820-0332 1-1

Introduction

Theory of Operation

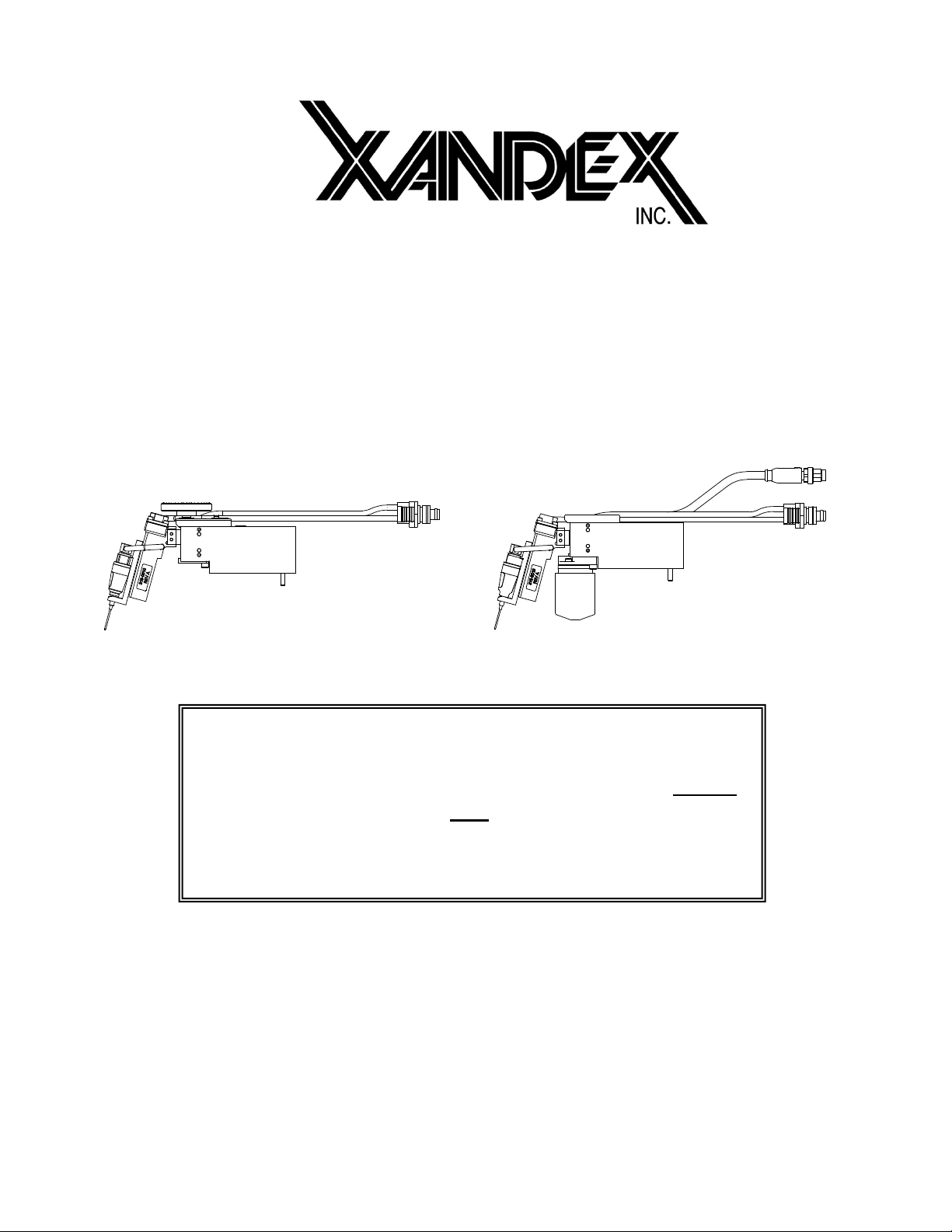

The X7110 Manual and X7120 Motorized

Micro-Z pneumatic inkers are designed for

use in cabled in-line and off-line inking. The

innovative Micro-Z design combines op-

erator friendly Micro-Z movement ca-

pability in both Manual or Motorized

models which provides fast, precise Z

adjustment, with a dual air regulation system

to produce small ink dots of 5 mil or less

with consistent geometry and extreme

repeatability.

The Micro-Z series inker also incorporates

the convenience of a new A4 model

DieMarkdisposable ink cartridge for the

ultimate small dot inking solution.

Ink dots are deposited via pneumatic actuation of the inker shuttle mechanism and a

simultaneous pulse of air into the cartridge reservoir. There is no filament and no direct

contact with the wafer surface. A prober signal to the controller initiates the inking

sequence, actuating the shuttle mechanism downward and sending an air pulse to the

cartridge.

As the shuttle extends to the downward position, the air pulse to the cartridge forces ink

out of the cartridge barrel and forms a drop at the end of the needle tip. When the shuttle

is at its lowest position, the drop makes contact with the wafer surface and forms a dot.

After several milliseconds the shuttle returns to the normal position. After completion of

each dot, slightly lower pressure is developed in the cartridge by the closure of the valve,

causing the ink to back up into the cartridge reservoir, preventing dripping.

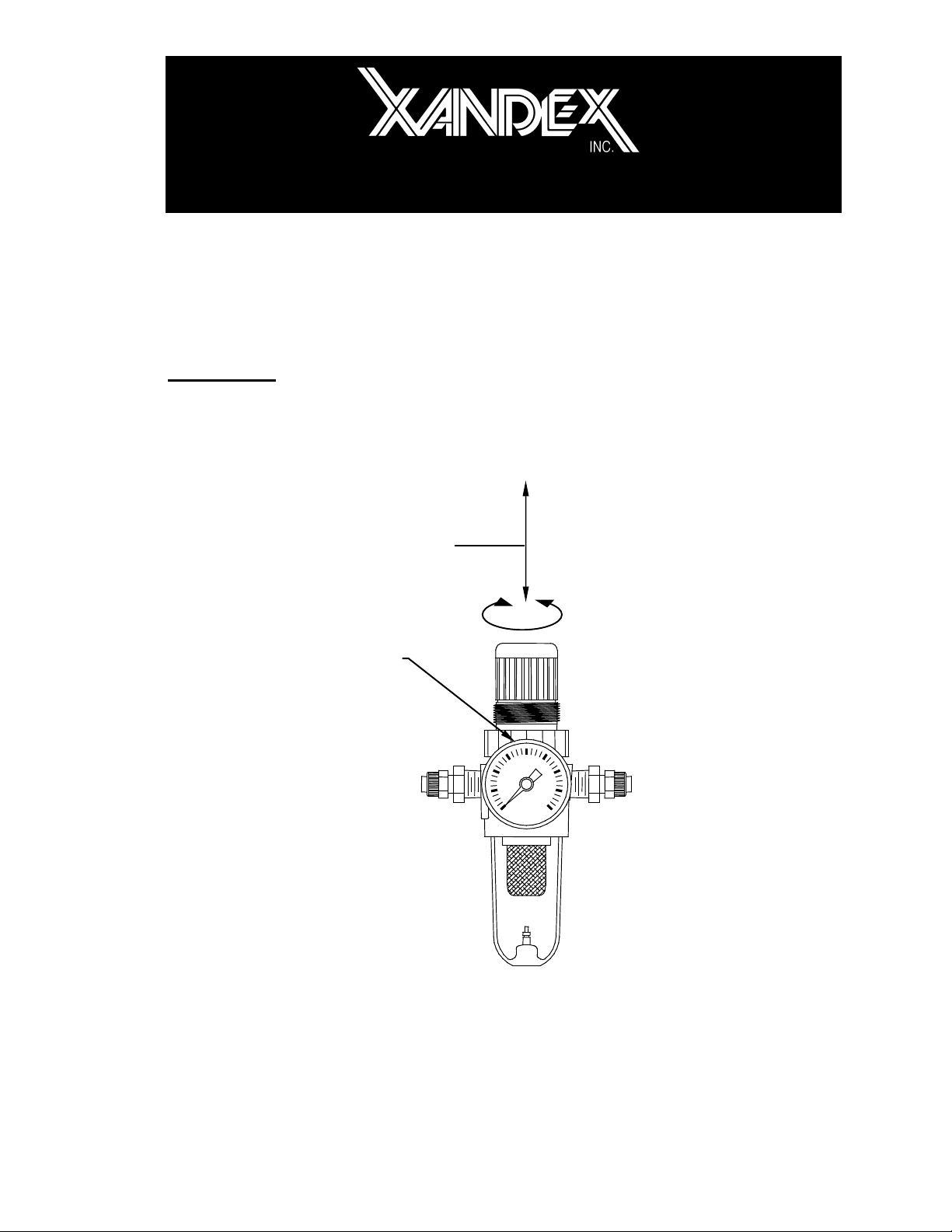

The dot size is determined by cartridge air pulse duration. Adjust the controller setting to

change the dot size - without changing the cartridge. Pneumatic cartridges are factory

tuned, ensuring consistent dots and contain 40% more ink than standard DieMark

filament ink cartridges.

Thank you for selecting Xandex as your inking choice. Please spend a few minutes

familiarizing yourself with the unit. Most questions you may have will be answered in this

manual. If you would like further assistance, please contact your local Xandex distributor

or call us at (707) 763-7799 or Toll Free in the U.S: (800) 767-9543. FAX (707) 763-

2631. For more information about Xandex and our complete line of quality inking and

interfacing products, visit us on the Internet at www.xandexsemi.com or email: us at