63062506_201803.indd

Installation instructions

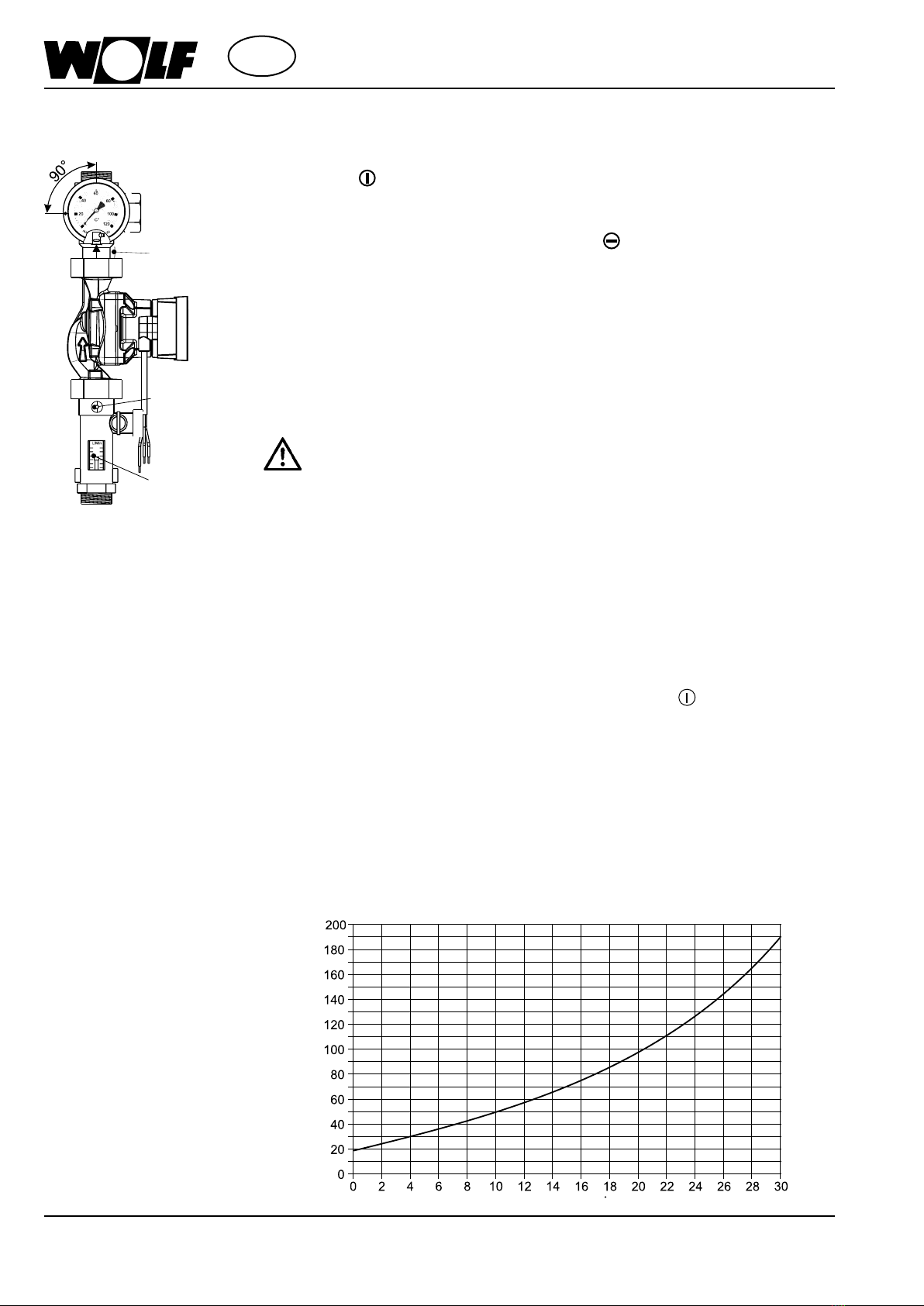

Solar pump assembly 10E / 20E

GB

Installation location The solar pump assembly is to be installed in the solar return line.

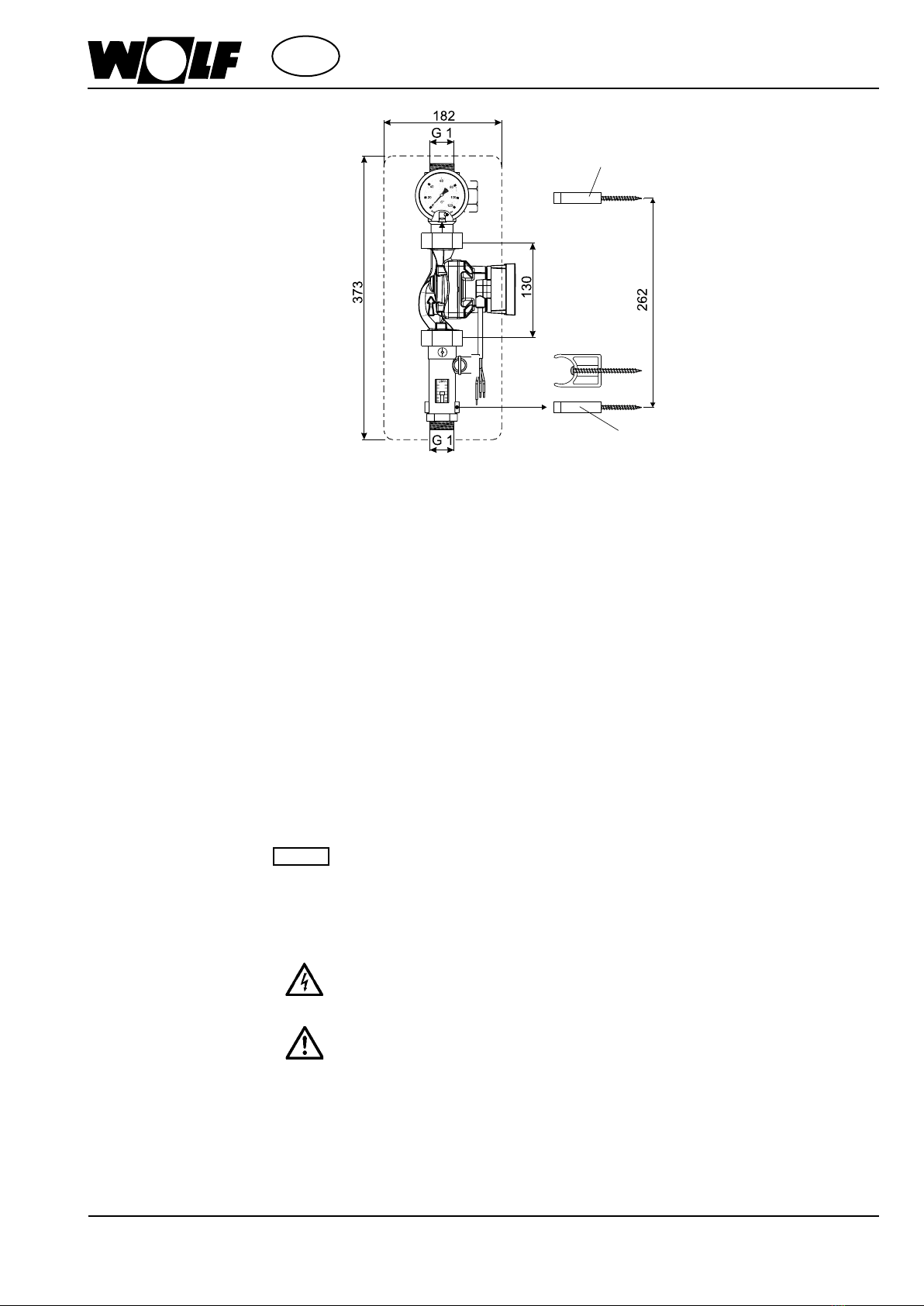

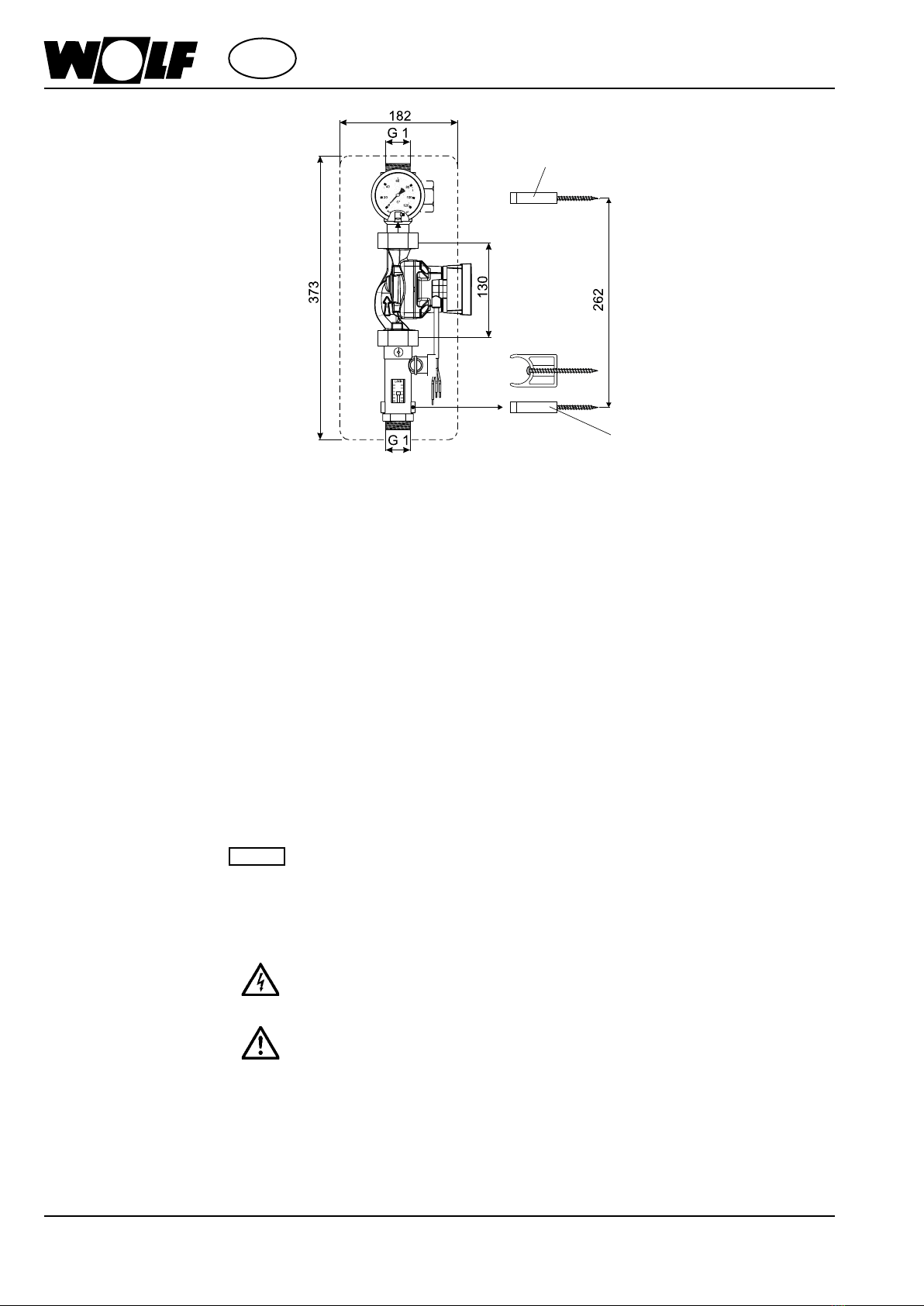

Connection dimensions

installation of the

connecting lines

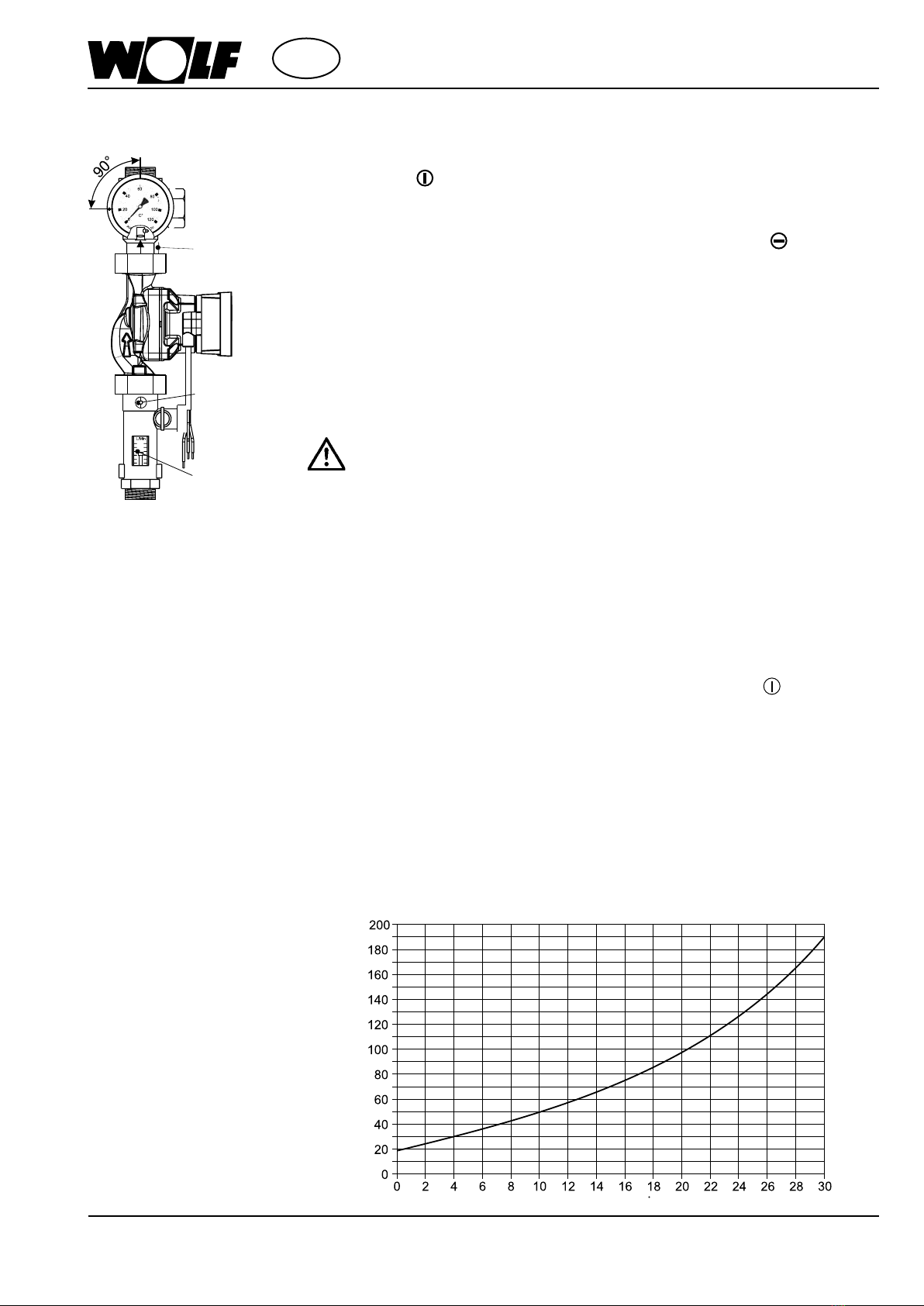

- Use clamping ring unions to t the pipes of the solar heating system to the upper and

lower connections. Insert the pipe ends, cut off at right angles and deburred, as far

as they will go and use an open-ended spanner to rmly tighten the clamping ring

unions. Counter while tightening.

If copper tubes with a wall thickness of ≤ 1 mm are employed, in particular

soft copper tubes (rolled goods), support sleeves are to be used for additional

stabilisation of the pipes.

Warning

Wall mounting bracket top

Wall mounting bracket bottom

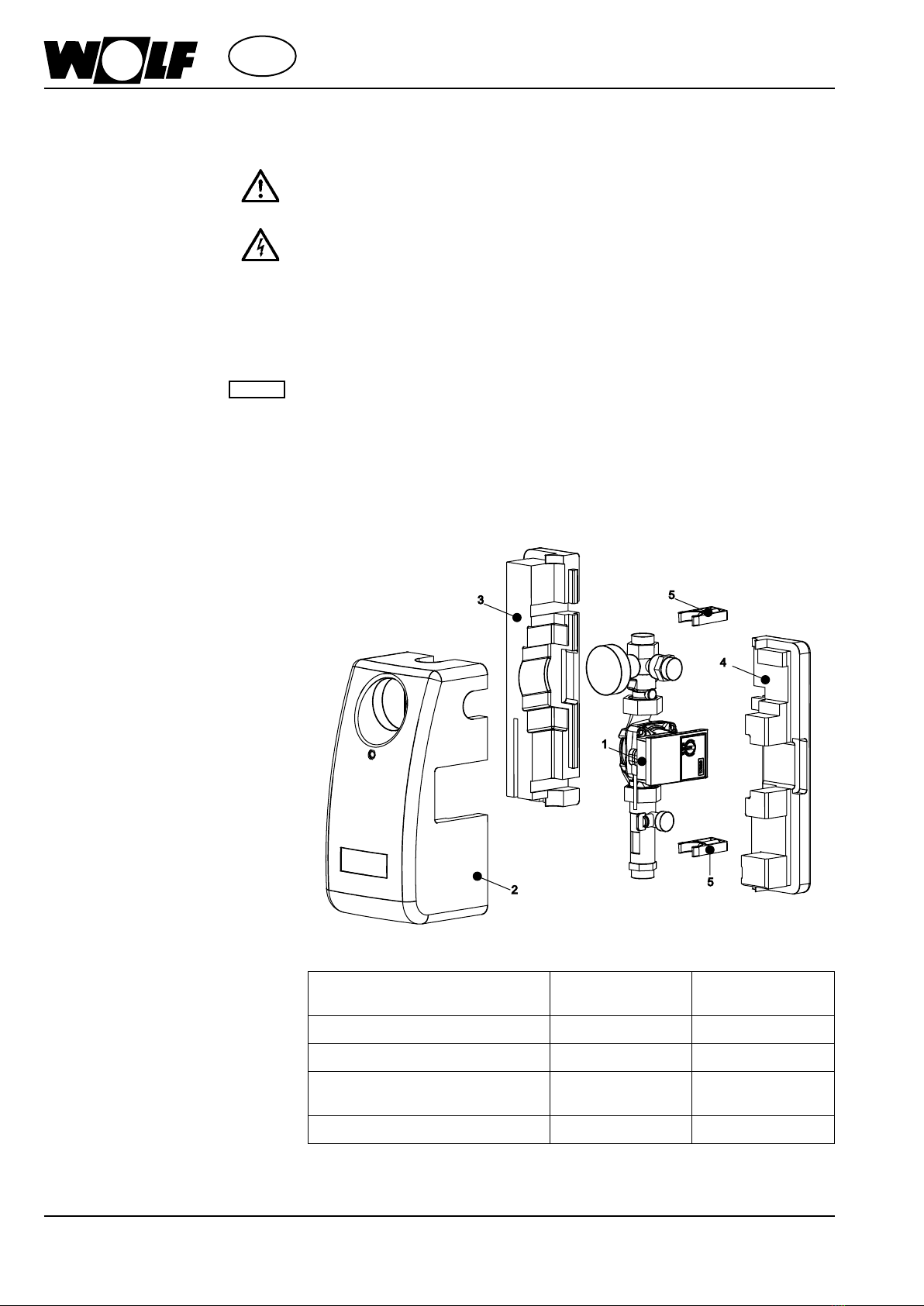

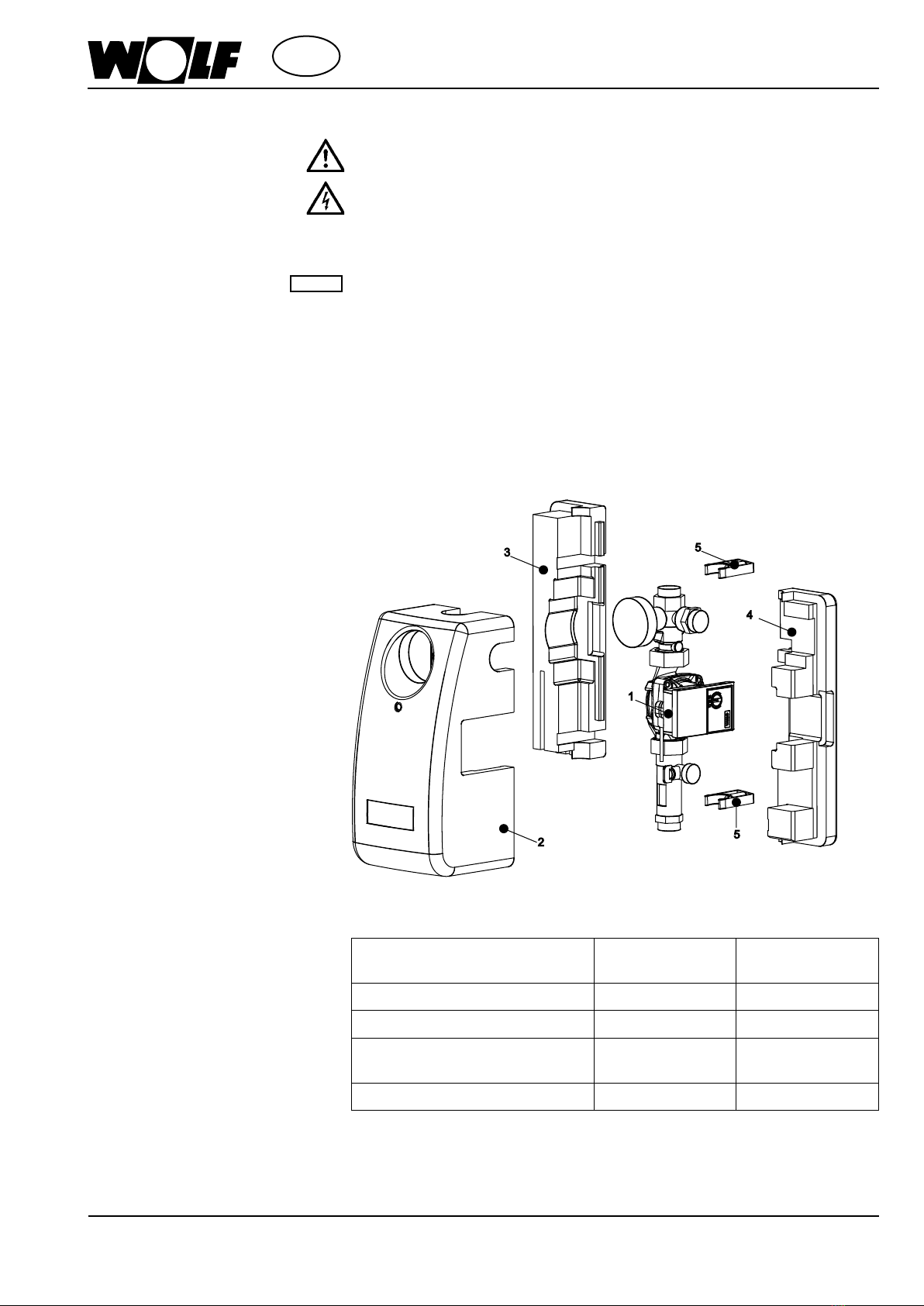

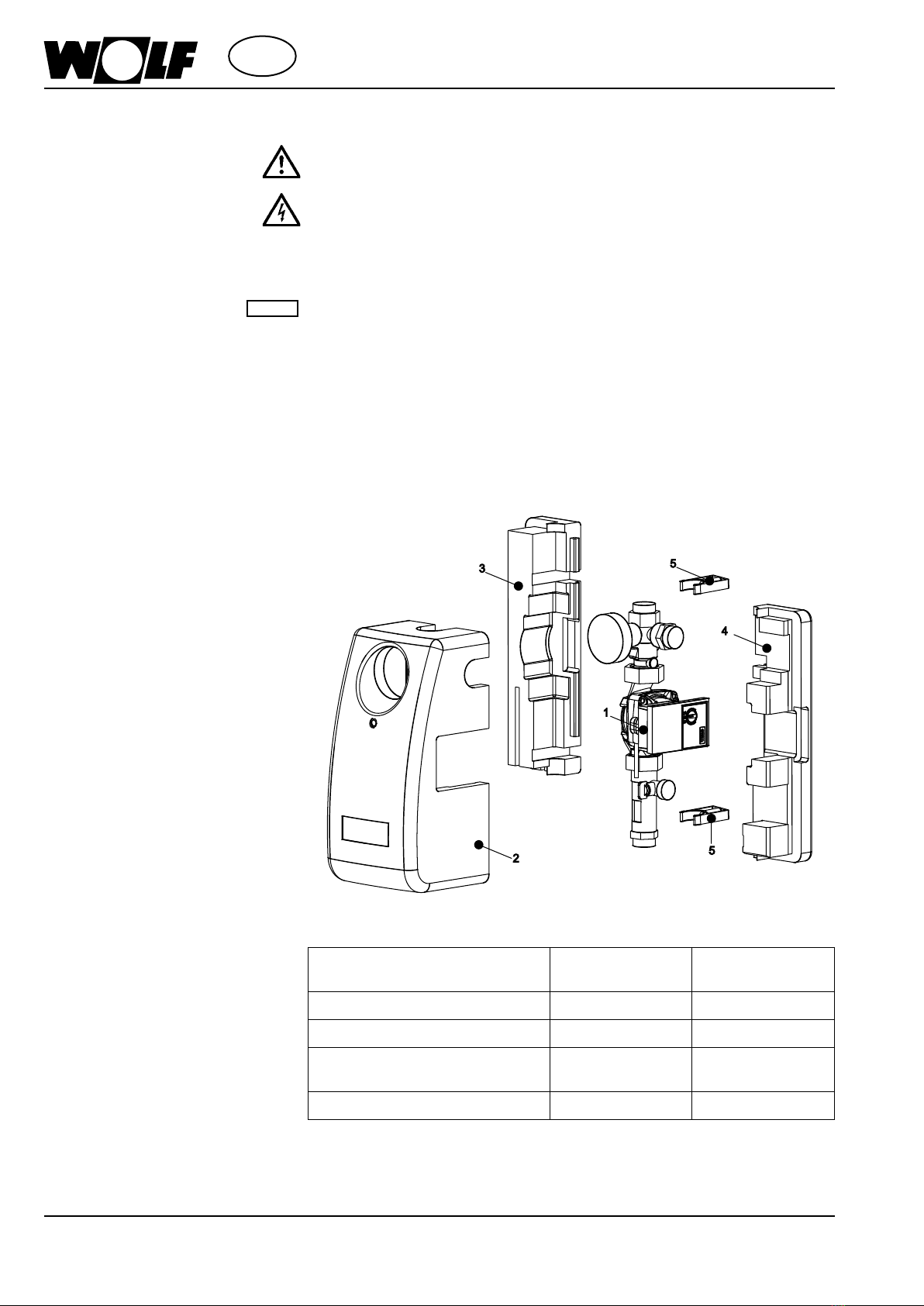

Wall mounting - Take the solar pump assembly out of its packaging and remove the insulating

shells (2, 3 & 4).

- Mark drill holes (spacing between centres 262 mm), drill (Ø 8 mm) and t the

wall plugs.

- Unclip the return branch (1) from the upper and lower wall mounting bracket (5)

- Mount the wall mounting brackets (5) using the screws provided

- Connect the rear insulating shells (3) and (4) together over the wall mounting

bracket

- Clip the return branch (1) back into the wall mounting bracket (6).

Electrical connection

of the circulation pump

- Only specically trained and qualied persons are permitted to work on electrical

components. Pass the connecting cable of the circulation pump through the insulation

and connect as described in the installation instructions for the solar control unit.

There is a possibility of destruction or perilous voltage on the device.

Do not ll the system in strong sunlight, or cover the collectors. There is a risk

of burns! Only use undiluted ANRO to ll the system. The addition of water or

other process media is not permissible. There is a danger of occulation and

protection against frost and corrosion is no longer ensured. This can lead to the

complete failure of the system.

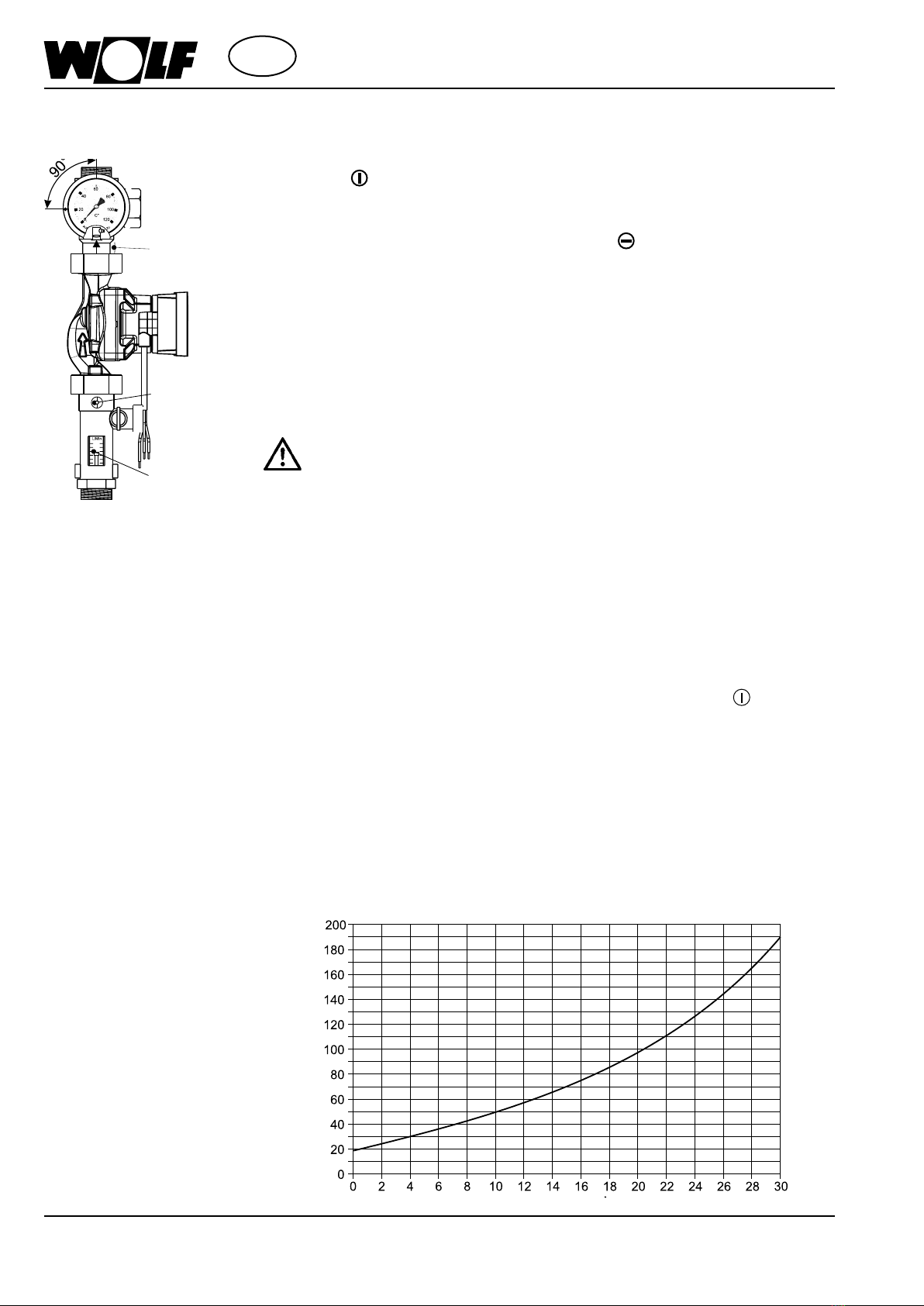

For lling and ushing the solar heating system we recommend the use of a lling and

ushing pump for at least 20 to 60 minutes! The ow velocity must be > 4 m/s in order

to be able to drag along air pockets and contamination. Manual venting can then be

dispensed with.

Filling and ushing the

system