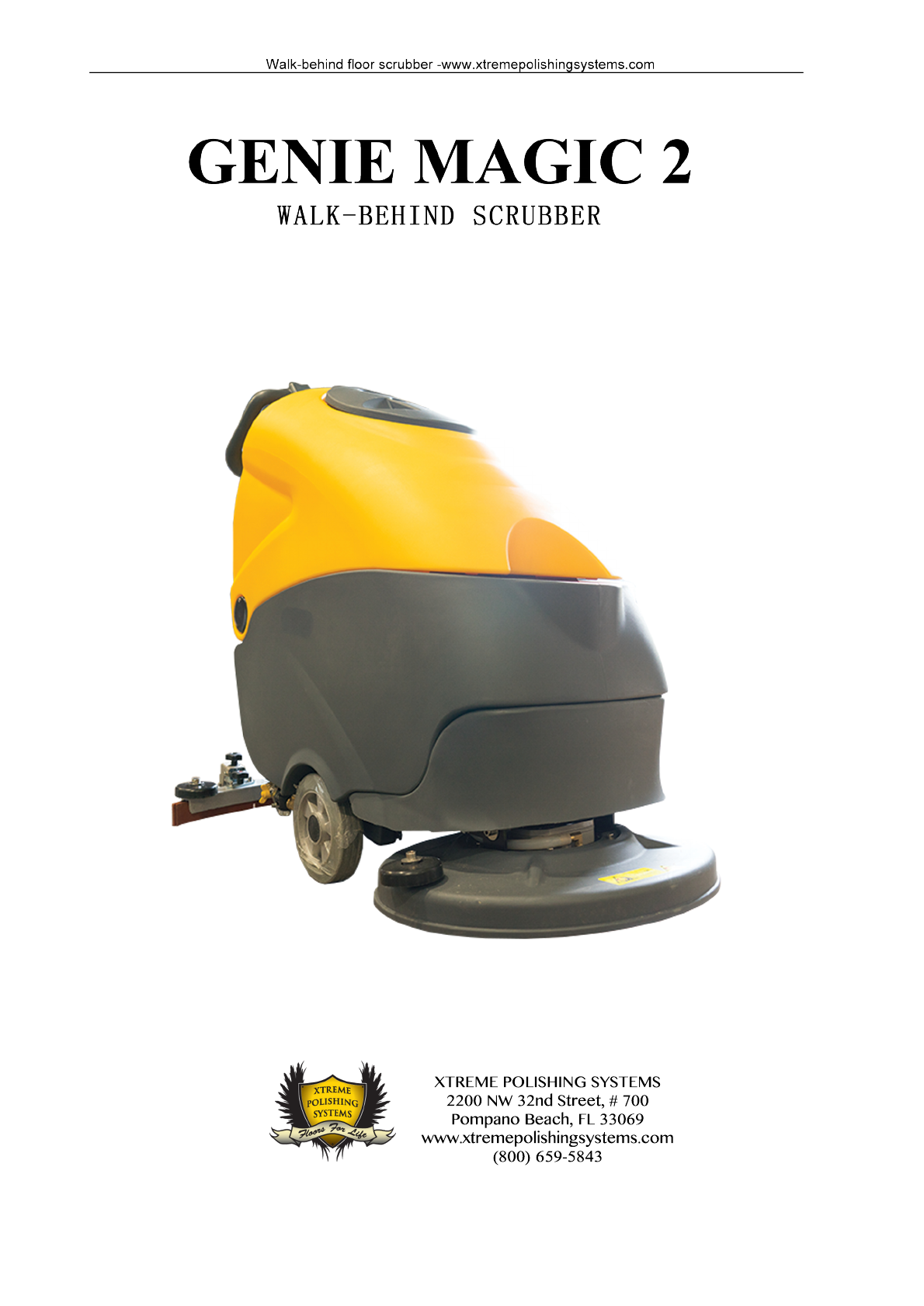

Walk-behind floor scrubber -www.xtremepolishingsystems.com

1.Index.............................................................................................................................................................. 4

2. GENERAL

INFORMATION

....................................................................................................................... 4

2.1.Scope

of

the

manual

........................................................................................................................ 4

2.2.Identifying

the

machine

................................................................................................................... 5

2.3.Documentation

provided

with

the

machine

.................................................................................. 5

3.TECHNICAL

INFORMATION

.................................................................................................................... 5

3.1.General

description

.......................................................................................................................... 5

3.2.

Legend

............................................................................................................................. 6

3.3.

Danger

zones

............................................................................................................................. 6

4.SAFETY

INFORMATION

........................................................................................................................... 7

4.1.Safety

regulations

............................................................................................................................ 7

5.HANDLING

AND

INSTALLATION

........................................................................................................... 10

5.1.Lifting

and

transporting

the

packaged

machine

......................................................................... 10

5.2.Checks on delivery ........................................................................................................................ 10

5.3. Unpacking ........................................................................................................................... 10

5.4

Power

supply

batteries

(battery

models)

.................................................................................... 11

5.4.1Batteries:

preparation

.......................................................................................................... 11

5.4.

2

Batteries:

installation

and

connection

........................................................................... 11

5.5

Battery

charger

(battery

models)

................................................................................................. 13

5.5.1.

Choosing

the

battery

charger

....................................................................................... 13

5.5.2

Preparing

the

battery

charger

.......................................................................................... 13

5.6

Lifting

and

transporting

the

machine

........................................................................................... 13

6.PRACTICAL

GUIDE

FOR

THE

OPERATOR

........................................................................................ 14

6.1.Controls

-

Description

.................................................................................................................... 14

6.2.Mounting

and

adjusting

the

squeegee

........................................................................................ 15

6.3.Moving

the

machine

when

not

in

operation

............................................................................... 16

6.4.Mounting

and

changing

the

brush/drive

disks

........................................................................... 16

6.5.Detergents

-

Instructions

............................................................................................................... 17

6.6. Preparing

the

machine

for

work

.................................................................................................. 17

6.7 start working

.................................................................................................................................... 18

6.8.Some

useful

tips

to

get

the

most

from

your

scrubber

drier

...................................................... 20

6-9 Pre-wash

......................................................................................................................................... 20

6.9.1

Drying

................................................................................................................................ 20

6.9.2Draining

the

dirty

water

....................................................................................................... 20

6.10 empty water tank

......................................................................................................................... 21

7. PERIODS

OF

INACTIVITY

..................................................................................................................... 21

8.BATTERY

MAINTENANCE

AND

CHARGING

...................................................................................... 22

8.1 Charging.......................................................................................................................................... 22

8.1.Recharging

procedure

........................................................................................................... 22

9.MAINTENANCE INSTRUCTIONS ......................................................................................................... 22

9.1.Maintenance

-

General

rules

........................................................................................................ 22

9.2.Routine

maintenance

..................................................................................................................... 23

9.2.1Suction

motor

air

filter

and

float

switch:

cleaning

............................................................ 23

9.3Detergent

filter:

cleaning

................................................................................................................ 23

9.4Squeegee

blades:

replacing

.......................................................................................................... 23

9.5Fuses:

replacement

........................................................................................................................ 25

9.6.Routine

maintenance

..................................................................................................................... 25

9.6.1

Daily

operations

.................................................................................................................. 25

9.6.2 Weekly.................................................................................................................................. 25

9.6.3.

Six

monthly

operations

..................................................................................................... 26

10.Trouble solution....................................................................................................................................... 26

10.1

How

to

resolve

possible

problem

.............................................................................................. 26