SI 675

Issue B

EDI 8262

Telescopic cranes with derrick pressure sensors CALIBRATION W2245

9

3.0 INSTALLATION

3.1 Load (pressure) sensor

Refer to section 3.4.3.3 before installation. After installing, make sure that the

load sensor(s) operate properly at all boom angles by using the diagnostic menu

(Refer to operators manual).

3.2 Anti-Two-Block switch

If two switches are to be used at the same time, make sure the proper switch or

junction box is used at the boom tip.

If only one switch will be used and has to be moved from the main tip to the jib tip,

it can be done using an extension wire

No extra wiring is needed, since a standard connector is supplied for the switch. If

a junction box is used, wire according to the supplied drawing.

3.3 Display

The display should be located at the front of the cab, where it is readily visible

from the operator’s control position. Take care not to obscure any displays,

control levers, switches or the operator view of the load. Leave sufficient room for

the sensor wires to be fed to the bottom of the display.

If the unit is pre-wired with connectors, simply plug in the connectors. If the unit is

not pre-wired, use the following instructions.

Loosen the four top screws and flip the cover over the box. Proceed gently in

order not to damage the wires or the keypad.

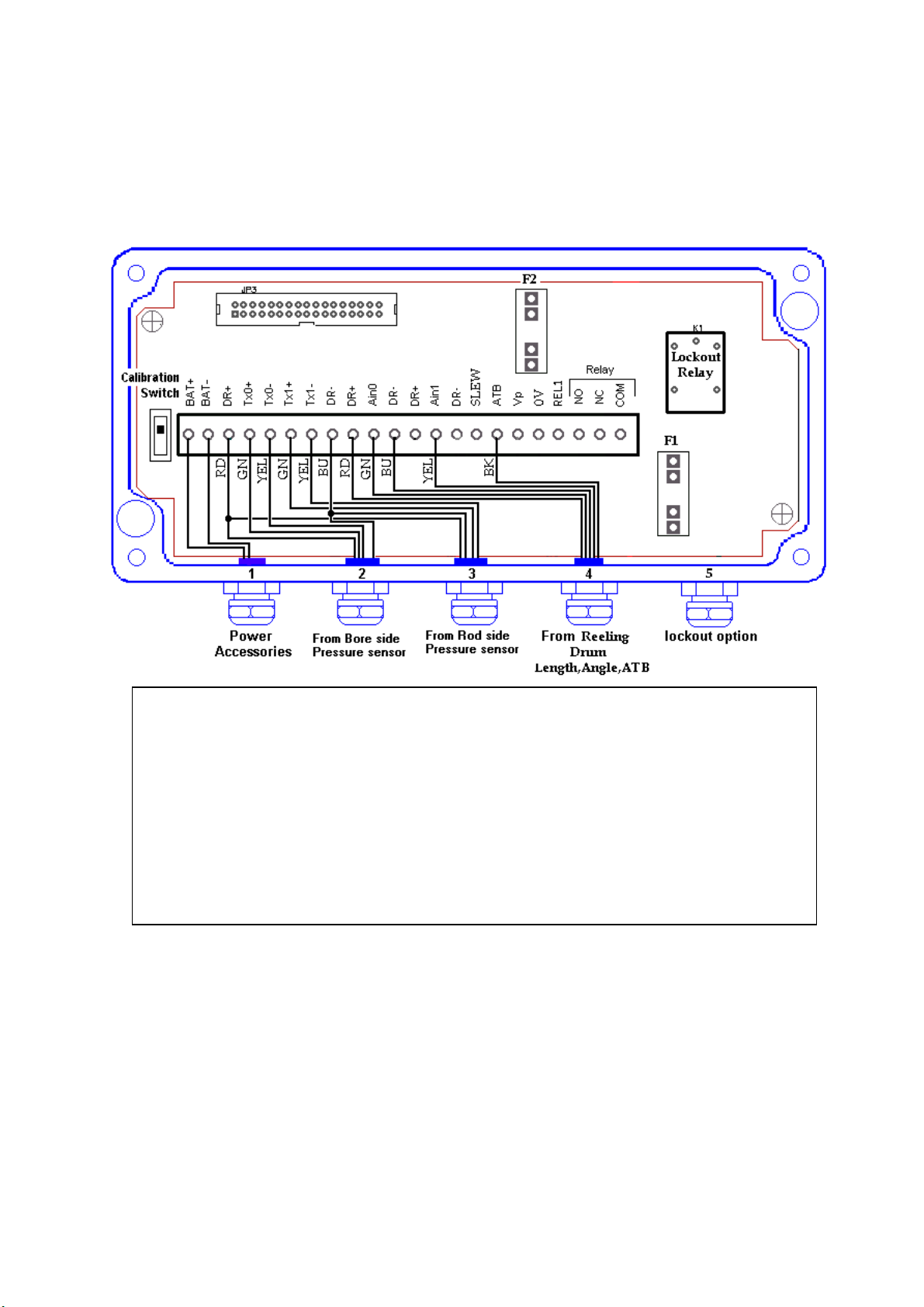

Wire according to the supplied drawing on Figure 3.5. or Figure 3.6, depending if

you use a junction box. Make sure all connections are made properly and

completed before powering the system. When stripping wires, do not drop any

wire ends or debris into the box.

All cable screens should be grounded to the glands of the display box only. Fold

the screen over the rubber sleeve as shown in the diagram below. Use the brass

ring.

Power supply must be from 11 to 28 Volts DC only. If not available, an external

power supply to convert to 12 Volts DC is required. The power lead must be able

to sustain a minimum of 11 Volts with a current of 5 amps if the unit is connected

to a lockout device.