3

1General Information

Read all these instructions & warnings fully before

commencing installation.

These installation and operating instructions must

be observed during installation, operation, service

and maintenance. This MVHR should only be in-

stalled and repaired by a qualified service techni-

cian. Improper repairs may expose the user to con-

siderable danger. Under current regulations, the

installation and operating instructions must be ac-

cessible at all times and must be handed to the

technician for reference whenever work is being

done on the MVHR. We would therefore ask that

upon moving out of these premises, you pass the

instructions on to the next tenant/owner. Should

there be any visible damage the MVHR must not be

connected. In this case, it is imperative that you

contact your supplier. Only use original spares in

order to avoid secondary damage. Please ensure

that all packaging materials are disposed of prop-

erly in accordance with current environmental re-

quirements.

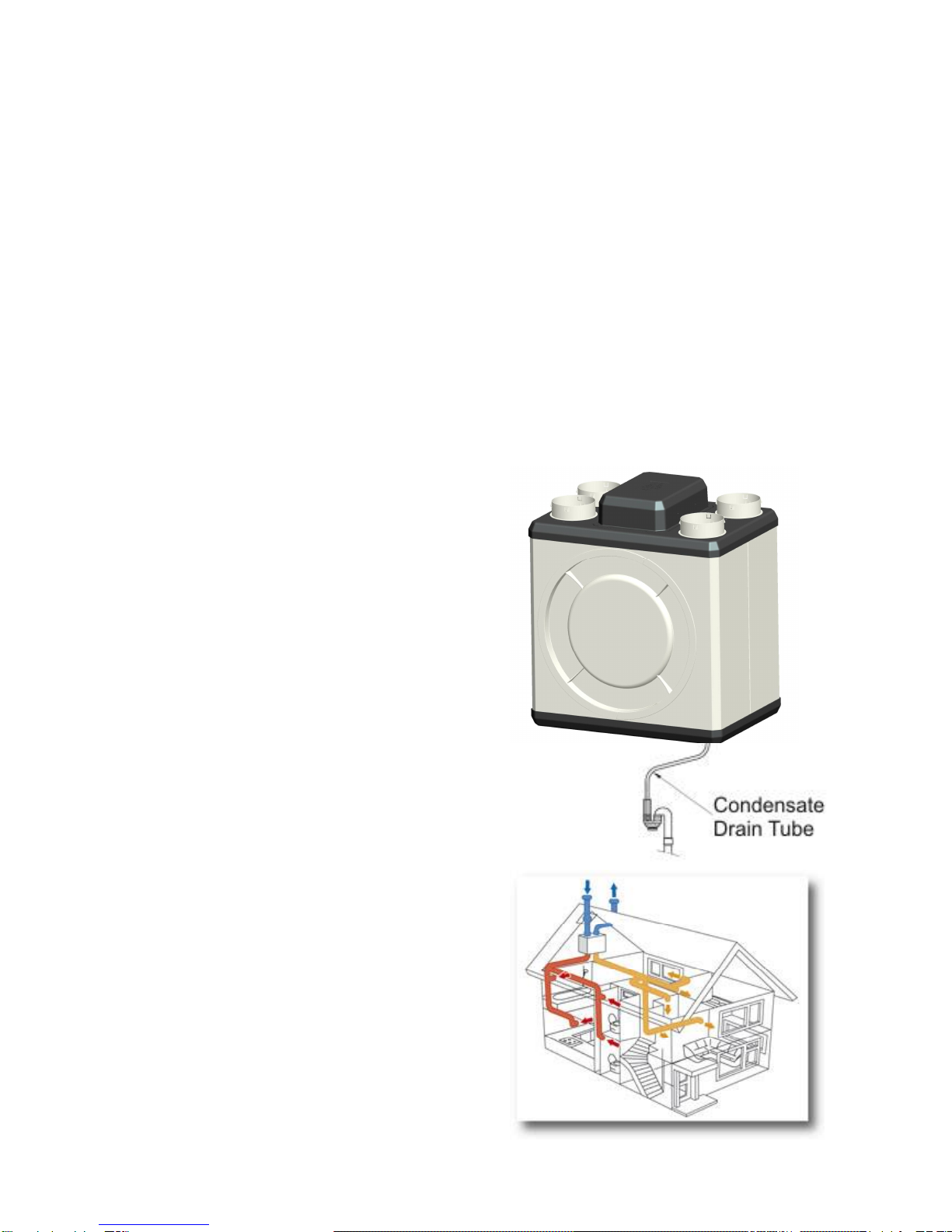

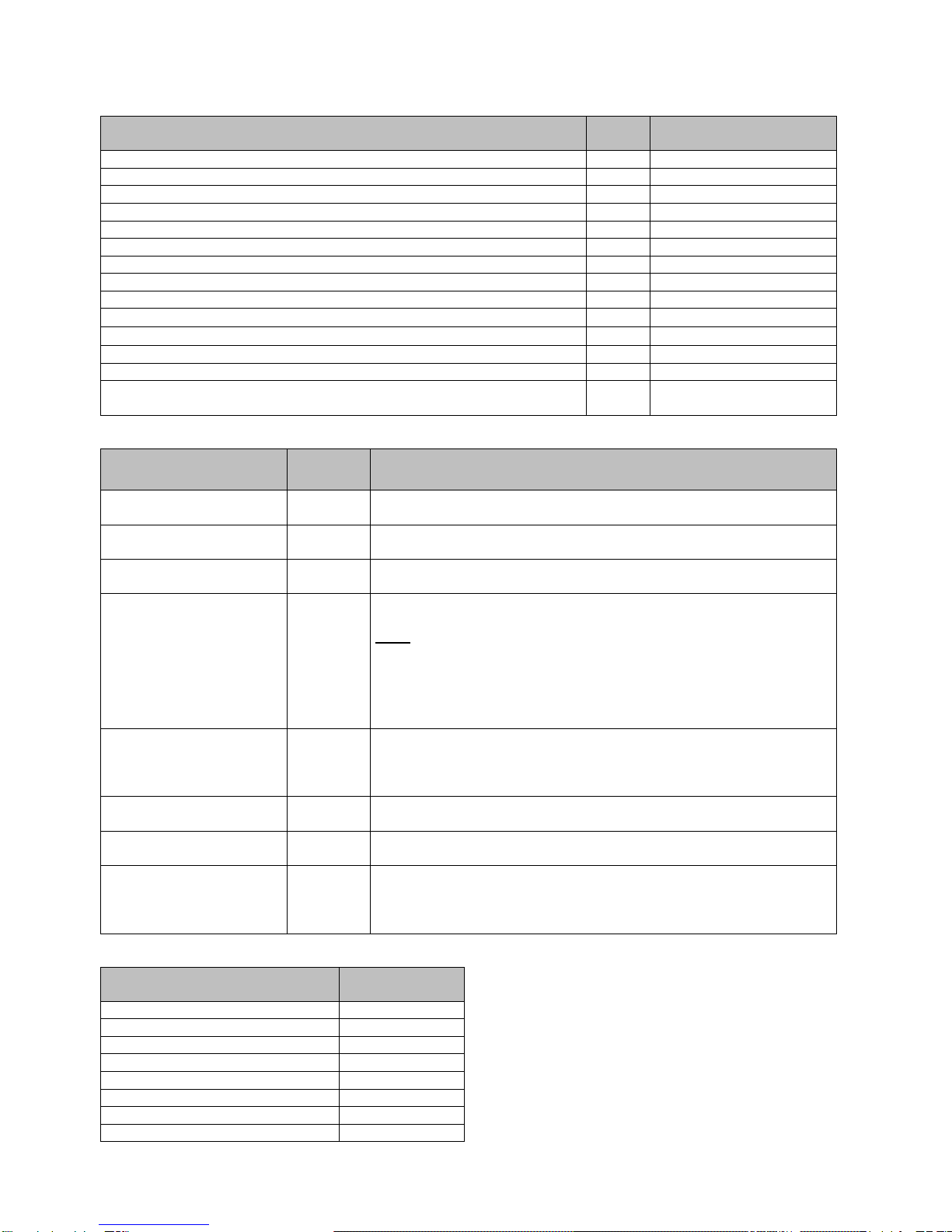

2Components and Materials of Construction

The MVHR comprises of the following main compo-

nents:

Outer Panels:

PE plastic, white

PS plastic, black

Maintenance access cover:

PS plastic

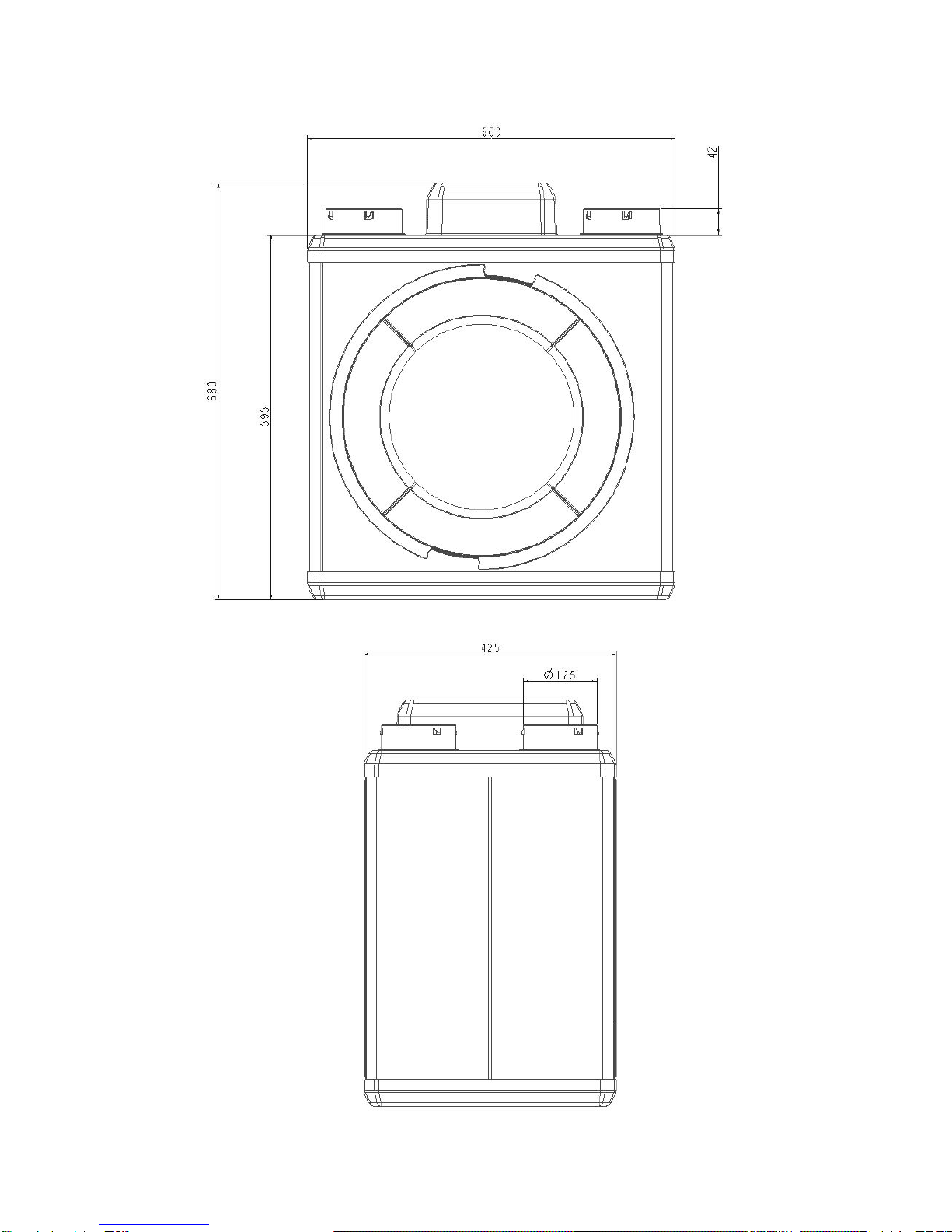

Ducting spigots, Ø125mm:

PP plastic, light grey

Internal air paths / casing:

EPP, black

Filters:

G4 fitted as standard. External filter box F5 or F7

available as special accessory

Heat exchanger:

The heat exchanger is made from fully recyclable

PS plastic. The heat exchanger integrated into the

MVHR is based on the counter flow principle with

triangular air ducts for supply and exhaust air.

Fans:

Energy-saving EC DC fans with optimal efficiency.

3Regulations and Safety Instructions

The Xcell150 MVHRs are tested in accordance with

the low-voltage directive 2006/95/EC and EMC

directive 2004/108/EC.

This appliance is not intended for use by persons

(including children and the infirm) with reduced

physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been

given supervision or instruction concerning use of

the appliance by a person responsible for their

safety.

Ensure that all relevant safety precautions (correct

eye protection and protective clothing etc) are taken

when installing, operating and maintaining this

MVHR. Observe the safety regulations and warn-

ings contained in this manual at all times. Failure to

do so may result in damage to the unit or personal

injury.

This MVHR is intended for connection to fixed wir-

ing.A means for disconnection must be incorpo-

rated in the fixed wiring. Installations and wiring

must conform to current IEE Regulations (UK), local

or appropriate regulations (other countries). All

installations must be supervised by a qualified elec-

trician. It is the installer’s responsibility to ensure

that the appropriate building codes of practice are

adhered to.

This MVHR must not be installed near to sources of

direct heat such as cookers/grills or where ambient

temperatures may exceed 50•C.

When the MVHR is installed in a room containing a

fuel burning appliance, precautions must be taken

to avoid the backflow of gases into the room from

the open flue of the fuel burning appliance.

The instructions on periodic cleaning and/or chang-

ing of the filters, the air inlet/outlet valves and the

air inlet/outlet grilles must be strictly observed.

The unit may only be connected to a 220-240V AC

power supply.

The following applications / installations are

prohibited:

The use of excessive fat-contaminated exhaust

air, extracting explosive gases, extracting parti-

cle-contaminated air, extracting adhesive par-

ticulate matter.

Installing the MVHR outdoors

Connecting extractor hoods in the ventilation

system

Servicing of the MVHR may only be carried out by a

qualified service technician. Contact details for

authorised servicing by Xpelair approved techni-

cians can be found on the back of this booklet.