9

TESTING

Inspection before use

Trial

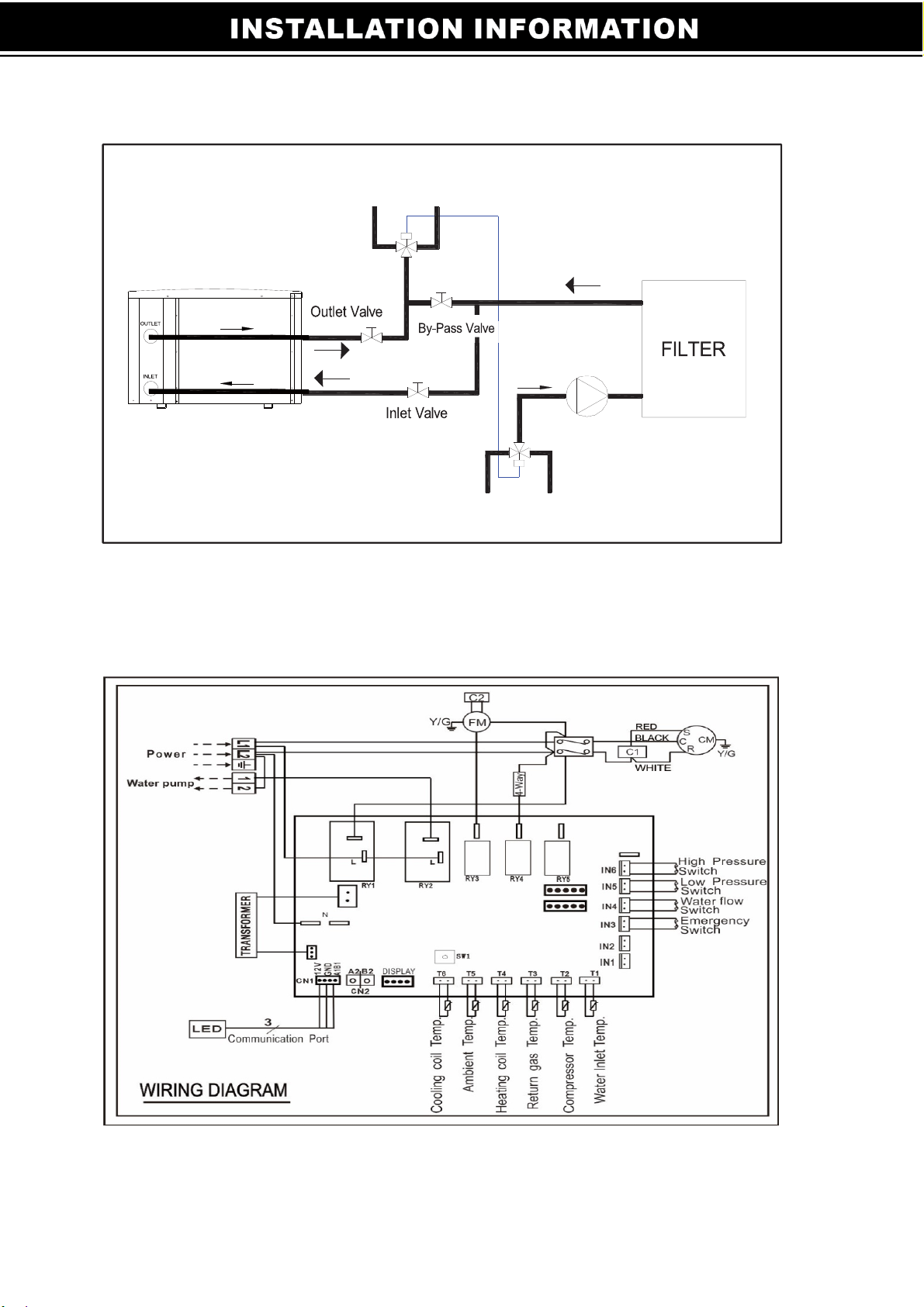

oCheck installation ofthe whole machine and the pipe connections according to the pipe

connection diagram

oCheck the electric wiring according to the electric wiring diagram; and make sure the Heat Pump is

bonded

oMake sure that the main machine power switch is off

oCheck the temperature setting.

oCheck the air inlet and outlet.

•The user must “Start the Pump before the Machine, And Turn off the Machine before the

Pump”, or the machine will be damaged

•The user should start the pump, check for any water leakage of water; set temperature

in the thermostat, and then switch on power supply.

•In orderto protect the swimming pool heat pump, the machine is equipped with a time delay

starting function, when starting the machine, the blower will run for 3 minutes before the

compressor starts.

•If at anytime there is an abnormal noise, smell, smoke, electricity leakage, please switch off power

immediately and contact your local dealer.

Attention

oSet temperature control to achieve a comfortable water temperature and to avoid overheating or

over cooling.

oAlways install the machine outdoors, while noting the minimal clearances needed for proper operation

and heating. DO NOT place the unit next to shrubs, fences, etc. which can block the air inlet. These

locations deny the unit acontinuous source of fresh air which reduces its efficiency and may prevent

adequate heat delivery.

oNever put hands or any objects into outlet of the swimming pool heat pump, and don’t remove the screen

over the fan at any time.

oIf at any time there is an abnormal noise, odor, smoke, electricity leakage, please switch off power

immediately and contact your local dealer.

oDo not use orstock combustible gas or liquids such as paint thinners, paint, fuel near or aroundthe heat

pump.

oAs with all pool heat pumps, you are advised to use a pool cover at night and when the pool is not in

use.

oThe heat pump should be installed within 10m of the pool to minimize heat loss in the underground

pipes.

Safety

Please keep the main power supply switch out of reach from children.

oIf there is a power outage while the machine is in operation, the heat pump will start up automatically

when power is restored.

oPlease switch off the main power supply during lightening storms to prevent any damage to the unit.

oIf the machine is stopped for a long time, please cut off the power supply and drain water of the machine

by opening the tap of inlet pipe. If the unit is stopped for a long period of time or for winterizing, the unit

must be drained of all its water. You will need to disconnect the IN and OUT water connections. Then the

unit must be tilted or blown out with air until all water is out.