- 6 -

Safety

AAA-06462-CK

AAA-06462-BVAAA-06462-BT

&+(&.1876

3(5,2',&$//<

72548(72

)7/%6

:7&$$$%7

&+(&.1876

3(5,2',&$//<

72548(72

)7/%6

:7&$$$%9

&+(&.1876

3(5,2',&$//<

72548(72

)7/%6

:7&$$$&.

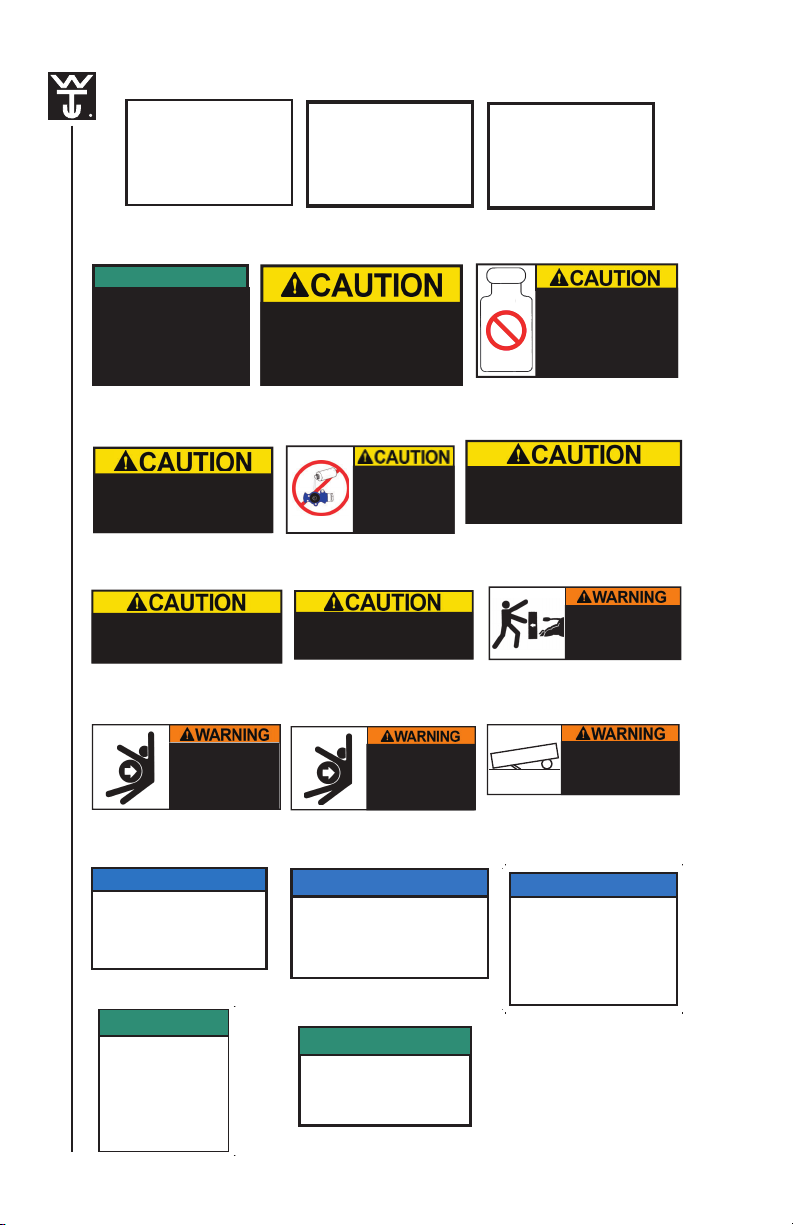

'RRUDQGJDWHORFNVZKLFK

VKRZH[FHVVLYHZHDUVKRXOG

EHUHSODFHGLPPHGLDWHO\

:7&$$$$:

$/,*10(17&+(&.

)RUH[WHQGHGWLUHZHDU

VXVSHQVLRQDOLJQPHQW

PXVWEHFKHFNHGDIWHU

DQLQLWLDOEUHDNLQ

SHULRGDQGDWUHJXODU

LQWHUYDOV

:7&$$$$.

AAA-06462-AW

AAA-06891-AK

0DNHFHUWDLQUROOXSVZLQJDQG

KDOIVOLGHJDWHVDWWKHUHDUHQG

DUHFORVHGZKLOHWUDLOHULVEHLQJ

RSHUDWHGRUSDUNHG

:7&$$$&'

AAA-06462-CD

6WURQJDFLGFOHDQHUVFRQWDLQLQJK\GURÀRXULF

DFLGVXOIXULFDFLGRUSKRVSKRULFDFLGFDQ

GDPDJHWUDLOHUVWUXFWXUHDQG¿QLVK

7RDYRLGVWUXFWXUDOGDPDJHZDVK\RXUWUDLOHU

ZLWKDPLOGFDXVWLFRUDONDOLQHFOHDQHUIROORZHG

E\DWKRURXJKZDUPZDWHUULQVHPD[S+

6WUXFWXUDOGDPDJHFDQUHVXOWIURPXVHRIVWRQJ

DFLGLFFOHDQHU

:7&$$$&=

$&,'

12

$

,'

12

AAA-06891-CZ

'RQRWSRXUDQ\ÀXLGLQWR

VHUYLFHJODGKDQG

'RLQJVRZLOOUHVXOWLQ

YDOYHIDLOXUHDQGYRLG

ZDUUDQW\

:7&$$$*7

AAA-06891-GT

&KHFNEDWWHU\EHIRUHWRZLQJ&KDUJHG

EDWWHU\UHTXLUHGIRUSURSHURSHUDWLRQRI

WKHEUHDNDZD\EUDNHDSSOLFDWLRQ

:7&$$$%4

AAA-06462-BQ

%HFHUWDLQWKDWFRXSOHUORFNKDQGOH

LVFRPSOHWHO\HQJDJHGEHIRUHWRZLQJ

WUDLOHU

:7&$$$%3

'RQRWDWWDFKFDEOHWRWKHKLWFKEDOO

&DEOHPXVWEHDWWDFKHGWRWKHWRZLQJ

YHKLFOHIRUWKHSURSHURSHUDWLRQRIWKH

YHKLFOH :7&$$$%2

AAA-06462-BP AAA-06462-BO

7RSUHYHQWSHUVRQDOLQMXU\

VWDQGFOHDURIVZLQJLQJ

JDWHVXQWLOVODPORFNVDUH

HQJDJHG

:7&$$$%/

AAA-06462-BL

&KHFNZKHHOQXWVDIWHULQLWLDO

WRPLOHVRIVHUYLFH6HH

2ZQHU¶V0DQXDOIRUFRUUHFW

WRUTXHUHTXLUHPHQWV)DLOXUHWR

GRVRPD\UHVXOWLQHTXLSPHQW

GDPDJHRUSHUVRQDOLQMXU\

:7&$$$&

AAA-06891-C

)DLOXUHWRXVHSURSHUO\

PDWFKHGZKHHOVVWXGV

EUDNHGUXPVRUFDSQXWVZLOO

UHVXOWLQHTXLSPHQWGDPDJH

DQGFRXOGUHVXOWLQLQMXU\RU

'($7+LIZKHHOFRPHVRႇ

:7&$$$$+

AAA-06891-H

(TXLSPHQWGDPDJHRUFUXVKLQJDQGLQMXU\

FDQRFFXUZKHQDLUVXVSHQVLRQSUHVVXUH

OHDNVRႇ

([KDXVWDLUVXVSHQVLRQEHIRUH

GLVFRQQHFWLQJIURPWUDLOHU

:7&$$$*&

AAA-06891-GC

,03257$17

23(5$7,1*,16758&7,216

%()25(75$9(/,1*%(685(7+$7

'LYLGHJDWHVDUHVHFXUHGLQHLWKHU³23(1´RU

³&/26('´SRVLWLRQ,QVWDWLRQDU\GHFN

PRGHOVJDWHVPXVWEHFORVHGDQGODWFKHG

5ROOXSHQGJDWHVDUHFORVHG

&OHDQRXWGRRUVDUHFORVHGDQGODWFKHG

5RRIKDWFKHVDQGWUDSGRRUVDUHFORVHG

/LIWGHFNVDUHUHVWLQJ¿UPO\RQGHFNUDLOVZLWK

VODFNFDEOHV

:7&$%%$

3OHDVHEHDZDUHWKDWVWDLQLQJGLVFRORUDWLRQDQGFRUURVLRQ

FDQDQGPD\DSSHDURQDOXPLQXPWUDLOHUV7KLVFDQDSSHDU

DWDQ\WLPHIRUYDULRXVUHDVRQVDQGLVEH\RQGWKHFRQWURORI

:LOVRQ7UDLOHU

([SRVXUHWRFOHDQVHUVKLJKZD\WUHDWPHQWDQGGHLFLQJ

FKHPLFDOVDORQJZLWKJHQHUDOZHDWKHUFRQGLWLRQVRUD

FRPELQDWLRQRIWKHDERYHFDQEHFDXVHIRUVWDLQLQJDQG

FRUURVLRQ

:LOVRQ7UDLOHULVQRWUHVSRQVLEOHIRUWKHVHRFFXUDQFHVDQG

DQ\VWDLQLQJRUGLVFRORUDWLRQLVQRWFRYHUHGE\:LOVRQ7UDLOHU

ZDUUDQW\

:7&$$$0$

NOTICE

AAA-06891-MA

:7&$$$*%

7KH2ZQHUV0DQXDOFRQWDLQV

LPSRUWDQWLQIRUPDWLRQUHJDUGLQJ

VDIHDQGSURSHURSHUDWLRQRIWKLV

WUDLOHU5HDG2ZQHUV0DQXDO

EHIRUHXVLQJWUDLOHU

NOTICE

AAA-06891-GB

NOTICE

7KLVWUDLOHULVHTXLSSHGZLWKDXWRPDWLFIRUZDUG

DGMXVWEUDNHV7RHQVXUHWKHSURSHURSHUDWLRQ

RIWKHDGMXVWHUVSOHDVHLQVSHFWWKHEUDNHV

IRUSURSHUDGMXVWPHQWHYHU\PLOHVRUDV

QHFHVVDU\,IEUDNHDGMXVWPHQWLVUHTXLUHGXVH

WKHSURFHGXUHVLQWKH'H[WHU6HUYLFH0DQXDO

:7&$$$(%

AAA-06891-EB

:7&$$$(&

7KLVWUDLOHULVHTXLSSHGZLWKPDQXDODGMXVW

EUDNHV&KHFNWKHEUDNHDGMXVWPHQWDIWHU

WKH¿UVWPLOHVDQGHYHU\PLOHVRU

DVQHFHVVDU\WKHUHDIWHU,IEUDNHDGMXVWPHQW

LVUHTXLUHGXVHWKHSURFHGXUHLQWKH'H[WHU

VHUYLFHPDQXDO

,1)250$7,21

AAA-06891-EC

ABB-01545-A

(Rev. 4-19)