2

Warning

Using with dangerous liquids or atmosphere

When transferring dangerous liquid using this pump, or using in potentially explosive atmospheres (only

explosion-proof type), observe the equipment standards set forth by law and make sure to perform daily

inspection to prevent liquid leakage. If the pump is operated under the abnormal conditions such as liquid

leakage, it may cause a severe accident, such as a physical injury, an explosion, or fire. Always comply

with instructions of the supplier or manufacturer of liquids.

Prohibited use of a damaged or modified pump

Using a damaged or modified pump may cause a physical injury, electric shock, or product failure. Such

usage will not be covered by our warranty.

Cautions on transporting and lifting the pump

Use the hoist bolts when lifting a pump. If a hoist bolt is not available, use a belt sling to lift the pump with

careful attention to the weight balance. Only a qualified person should perform this with a strong enough

sling. The lightest pump weighs approximately a minimum of 50lbs (23kg). Do not hand carry the pump as

much as possible, as it may cause an accident.

Prohibited work with the power ON

Do not perform inspection or disassembly of the pump or motor while the power is ON. Rotating parts can

cause physical injury. You can also be subject to electric shock. In addition to confirming the main power

is OFF, check the hand switch of the pump as an additional safety measure before performing any work.

Connection of a ground wire

Using the motor without a ground wire connected may cause an electric shock. A qualified person must

ground it according to the electric equipment technical standards and wiring regulations.

Protection of a power cord

Pulling, tucking, or damaging a power cord or motor lead wire may damage the cable, causing fire or an

electric shock. Install the terminal box cover in the designated position after wiring.

Installation of Ground Fault Interrupter (GFI)

If a ground-fault interrupter is not installed when using the pump, an electric shock may occur. Install a

ground-fault interrupter or overcurrent protective device to prevent electric accidents or motor damage.

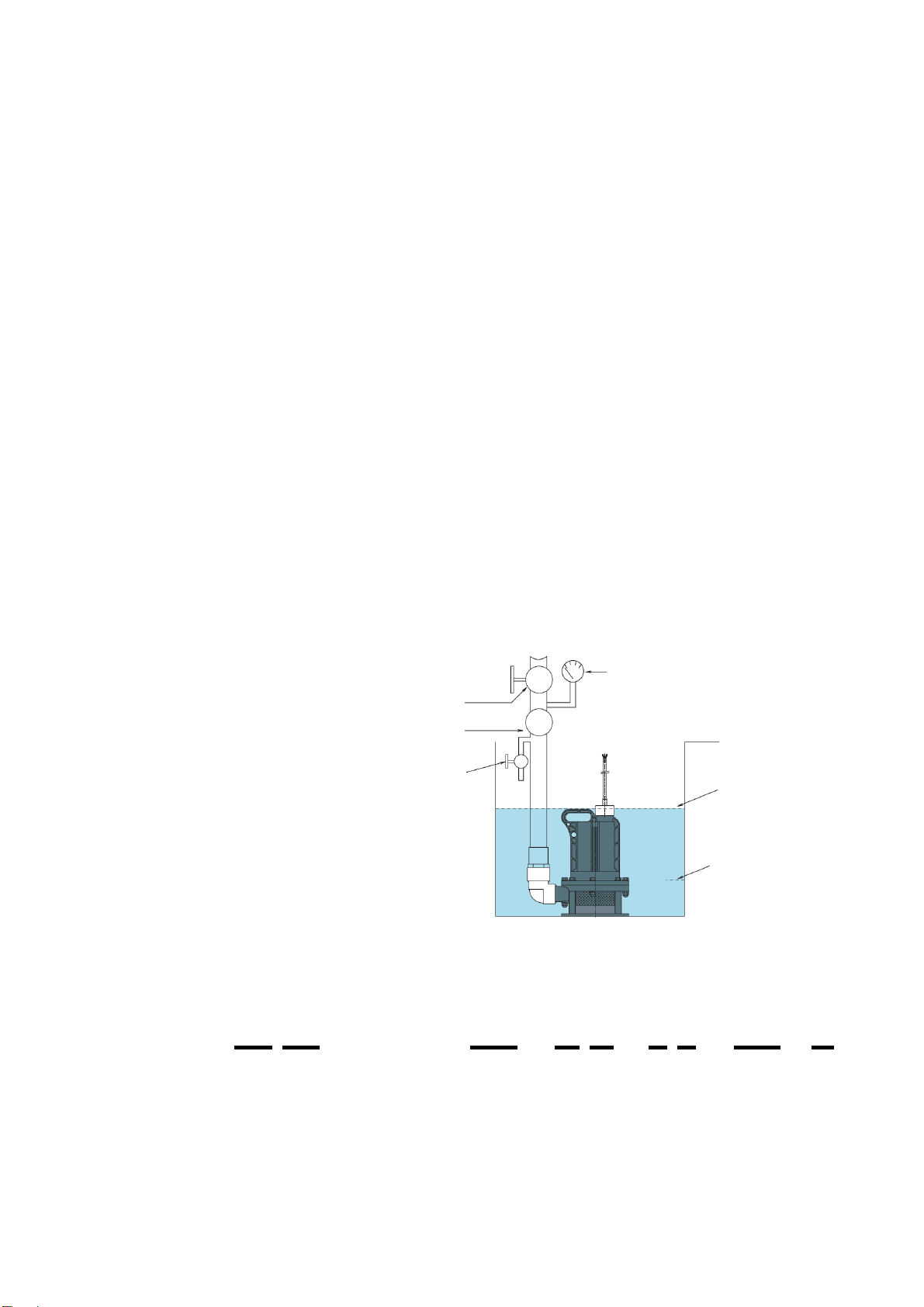

Cautions on removing the pump

When removing the pump from pipes, close the suction and discharge pipe valves to ensure no spillage

occurs. Directly touching chemical liquid may be hazardous, and may cause severe injuries. Wear

protective equipment before starting work.