5

EASY OPERATION, MAINTENANCE

Maximum reliability and minimal maintenance

In addition to the spacious large clearance between the jaw

crusher and the conveyor belt, the crusher’s bottom area is

sealed with covers. This design prevents re-bar from being

caught by the crusher’s member

structure. Wide openings on the

side frames also ensure easy

access to the space below the

crusher to remove clogged

foreign material.

Maintenance

Comfortable design

●To prevent dust, sprinkler nozzles at the top of the jaw

crusher are provided as standard equipment.The nozzles at

the tip of the conveyor and the

intermediate part (under the

engine) are prepared as

optional equipment.The water

tank and spraying system are

also prepared as optional

equipment.

Ease of operation

●All the switches necessary for operation are located on the

main control panel, making it easier for the operator

standing on the ground to reach and control the operation.

As the control system is equipped with the one-touch start

feature, all you have to do is to push the start switch. This

simple operation will sequentially start the operation of the

magnetic separator, belt conveyor, jaw crusher and feeder.

●The multi-function monitor displays the status of all

components in real time. With this monitor, you can easily

identify the location of a problem.

●Wired remote controller for travel

Wired remote controller allows travel control while standing

on the ground.

The controller facilitates travel control by

eliminating the need to get on the machine.

Since the connector for the remote

controller is provided both on the front and

rear of the machine, you can select either

one according to your needs. In addition,

conventional on-board travel control lever

system is optionally available.

●Radio remote controller (Option)

With this controller, you can change the

mode between “Travel” and “Operation”,

while remaining onboard.You can also use

it to operate the one-touch start feature, in

addition to the feeder On/Off function.

4

PRODUCTIVITY FEATURES

BR580JG-1

MOBILE CRUSHER

BR580JG-1 MOBILE CRUSHER

Equipped with an eco-friendly engine

Equipped with the SAA6D125E-5 engine, this new mobile

crusher has a nominal output as high as 262.5 kW (352 HP).

The latest KOMATSU engine technology for construction

machinery, “ecot3”, greatly reduces NOx emissions. This eco-

friendly, clean engine, complies with various emission gas

standards, including the EPA Tier 3 requirements in North

America and the EU Stage 3A requirements in Europe.

New Komatsu Jaw Crusher

The large-capacity jaw crusher, KCJ4430, is another

successful example of Komatsu’s development efforts.

Crushing efficiency is improved dramatically with the

installation of a load-presetting semiautomatic feeder system.

High-speed, large-capacity conveyor belt

The high discharge height of 3000 mm (9'10") makes it easy

to configure a system with stock pile conveyor and screens.

With its width of 1050 mm (42") and a belt speed of 120 m

(394') /min., the belt conveyor has a high volume capacity. In

addition, the conveyor reverse mode is provided to facilitate

the removal of jammed foreign material.

Komatsu’s hydraulic crusher protection

mechanism

Jaw crushers typically protect themselves by bending toggle

plates when they are clogged or

jammed with metal or wood debris. The

KCJ4430 protects itself by allowing the

locking cylinders to fully open the

discharge port, which makes it easy to

remove clogged foreign material from

the crusher. (Patent pending)

Fully automatic discharge setting adjustment

system

The jaw crusher is equipped with an automatic discharge

setting adjustment system that makes it easy to change the

opening of the discharge port. Even as both of the jaw plates

or one wear, you can adjust the discharge setting with a

simple one-touch operation (adjustable within several minutes)

with this automatic system. On the monitor panel, you can

choose one of the three adjustment modes. (Patent pending)

Large production capacity

Komatsu’s original large-capacity jaw crusher and the most

advanced control systems have considerably increased its

output capacity, making it easy to manage large workloads.

High mobility

The conveyor elevation system secures sufficient ground

clearance, which provides the crusher with outstanding

maneuverability at any crushing site. In addition, improved

configuration and location of the guide handle makes it much

easier to operate the conveyor lifter.

The mobile crusher uses a new interlock system that controls

the travel and the operation (crushing), depending on the

conveyor's position.

The system helps prevent the conveyor from being dragged

or contacting the ground and provides clearance between the

jaw discharge and the conveyor belt.

Sprinkler Nozzle

Fuel pre-filter

(with water separator)

The engine oil drain valve

was attached remotely, and

connected the drain hose

Centralized greasing of the

crusher

Anti-slip plates

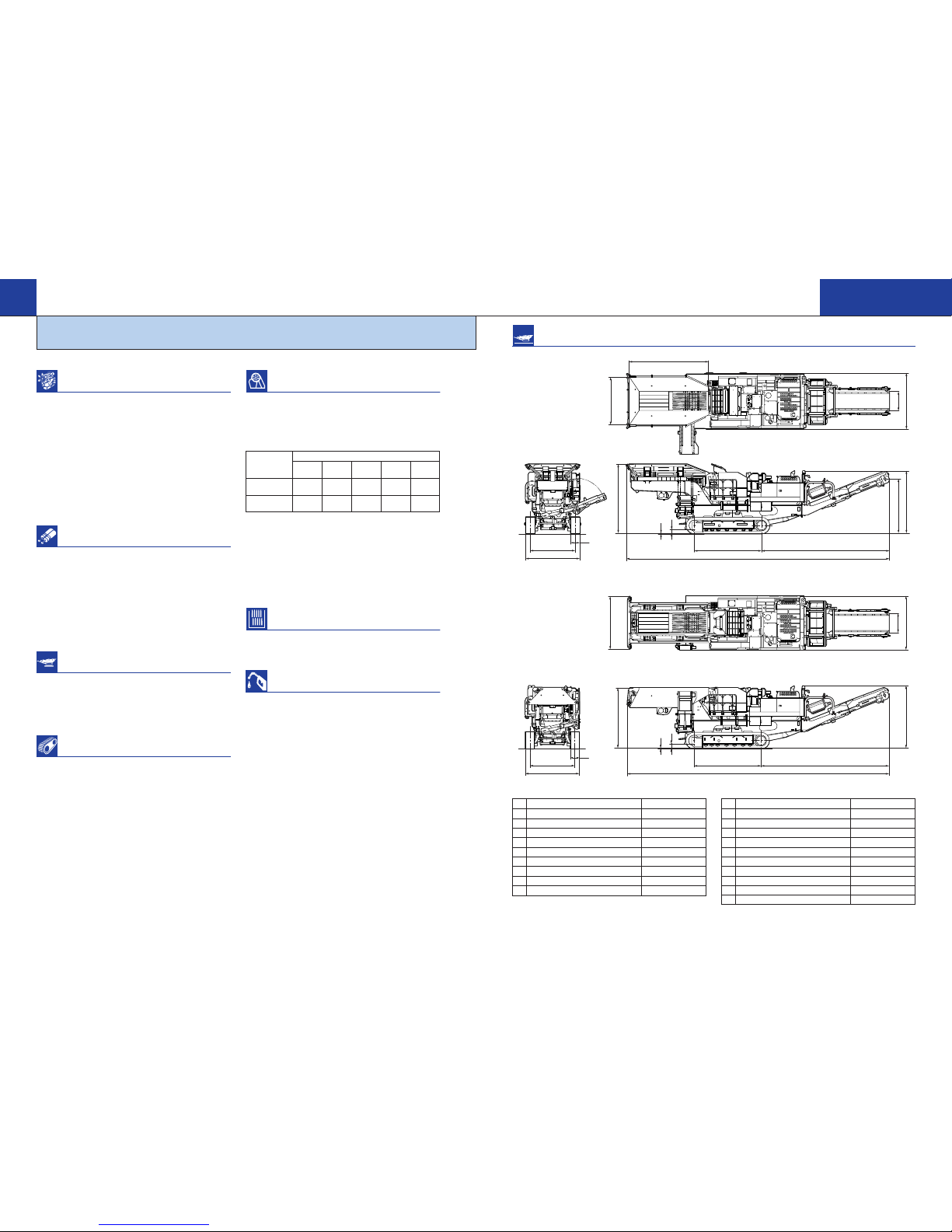

Feed opening:

1120 mm x 765 mm

44" x 30"

3000 mm

(9'10")

KCJ4430 Jaw

Mode A: Input a desired value

for the discharge

setting.

Mode B: Increase or decrease

the current discharge

setting.

Mode C: Press the manual

switch to increase or

decrease the present

discharge setting.

Link plate Fixed link

Locking cylinder

Minimum ground

clearance

Travel:

200/350 mm (7.9"/14")

Operation (Crushing):

100/200 mm (3.9"/7.9")

* “Travel” is prohibited by interlock when the

ground clearance is 100mm (3.9").

Conveyor Elevation System

Opening In The Engine Side

(left side of undercarriage)

Between the crusher discharge

and the belt conveyor

Opening In The Crusher Side

(both sides of undercarriage)

Main Control Panel

Travel Mode Operation Mode