Xicom SSPA User manual

MNC-0300-021 1 of 20 Revision D

Unpacking and Installation, Rack SSPA

Unpacking and Installation, Rack SSPA

Record of Changes

Revision ECO Description Date Initiated By

1Preliminary Release 03/10/2003 A.L. Crozier, Jr.

2Update to reflect new rear panel layout 06/16/2003 A.L. Crozier, Jr.

A 11267 Original Release 07/23/2003 A.L. Crozier, Jr.

B 12115 Content Update 04/21/2004 A.L. Crozier, Jr.

C 12372 Update to reflect CE compliance 07/19/2004 A.L. Crozier, Jr.

D 13469 Add Power Connector Wiring Diagram 10/13/2005 L. dell’Aquila

MNC-0300-021 2 of 20 Revision D

Unpacking and Installation, Rack SSPA

Table of Contents

Paragraph Title Page Number

Unpacking and Installation, Rack SSPA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rack Slide Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Waveguide Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Air Ducting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

RF Sample Port (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear Panel Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RF Output (J9) Waveguide Flange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Waveguide Switch (J3) (DB-25 Socket). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auxiliary Interface Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

External Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

RF Inhibit Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Summary Fault Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Output Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power and Interface Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Prime Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Serial Interface Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

COM1 RS-232 Interface (J5) (DE-9 Pin). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

COM2 RS-485 Interface (J6) (DE-9 Pin). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ethernet (J7) (EIA T568B). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RF Input (J1) Female Type N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MNC-0300-021 3 of 20 Revision D

Unpacking and Installation, Rack SSPA

List of Figures

Number Title Page Number

Figure 1, Typical 4 Screw Mounting Flange Tightening Sequence . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2, Typical 8 Screw Mounting Flange Tightening Sequence . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3, Rear Panel Connectors and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4, Front View of 15-Pin Connector (Socket). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5, Power Plug Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 6, Typical RS-485 2-Wire Duplex Implementation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 7, Typical RS-485 4-Wire Full Duplex Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MNC-0300-021 4 of 20 Revision D

Unpacking and Installation, Rack SSPA

List of Tables

Number Title Page Number

Table 1, Waveguide Flanges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2, Waveguide Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3, Waveguide Switch Connector (J3) Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4, COM1 RS-232 Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 17

Table 5, COM2 RS-485 Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 18

Table 6, Ethernet Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MNC-0300-021 5 of 20 Revision D

Unpacking and Installation, Rack SSPA

Unpacking and Installation, Rack SSPA

Unpacking and Inspection

Inspect the inside and outside of the shipping container for signs of

damage. If any shipping damage is detected, call the shipping

carrier and submit a damage report.

Unpacking

Compare the packing list to the contents of the container to be

certain that all enclosed material has been received. Save all data

sheets. They will be useful during any maintenance actions. Save

the shipping container and packing material and use it if you need to

reship the unit.

Inspection

Inspect all items for any damage received during shipment. If

shipping damage is detected, submit a damage report to the

shipping carrier. Failure to submit a report may invalidate any future

claims.

Mechanical Installation

When performing the procedures in this section refer to the

appendix titled Mechanical Drawings.

Rack Slide Installation

The amplifier is equipped with a pair of drawer slides. These slides

mate with a pair of cabinet slide assemblies mounted in a standard

19-inch rack (cabinet).

The chassis slide assemblies are mounted to the cabinet with

adjustable mounting brackets.

Note

Two chassis slide assemblies, four mounting brackets, four

nutplates, and mounting screws are supplied with the amplifier.

The specific installation details are dependent upon the cabinet

design. Two front mounting brackets (3 inches long) and two back

MNC-0300-021 6 of 20 Revision D

Unpacking and Installation, Rack SSPA

mounting brackets (9 inches long) are supplied. See appendix titled

Mechanical Drawings for specific mounting instructions pertaining to

your amplifier.

Waveguide Connection

Caution

Do not overtighten the waveguide mounting screws.

Overtightening may strip the threads in the waveguide

flange. Failure to comply could result in equipment

damage.

Achtung

Ziehen Sie die Halteschrauben des Hohlleiters nicht

zu fest an. Zu festes Anziehen kann das Gewinde am

Flansch des Hohlleiters beschädigen. Nichtbeachtung

dieses Hinweises kann zu Schäden am Gerät führen.

The RF input waveguide (where applicable) is located on the front

panel of the amplifier and RF output waveguide port is located on

the rear panel of the amplifier. Ensure that the proper matching

waveguide flange is used to connect the amplifier input and output

to the RF load.

Refer to Figure 1 , Typical 4 Screw Mounting Flange Tightening

Sequence or Figure 2 , Typical 8 Screw Mounting Flange Tightening

Sequence, for the proper tightening sequence on the flange types

installed on your amplifier.

Caution

When not connected to the external waveguide

system or a terminated load, waveguide flanges

should be covered with a protective cap or tape that

does not leave glue residue when removed. Xicom

recommends the use of Kapton® tape, 3M Brand,

#92, Xicom P/N 602-0001-001. Remove tape or cap

prior to final installation. Failure to comply could result

in contamination to the internal waveguide system or

TWT and equipment damage.

MNC-0300-021 7 of 20 Revision D

Unpacking and Installation, Rack SSPA

Vorsicht

Wenn die Flansche des Hohlleiters nicht mit einem

externen Hohlleitersystem oder einem Lastanschluss

verbunden sind, sollten diese mit einer

Schutzkappe oder einem Band abgedeckt werden,

das bei der Entfernung keine Kleberückstände

hinterlässt. Xicom empfiehlt die Verwendung von

Kapton® Band, Marke 3M, #92, Xicom P/N 602-0001-

001. Entfernen Sie das Band oder die Kappe vor der

endgültigen Installation. Nichtbeachtung kann zur

Verunreinigung des internen Hohlleitersystems oder

des TWT führen und Schäden am Gerät zur Folge

haben.

Use the following procedure to install the waveguides on your

amplifier.

1. Position the interconnecting waveguide flange with the

amplifier waveguide flange. Make sure that the flanges can be

mated without strain or torsion.

2. If the two flanges cannot be properly aligned or if the

installation is subject to vibration, a flexible waveguide section

should be utilized to eliminate potential strain on the waveguide

connection.

3. Insert any necessary gaskets and windows between the two

flanges.

Note

If the connecting waveguide is to be pressurized at

greater than 5 PSI, a waveguide window must be

installed at the output flange of the amplifier. Use an

absorptive type gasket to preclude radiation leakage.

4. Start by hand tightening all waveguide mounting screws.

5. Tighten all mounting screws with the appropriate size Allen

wrench.

6. Use a sequential tightening procedure. Proceed as follows:

•Partially tighten one of the screws (#1).

•Move the tool to the screw that is diagonally opposite to

the screw tightened in step 1 (#2) and partially tighten that

screw.

•Move clockwise to the next screw to be tightened (#3) and

partially tighten that screw.

MNC-0300-021 8 of 20 Revision D

Unpacking and Installation, Rack SSPA

•Move to the screw diagonally opposite screw #3 and

partially tighten that screw (#4).

•If required, repeat this process for the remaining screws

(#5-#6, #7-#8).

•When you reach the first screw tightened in this step (#1)

increase the torque on the screw and repeat the process

until the screws have all been tightened to the correct

torque.

Figure 1, Typical 4 Screw Mounting Flange Tightening Sequence

Figure 2, Typical 8 Screw Mounting Flange Tightening Sequence

MNC-0300-021 9 of 20 Revision D

Unpacking and Installation, Rack SSPA

Air Ducting Installation

The SSPA is cooled with a built-in fan. Heated exhaust air should

not be recirculated into the SSPA. The air intake is located on the

front of the SSPA, and an exhaust fan pulls air through the SSPA. A

clearance of 6-8 inches from the exhaust is recommended to allow

the heated exhaust air to clear the SSPA.

If the unit is installed in a closed cabinet or in a configuration that

would tend to recirculate the exhaust air, provisions should be made

to isolate the exhaust air from the intake air supply.

The Exhaust Port Guard can be removed and replaced with an air

duct to carry the exhaust away from the SSPA. The air duct is

available from XICOM Technology. See appendix titled Mechanical

Drawings.

RF Sample Port (Optional)

The RF Sample port (Type N Female Connector) provides a sample

of the RF Output Signal. There is a calibration label above the port

that provides the calibration factors of the sample port.

Refer to the Appendix titled Product Specifications to optional RF

Sample Port configurations.

MNC-0300-021 10 of 20 Revision D

Unpacking and Installation, Rack SSPA

Rear Panel Interfaces

The rear panel (Figure 3) has all the connections required to use the

SSPA. Not all of the connections are used in every configuration. The rear

panel connections are:

•RF Output

•Waveguide Switch

•Auxiliary Interface

•COM1

•COM2

•Ethernet

•RF Input

•Prime Power Input

The AC Power Switch turns the AC power ON or OFF. If the AC power is

ON, the Power Supply AC ON Indicator Lamp will be lit.

The Amplifier ON Indicator LED on the power supply shows whether the

Power Switch on the front panel is ON or OFF. If the LED is lit, the front

panel power switch is ON and the DC output of the power supply is being

applied to the amplifier.

Figure 3, Rear Panel Connectors and Indicators

MNC-0300-021 11 of 20 Revision D

Unpacking and Installation, Rack SSPA

RF Output (J9) Waveguide Flange

There are two waveguide flanges available. One for the C-Band SSPA

and one for the Ku-Band SSPA. Table 1 lists the waveguide flanges.

Waveguide Switch (J3) (DB-25 Socket)

The Waveguide Switches shown in Table 2 are recommended for use in a

redundant system.

The waveguide switch connects the built in controller to two SSPAs and

the Transfer Switches in a redundancy configuration. Table 3 lists the

switch connector pinouts.

Table 1, Waveguide Flanges

Frequency Band Flange Type Tapped Hole Size

C CPRG-137 10-32 UNF-2B

Ku WR-75 6-32 UNC-2B

Table 2, Waveguide Switches

Frequency Band Sector P/N Xicom P/N

C 3AG6AS 734-0032-001

Ku 75AP6AS 734-0037-001

MNC-0300-021 12 of 20 Revision D

Unpacking and Installation, Rack SSPA

Table 3, Waveguide Switch Connector (J3) Pinouts

Pin Function

1WG SW1 Pos A

2WG SW1 Pos B

3WGSW1Common

4WG SW2Pos A

5WG SW2 Pos B

6WGSW2Common

7 WG SW1 RF Inhibit

8 WG SW1 RF Inhibit Return

9 WG SW2 RF Inhibit

10 WG SW2 RF Inhibit Return

11 WG SW1 Select A

12 WG SW1 Select B

13 Ground

14 WG SW2 Select A

15 WG SW2 Select B

16 Ground

17 Ground

18 Ground

19 Summary Fault this SSPA

20 Summary Fault other SSPA

21-23 Not Used

24 SSPA A or (Not SSPA B) Select

25 Ground

MNC-0300-021 13 of 20 Revision D

Unpacking and Installation, Rack SSPA

Auxiliary Interface Connector

The Auxiliary Interface provides these interfaces for the use of the

customer:

•Two sets of Form “C” Relay contacts for Summary Fault

Indication

•External Interlock Input

•RF Inhibit Input

•24 VDC @ 100mA maximum

•±15 VDC for monitoring purposes only.

The pinout of the Auxiliary connector is shown in Table 4 on

page 17,.

External Interlock

The External Interlock (Pin 13) must be shorted to the External

Interlock Return (Pin 11) for the amplifier to operate. Removing the

short causes an External Interlock fault and turns transmitter OFF.

RF Inhibit Control

RF is inhibited when RF Inhibit (Pin 12) is connected to Ground (Pin

9 or optionally, pin 10). The amplifier inhibits RF by removing the

bias voltage to the SSA, thereby eliminating the RF drive to the

SSA.

The amplifier can be factory configured on customer request to

inhibit RF when the connection to ground is removed.

Figure 4 shows the pin layout and Table 4 lists the pin definitions,

functions, and comments for the Auxiliary Interface Connector.

Figure 4, Front View of 15-Pin Connector (Socket)

MNC-0300-021 14 of 20 Revision D

Unpacking and Installation, Rack SSPA

Note 1: Pins 3,4,5 — Form C contacts. Fault 1, Summary Fault.

Note 2: Pins 6,7,8 — Form C contacts. Fault 2, Summary Fault

(Used for redundant systems).

Pin Nr. Definition Comments

1 +24 VDC Current limit of 100mA.

2 +24 VDC Current limit of 100mA.

3 (Note

1) Summary Fault 1 Normally Open. Closes when fault occurs.

4 Summary Fault 1 Normally Closed. Opens when fault occurs.

5 Summary Fault 1 Common, Fault 1

6 Summary Fault 2 Common, Fault 2

7 (Note

2) Summary Fault 2 Normally Open. Closes when fault occurs.

8 Summary Fault 2 Normally Closed. Opens when fault occurs.

9 Ground

10 Ground

11 External Interlock

Return Pin 11 must be connected to Pin 13 to enable

High Voltage ON.

12 RF Inhibit Connect Pin 12 to Pin 9 or Pin 10 to inhibit RF

Output.

13 External Interlock Pin 13 must be connected to Pin 11 to enable

High Voltage ON

14 +15 VDC Monitor Only

15 -15 VDC Monitor Only.

MNC-0300-021 15 of 20 Revision D

Unpacking and Installation, Rack SSPA

Summary Fault Indicators

Two sets of Form C relay contacts (Summary Fault 1 and Summary

Fault 2) are used to indicate that a fault has occurred.

The Summary Fault 1 indicator signals change state any time an

amplifier fault occurs. The user has the choice of a normally open or

normally closed circuit.

The Summary Fault 2 indicator signals change state any time a

summary fault occurs. The user has the choice of a normally open

or normally closed circuit.

Output Voltage

A + 24 VDC voltage is supplied that can deliver up to 100 mA. This

supply voltage is available on both Pins 1 and 2. The return for this

voltage is either Pin 9 or Pin 10.

MNC-0300-021 16 of 20 Revision D

Unpacking and Installation, Rack SSPA

Power and Interface Interconnections

When performing the procedures in this section refer to the Wiring

and Interconnect Drawings for your specific amplifier. These

drawings are located in the appendix titled Interconnect Drawings.

Prime Power Connections

The AC Prime Power receptacle (IEC-320 Connector) ) is located on

the amplifier rear panel. See the appendix titled Specification for

nominal line voltage and prime power connects. Figure 5 shows the

plug wiring diagram.

Figure 5, Power Plug Wiring Diagram

Serial Interface Ports

Dual serial interface connectors (COM1 and COM2), located on the

rear panel of the amplifier are available for remote control operation.

Both serial interface ports are always enabled. The amplifier will

respond to commands from either interface. The commands are

processed in the order received.

MNC-0300-021 17 of 20 Revision D

Unpacking and Installation, Rack SSPA

COM1 RS-232 Interface (J5) (DE-9 Pin)

This port is used by the customer to connect to a remote RS-232

port. Table 4 lists the pinouts for COM1.

COM 1 cannot be used for remote control when you are operating in

the redundant mode.

Table 4, COM1 RS-232 Pinouts

Pin No. Function

1 Carrier Detect

2 RXD—Received Data (from Controller)

3 TXD—Transmitted Data (to Controller)

4 DTR — Ready to Receive (Controller)

5 Ground and Signal Return

6 DSR—Request to Send Ready (Controller)

7 RTS—Request to Send (Amplifier)

8 CTS—Clear to Send (Amplifier)

9REPROGRAM COMPUTER

MNC-0300-021 18 of 20 Revision D

Unpacking and Installation, Rack SSPA

COM2 RS-485 Interface (J6) (DE-9 Pin)

This port is used by the customer to connect to a remote RS-485

port. This port may be either a 2-wire or 4-wire port. Table 5 lists the

pinouts for COM2. Figure 6 and Figure 7 show the 2-wire and 4-wire

implementation.

Figure 6, Typical RS-485 2-Wire Duplex Implementation

Table 5, COM2 RS-485 Pinouts

Pin No 2-Wire System 4-Wire System

1 (-) Data (-) Transmit Data

2 (-) Data (-) Receive Data

3 No Connection No Connection

4 No Connection No Connection

5 Ground Ground

6 (+) Data (+) Transmit Data

7 (+) Data (+) Receive Data

8 No Connection No Connection

9 No Connection No Connection

MNC-0300-021 19 of 20 Revision D

Unpacking and Installation, Rack SSPA

Figure 7, Typical RS-485 4-Wire Full Duplex Implementation

Ethernet (J7) (EIA T568B)

The Ethernet Interface allows the user to connect the amplifier to a local

network. Table 6 lists the Ethernet pinouts.

RF Input (J1) Female Type N

This is the connection used by the customer to supply a RF signal to the

SSPA.

Table 6, Ethernet Pinouts

Pin Function

1RX+

2RX-

3TX+

6TX-

MNC-0300-021 20 of 20 Revision D

Unpacking and Installation, Rack SSPA

Grounding

WARNING

To prevent Electric Shock the amplifier should be securely

connected to the grounding stud. Failure to comply could result in

personnel injury or death.

WARNUNG

Zur Vermeidung elektrischer Schläge muss der

Verstärker sicher mit der Erdklemme verbunden sein.

Die Nichtbeachtung dieser Warnung kann zu

Personenschäden oder zum Tod führen.

Table of contents

Popular Rack & Stand manuals by other brands

IRONRIDGE

IRONRIDGE AIRE installation manual

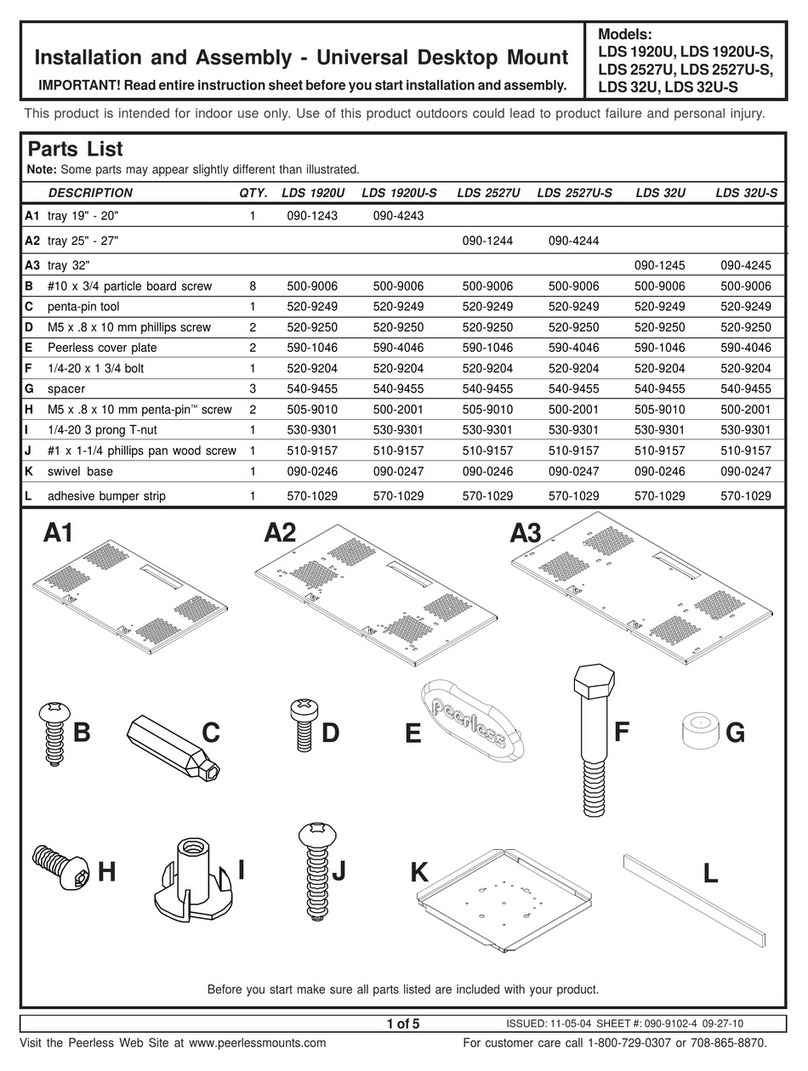

PEERLESS

PEERLESS LDS 1920U Installation and assembly

Christie

Christie 38-817001-01 Series installation instructions

Stell

Stell SHT B331 General instructions for installation and use

NEC

NEC Wall Mount PDW S 32-55 P (WMS 32-55 P user manual

Sony

Sony SU-46NX1 instructions