2

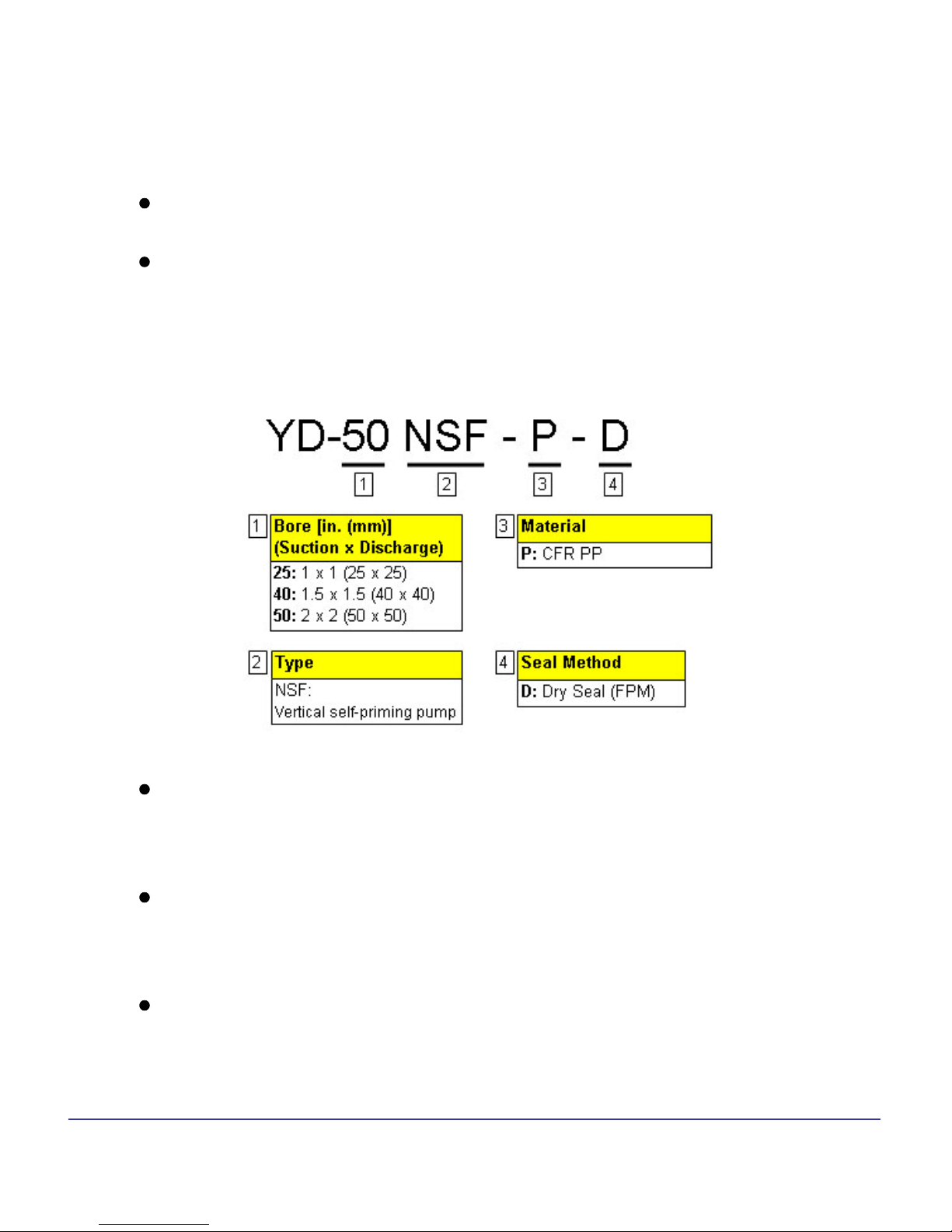

FEATURES

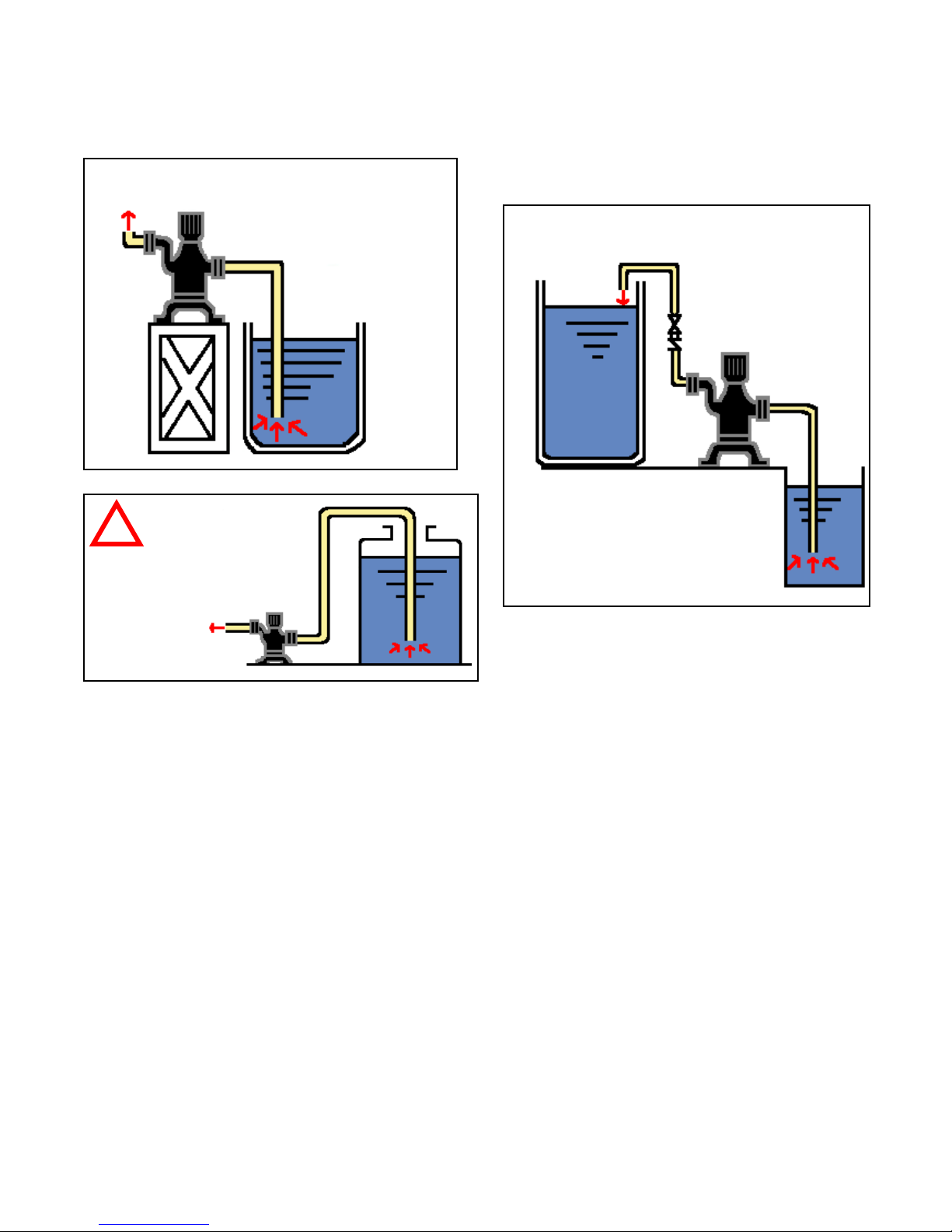

Valveless

This patented VALVELESS feature has been a World Chemical trademark since

1971. Because of this unique priming mechanism, this pump does not require any

foot valves. Also, the built-in check valve reduces backflow velocity to retain

maximum liquid in the priming chamber at pump shutdown.

(continued)

Uniquely resistant to high temperatures

Our originally engineered design has the unique capability of constantly and smoothly

self-priming and suctioning even in temperatures as high as 184 °F (70 °C ).

Resistant to wide range of chemicals

Parts such as the pump base and the motor bracket that come in contact with

chemical solvents are constructed with a high resistant resin. Thus the pump will not

erode from chemicals or atmospheric gases, and can also be used with hard-to

handle chemicals such as sulfuric acids, nitric acids, caustic sodas, hydrofluoric acids

and electro-less nickel plating solutions.

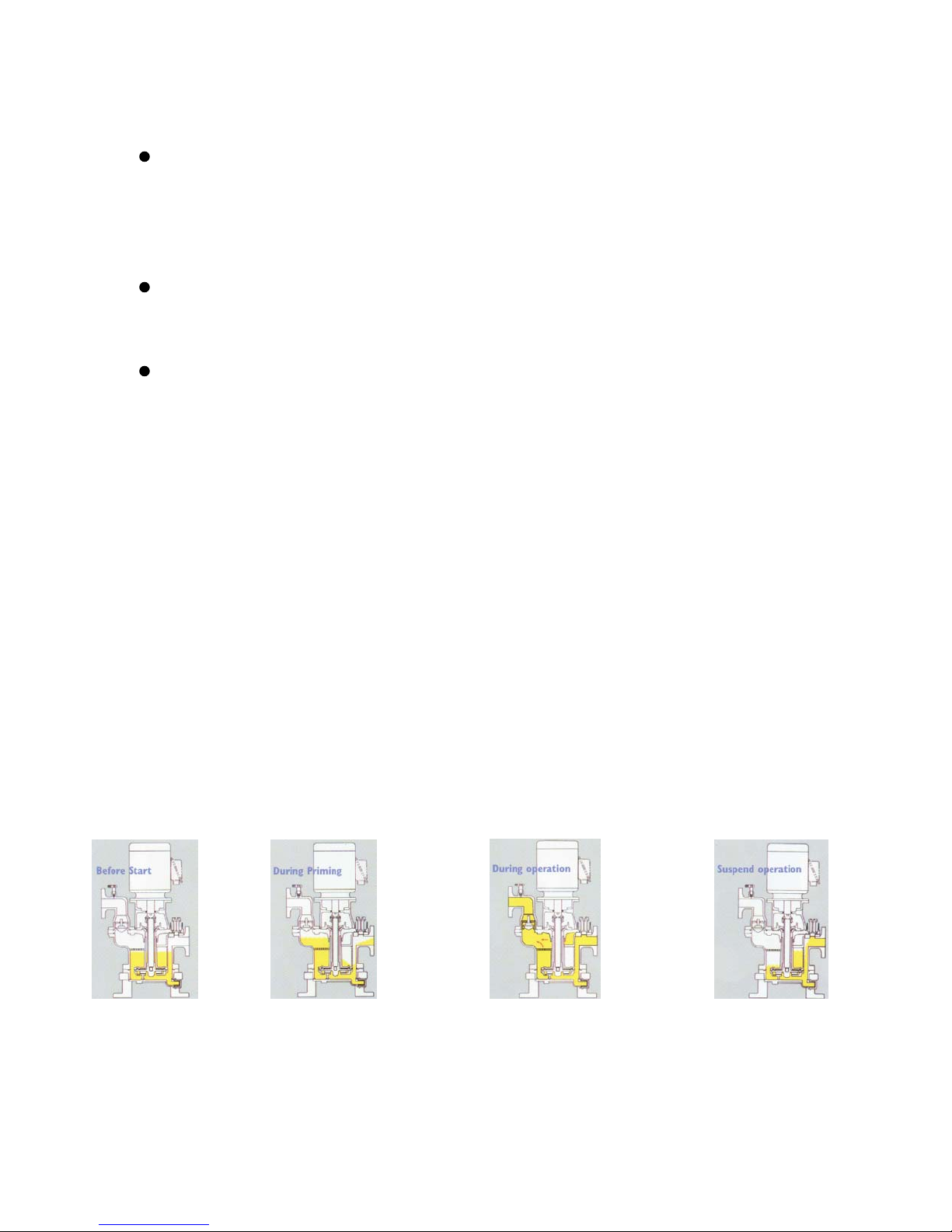

THE PRINCIPLE OF SELF-PRIMING

The NSF/SF series is a uniquely developed sealless and valveless self-priming

centrifugal chemical pump. The primed water that fills the whole interior of the pump

moves to the self-priming chamber guided by the impeller after the pump is turned on.

In the self-priming chamber, the air and water separate as they rotate. The water is

propelled into the impeller as it leaves the self-priming rotational outlet located on the

bottom of the pump, and continues its repetitive cycle of self-priming. Air from the

shaft is sealed by the seal blades during self-priming. As an added measure, a

balance hole is constructed on the casing to release air into the self-priming chamber,

ensuring that the self-priming operation is not affected. While the pump is not in use,

the siphon cut hole located on the interior of the self-priming chamber and the suction

chamber blocks the backflow from the siphoning action. Water that is necessary for

the subsequent prime remains in the suction chamber for smooth pumping

Pump is filled with

water.

Just as the pump is turned on,

the liquid in the suction

chamber is sucked up, as the

rotational movement creates

a stronger vacuum seal.

All of the air in the main body of

the pump is discharged and will

allow normal smooth operation.

Should even a little amount of air

enter, it will be discharged

without causing any operational

difficulty.

When the pump is stopped, the

siphon cut hole will minimize

the liquid backflow and secure

enough liquid in the suction

chamber for the next prime.