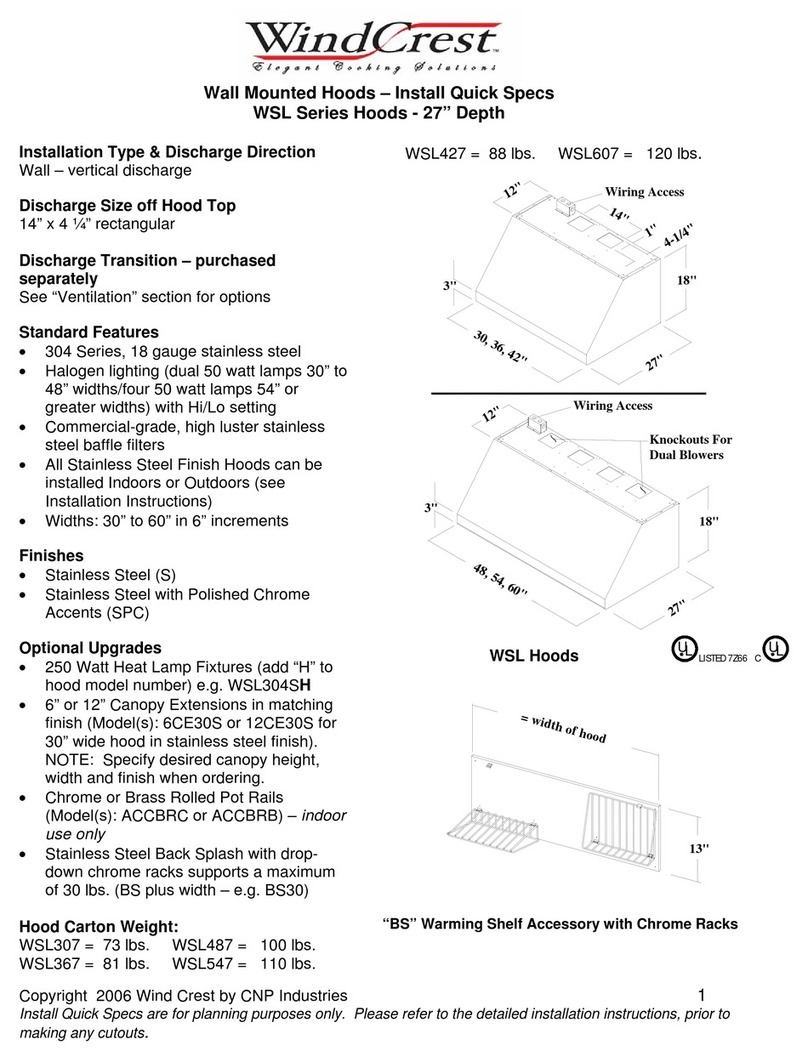

2 of 9 Rev A

.

NOTE: Unit must be vented

to outside of the building.

BEFORE STARTING INSTALLATION, YOU MUST IDENTIFY THE VENTILATOR MODEL BEING USED

AND IF A TOP OR REAR EXHAUST IS TO BE USED.

NOTE: VEN120I cannot be used in rear exhaust applications or on Models with Heat-

Lamps.

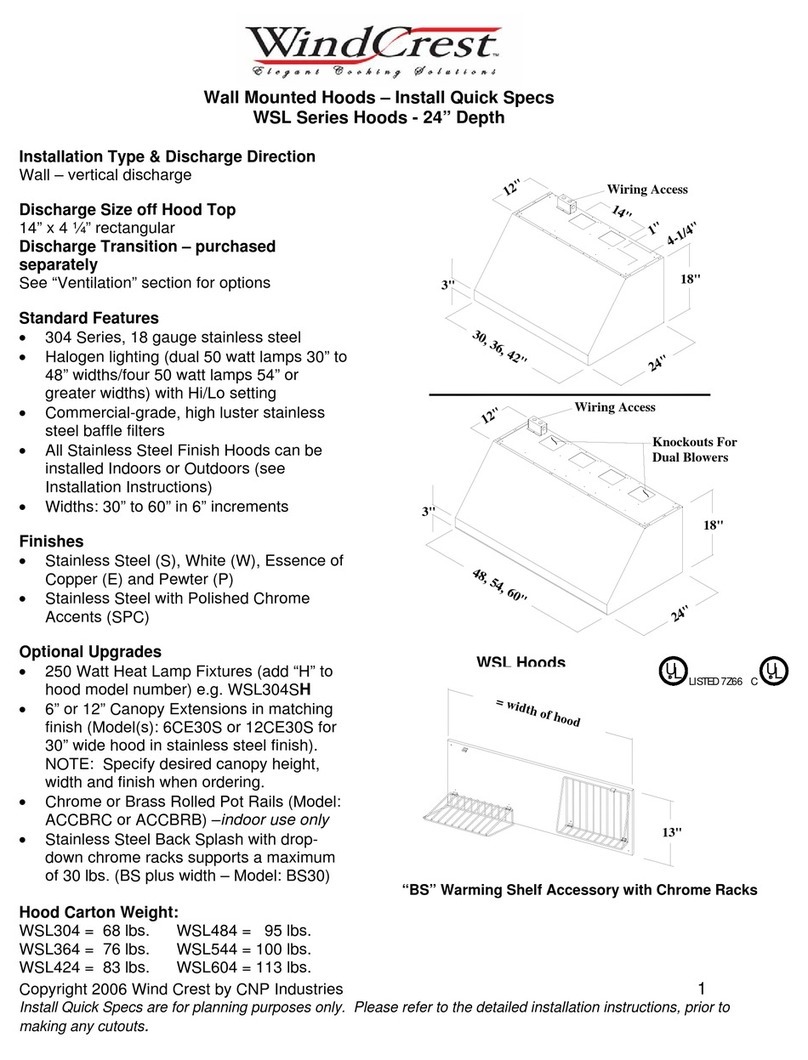

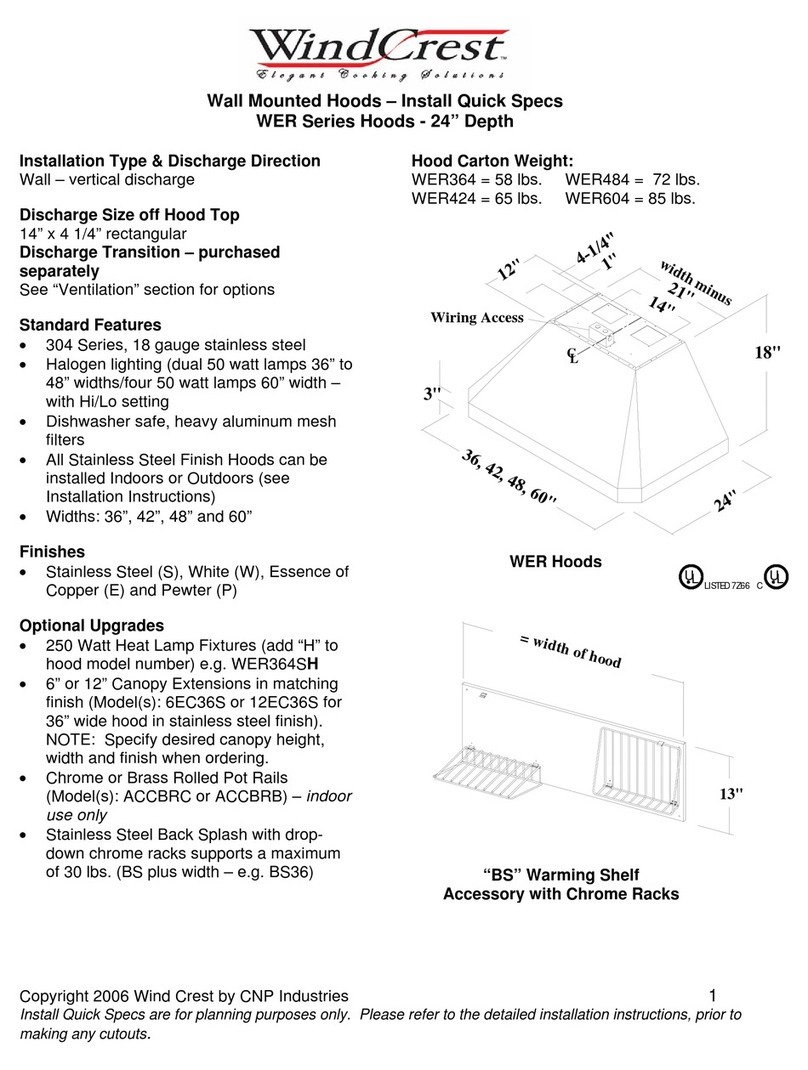

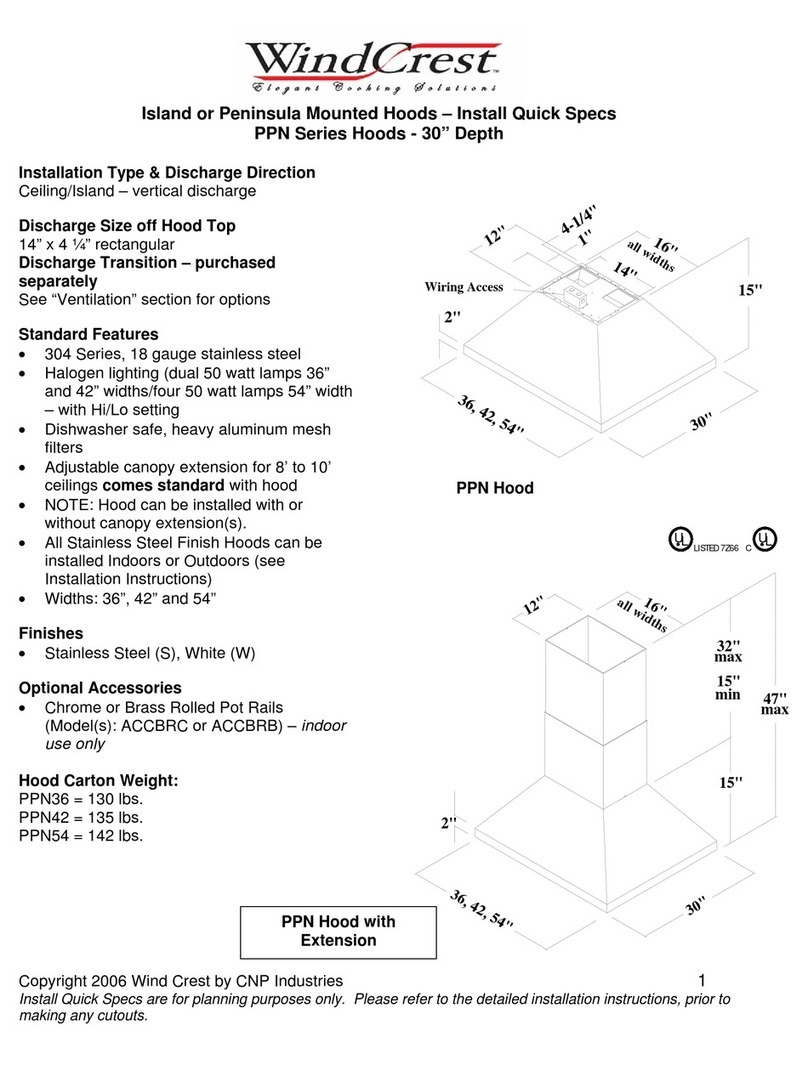

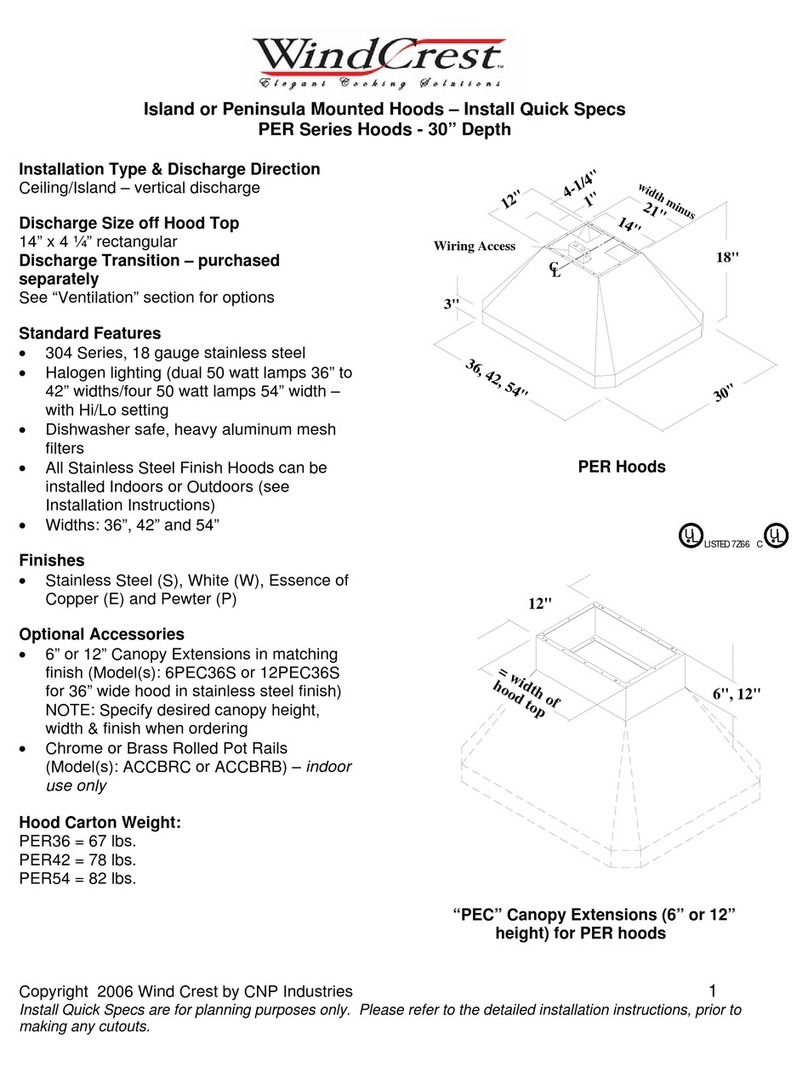

Prepare cabinet and/or wall for mounting either top (Fig -

3) or rear (Fig - 6) exhaust. Use furring strips to level

cabinet mounting surface with any cabinet trims.

For knock out removal see Fig- B

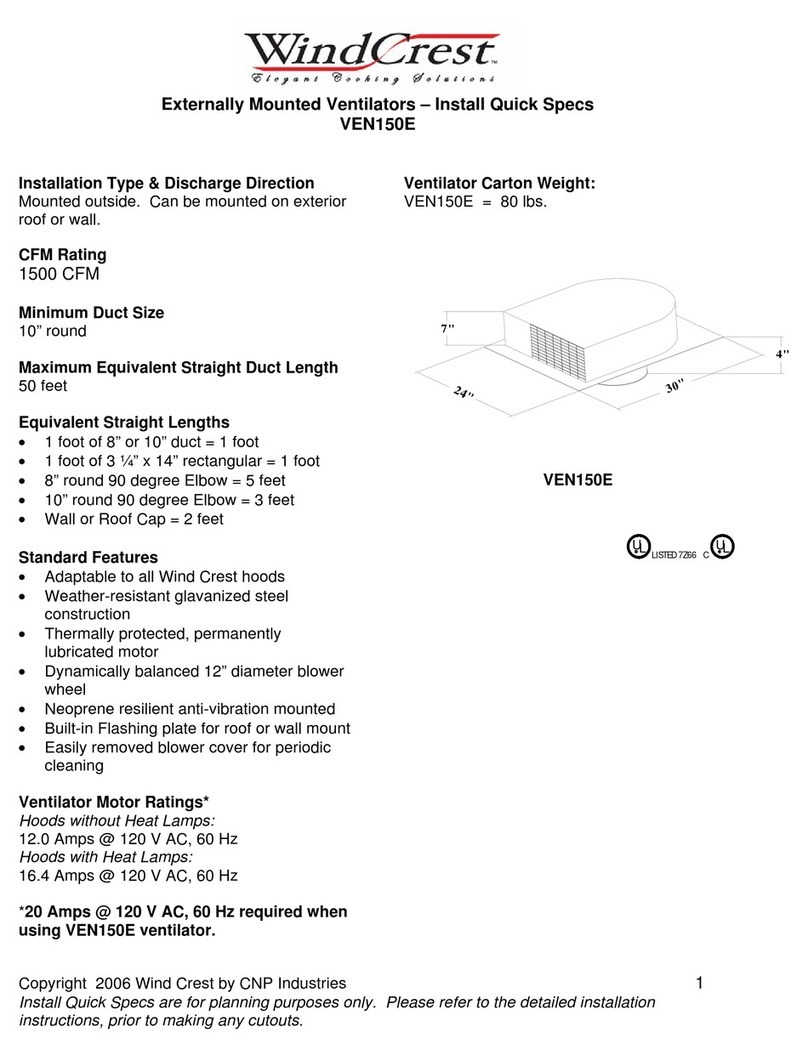

Remove See

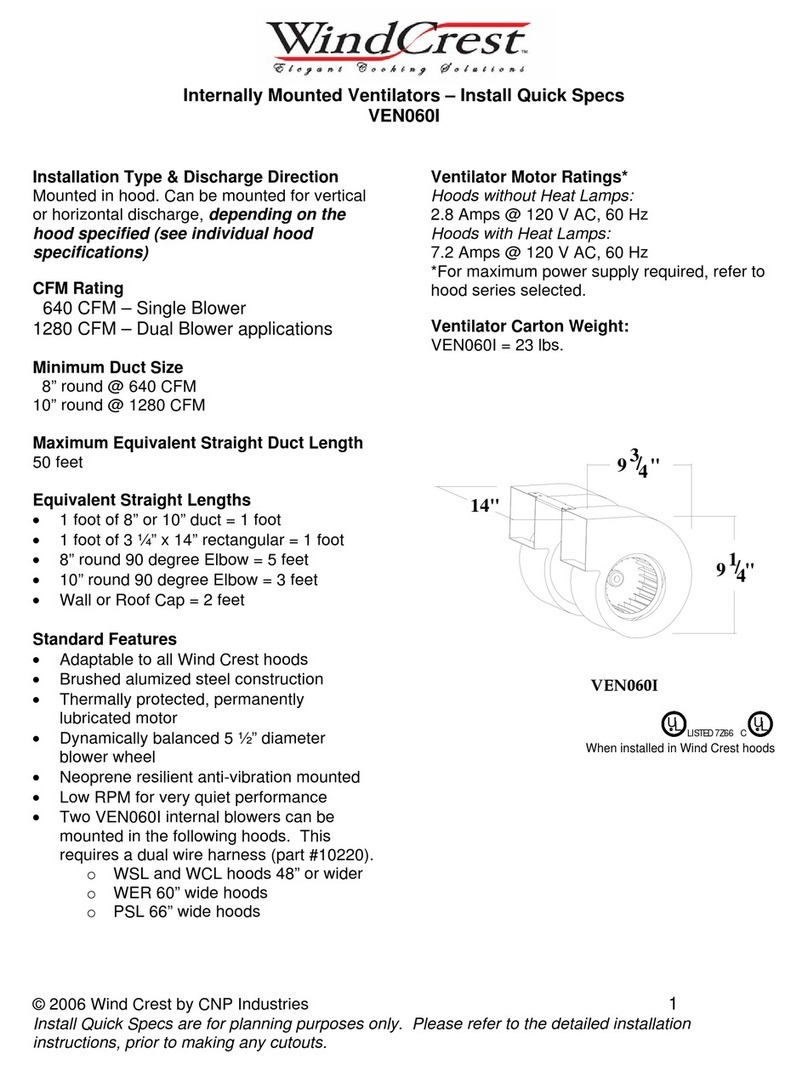

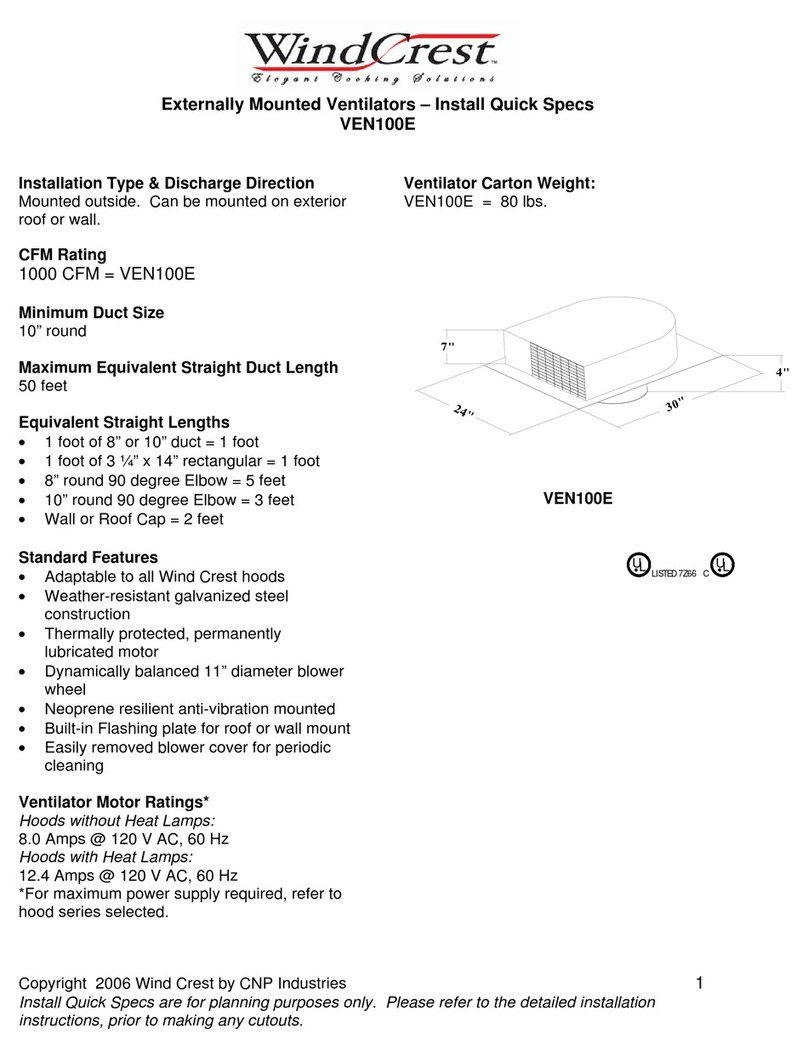

Ventilator Model Knock out # Transition # Fig

VEN060I Top Exhaust 2 10100.00 1,3

VEN120I Top Exhaust 2 & 3 11257.00 2,3

VEN100 & VEN150 2 & 3 11257.00 3

External, Top Exhaust

VEN060I Rear Exhaust 1 11254.00 4,5,6

Break the metal webs by placing a screwdriver at one

corner of the plate and hitting screwdriver sharply with a

hammer. After breaking a second web the plate can be

flexed to break other webs.

Wear eye protection when using tools.

Caution: When knock outs are removed

the edges will be sharp!!!!!!!!! Sharp Edges

should be Filed or Covered with Metal

Tape.

Attach and secure the transition to the hood with #6x3/8

sheet metal screws and tape all joints prior to installing the

hood. Attach hood to cabinet using #10 wood screws. If

duct cover is used refer to Instructions on Page –6. Holes

are located in the back panel and top panel of the hood for

mounting. Use a minimum of four #10x3/4 wood screws

to mount the hood. Longer screws are required if wall

board or other nonstructural surfaces are used between the

hood and main mounting surface which should be a

minimum of 3/4”thick. When using rear holes for

additional mounting use appropriate anchors if not

engaging the wood structure.

HINT: If you find vibration noise is present because of

cabinet structure use additional screws, in holes available,

to make the mounting more ridged.

Connect 120 volt, 60 Hz power through the conduit hole

in top of hood, connecting to pigtail in hood junction box,

white to white, black to black and connect green ground

wire to the power supply ground wire per local codes. See

Fig –A.

The recommended height from countertop or cooking

surface to the bottom edge of the hood is 30 to 36 inches.

Hood is recommended for use over domestic gas or

electric appliances. Not recommended for use over solid

fuel fired appliances.

After installing the hood, install the internal blower

(Top Exhaust See Fig 1 & 2; Rear Exhaust See Fig -

4) unit by positioning the blower onto bracket-A,

notched blower bracket will center blower. Rotate

into position against hood and secure Bracket –B to

Hood with #8 sheet metal screws. If the remote

ventilator is used see related instructions and Fig - 3.

The VEN100E/150E ventilator will require revision

of some wiring in the hood receptacle box - See

VEN100E/150E instructions.

NOTE: VEN150E requires a dedicated 20 AMP

Power Supply. All other ventilators require a

dedicated 15 AMP Power Supply

CAUTION: The hood is of sufficient weight that two

installers are recommended to prevent injury or damage to

the hood in handling.

Turn the power on at the service entrance and check the

operation of the controls.

NOTE: be sure that all dampers are operating properly

and are free to open.

: It is recommended that a backdraft damper

(#10288.00 for 8” round ducts, #10289.00 for 10” round ducts) be used in all

installations. In cold weather installations it is necessary to use a backdraft

damper to minimize backflow of cold air into room. A non-metallic thermal

break should also be used to minimize conduction of outside temperatures

through the ductwork. The thermal break should be located as close as possible

to where the ducting enters the heated portion of the house.

Turn off power circuit at

the service entrance and

lockout panel before

wiring the range hood.