WindSonic Doc No 1405 PS 0019 Issue 25 February 2017

10

6 PRE-INSTALLATION

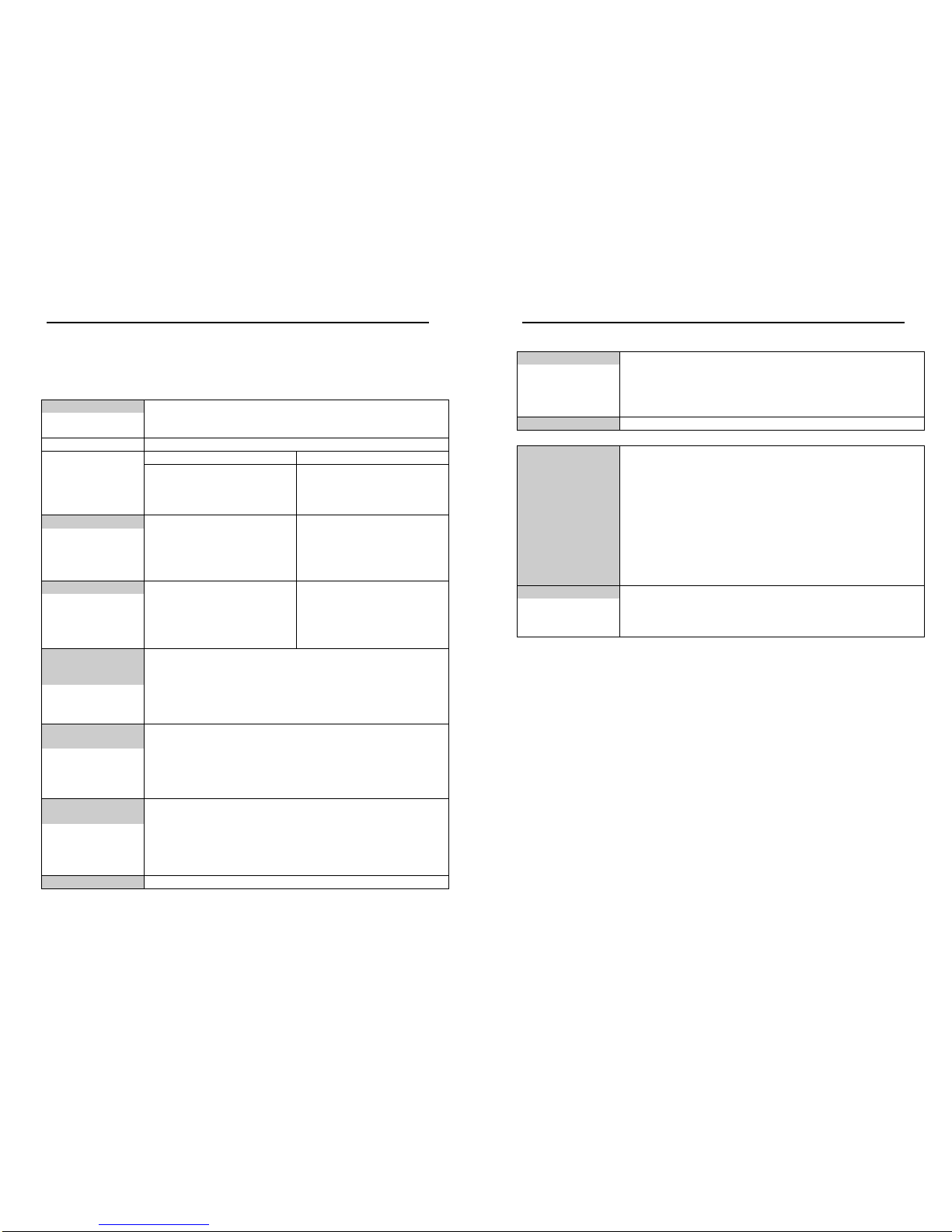

6.1Equipment supplied

Item Quantity

WindSonic 1

Connector and Mounting Screws comprising:-

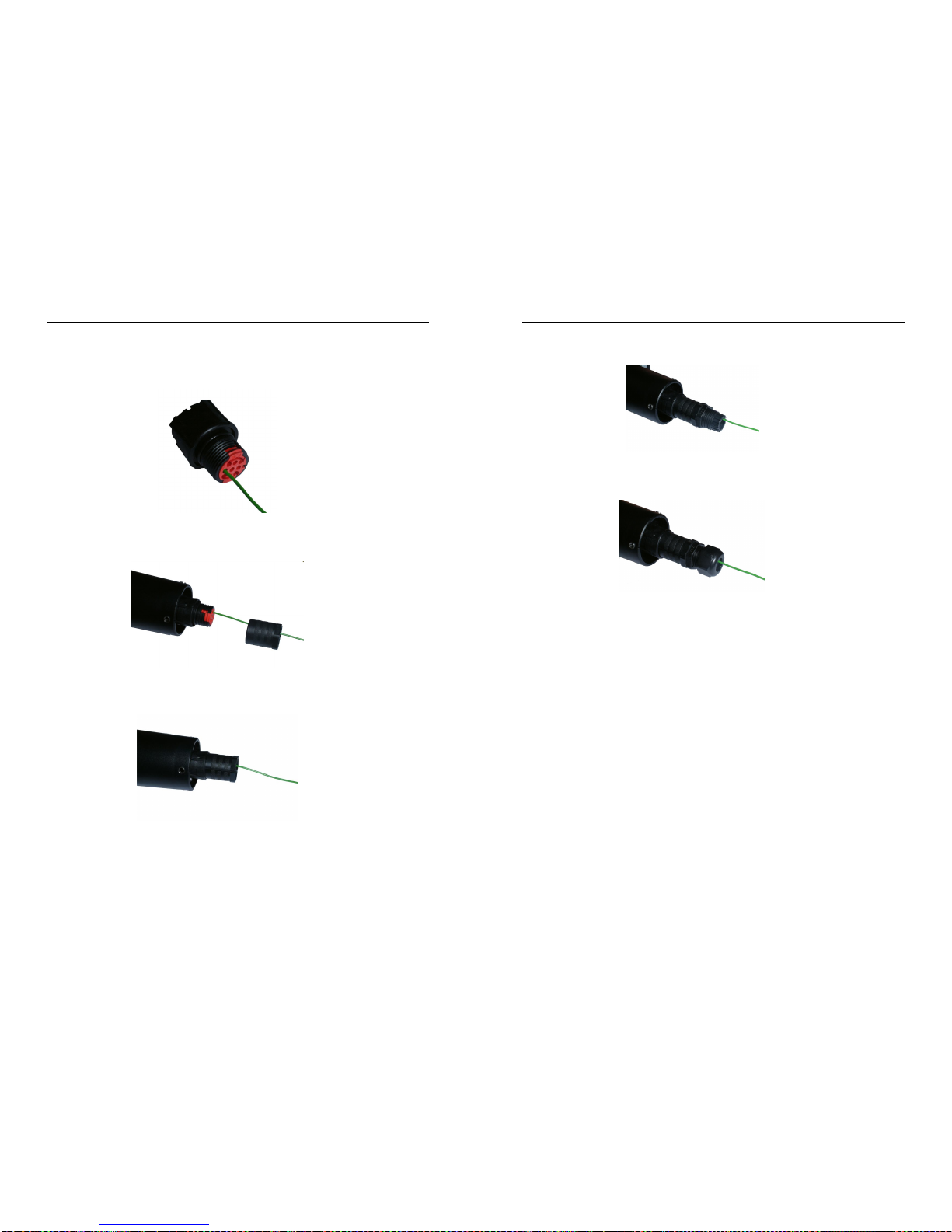

9 Way connector

Connector Contacts

Sealing Gland

Sealing Washer

1

9

1

1

Washer shake proof 3

Screws – M5 stainless steel 3

User Manual, Wind and WindView Software on the CD 1

Wind and WindView software is available free of charge from the Gill website –

http://gillinstruments.com/main/software.html

6.1.1 WindSonic Part Numbers

1405-PK-021 Black WindSonic Option 1 – RS 232 output only

1405-PK-068 White WindSonic Option 1 – RS 232 output only

1405-PK-038 Black WindSonic Option 2 – RS 232, 422 & 485 (point to point) output

1405-PK-072 White WindSonic Option 2 – RS 232, 422 & 485 (point to point) output

1405-PK-040 Black WindSonic Option 3 – RS 232, 422, 485 p to p & analogue output

1405-PK-073 White WindSonic Option 3 – RS 232, 422, 485 p to p & analogue output

1405-PK-100 Black WindSonic Option 4 – SDI-12 output only

1405-PK-110 White WindSonic Option 4 – SDI-12 output only

1405-PK-400 Black WindSonic 75 Option 1- RS232 output only

1405-PK-420 Black WindSonic 75 Option 2 RS 232, 422 & 485 (point to point) output

1405-PK-423 Black WindSonic 75 Option 3 RS 232, 422 & 485 p to p & analogue op.

Optional extras:

Item Part No

Cable 4 Pair, twisted and shielded 24 AWG 026-03156

Cable 3 Pair, twisted and shielded 24AWG

Cable 15 metres (4 pair twisted and shielded 24AWG – Connector

pins attached to one end and stripped wires the other).

WindSonic connector (1 supplied as standard see above)

WindSonic Support Tube 0.5 metre (Aluminium)

026-02660

1405-10-080

1405-PK-069

1405-30-056

Bracket for mounting to a Pole, includes a WindSonic Adaptor 1771-PK-115

WindSonic Doc No 1405 PS 0019 Issue 25 February 2017

11

6.2Packaging

Whilst the WindSonic is being moved to its installation site, the unit should be kept in its

inner packaging. All the packaging should be retained for use if the unit has to be returned at

any time, or if a self-test is performed.

6.3Installation requirements

Host system - One of the following:

PC fitted with a suitable interface to match the chosen communication format

(RS232, RS422, or RS485 (point to point), compatible with the WindSonic option

selected,

and a suitable Terminal Emulation software package. For example HyperTerminal for

Windows or Wind Software that is available from the Gill website at

http://gillinstruments.com/main/software.html.

Gill WindDisplay (WindSonic option 2 or 3 only).

Other equipment with input/output compatibility to the WindSonic Option selected.

For example, Data loggers.

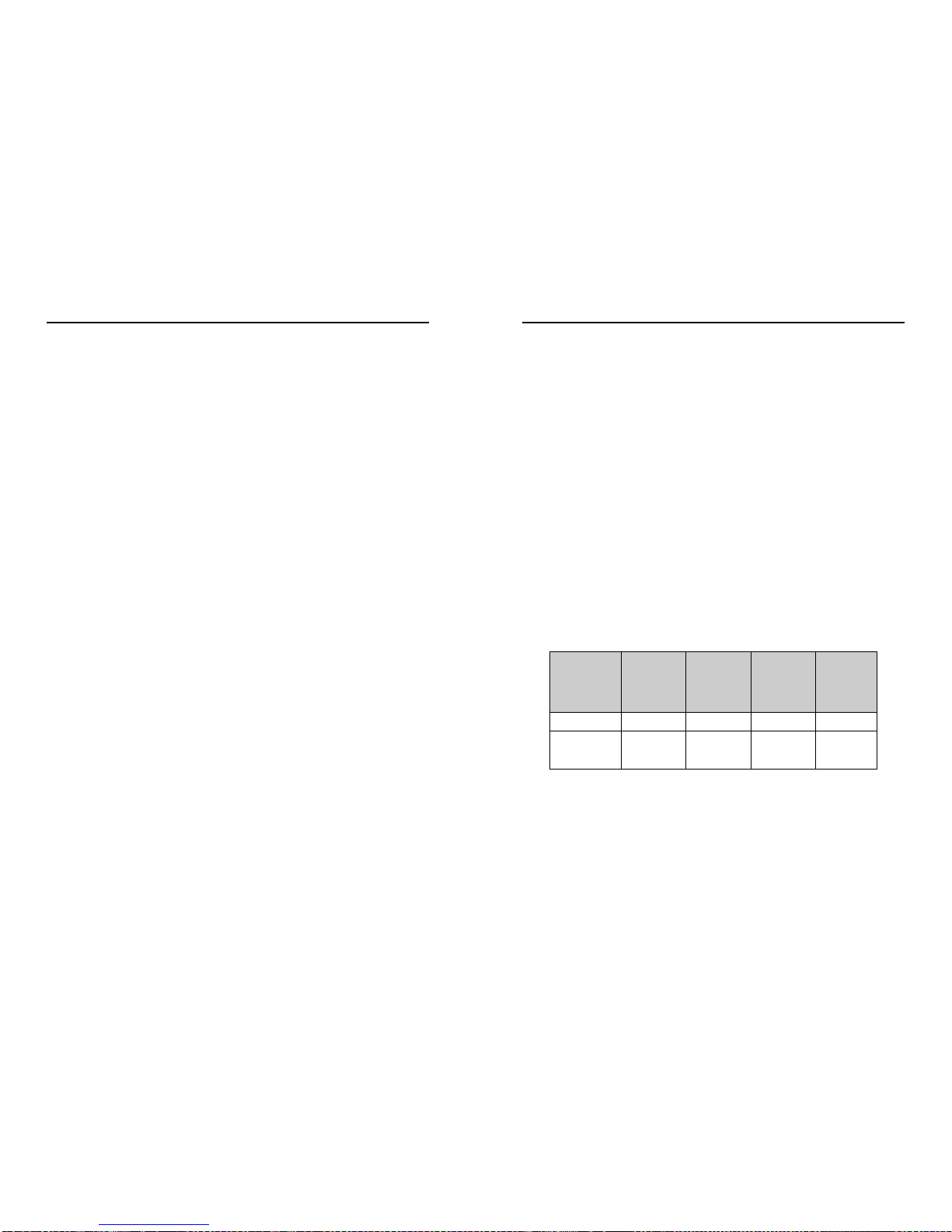

Cable - To connect between the WindSonic and the host system

See Section 7.3.1 Cable type for cable specification.

There are restrictions on the maximum cable lengths for correct operation.

The cable should be routed up the inside of the mounting tube.

Mounting tube (e.g. 0.5 metre long Gill part 1405-30-056)

Standard tube 1.75 inches (44.45mm) Outside Diameter x 3mm wall thickness. Note it is

important that the correct diameter tube is usedto prevent damage to the

WindSonic lower moulding when tightening the screws.

See Figure 3, Alignment & Mounting Details on page 26.

For non-hostile environments, Aluminium tube can be used.

For hostile environments, you should select a material suitable for the intended

environment. For example, stainless steel 316 for marine use.

Mounting Bracket (Gill Part 1771-PK-115)