XL2ASSEMBLY MANUAL 74302 1/11

5

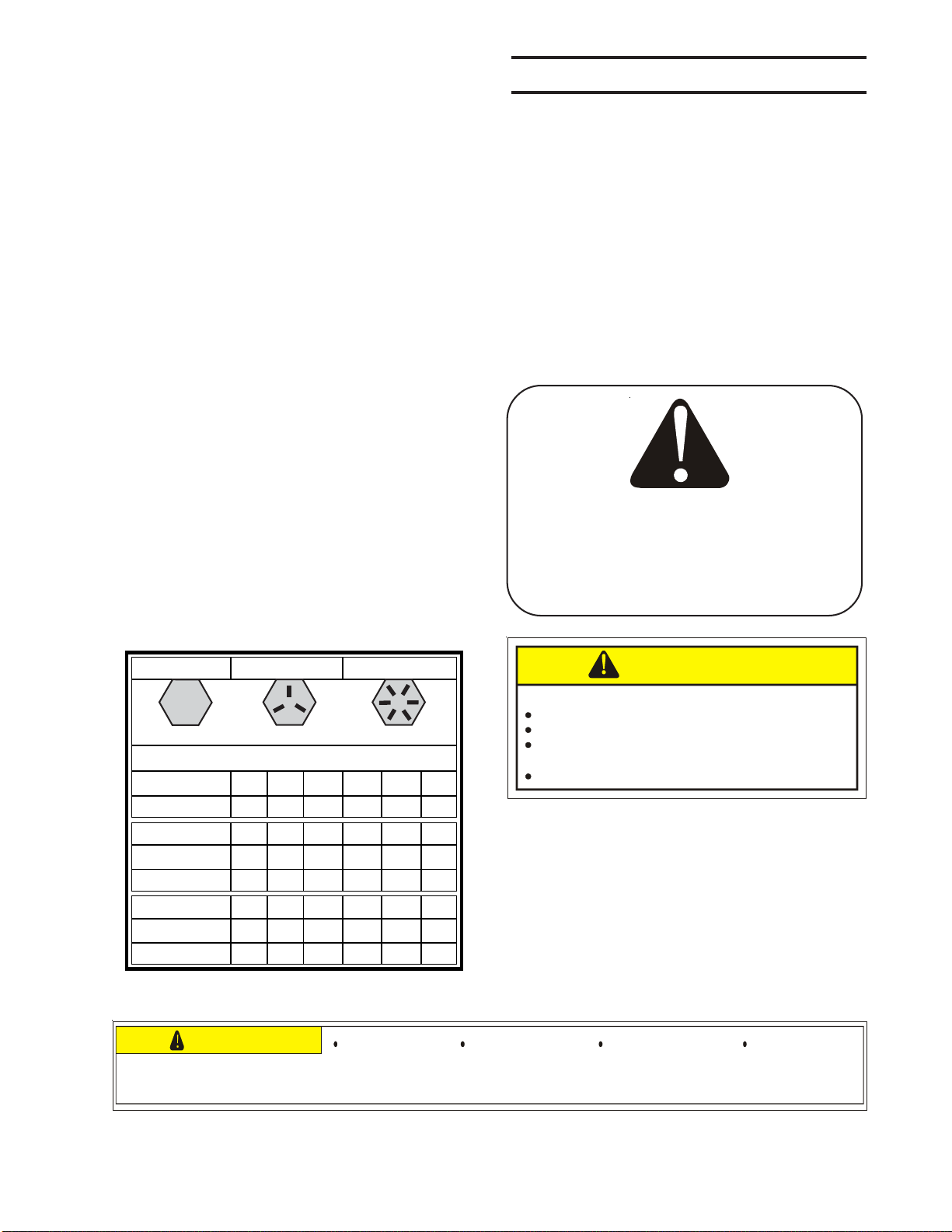

GRADE 2 GRADE 5 GRADE 8

TORQUE IN FOOT POUNDS

BOLT DIA 3/8 1/2 5/8 3/4 7/8 1

HEX HEAD 9/16 3/4 15/16 1-1/8 1-5/1 1-1/2

UNC GR2 18 45 89 160 252 320

UNC GR5 30 68 140 240 360 544

UNC GR8 40 100 196 340 528 792

UNF GR2 21 51 102 178 272 368

UNF GR5 32 70 168 264 392 572

UNF GR8 48 112 216 368 792 840

When replacing a bolt, use only a bolt of the

same grade or higher. Except in shear bolt

applications, where you must use the same

gradebolt.

Bolts with no markings are grade 2

Grade5 boltsfurnishedwith the machineare

identifiedby three radial lines on the head.

Grade8 boltsfurnishedwith the machineare

identifiedbysixradiallinesonthehead.

AllU-boltsare grade 5.

THISSYMBOLUSEDTOCALLYOURATTEN-

TIONTOINSTRUCTIONSCONCERNINGYOUR

PERSONALSAFETY.

BESURETOOBSERVEANDFOLLOWTHESE

INSTRUCTIONS

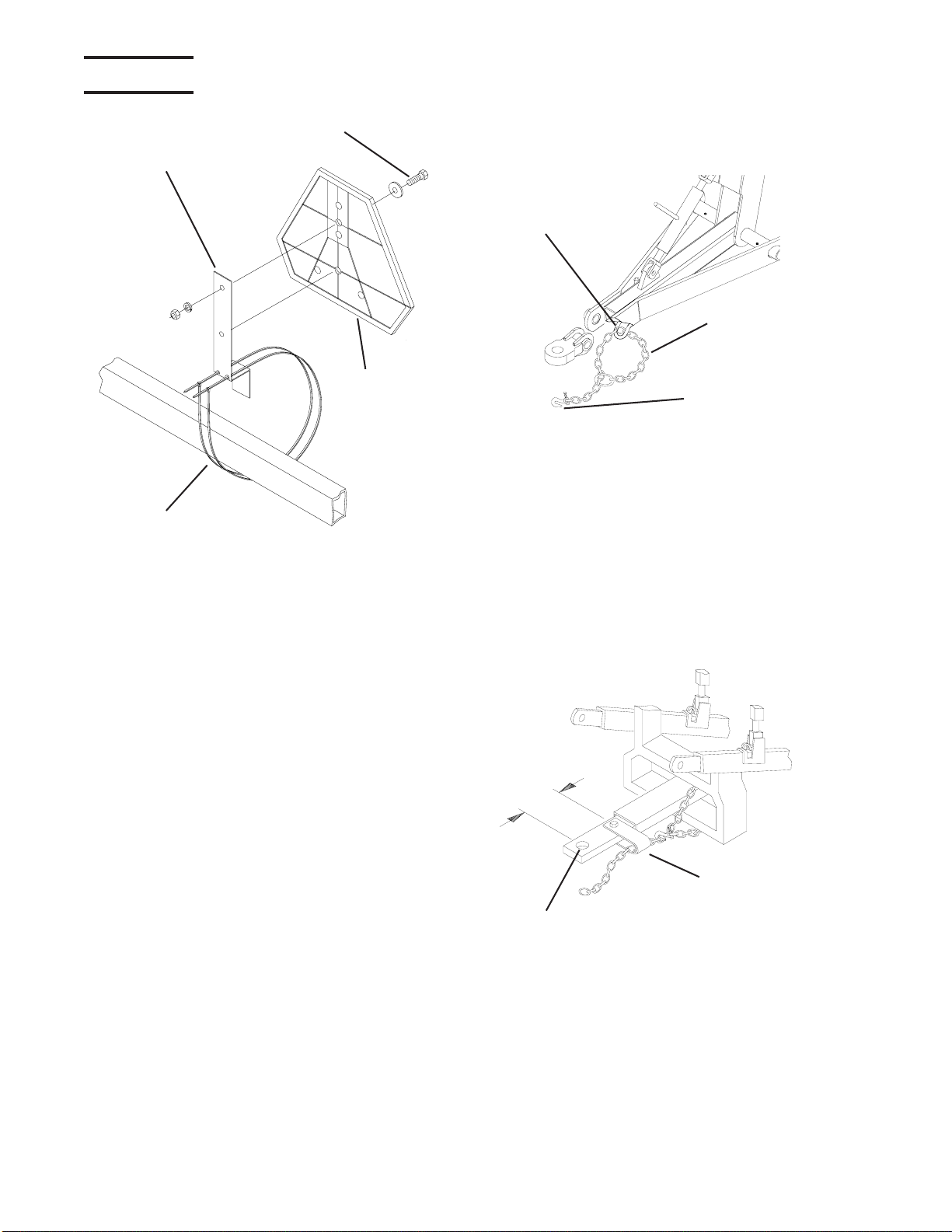

Removeall wires andarrangetheparts con-

veniently.

NOTE: Always wear safety glasses or

goggles and be careful when cutting wires

andsteelbandsastheyareundertensionand

willspring backwhencut.

Wherevertheterms"left"and"right"areused,

it must be understood to mean from a posi-

tionbehind and facingthemachine.

Lubricate all bearings and moving parts as

youproceedandmake surethey workfreely.

Loosely install all bolts connecting mating

partsbefore final tightening.

Whentightening bolts, they mustbetorqued

totheproper number of foot-pounds as indi-

cated in the table unless specified. It is im-

portantthat all bolts be kepttight.

Onnewmachines,all nutsandbolts mustbe

recheckedafter a few hours of operation.

ASSEMBLY INFORMATION

Refer to Operator's Manual for safety instructions.

Do not stand or climb on machine when operating.

Use clean hazard flashers and SMV sign when

transporting.

Observe highway traffic regulations.

TO AVOID INJURY AND/OR MACHINE DAMAGE:

CAUTION

23325

FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN PERSONAL

INJURYAND/OR EQUIPMENT DAMAGE.

CAUTION

53334

Just before and during

operation be sure no one is

on or around the

implement.

Before activating the

hydraulic system, check

hoses for proper

connections.

With wings down always

install hydraulic cylinder

channel lock(s) for

transporting.

Before lowering the wings for

the first time, make sure the

entiresystemhasbeen charged

withoil.

MODIFICATIONS

Itis the policy ofWil-Richto improve its prod-

uctswheneverpossibleandpracticaltodoso.

We reserve the right to make changes, im-

provements and modifications at any time

without incurring obligation to make such

changes, improvements on any equipment

soldpreviously.