2

WARNING

(1) Dangerous liquids and surroundings.

When using the pump for dangerous liquids or in surroundings (only explosion prevention

specifications), adhere to facility standards determined by law and conduct daily check to prevent

leakage. If operate the pump under abnormal conditions, such as liquid leakage, it may cause

serious accidents such as explosion or fire and personal injury. Regarding handing liquid, follow the

liquid manufacturer.

(2) Do not use damaged or modified pumps.

Using the damaged or modified pumps may cause fatal accident, electric shock or pump damage. It

is not covered by our warranty.

(3) Caution when transporting or lifting the pump.

Always use the hoist belt for pumps that come with them. When pumps do not have hoist belts, lift

them with bolt slings while watching the weight balance. It should be performed by qualified

personnel with enough strong slings. The lightest pumps’weight is around 10kg (22 lbs.), and do not

carry the by hands as much as possible.

(4) Do not operate pumps with power on.

Do not inspect or dismantle pumps or motors with the power on. It may lead to personal injuries such

as electric shock or getting caught in the rotor. Operate it with multiple safety devices such as the

switch for main power supply, the operation switch, and the hand switch for the pump.

.

(5) Connecting earth cable.

If using the pump without connecting earth cable to the motor, it may cause electric shock. Connect it

by qualified personnel under the electric facilities’ technical standards and interior wiring regulations.

(6) Protect power supply cord.

Over-stretching, pinching and damaging power supply cords or motor lead wires may cause fire or

electric shock to damage it. Place the terminal box cover at the original position.

(7) Install Current Leak Circuit Breaker.

The operation without a current leak circuit breaker may cause electric shock. Install it or an over

current protection device and prevent electric accidents or pumps damage.

(8) Caution when removing pump.

When removing the pump from piping, make sure to close valves on the suction/discharge piping and

check no liquid leakage. Direct contact with liquid may be harmful and wear protective gear when

performing operation.

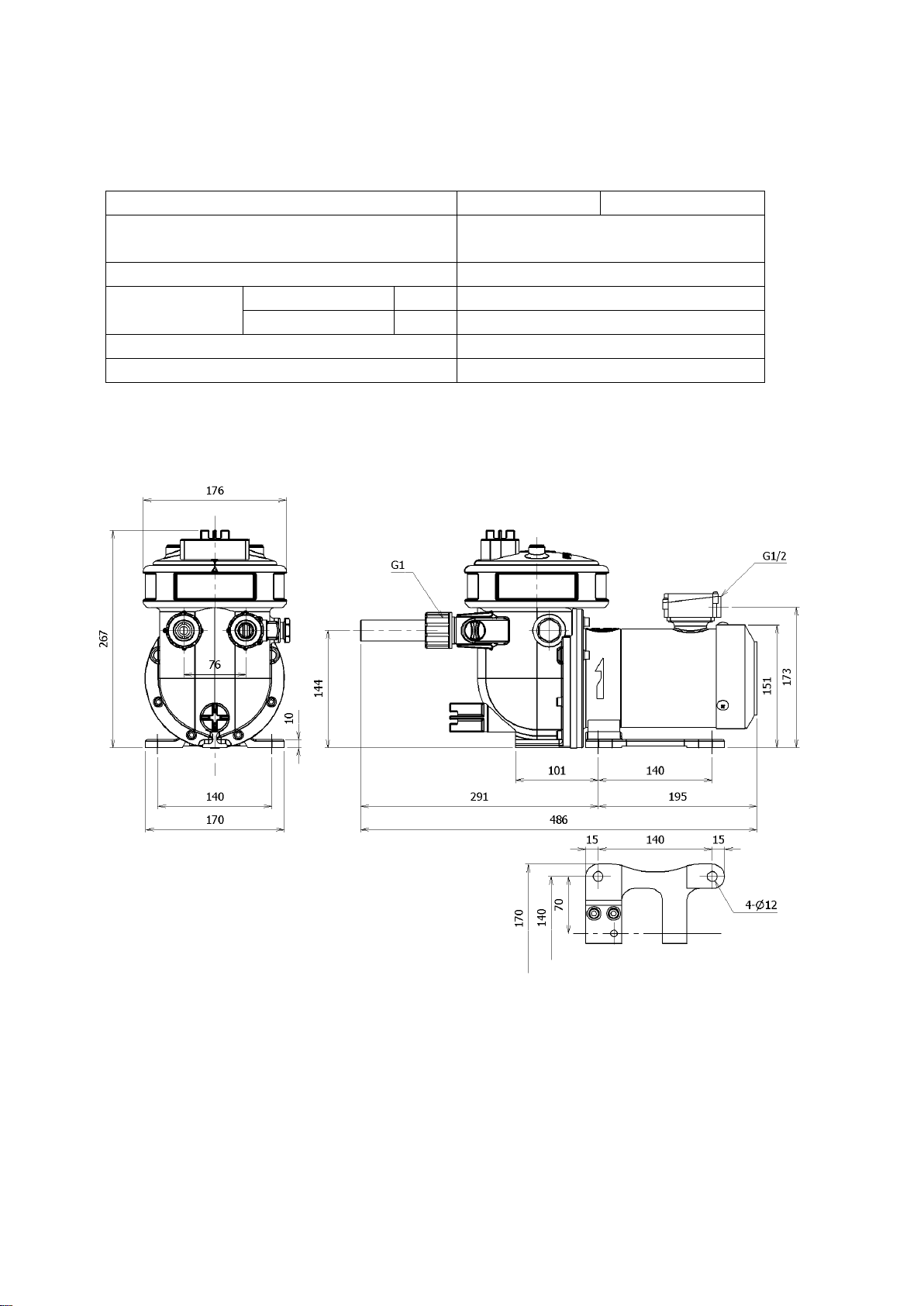

The hole on the bracket is for the check of the coupling rotation state when installing/removing the

coupling with the motor shaft or maintenance.