Getting started with the Ultimate 2’s (U2) basic functions

The Ultimate system is designed to run both12/24 volt cameras, film or video.

The owner can use any type of battery chemistry in any combination.

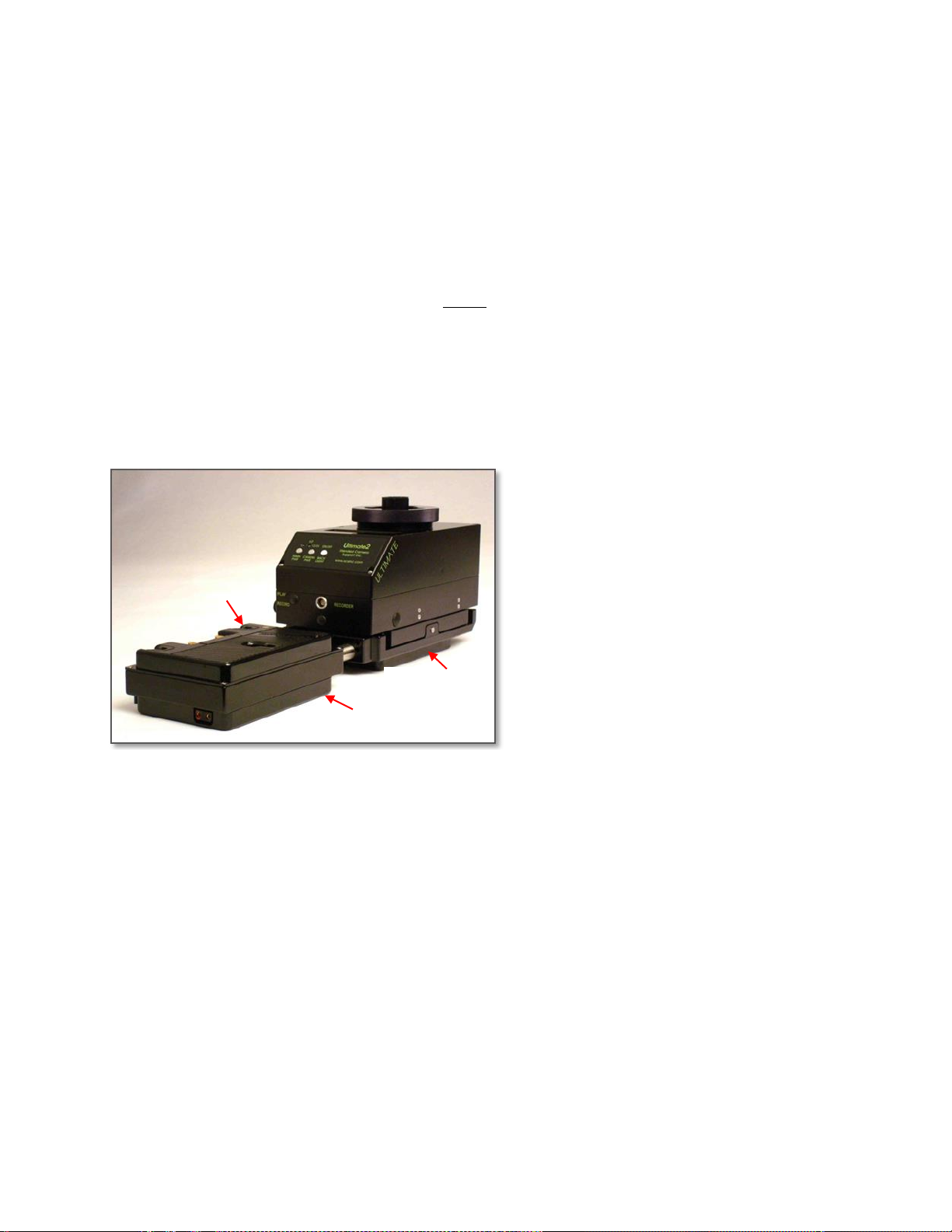

The lower electronics housing will accept up to three 14.4 volt battery packs or up to two 14.4 battery

packs and one 24 Vdc battery pack at the same time.

The sled can deliver battery voltage when using 1, 2, or 3 14.4 volt batteries in 12 volt mode.

The sled can provide both 14.4 and 28.8 volts combined battery voltage, when using two or more 14.4

volt batteries in 24 volt mode.

In 24 volt mode a 14.4 battery must be on battery plate # 3 and additional on positions 1 or 2 or both.

The sled can provide both 14.4 and 28.8 volts when using one or more 14.4 volt batteries and one 24 volt

battery.

All the sleds 12 volt outputs and all 24 volt outputs are common. One of the unique design features is that

it does not provide an isolated 14.4 volt power source. Power noise filtering is used to eliminate hum

common in other sled systems and reduce the crosstalk that is possible in HD in high RF environments.

Backlit LCD screen- The LCD displays current individual battery voltage of all attached batteries in 12

volt mode. A combined voltage of battery position 3 in 24 volt mode and individual status of all other

batteries attached. Also displayed on sled power up for four seconds is the Serial number and software

revision level. System warnings will be displayed in case there power or over current, dead short in

cables, cameras, accessories.

MAIN PWR- Pushbutton turns the system on/off.

There is an amber LED pwr on indicator.

When turning OFF the power, button must be held

down for at least 1 second.

LO battery indicator- Amber LED blinks when the

voltage drops below the user selectable voltages.

Factory preset for the warning indicator as follows:

12 volt mode- Indicator blinks at 13.4 volts

24 volt mode- Indicator blinks at 24.2 volts

In 12 volt mode the 8 selectable settings are:

12.4, 12.6, 12.8, 13.0, 13.2, 13.4, 13.6, 13.8 volts

In 24 volt mode the user selectable settings are:

23.0, 23.2, 23.4, 23.6, 23.8, 24.2, 24.4, 24.8 volts

User has two different 8 position rotary switches labeled SW1 (24 volt mode) SW2 (12 volt mode)

located inside the electronics housing and can be accessed by removing the 6 screws holding the

housing cover together to select your preference for the low battery indication.

12/24 Camera Pwr button- Allows the operator to select the power Mode the system will be running at.

12V Mode for 12 volt camera systems and accessories.

24V Mode for 24 volt camera systems and accessories, while still delivering 14.4 volts to all 14.4 volt

output connectors. To achieve 24 volts when using 14.4 batteries you need to have at least two battery

packs and one pack has to be on battery plate #3. Or you can use a 24 volt battery on plate #3.

ON/OFF BACKLIGHT button- Turns the LCD screen backlight on/off.

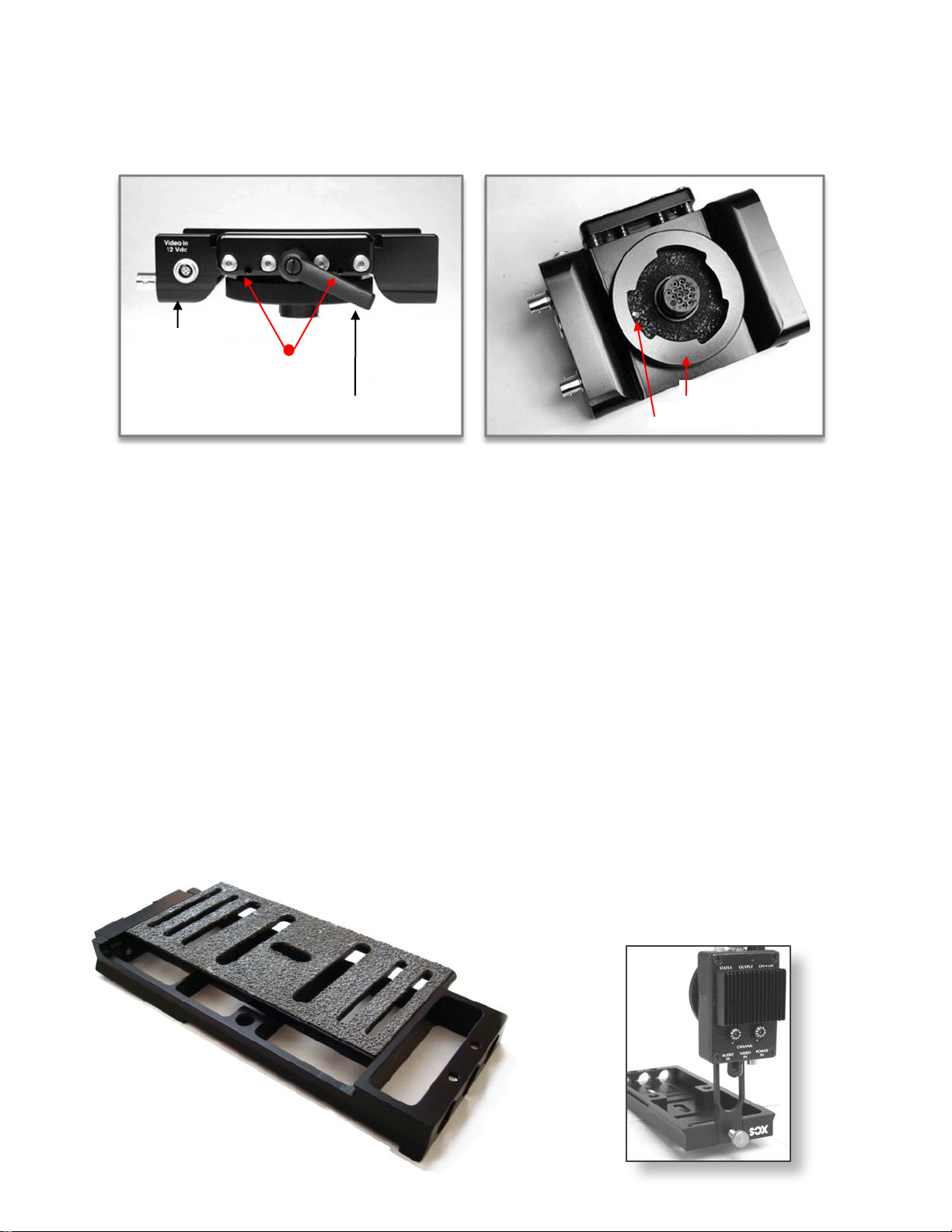

Connectors on the LEH

These are the standard connectors and connections. Options available.

1B 308- Provides 14.4 battery voltage, video signal out 1V Peak-Peak from top stage.

0S 304- Provides 14.4 battery voltage, video signal out 1V Peak-Peak from top stage for video

transmitter.