Page 1

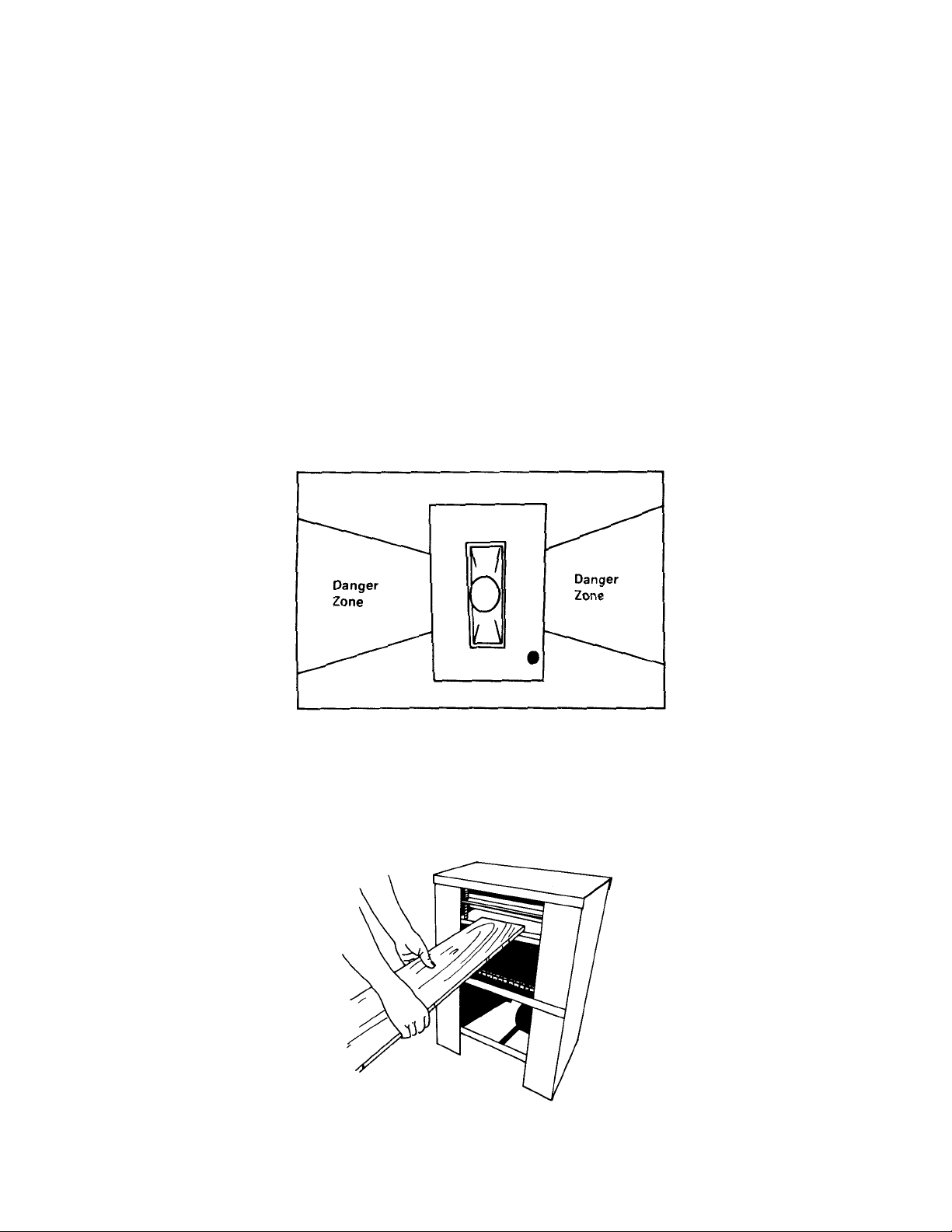

GENERAL SAFETY INSTRUCTIONS

Know your power tool – Read the owner’s manual carefully. Learn the applications and

limitations of your sander as well as the potential hazards this particular tool presents.

Ground all tools – Check the receptacles in your shop. They should all be approved

3-prong grounding type. If they are not, a qualified electrician should install grounded

receptacles throughout your shop. Any tool that has a three-pronged plug should be

connected to a grounded receptacle. Double insulated tools do not require this type plug,

however, only a small proportion of the tools manufactured today are double insulated.

Protect yourself – Use full face shield or approved safety glasses with side shields.

Everyday eyeglasses should not be used as safety glasses. Use dust mask when sanding.

Wear safety approved hearing protectors. Extended exposure to noise from power tools

can damage your hearing.

Never operate power equipment if you are fatigued, taking medication or drinking

alcohol.

Keep all machine guards in place and in working order.

Remove adjusting keys and wrenches – Any time you attach accessories, change belts

or make adjustments to any tool, make sure that all keys, adjusting wrenches and other

tools are removed from the machine before turning it on.

Keep your shop clean, well lot, and dry. Clutter invites accidents. You can make your

shop time more comfortable with proper lighting – eye strain fatigues your entire

body. Particular attention should be paid to moisture. Using power tools in damp or wet

locations can result in electrocution.

Keep children away – All visitors should be kept at a safe distance from work area and

should wear eye and ear protection.

Maker workshop childproof – Use padlocks, master switches, or any system that

prevents children or other unauthorized persons from starting machinery.

Use the right tool at the recommended rate – Don’t force tools or attachments to do a

job for which they were not designed. Learn the recommended rate of use for each tool.