10

MIG WELDING GUN OPERATION MANUAL

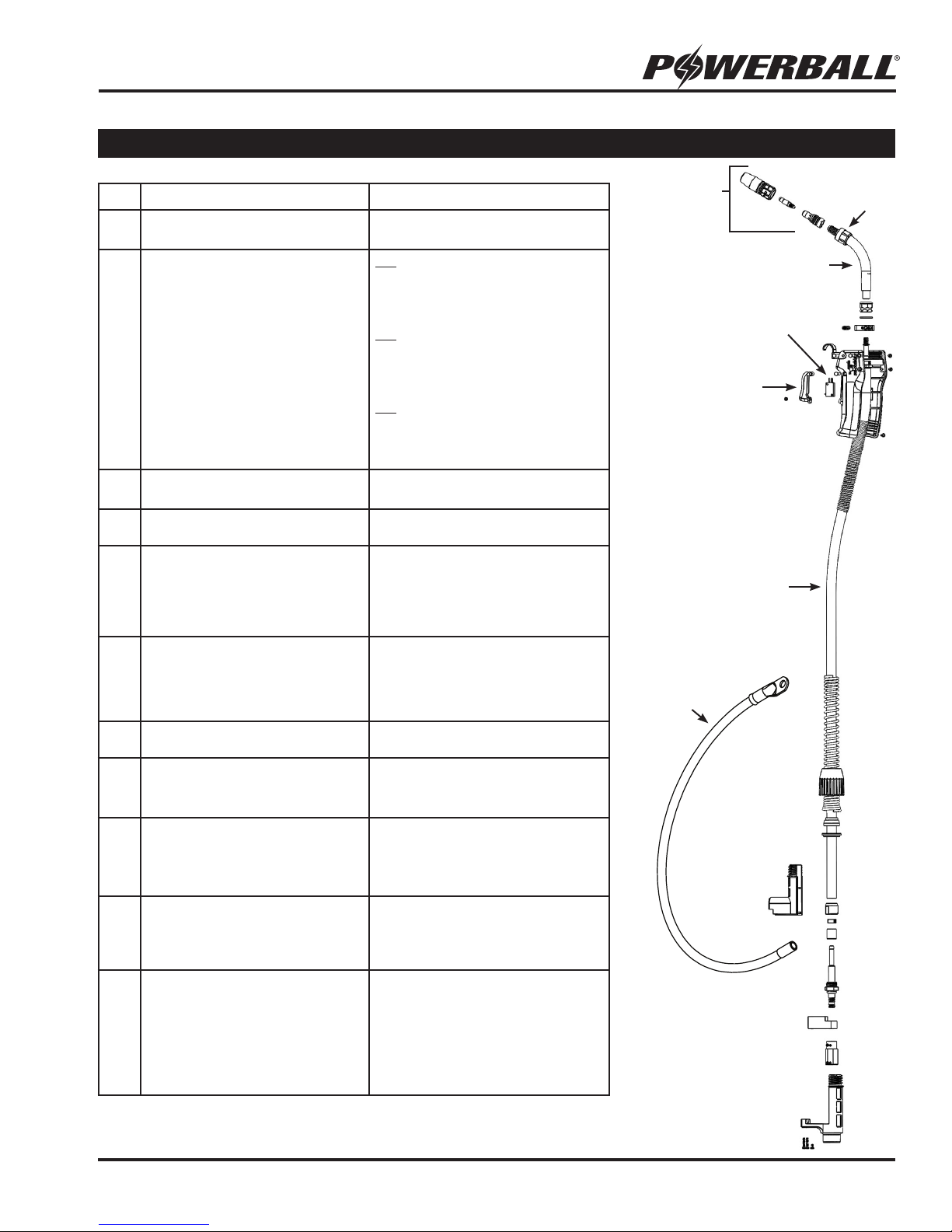

9.0 CONSUMABLES & TORCH ACCESSORIES

WTP‐035‐PB‐1 .035(0.9mm)POWERBALLTIPS‐10pk.

WTP‐035T‐PB‐1 .035(0.9mm)TIGHTTOLERANCEPOWERBALLTIPS‐10pk.

WTP‐040‐PB‐1 .040(1.0mm)POWERBALLTIPS‐10pk.

WTP‐045‐PB‐1 .045(1.2mm)POWERBALLTIPS‐10pk.

WTP‐045T‐PB‐1 .045(1.2mm)TIGHTTOLERANCEPOWERBALLTIPS‐10pk.

WTP‐3/64‐PB‐1 3/64(1.2mm)POWERBALLTIPS‐10pk.

WTP‐3/64A‐PB‐1 3/64(1.2mm)POWERBALLTIPSFORALUMINUMWIRE‐10pk.

WTP‐052‐PB‐1 .052(1.3mm)POWERBALLTIPS‐10pk.

WTP‐062‐PB‐1 .062(1.6mm)POWERBALLTIPS‐10pk.

WTP‐5/64‐PB‐1 5/64(2.0mm)POWERBALLTIPS‐10pk.

WTP‐035‐PB‐3 .035(0.9mm)POWERBALLTIPS‐10pk.

WTP‐040‐PB‐3 .040(1.0mm)POWERBALLTIPS‐10pk.

WTP‐045‐PB‐3 .045(1.2mm)POWERBALLTIPS‐10pk.

WTP‐052‐PB‐3 .052(1.3mm)POWERBALLTIPS‐10pk.

WTP‐062‐PB‐3 .062(1.6mm)POWERBALLTIPS‐10pk.

WTP‐3/32‐PB‐3 3/32(2.4mm)POWERBALLTIPS‐10pk.

WTP‐035‐PB‐5 .035(0.9mm)POWERBALLTIPS‐10pk.

WTP‐035T‐PB‐5 .035(0.9mm)TIGHTTOLERANCEPOWERBALLTIPS‐10pk.

WTP‐040‐PB‐5 .040(1.0mm)POWERBALLTIPS‐10pk.

WTP‐045‐PB‐5 .045(1.2mm)POWERBALLTIPS‐10pk.

WTP‐045T‐PB‐5 .045(1.2mm)TIGHTTOLERANCEPOWERBALLTIPS‐10pk.

WTP‐052‐PB‐5 .052(1.3mm)POWERBALLTIPS‐10pk.

WTP‐062‐PB‐5 .062(1.6mm)POWERBALLTIPS‐10pk.

WTP‐ELD‐PB‐2 POWERBALL®DIFFUSERS‐5pk.

WTP‐ELL‐3545‐10 10FT(3m)TORCHLINERFOR.035‐.045(0.9‐1.2mm)WIRE

WTP‐ELL‐3545‐15 15FT(4.6m)TORCHLINERFOR.035‐.045(0.9‐1.2mm)WIRE

WTP‐ELL‐3545‐25 25FT(7.6m)TORCHLINERFOR.035‐.045(0.9‐1.2mm)WIRE

WTP‐ELL‐45116‐10 10FT(3m)TORCHLINERFOR.045‐1/16(1.2‐1.6mm)WIRE

WTP‐ELL‐45116‐15 15FT(4.6m)TORCHLINERFOR.045‐1/16(1.2‐1.6mm)WIRE

WTP‐ELL‐45116‐25 25FT(7.6m)TORCHLINERFOR.045‐1/16(1.2‐1.6mm)WIRE

WTP‐ELL‐564‐10 10FT(3m)TORCHLINERFOR5/64(2mm)WIRE

WTP‐ELL‐564‐15 15FT(4.6m)TORCHLINERFOR5/64(2mm)WIRE

WTP‐ELL‐564‐25 25FT(7.6m)TORCHLINERFOR5/64(2mm)WIRE

WTP‐ELL‐332‐10 10FT(3m)TORCHLINERFOR3/32(2.4mm)WIRE

WTP‐ELL‐332‐15 15FT(4.6m)TORCHLINERFOR3/32(2.4mm)WIRE

WTP‐ELL‐332‐25 25FT(7.6m)TORCHLINERFOR3/32(2.4mm)WIRE

WTP‐HTL‐3545‐10 10FT(3m)TORCHLINERFOR.035‐.045(0.9‐1.2mm)NON‐FERROUSWIRE

WTP‐HTL‐3545‐15 15FT(4.6m)TORCHLINERFOR.035‐.045(0.9‐1.2mm)NON‐FERROUSWIRE

WTP‐HTL‐45116‐10 10FT(3m)TORCHLINERFOR.045‐1/16(1.2‐1.6mm)NON‐FERROUSWIRE

WTP‐HTL‐45116‐15 15FT(4.6m)TORCHLINERFOR.045‐1/16(1.2‐1.6mm)NON‐FERROUSWIRE

POWERBALL®TORCHLINERS

E‐POWER®STEELLINERSFORFERROUSWIRES

E‐POWER®HI‐TEMPPOLYMERLINERSFORALUMINUM/NON‐FERROUSWIRES

POWERBALL®CONTACTTIPS

PB‐1STYLETIPS,STANDARD

PB‐3STYLETIPSFORHEAVYDUTYAPPLICATIONS

PB‐5STYLETAPEREDTIPSFORNARROWTORCHNOZZLES

POWERBALL®DIFFUSERS

PART# DESCRIPTION MATERIAL

WTP‐ELN‐50B‐TSRB 1/2”(12.7mm)BOTTLENOSE,STANDARDDUTY‐RECESSEDTIP‐5pk. BRASS

WTP‐ELN‐50B‐TSFB 1/2”(12.7mm)BOTTLENOSE,STANDARDDUTY‐FLUSHTIP‐5pk. BRASS

WTP‐ELN‐50B‐TSRC 1/2”(12.7mm)BOTTLENOSE,STANDARDDUTY‐RECESSEDTIP‐5pk. COPPER

WTP‐ELN‐50B‐TSSB 1/2”(12.7mm)BOTTLENOSE,STANDARDDUTY‐PROTRUDINGTIP‐5pk. BRASS

WTP‐ELN‐50B‐TSSC 1/2”(12.7mm)BOTTLENOSE,STANDARDDUTY‐PROTRUDINGTIP‐5pk. COPPER

WTP‐ELN‐50T‐TSRC 1/2”(12.7mm)TAPERED,STANDARDDUTY‐RECESSEDTIP‐5pk. COPPER

WTP‐ELN‐62B‐THFB 5/8”(15.9mm)BOTTLENOSE,HEAVYDUTY‐FLUSHTIP‐5pk. BRASS

WTP‐ELN‐62B‐THFC 5/8”(15.9mm)BOTTLENOSE,HEAVYDUTY‐FLUSHTIP‐5pk. COPPER

WTP‐ELN‐62T‐THFB 5/8”(15.9mm)TAPERED,HEAVYDUTY‐FLUSHTIP‐5pk. BRASS

WTP‐ELN‐62T‐THFC 5/8”(15.9mm)TAPERED,HEAVYDUTY‐FLUSHTIP‐5pk. COPPER

WTP‐ELN‐62T‐THRB 5/8”(15.9mm)TAPERED,HEAVYDUTY‐PROTRUDINGTIP‐5pk. BRASS

WTP‐ELN‐62T‐THRC 5/8”(15.9mm)TAPERED,HEAVYDUTY‐RECESSEDTIP‐5pk. COPPER

WTP‐ELN‐62T‐TSSC 5/8”(15.9mm)TAPERED,HEAVYDUTY‐PROTRUDINGTIP‐5pk. COPPER

POWERBALL®TORCHNOZZLES

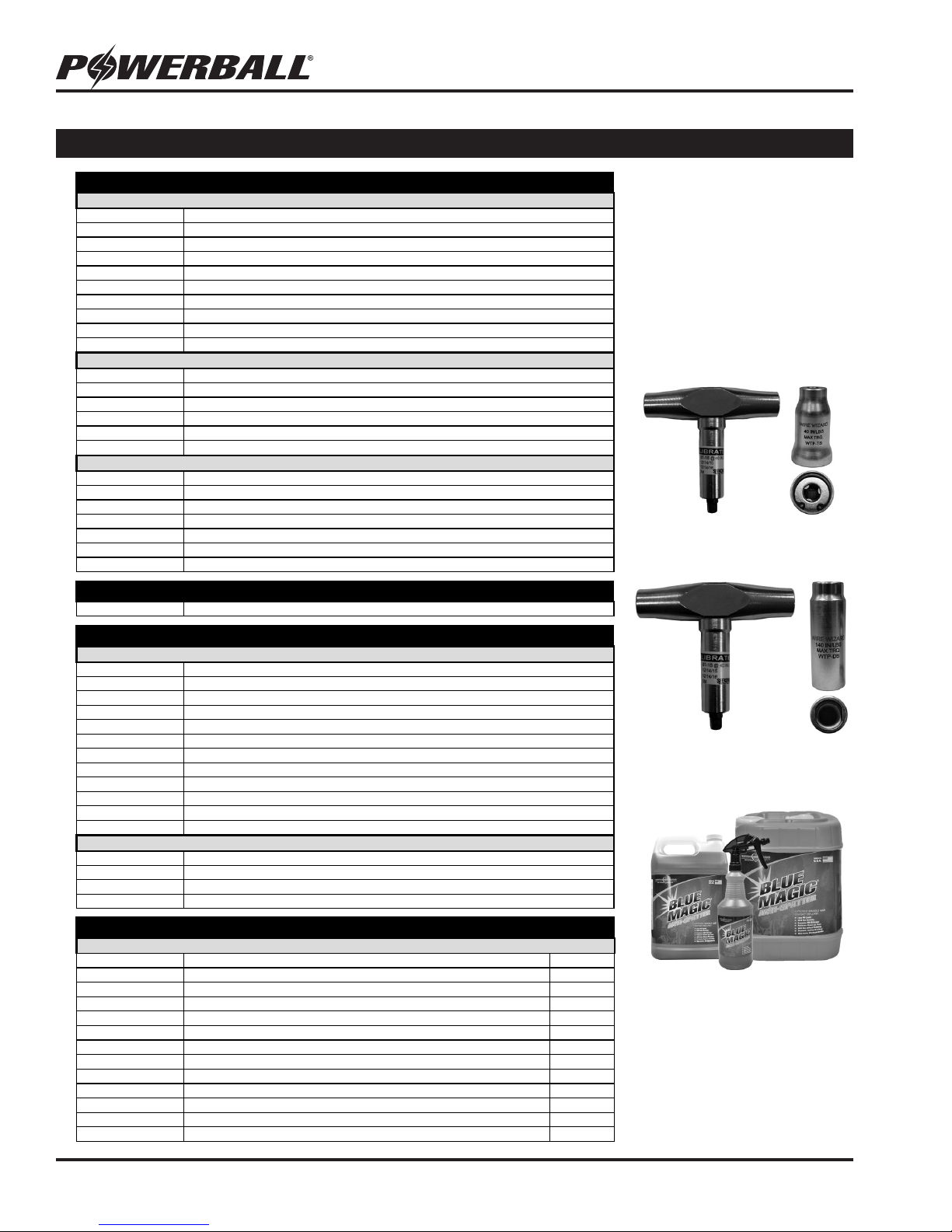

WTP-TS

Tip Socket

WTP-TTW

Calibrated Tip Wrench

(40 in/lbs)

WTP-DTW

Calibrated Diffuser

Wrench (140 in/lbs)

WTP-TS

Diffuser

Socket

Tip & Diffuser Sockets

and Calibrated Wrenches

The 9mm Quick-Grip Torch Tip socket

(1/4”) features an innovative design

with grippers that easily installs and

removes 9mm PowerBall® torch tips.

The 15mm Diffuser Socket (3/8”) is

compatible with all Diffusers with

15mm wrench ats. Saves time and

allows for an accurate torque setting

for consistent contact. Consistent

contact = consistent welds!

Blue Magic®Anti-spatter

Blue Magic® Anti-spatter from Wire

Wizard® Welding Products is highly

recommended for reduced spatter

build-up and adhesion. Specially

formulated for industrial use, this

premium anti-spatter is trusted by

top manufacturers around the globe!

Available through your local welding

product distributor.