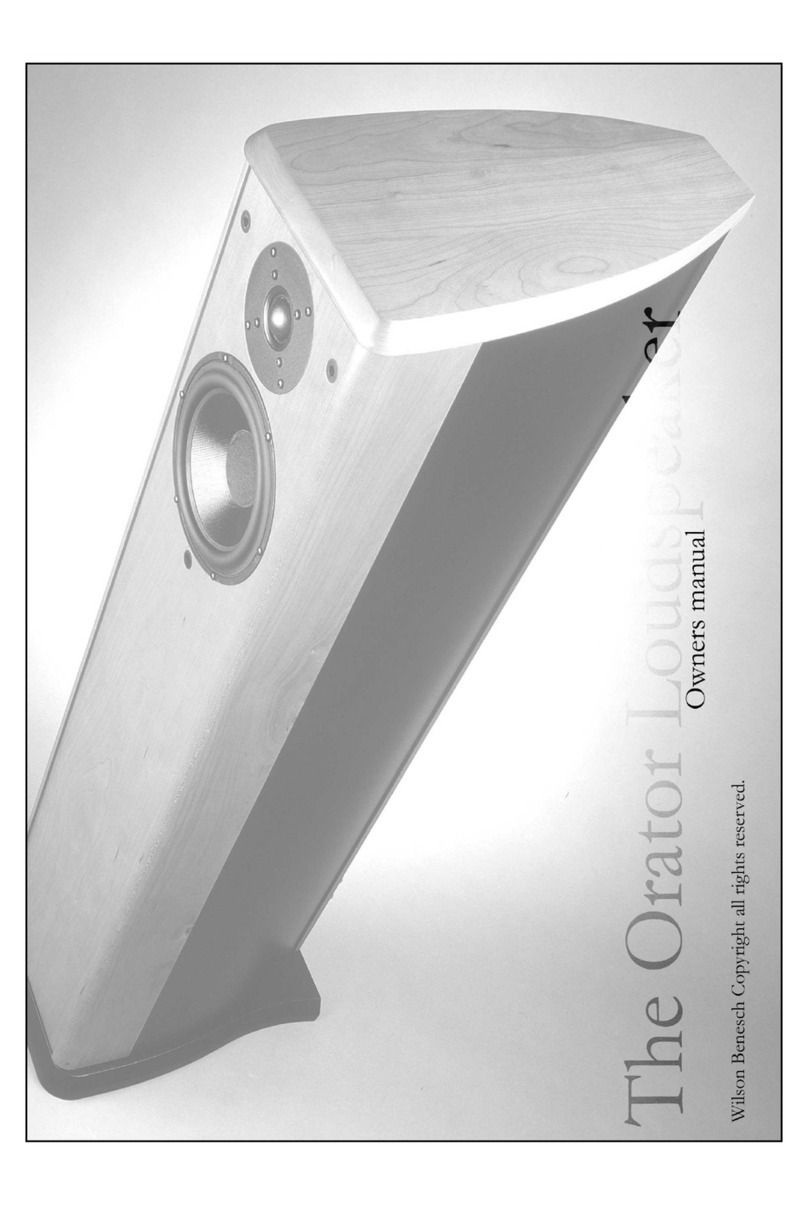

The Bishop was developed with two discrete isolated enclosures for the low

frequency, mid range and high frequency systems. This immediately reduces

corruption from cross communication. A two ox system also provides other

advantages in terms of manufacturing and installation. Curved pre stressed

Advanced Composite Technology panels are key structural components in oth

ca inets. An organic moulded car on component has een developed to facilitate

low defraction and negligi le resonance from this critical part of the structure. The

form and angle of rake eliminates the potential for ceiling to ox top interactions.

The whole system is mounted on a su stantial foot system which also houses the

adjusta le crossover system whilst providing a high degree of sta ility. All

components are manufactured in house with the exception of the tweeter which is

specified to Wilson Benesch specifications and mounted in a simple ut very

effective damping ring on the alloy MDF composite affle structure. It provides

clearly defined information from 5kHz to 20 kHz via a single inductor capacitor 1

st

order crossover network. Its position has een derived from trials which focused

upon phase coherence. The Mid range units are driven well within their prescri ed

specification and are controlled y a andpass filter. All low frequency information

eing devoted exclusively to the Iso aric Tactic® system. Significantly low

frequency energy is provided y drivers that are almost identical to the mid range

systems. This dictates that integration and phase coherence will e virtually

guaranteed. To further overcome the enormous challenge of low frequency

reproduction these units have een mounted in a clamshell composite configuration

which we call the Isobaric Tactic®. By exploiting the principles of the Iso aric

loading the volume required y the low frequency driver array, ( eight in each

channel ) has een minimised despite this advantage it is still five times greater than

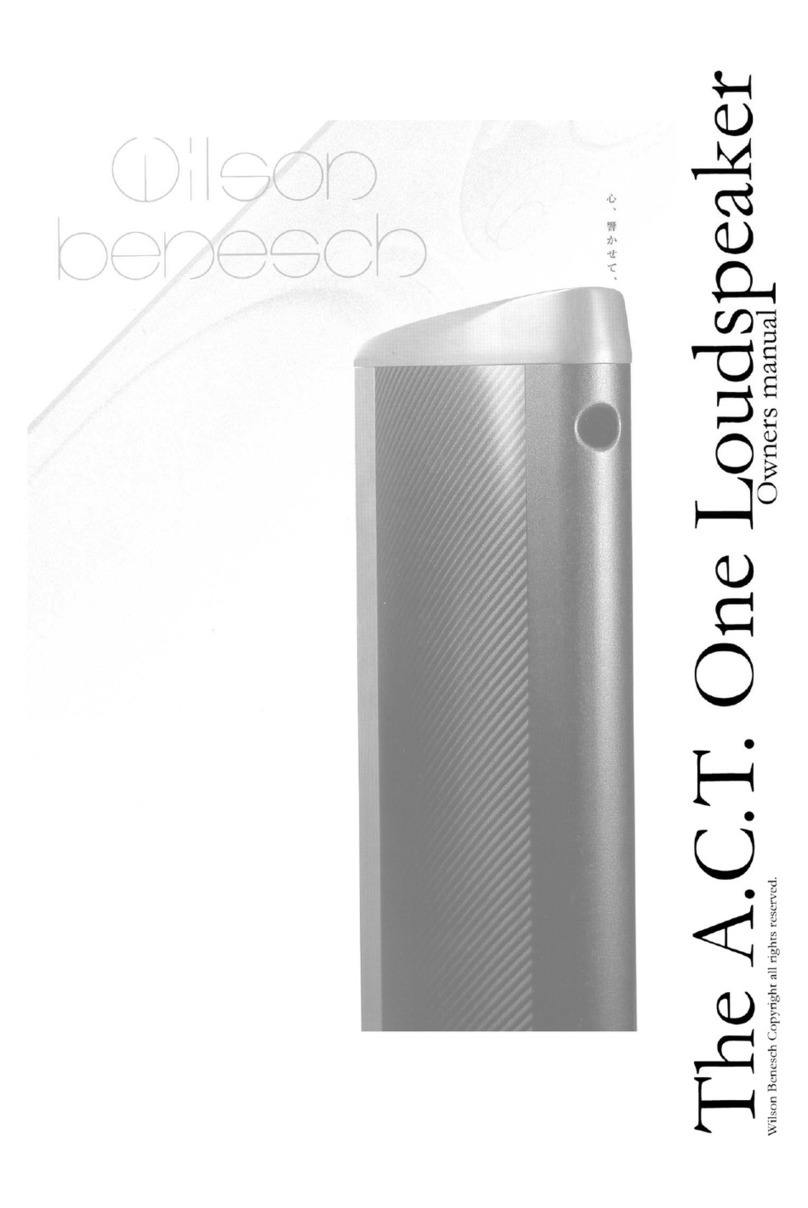

that of the A.C.T. One Loudspeaker low frequency enclosure. This has een

achieved y extending oth height and depth ut not width. This important detail

maintains the slim forward facing profile which is crucial for imaging and

transparency. Moreover, the exterior has een extended without accepting the

unaccepta le compromise of the flat surface. Low frequency production is extended

down to 30Hz without the use of the ported enclosure loading which is

compromised from the outset due to the highly resonant characteristics of the port

output which is of course is always 180 degrees out of phase. This delay is

eliminated in the infinite affle arrangement. The speed of the attack and decay are

the main enefactors as a result of this approach.

The Tactic® Dynamic Driver.

Early in 1996 a 12 month feasi ility study concluded that currently availa le driver

technology would not e capa le of taking the companies am itions forward. The

study indicated further, that significant potential for development existed ut that it

would e a major under taking. The decision was taken for us in many ways, the

moment we realised how innovative the final product would e. At that time our

attentions were focused on the creation of low frequency information and in

particular the a ility of that system to integrate well with the improved mid range

performance. A variety of diaphragm sizes were assessed including race track types.

Orientation was also studied, side firing nota ly eing the most un-popular. Loading

the system with transmission lines was appraised as was the closed ox. Many hours

of research was devoted to the

search for a solution to the pro lem. The reakthrough was made when the Iso aric

method was explored. Using B stock Scan drivers in a hastily assem led MDF ox,

for the first time, it was instantly recognised as the right solution. An o vious

answer in

retrospect for with drivers of similar physical proportions to the mid range system

matching would e axiomatic. For the first time we could hear highly integrated,

high performance reproduction that was un-questiona ly superior to the A.C.T.

One.