About these instructions 50103430000_Varitain-PI(Ver1.4)Rev 01122018E.docx

2

Contents

1. ABOUT THESE INSTRUCTIONS................................................ 3

1.1 Symbols and guidance signs in these instructions................3

1.2 Who are these instructions for?.............................................3

2. SYSTEM DESCRIPTION ............................................................. 4

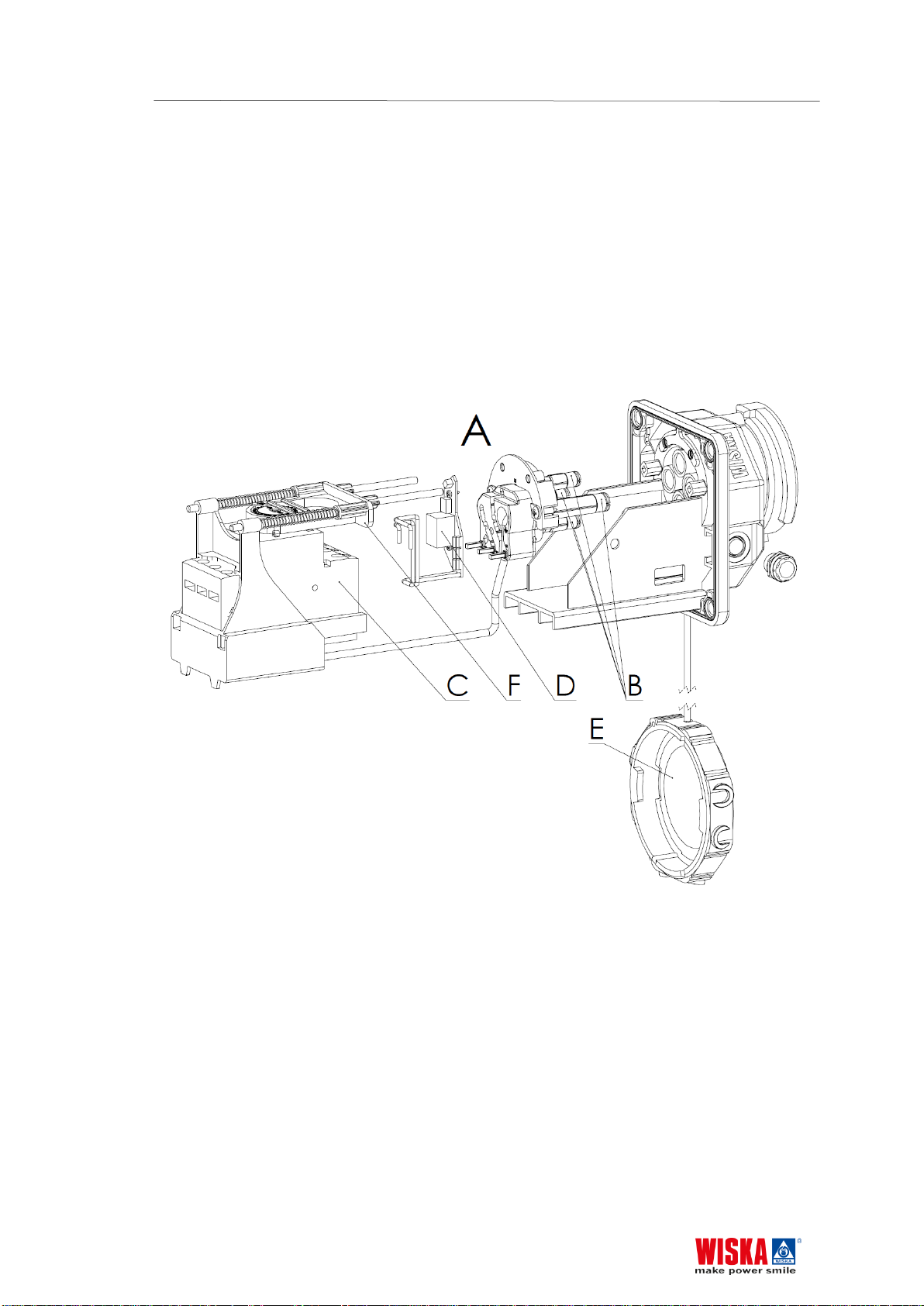

3.1 The system components........................................................ 5

3. DESCRIPTION............................................................................. 6

4.1 Casing....................................................................................6

4.2 CEE socket insert .................................................................. 6

4.3 LED unit ................................................................................. 6

4.4 Locking system ...................................................................... 7

4.5 Circuit-breaker .......................................................................8

4.6 Connection terminals............................................................. 8

4. REPAIR AND MAINTENANCE ................................................... 9

5.1 Maintenance .......................................................................... 9

5.2 Repair..................................................................................... 9

5.3 Replacement of the CEE-socket plug-in unit.........................9

5.4 Replace of the LED-module.................................................12

5.6 Replacement of the MCCB..................................................13

5.7 Replacing the housing seal (seal between housing and

cover) 16

5. ELECTRICAL CIRCUIT DIAGRAMS ........................................ 18

6.1 Circuit diagram without current limiter .................................18

6.2 Circuit diagram with current limiter ...................................... 19

6. GL TYPE APPROVAL ...............................................................20