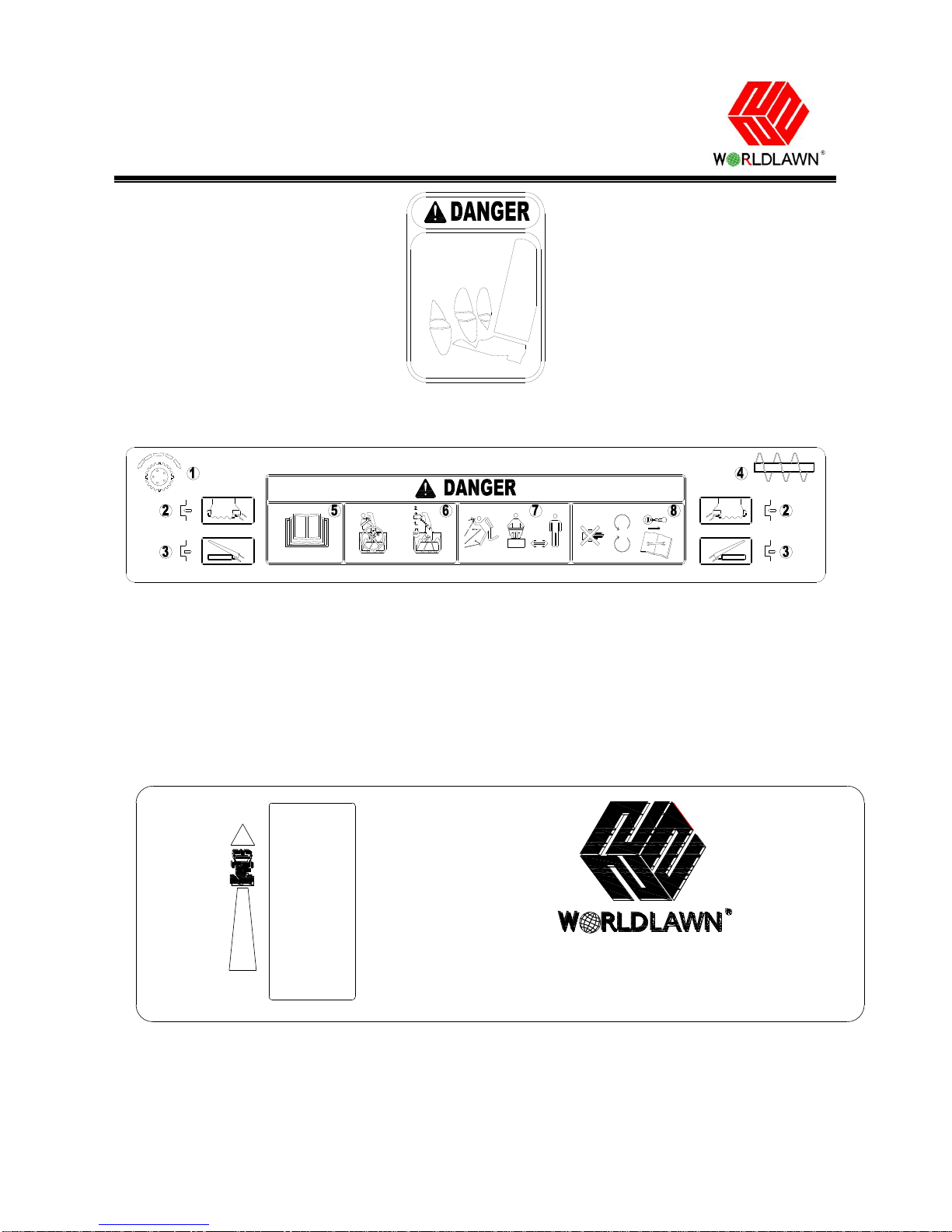

1.4 Operation

1.4.1 Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at all times.

1.4.2 Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

1.4.3 After striking a foreign object, stop the engine,

remove the wire from the spark plug, thoroughly

inspect the snow thrower for any damage, and repair

the damage before restarting and operating the snow

thrower.

1.4.4 If the unit should start to vibrate abnormally,

stop the engine and check immediately for the cause.

Vibration is generally a warning of trouble.

1.4.5 Stop the engine:

Whenever you leave the operating position.

When making any repairs, adjustments, or

inspections.

Before unclogging the auger/impeller housing or

discharge chute.

1.4.6 When cleaning, repairing, or inspecting the snow

thrower, stop the engine and make certain the

anger/impeller and all moving parts have stopped.

Disconnect the spark plug wire and keep the wire

away from the plug to prevent someone from

accidentally starting the engine.

1.4.7 Do not run the engine indoors, except when

starting the engine and for transporting the snow

thrower in or out of the building. Open the outside

doors; exhaust fumes are dangerous.

1.4.8 Exercise extreme caution when operating on

slopes.

1.4.9 Never operate the snow thrower without proper

guards and other safety protective devices in place and

working.

1.4.10 Never direct the discharge toward people or

areas where property damage can occur. Keep children

and others away.

1.4.11 Do not overload the machine capacity by

attempting to clear snow at too fast a rate.

1.4.12 Never operate the machine at high transport

speeds on slippery surfaces. Look behind and use care

when operating in reverse.

1.4.13 Disengage power to the auger/impeller when

snow thrower is transported or not in use.

1.4.14 Use only attachments and accessories approved

by the manufacturer of the snow thrower.

1.4.15 Never operate the snow thrower without good

visibility or light. Always be sure of your footing, and

keep a firm hold on the handles. Walk; never run.

1.4.16 Never touch a hot engine or muffler.

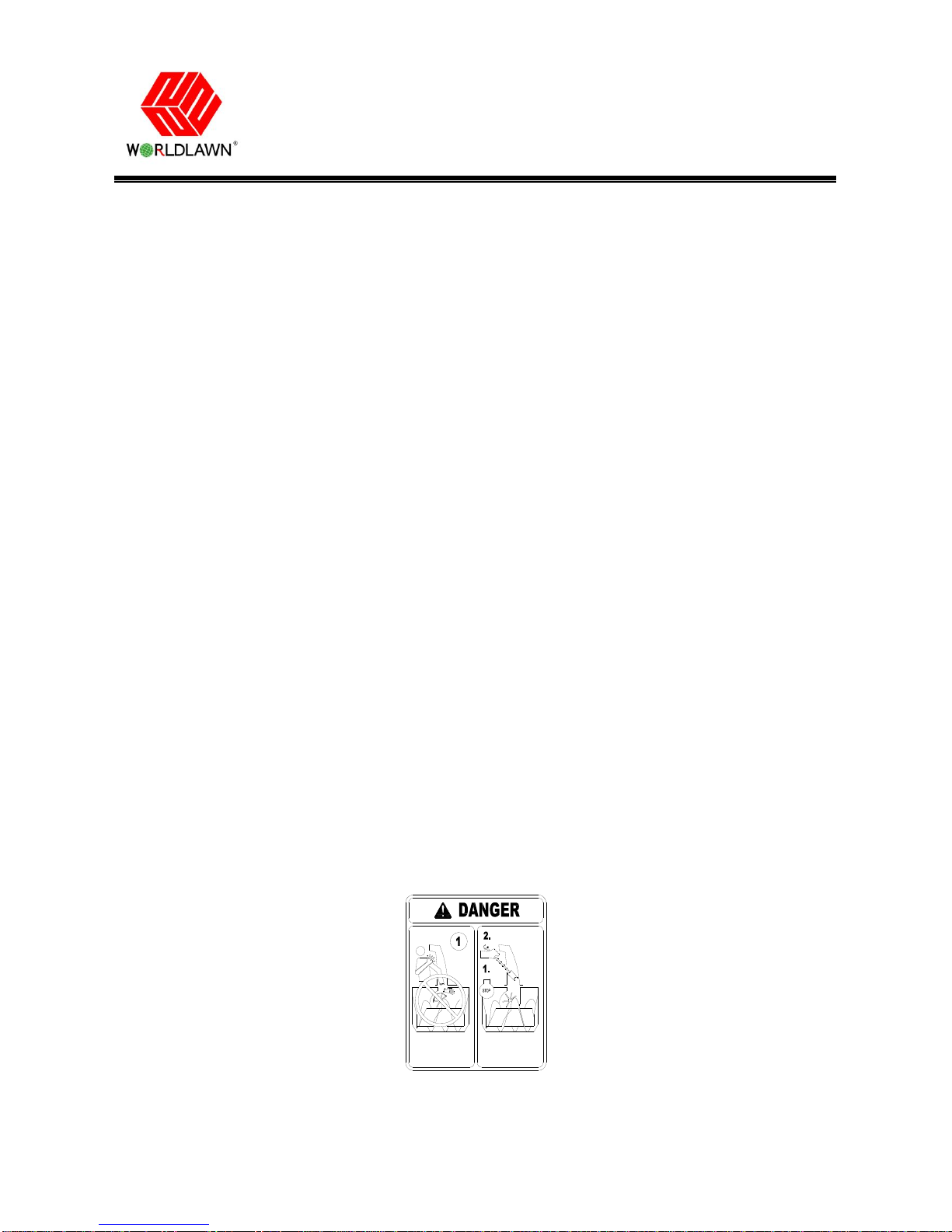

1.5 Clearing a Clogged Discharge Chute

Hand contact with the rotating rotor blades inside the

discharge chute is the most common cause of injury

associated with snow throwers. Never use your hand

to clean out the discharge chute.

To clear the chute:

Shut the engine off!

Wait 10 seconds to be sure the impeller blades

have stopped rotating.

Always use a clean-out tool, not your hands.

1.6 Maintenance and Storage

1.6.1 Check all fasteners at frequent intervals for

proper tightness to be sure the equipment is in safe

working condition.

1.6.2 Never store the machine with fuel in the fuel

tank inside a building where ignition sources are

present, such as hot water heaters or clothes dryers.

Allow the engine to cool before storing in any

enclosure.

1.6.3 Always refer to the Operator's Manual for

important details if the snow thrower is to be stored

for an extended period.

1.6.4 Maintain or replace safety and instruction labels,

as necessary.

1.6.5 Run the machine a few minutes after throwing

snow to prevent freeze-up of the auger/impeller

blades.