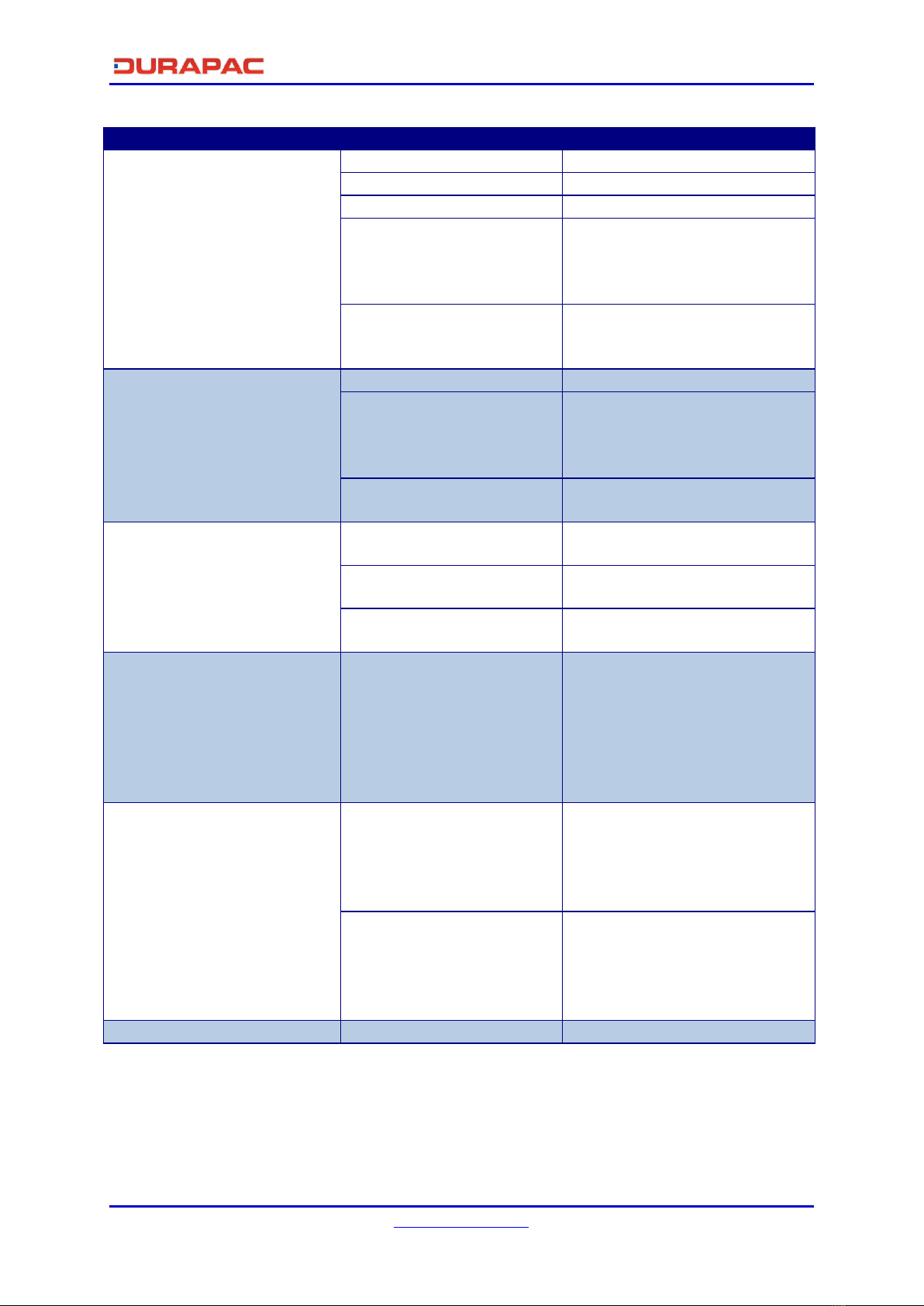

Item Description Part No. Qty Item Description Part No. Qty

1 Piston pump body ZCZ1001 1 46 Reservoir cover ZCZ1046 1

2 Relief valve ZCZ1002 1 47 Oil outlet o-ring* ZCZ1047 1

3 Relief valve body ZCZ1003 1 48 Air vent o-ring* ZCZ1048 1

4 Relief valve one-way valve* ZCZ1004 1 49 Air inlet o-ring* ZCZ1049 1

5 Relief valve ball holder ZCZ1005 1 50 Oil outlet valve block ZCZ1050 1

6 Relief valve spring* ZCZ1006 1 51 Anti-dust ring ZCZ1051 1

7 Adjustment plug ZCZ1007 1 52 Muffler ZCZ1052 1

8 Copper washer ZCZ1008 1 53 Oil drain spring* ZCZ1053 1

9 Suction filter ZCZ1009 1 54 Oil drain switch ZCZ1054 1

10 Suction filter one-way valve* ZCZ1010 1 55 Oil drain pressure bar o-ring* ZCZ1055 1

11 Copper washer ZCZ1011 1 56 Oil port end cap ZCZ1056 1

12 Piston body ZCZ1012 1 57 Oil port end cap o-ring ZCZ1057 1

13 Piston seal washer* ZCZ1013 1 58 Air inlet valve body ZCZ1058 1

14 Piston seal washer* ZCZ1014 1 59 Air inlet switch ZCZ1059 1

15 Front cover ZCZ1015 1 60 Air inlet switch o-ring* ZCZ1060 1

16 Oil outlet one-way valve* ZCZ1016 1 61 Washer* ZCZ1061 1

17 Spring* ZCZ1017 1 62 Air inlet seal washer cap ZCZ1062 1

18 Pressure stem ZCZ1018 1 63 Air inlet spring* ZCZ1063 1

19 HP nozzle o-ring* ZCZ1019 2 64 Pin ZCZ1064 1

20 Oil drain valve ZCZ1020 1 65 Foot pedal ZCZ1065 1

21 Oil drain valve spool ZCZ1021 1 66 Return spring ZCZ1066 1

22 Oil drain valve spring* ZCZ1022 1 67 Reservoir seal washer* ZCZ1067 1

23 Oil drain one way valve* ZCZ1023 1 68 Reservoir ZCZ1068 1

24 Oil drain ball holder* ZCZ1024 1 69 Air inlet connector ZCZ1069 1

25 Oil drain thimble* ZCZ1025 1 70 Snap ring ZCZ1070 2

26 Oil drain valve o-ring* ZCZ1026 1 71 Washer ZCZ1071 2

27 Copper washer ZCZ1027 1 72 Bolt ZCZ1072 2

28 Air cylinder seal ring* ZCZ1028 2 73 Breathing valve ZCZ1073 1

29 Cylinder bore ZCZ1029 1 74 O-ring ZCZ1074 1

30 Piston return spring* ZCZ1030 1 75 Breathing cap ZCZ1075 1

31 Piston stop plate ZCZ1031 1 76 Seal ZCZ1076 1

32 Pump piston ZCZ1032 1 77 Bolt ZCZ1077 1

33 Washer* ZCZ1033 1 78 Nylon washer ZCZ1078 1

34 Large piston ZCZ1034 1 79 Oil return filter* ZCZ1079 1

35 Large piston o-ring* ZCZ1035 2 80 Snap ring ZCZ1080 1

36 Large piston seal* ZCZ1036 2 81 Air inlet filter ZCZ1081 1

37 Small piston ZCZ1037 1 82 Snap ring ZCZ1082 1

38 Small piston o-ring* ZCZ1038 1 83 Bolt ZCZ1083 1

39 Small piston return spring* ZCZ1039 1 84 Bolt ZCZ1084 1

40 Large piston seal washer* ZCZ1040 1 85 Filter ZCZ1085 1

41 Large piston cover ZCZ1041 1 86 Snap ring ZCZ1086 1

42 Small piston seal washer* ZCZ1042 1 87 Spring washer ZCZ1087 1

43 Cylinder head spring* ZCZ1043 1 88 Bolt ZCZ1088 1

44 Back cover ZCZ1044 1 * Repair kit ZCZ1089 1

45 Pump cover seal washer* ZCZ1045 1 Oil Drain Assembly Kit ZCZ1000 1