Site Planning

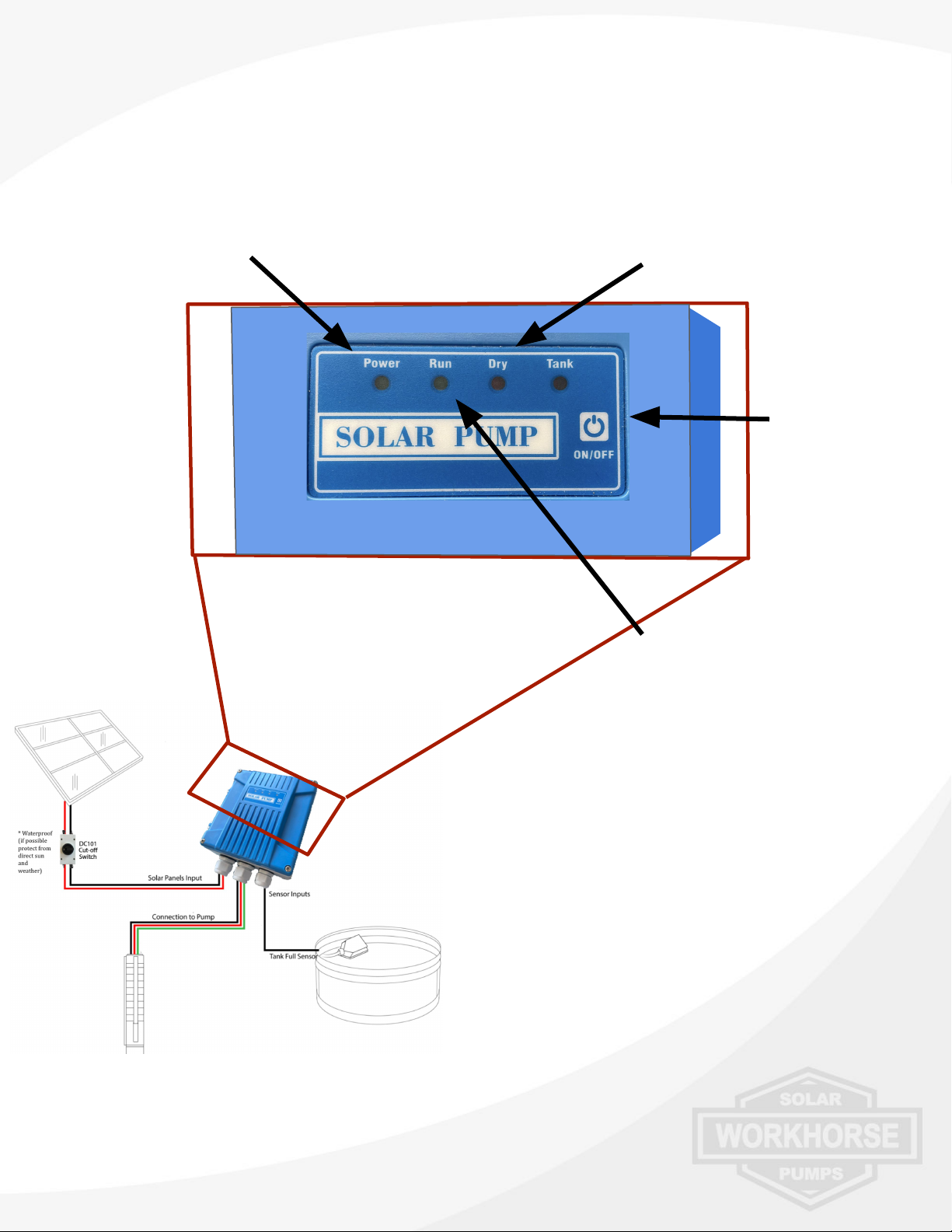

✓PANEL LOCATION- Solar panels

should be mounted on a secure

structure, ground mount or top of

pole mount. Panels should face true

South and at an angle appropriate

for your latitude. If you are

mounting your panels on an already

existing structure, try to get as close

to the correct angle as possible.

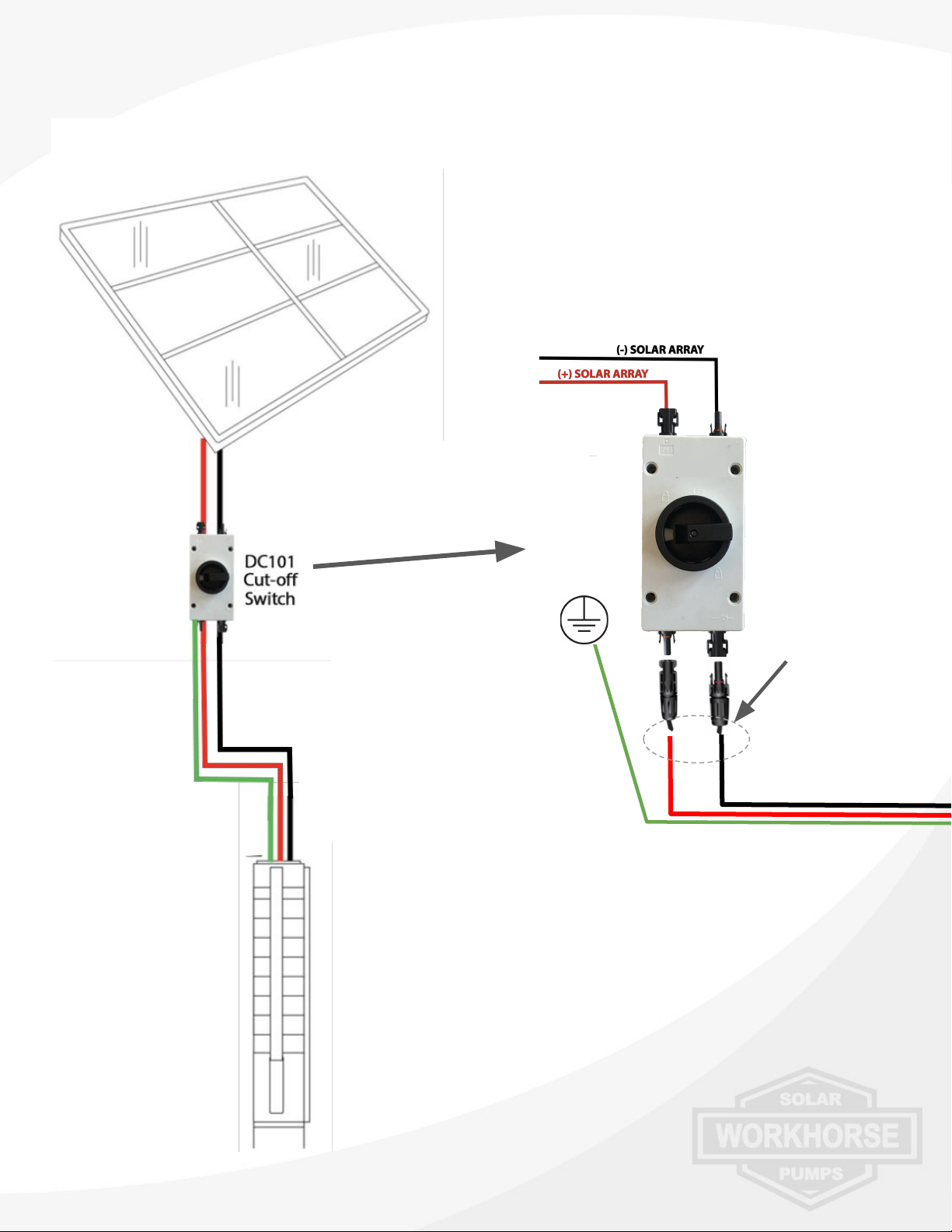

✓GROUNDING- It is important to

ground the entire solar well pump

system to ensure proper safety

and to prevent damage in the

event of a lightning strike but also

to prevent static buildup. In

lightning prone areas, this is

especially important and a long

dedicated copper ground rod

should be installed near the solar

panels and controller. If the well

casing is metal and local code

allows, it can be used for an Earth

ground, instead of dedicated

ground rod. Do not connect the

sensors or the solar panel returns

(-) to Earth ground.

✓No AC POWER- Without an

external converter box that

converts AC to DC for the W3DC

pumps, AC power cannot be used.

KEY POINTS

●Mount the solar panels facing south at

an angle appropriate for your latitude.

●Avoid all shadows on the solar array.

Even a small shadow on one part of a

panel can restrict current for all of the

panels, significantly affecting system

performance.

8

✓AVOID SHADOWS- Choose a location

for the panels that gets plenty of sun

and is free from daily shadows. One of

the most common issues with low

performing systems is shadows on the

solar arrays. Even a small shadow on

one part of a panel can restrict current

for all of the panels, significantly

affecting system performance.

WorkhorsePumps.com | 916-623-4621