YD-EM279

03

PREMIUM E-MOBILITY

1 General information

1.1 Warnings and precau-

tions

Warning, caution and tips

"Warning", "Caution" and "Tips” mean the following:

Warning: Procedures must be strictly followed to

avoid possible injury to personnel.

Caution: Draw your attention to follow procedures to

prevent damage to components.。

Tips: Provide some helpful information.

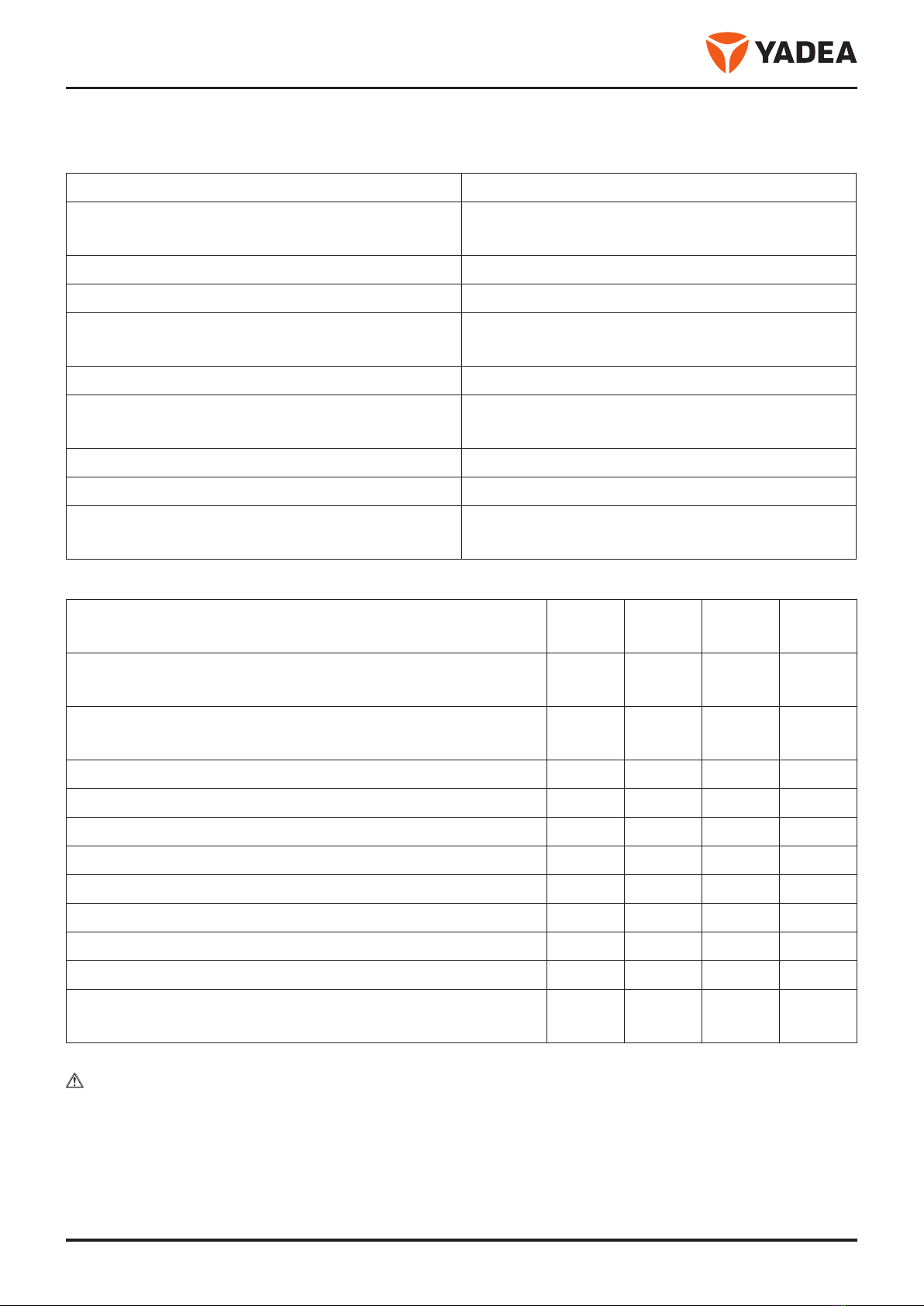

1.1.1 Description

Please use the parts recommended by the Company

only when required.

Pay special attention to the following points, which are

related to the maintenance or replacement of parts:

●Use of parts other than those recommended by the

Company may weaken the safety factor and anti -

corrosion measures of the vehicles. In some areas, it is

legally prohibited to use any parts beyond the manu-

facturer's specifications.

●Torque values given in this manual must be followed.

Locking devices, when specifically specified, must be

installed. A locking device must be replaced if its lock-

ing effect is affected after disassembly.

●The accessories, purchased by the user while travel-

ing in a foreign country, and their installation sites shall

comply with legal requirements.

●The vehicle warranty does not apply to the parts not

recommended by the Company. All parts recommend-

ed by the Company can enjoy the vehicle warranty. Our

dealers must supply only the parts and components

recommended by us.

1.1.2 Warning label

Warning: Read the high - pressure warning label in-

structions carefully before working

This part is a high voltage part with high volt-

age risk. The user is prohibited to touch this

part at will, so as not to cause electric shock

and other casualties.

Danger: Ignoring the text can lead to accidents

or injuries to passengers and drivers.

Warning: Ignoring the warning can lead to se-

rious injury or death.

Caution: You must strictly observe the matters

stated here, otherwise it may damage your

vehicle.

Environmental protection: the matters

stated here are related to environmental

protection.

1.2 Notes for disassembly

1.2.1 Parts disassembly

Disassembly

Parts and surrounding area shall be cleaned as

much as possible prior to disassembly.

●Empty space shall be covered after parts disas-

sembly.

●The disassemblyd parts shall be quickly placed in

the appropriate containers, and each part and its

related parts are placed in different containers by

class.

Clean the workbench and prepare marking ma-

terials, labels, and containers before parts dis-

assembly

Caution:

The parts, especially brake, shall be kept clean

during disassembly. The tiny dirt and cloth

pieces left in these parts may result in vehicle

faults.

●The parts to be replaced and the parts to be

checked and installed shall be labeled respective-

ly and placed in separate containers.

●Do not discard any parts to be replaced. Com-

pare them with the new parts first to see if you've

got the right parts.

1.2.2 Parts cleaning

The recommended cleaning agent or similar

products shall be used. Attention shall be paid

to adequate ventilation when using a solvent

for grease removal. Do not use grease removal

equipment that can damage parts.

1.2.3 Parts check

All parts shall be checked for damage or wear be-

fore installation.

Do not check for damage or measure the size if

the parts are clean.

A small amount of grease can cause great dam-

age to the vehicle.