9OPM-173/A

EXHAUST INSTALLATION

WARNING: PERSONAL INJURY

Improper exhaust installation will allow dangerous

gases to seep into enclosed spaces causing a hazard to

your health and/or death.

All exhaust must be piped out of the enclosure. When

selecting a location to exhaust fumes make sure that the

potential for contact with people is controlled. Exhaust can

enter buildings through windows, ventilation systems and

other openings if proper precautions are not followed.

The exhaust must be isolated from the vibration of the

engine. If the exhaust is connected in a rigid system it will

result in damage to the engine. The generator comes

equipped with an engine mounted flex pipe to aid your

installation. Ensure proper alignment with the generator.

The flex can be eliminated if it is pushed to one side to make

a connection.

The most direct path possible should be used to get to the

outside of the enclosure. Each bend restricts the pipe and

increases back pressure. It may be necessary to increase the

exhaust pipe diameter in some applications.

The exhaust pipe is very hot. When passing through the

structure it is critical that a thimble or other appropriate

technique is used to dissipate the heat and prevent the

structure from catching on fire.

It is preferable to exhaust out the side of the enclosures.

Slope the pipe slightly downward away from the engine

to cause any water in the exhaust to run away from the

engine. Do not exhaust near intake. Once outside the

enclosure a rain cap or other technique must be used to

keep water out of the exhaust. In mobile applications make

sure the rain flap faces to the rear of the vehicle so that it is

not blown open during transportation.

The generator ships with a critical grade muffler that should

be installed to decrease noise. It can be mounted either

internally or externally to the enclosure. The muffler cannot

increase back pressure to more than 0.725 psi.

FUEL INSTALLATION

The fuel supply should be as close as possible to the

engine. This will reduce the installation cost of fuel runs.

The information in this manual is offered to assist you in

providing the proper fuel for your engine. However, this

information is only provided to inform you of the engine’s

requirements and assist in making you aware of the

decisions you must make. In no case should the instructions

and information provided be interpreted to conflict with

any local, state or national codes. If in doubt, always consult

your local fire marshal, gas supplier or building inspector.

WARNING: FIRE HAZARD

All fuel runs should be installed by a licensed fuel

supplier.

In no case should the instructions or information provided

be interpreted to conflict with any local, state, or national

codes. If in doubt, always consult your local fire marshal or

fuel supplier.

INSTALLING THE FUEL LINE

WARNING: FIRE DANGER

Connecting rigid fuel line (i.e. steel or copper line)

directly to the inlet fuel filter or fuel pump may cause

the fuel line to crack during operation creating a

serious fire hazard.

The fuel supply should be as close to the engine as

possible. This will reduce the installation cost of fuel runs

and minimize line losses. The diesel fuel supply should be

no more than 3 feet below the fuel inlet on the pump. If

your fuel supply is lower than three feet you may have to

install an additional lift pump to bring the fuel up to the

mechanical fuel pump on the engine.

The information in this manual is offered to assist you in

providing the proper fuel for your engine. However, this

information is only provided to inform you of the engine’s

requirements and assist in making you aware of the

decisions you must make. In no case should the instructions

or information provided be interpreted to conflict with any

local, state, or national codes. If in doubt, always consult

your local fire marshal or fuel supplier.

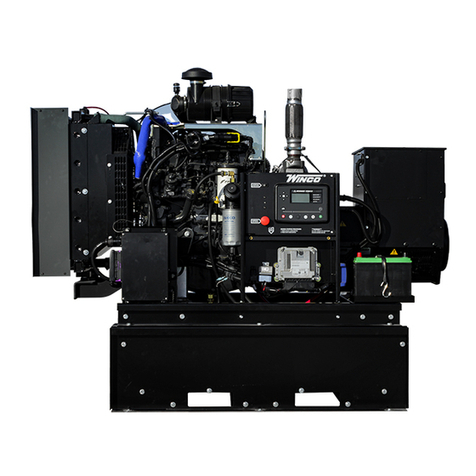

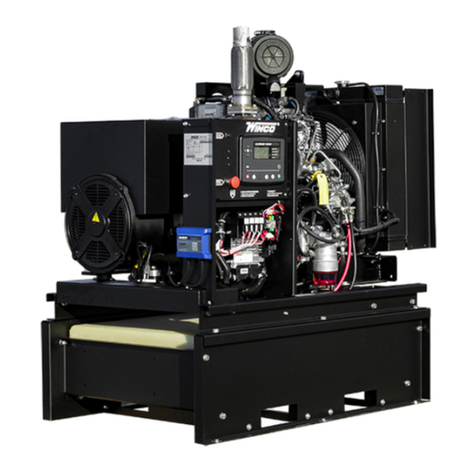

Engine generator sets are properly adjusted before they

leave the factory. Connecting a fuel supply with adequate

supply volume is critical to reliable operation. Diesel units

with optional base mounted fuel tanks are pre-plumbed to

the mechanical fuel pump on the engine.

Open skid mounted diesel units are often supplied with

capped inlet and return lines. The use of a sustainable

customer supplied flexible fuel line is essential between

the engine and fuel supply to provide a vibration break

between your fuel supply and the engine.

GROUNDING

Proper grounding of your generator is application

dependent. Carefully evaluate your planned use of your

generator to understand which grounding you require.

If you are not sure what to do, contact a competent

professional to assist you. The NFPA 70 250:34-35 are good

technical references.

VEHICLE-MOUNTED GENERATOR

Your WINCO generator ships with a bonded neutral.

When mounted to a vehicle to safely distribute power it is

necessary that the generator frame is bonded to the vehicle

frame. The generator should only supply equipment that

is cord and plug connected through customer installed

receptacles mounted on the generator or the vehicle.

PERMANENTLY INSTALLED GENERATORS

This WINCO portable generator ships with a bonded

neutral. NFPA 70 refers to this as a “separately derived

system.” When connecting it to a building a transfer

switch specifically designed for GFCI and bonded neutral

generators is required or the ground or the neutral to

ground bond must be broken and the panel relabeled.