8

OPM-160/B

system installation. The information in this manual is offered

only as a guide to finalizing your installation plans.

WARNING: PERSONAL INJURY

The enclosures on these units can become very hot

adjacent to the exhaust areas. Special care must be taken

when installing these units to insure that the risk of

contact by people is minimized.

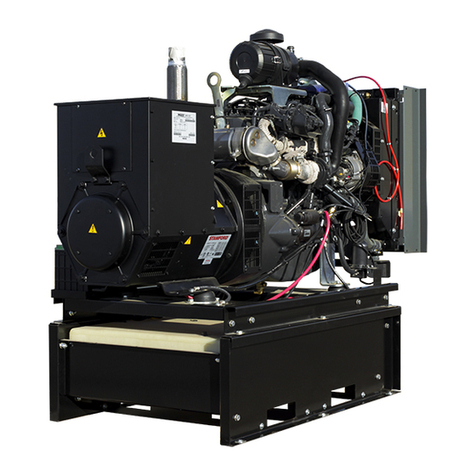

The unit’s main frame should be bolted to a pad that meets

local code. Various materials, including concrete and

composites, are acceptable as long as they are structurally

sound supporting the weight of the unit and preventing

movement during operation. The mounting holes on the

base of this unit is 0.625” in diameter. The engine-generator

is mounted on a sub-frame which is isolated with special

shock mounts on the main frame. This allows the engine-

generator to vibrate without affecting the control panel on

the main frame.

Do not install any shock mounts between the base frame

and the pad. Engine vibration will be transmitted to the

control panel causing erroneous start/stop cycles and

premature control failure.

These units should be mounted a minimum of 24” from a

structure. This will allow for ample room to maintain and

work on the generator set.

Units must be installed in accordance with all local, state,

and national codes. Consult your local agency for specific

requirements.

VENTILATION REQUIREMENTS

OPEN SKID

WARNING: EQUIPMENT DAMAGE

It is the installer’s responsibility to ensure that there is

sufficient cooling air available to prevent the engine

and generator from over heating. Damage caused by

overheating is not covered by warranty.

Providing proper air movement during your installation

planning is essential. You will need to provide a fresh air

inlet as well as a hot air outlet (to the outside of protection

housing) for proper engine performance. These engine-

generator sets are equipped with unit mount radiators and

the engine is equipped with a pusher type fan. The hot

air from the face of the radiator must be ducted out of the

enclosure to ensure proper cooling. Failing to do so will

allow the hot air to recirculate around the radiator causing

the engine to overheat, resulting in an engine shutdown

and damage. If louvers are used in front of the hot air duct

to protect the unit from outside weather, the louvers should

be 1½ times as large as the area of the radiator face to

prevent back pressure.

Foam or other seals can be used to form a tight lip forcing

all of the air from the engine fan out of the enclosure.

In addition to a hot air discharge, you must plan a fresh air

intake opposite the radiator discharge. Their fresh air inlets

should be 1½ to 2 times larger than the radiator face. The

INSTALLATION

This unit should be installed in a well ventilated area,

ensuring the exhaust air cannot be recirculated back into

the engine.

CAUTION:

This unit will get hot while it is running and for some time

afterward.

WARNING

Before proceeding with the installation, be sure

the engine control is in the “stop” position and the

emergency stop depressed. Also, be sure the generator

MLCB (main line circuit breaker) is in the “off” position and

the unit starting battery is disconnected.

PRIME POWER

Some configurations of the PSS60F4 are available with

EPA Prime power certifications. These configurations are

outfitted with a catalyst to meet current regulations. When

operating prime power derate the load at least 10% for a

variable load. If the load is continuous at one current rating

ensure that it does not exceed 80% of the standby rating.

Prime power configurations can be installed in mobile

or stationary applications as long as sound engineering

practices are followed to accommodate the structural

and cooling considerations outlined in this manual.

Prime applications will require close observation of actual

conditions requiring a shortening of maintenance intervals.

GENERAL INFORMATION

Before beginning the installation process, recheck the

voltage, phase, and amperage rating of the generator

set. Be certain it can handle the intended load and is

compatible with the intended loads. Plans for installation

should be prepared with proper attention to mechanical

and electrical engineering detail to assure a satisfactory

system installation. The installation must comply with all

national, state, and local codes.

The information in this manual is offered only as a guide to

finalizing your installation plans and does not substitute for

sound engineering judgment for the specific application.

ENGINE-GENERATOR SET MOUNTING

These engine-generator sets are designed to be mounted

on a pad where there is proper ventilation. The transfer

switch is mounted next to your electrical entrance or

distribution panel inside or outside the building. Consult

a qualified, licensed electrician or contractor to install and

wire the transfer switch. The installation must comply with

all national, state and local codes. Before beginning the

installation process check the rating of the generator set

and its transfer switch rating. Be certain they can handle

the intended load and are compatible with the entrance

voltage, phase and current ratings. Plans for installation

should be prepared with proper attention to mechanical

and electrical engineering detail to assure a satisfactory